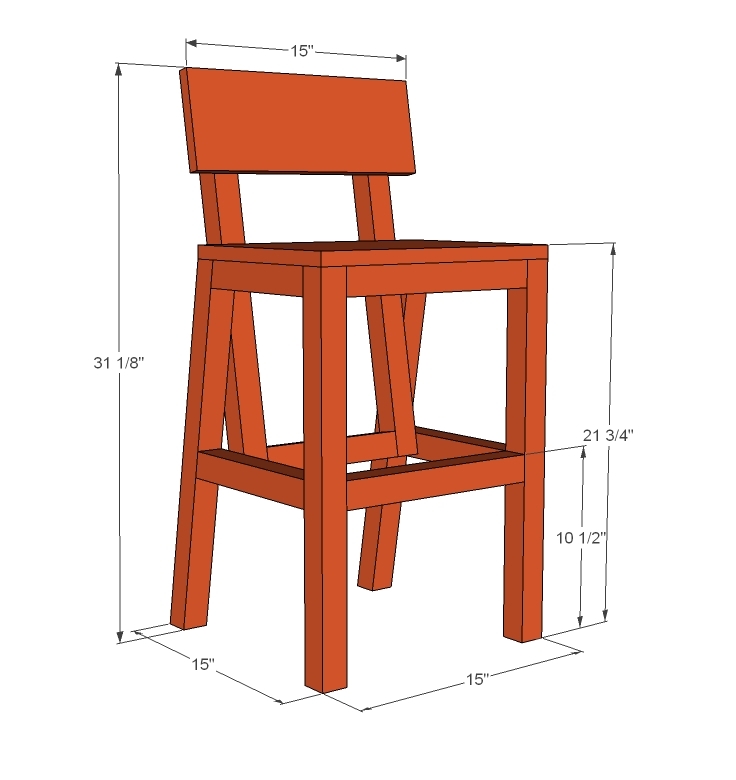

Is your child to old for a high chair, but too short for a standard chair?

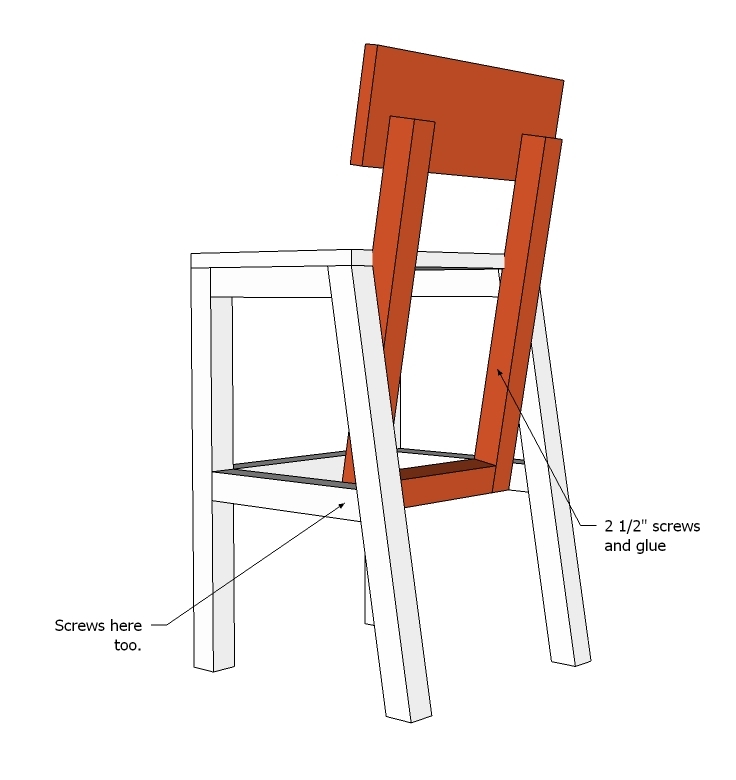

For the cost of a cheapo plastic booster seat, you can build your child a modern higher chair. This simple sturdy plan is easy to build, features a foot rest and is easy for youngsters to climb up on. This chair is not meant to replace a high chair, and does not offer the security and safety of a high chair.

Preparation

- 2 - 2x2 @ 8 feet long

- 1 - 1x12 @ 15" long

- 1 - 1x6 @ 15" long

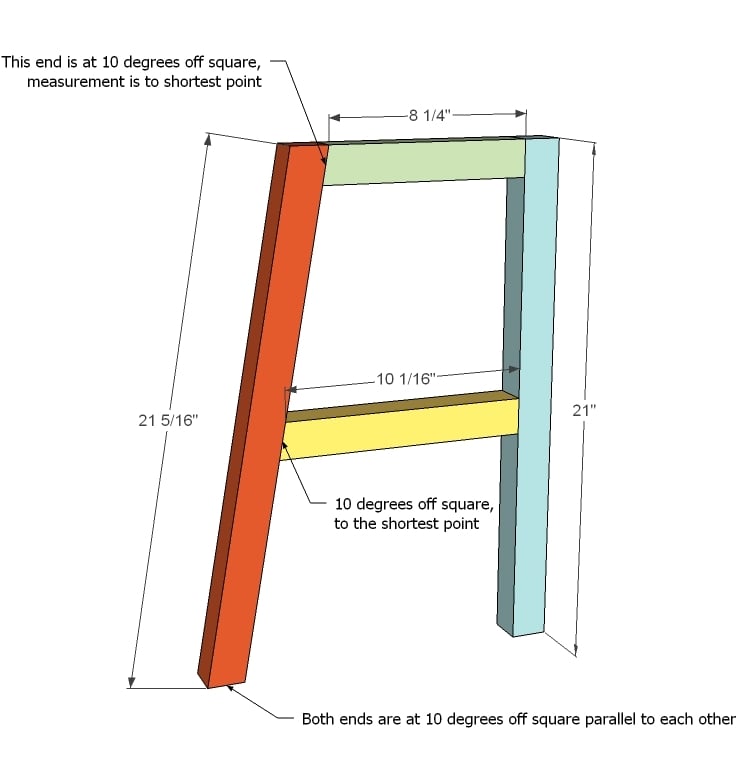

- 2 - 2x2 @ 8 1/4" - one end at 10 degrees off square, shortest point

- 2 - 2x2 @ 10 1/16" - one end at 10 degrees off square, shortest point

- 2 - 2x2 @ 21 5/16" - both ends at 10 degrees off square, parallel to each other

- 2- 2x2 @ 21" (Front Legs)

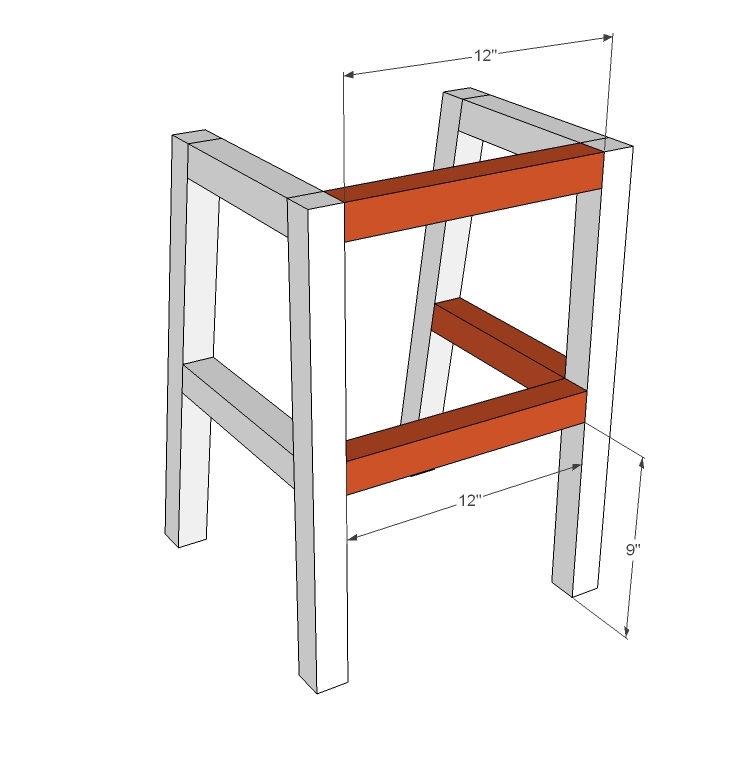

- 2 - 2x2 @ 12" (Front Support/Apron)

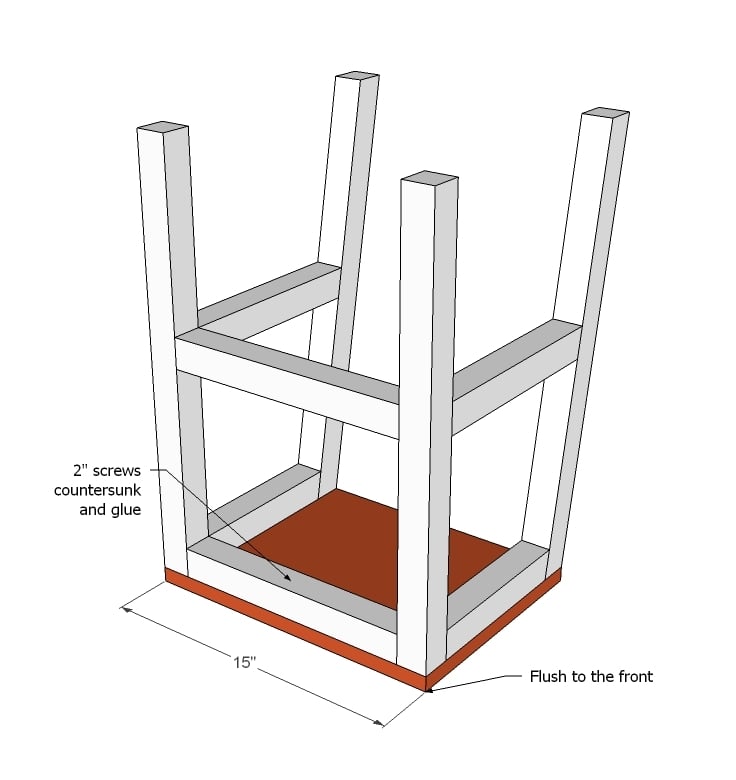

- 1 - 1x12 @ 15" (Seat)

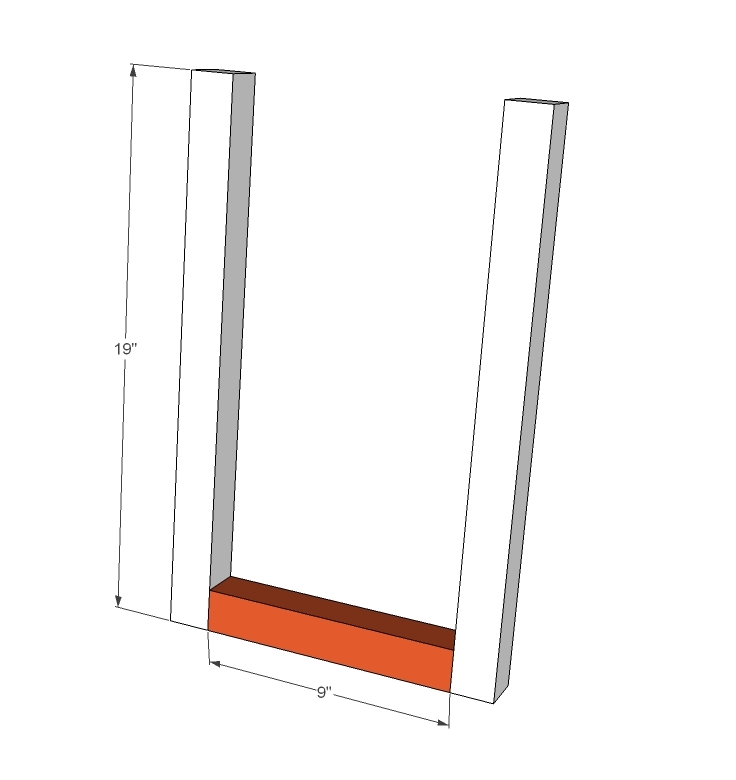

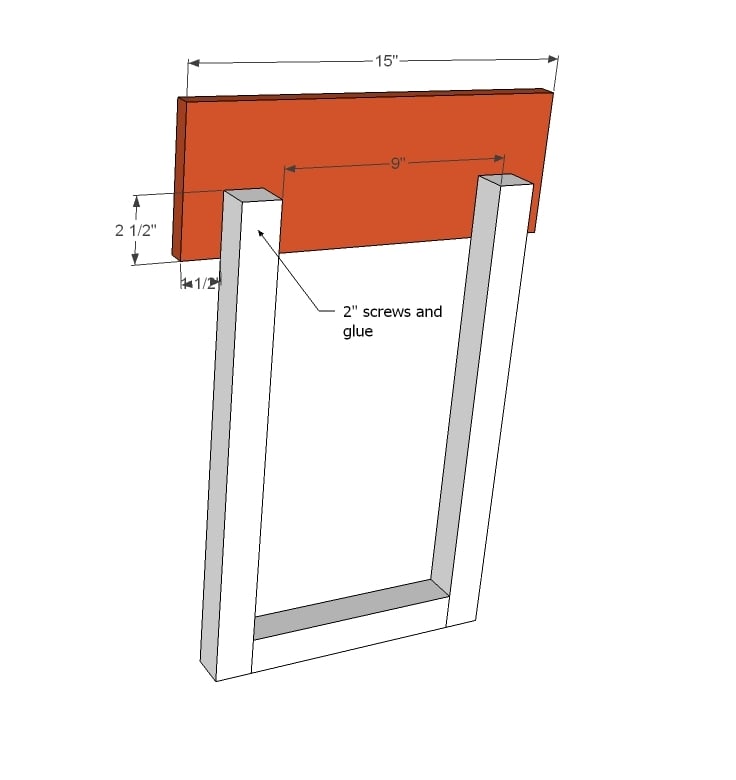

- 2 - 2x2 @ 19" (Back Supports)

- 1 - 2x2 @ 9" (Back Base)

- 1 - 1x6 @ 15" (Backrest)

Please read through the entire plan and all comments before beginning this project. It is also advisable to review the Getting Started Section. Take all necessary precautions to build safely and smartly. Work on a clean level surface, free of imperfections or debris. Always use straight boards. Check for square after each step. Always predrill holes before attaching with screws. Use glue with finish nails for a stronger hold. Wipe excess glue off bare wood for stained projects, as dried glue will not take stain. Be safe, have fun, and ask for help if you need it. Good luck!

Instructions

Step 1

Step 2

Step 3

It is always recommended to apply a test coat on a hidden area or scrap piece to ensure color evenness and adhesion. Use primer or wood conditioner as needed.

Comments

Kate (not verified)

Wed, 03/23/2011 - 06:09

Love this one! I don't have

Love this one! I don't have any kids yet, but I'm going to suggest this to my sister in law. She has a little one who is too big for a high chair and refuses to sit in the "baby" (booster) seat. Might be a perfect solution!

Nichole (not verified)

Wed, 03/23/2011 - 06:40

I love this... Those cheapo

I love this... Those cheapo plastic boosters ruined the finish on my chairs last time... I am so going to build this when my baby is in that stage.

smasumur

Wed, 03/23/2011 - 07:23

Love this chair!

I'd seen the boosterless booster chair at <insert big Swedish furniture maker here> before and though, what an awesome idea. Of course, since I've had kids, I've completely forgotten about it. Now I'm going to have to go build myself at least one of these, maybe more. My kids will love you!

maura (not verified)

Wed, 03/23/2011 - 07:52

Aww, Maaaan :P

I JUST bought a chair of this size from <smasumur knows what Swedish mega store I'm talking about>. Less than a week ago! I should have known better!

Ashley @ pure … (not verified)

Wed, 03/23/2011 - 14:13

woot! woot!

LOVE the chair. and LOVE my dear friend Shaunna! Great feature, as usual, Ana! ;)

annalea

Wed, 03/23/2011 - 20:39

This is great!

I so need one of these. Thank you for posting the plans. As I read, I remembered that my husband's grandmother called her vintage version of this the "junior chair". And it fits. :)

LauraDST (not verified)

Fri, 06/08/2012 - 17:40

Looking at comments on this

Looking at comments on this chair and saw your cute picture and smiled. So should I just have the hubby make a bunch of these?

Guest (not verified)

Tue, 03/29/2011 - 14:21

You read my mind!

I have been looking at your plans longingly without actually building anything because I'm quite the novice. When I saw the plans for the Harriet chair though, I thought, maybe now's the time...and how can I modify that to make it a little higher for my 3 year old? Thanks for not making me tweek it one bit!

Guest (not verified)

Wed, 04/13/2011 - 05:44

Thanks for all your plans!

I can't wait till the snow is all melted and I can make a few of these projects. My girls are going to be spoiled rotten :D Thanks Ana for all your work. MUCH appreciated!!!

Chad (not verified)

Thu, 12/08/2011 - 09:20

A great addition for my daughter's craft station

I built four of these chairs last weekend to go along with a large crafting table I am builing for my six-year-old daughter for Christmas. Paying $40-60 each for four chairs was simply out of the question. I saw these plans and they matched the design of the table project better than anything I had seen in stores. The simple design and low cost were great added benefits! The build was quick and easy, and after filling all of the seams, screw holes and end grains (and LOTS of sanding), the finished product looks great. I can't wait to see the look on my daughter's face and I'm sure these chairs will last for many years to come!

On a side note, I did have one minor issue with the build that was eaisly solved by picking up and extra 2x2. The shopping list calls for 2-2x2x8 (192 board inches) but the cut dimensions equal 192.25 board inches. Try as I might, I couldn't get my board stretcher to work, so I opted to purchase an extra stick. That drove my total cost per chair to a "whopping" $10.25...including the finish! I was able to build 4 chairs for about the same cost as one of the lower-priced "store-bought" chairs. Thanks for the plans and keep up the good work!

jart545 (not verified)

Sat, 06/09/2012 - 12:32

inquiry

Nice chair. Thanks for sharing.

By the way, can you share the materials and specs of the table. I think it is very nice to make both.

Thanks so much.

Jake

moonhopping

Sat, 11/17/2012 - 18:03

pocket holes

This is my second chair. But my first since I got my kreg jig, i am having difficulty with the pocket holes. The drill and bit are to long to fit between the legs and supports. Any tips or ideas?

moonhopping

Sat, 11/17/2012 - 18:05

pocket holes

This is my second chair. But my first since I got my kreg jig, i am having difficulty with the pocket holes. The drill and bit are to long to fit between the legs and supports. Any tips or ideas?

gretaWEBB

Mon, 08/31/2020 - 16:23

Grandson Loves his chair

built this is two (very hot TX) days. we used 1x6 for the seat, cut two, leaving a gap for small fingers to grip as they climb up. Grandson (2.5 year old) mastered the climb the second time. All grown up tested it and love the design and sturdiness of it.