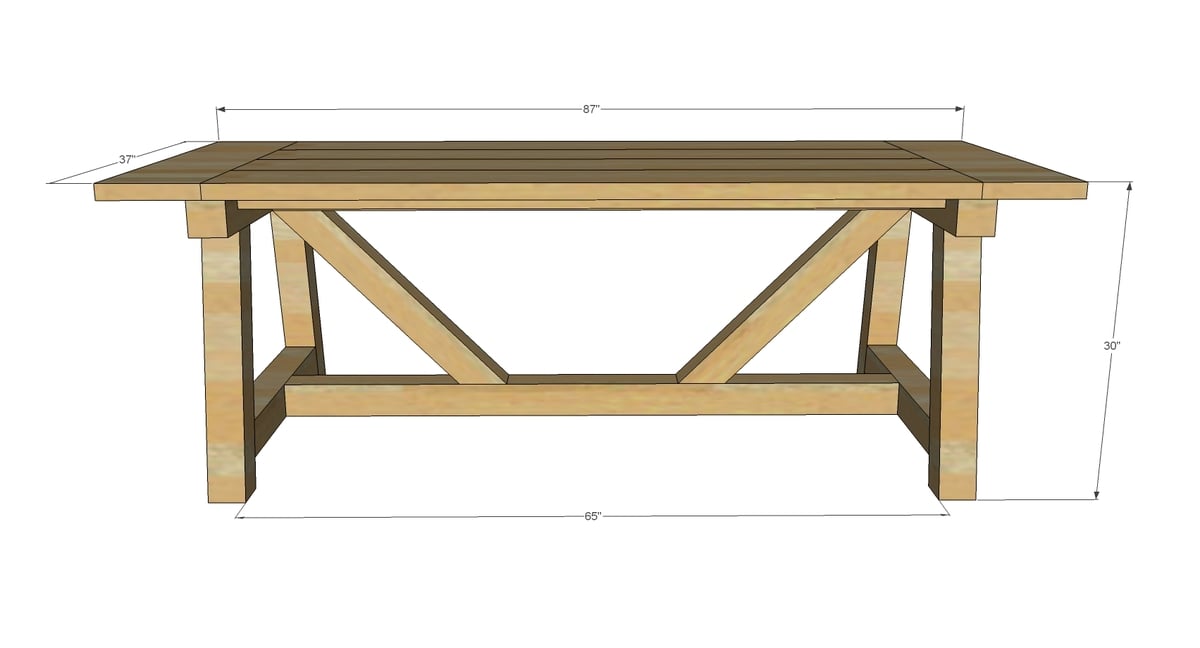

Build the truss beam farmhouse table! Free step by step plans from Ana-White.com

Pin For Later!

Preparation

5 - 4x4 @ 8 feet long

2 - 2x4 @ 8 feet long or stud length

2 - 2x10 @ 12 feet long (tabletop boards - can be cut in half at store for easier transport)

1 - 2x10 @ 8 feet long (cut breadboards out of this board - can also use a 2x8 or 2x12)

Whitney used 2 1/2" Kreg HD Screws and a Kreg HD to build this table

You'll also need 2 1/2" pocket hole screws to put the tabletop together and to attach the tabletop to the aprons

2 - 4x4 @ 35"

4 - 4x4 @ 25 3/8" (both ends cut at 10 degrees off square, long point to short point, ends ARE parallel)

2 - 4x4 @ 28 1/4" (both ends cut at 10 degrees off square, long point to long point, ends are NOT parallel)

2 - 4x4 @ 65"

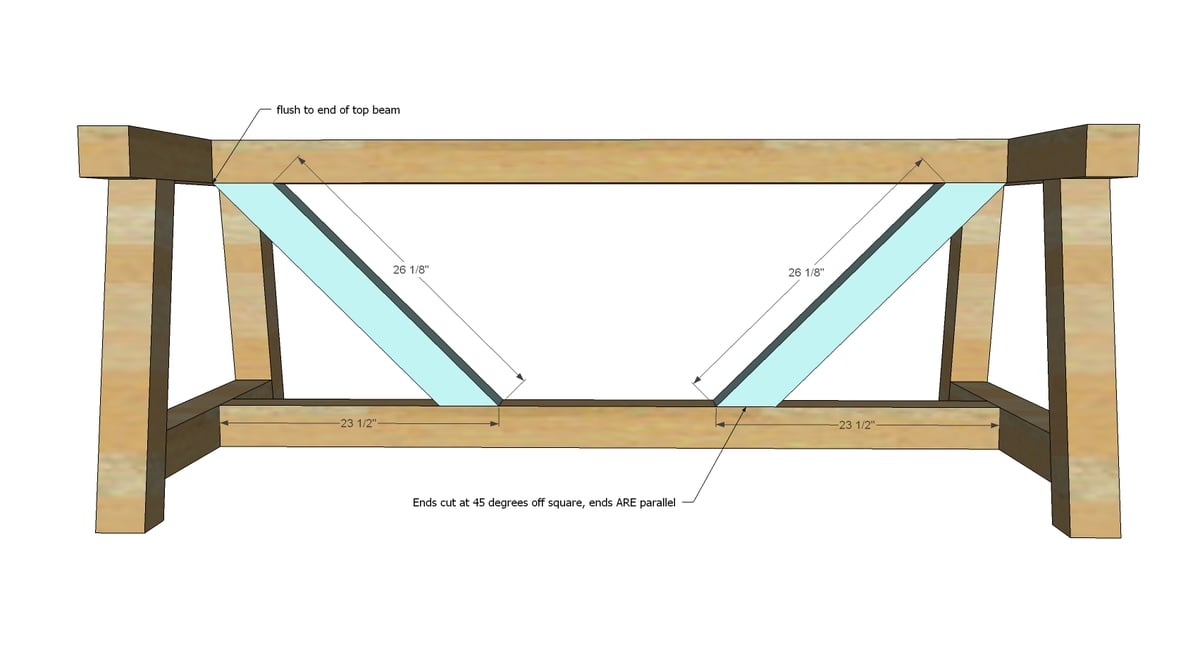

2 - 4x4 @ 26 1/8" (both ends cut at 45 degrees off square, long point to long point, ends ARE parallel)

2 - 2x4 @ 65"

4 - 2x10 @ 68 1/2" (tabletop boards)

2 - 2x10 @ approx 37" (cut breadboard ends to fit)

Please read through the entire plan and all comments before beginning this project. It is also advisable to review the Getting Started Section. Take all necessary precautions to build safely and smartly. Work on a clean level surface, free of imperfections or debris. Always use straight boards. Check for square after each step. Always predrill holes before attaching with screws. Use glue with finish nails for a stronger hold. Wipe excess glue off bare wood for stained projects, as dried glue will not take stain. Be safe, have fun, and ask for help if you need it. Good luck!

Instructions

Step 1

Step 4

Add the 2x4 aprons underneath for added support.

NOTE: We kept these flat to keep the look the Shanty girls were after, but to make this table stronger (especially if you were modifying the table to be longer) I recommend attaching the 2x4s vertically instead of flat. If you go this route, make sure you predrill 1 1/2" pocket holes facing upward in the aprons to attach the tabletop in the next step.

It is always recommended to apply a test coat on a hidden area or scrap piece to ensure color evenness and adhesion. Use primer or wood conditioner as needed.

Comments

jfb

Tue, 07/07/2020 - 16:11

Hello! I would like to know…

Hello!

I would like to know if some boards of the table top cracked over the years. Wich type of wood would be a good choice?

Thank you!

bpentony

Sun, 07/12/2020 - 16:05

This table is gorgeous but a…

This table is gorgeous but a little long for my available space. Is there a 72 inch modification available?

bchild87

Sun, 07/26/2020 - 02:13

I am also limited space and…

I am also limited space and would really love it if there were plans for a 72” table.

Devarious334

Tue, 09/15/2020 - 15:12

Downsizing Table

Any help converting this to a 6ft table?

PCMoates

Sun, 12/06/2020 - 17:23

Breadboard Pocket Holes

By using pocket holes and glue on the breadboards, have you seen any cracking or warping in the table?

Jessieh1981

Sat, 01/30/2021 - 15:05

How do you make the boards…

How do you make the boards completely level on the tabletop? I've sanded it over and over!

citadel96gh

Mon, 02/15/2021 - 07:01

Live this build and i’m just…

Live this build and i’m just about finishes. **Pay close attention. The cut list has the parallel cuts at long point to long point but they should be 26 1/8 long point to short point. The diagram shows it correctly.

Quick trip back to lumberyard fixed it for me.

Tucks98

Wed, 06/09/2021 - 16:44

Are there plans to similar…

Are there plans to similar to this for a 6 foot long dining table?

VanNater76

Mon, 01/24/2022 - 11:50

Wood for the 4 x 4 truss beams

Planning on building this table for our dining room, but I can't seem to find 4 x 4 beams in any of my local hardware stores except in either cedar or pressure treated lumber. The table top I'm just going to go with a pine variety. I did that with a table I made last year and it held up well. My question is, has anyone used cedar for the 4 x 4 beams of this table and the matching bench? How did it turn out? Any issues?