The farmhouse table goes cozy in this round version. Easy to build base from 2x4s. Free plans by ANA-WHITE.com

Preparation

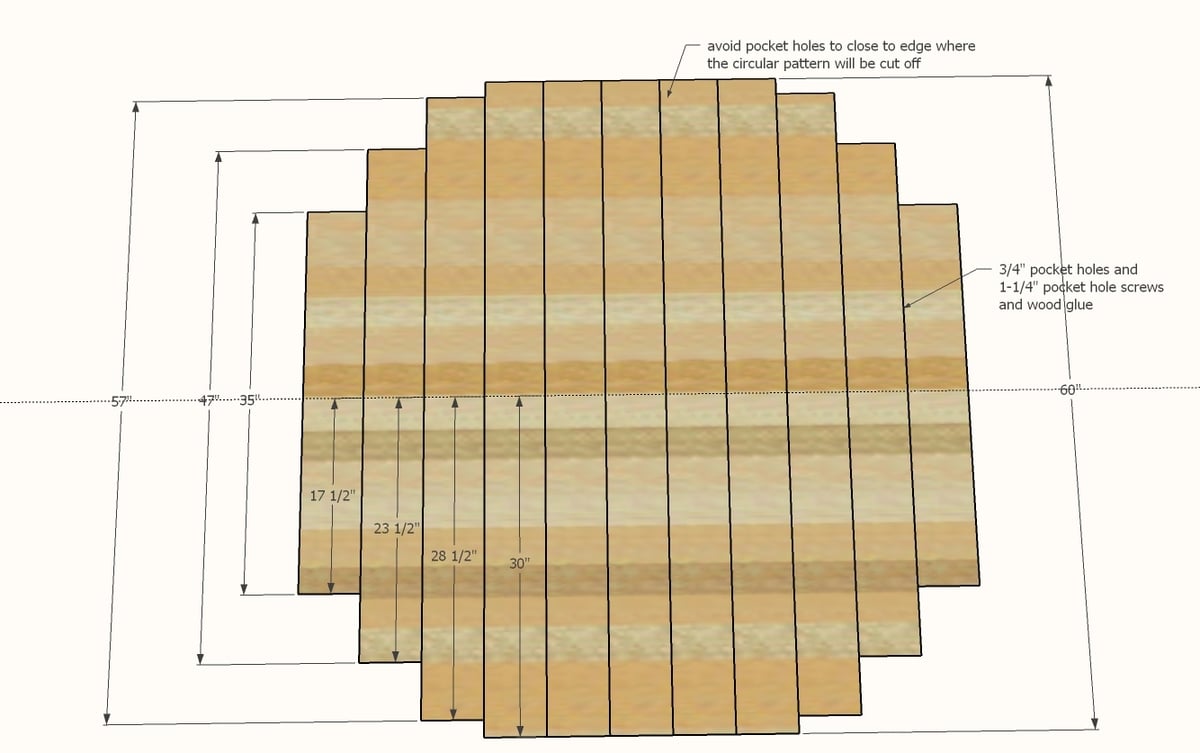

7 - 1x6 @ 10 feet long - cut longest boards first, work down to smallest boards with scraps

4 - 2x4 @ 12 feet long (can be in smaller pieces or 6 - 2x4 @ 8 feet long)

1 - 2x6 @ 8 feet or stud length

2 - 3/4" self tapping wood screws

1-1/4" self tapping wood screws

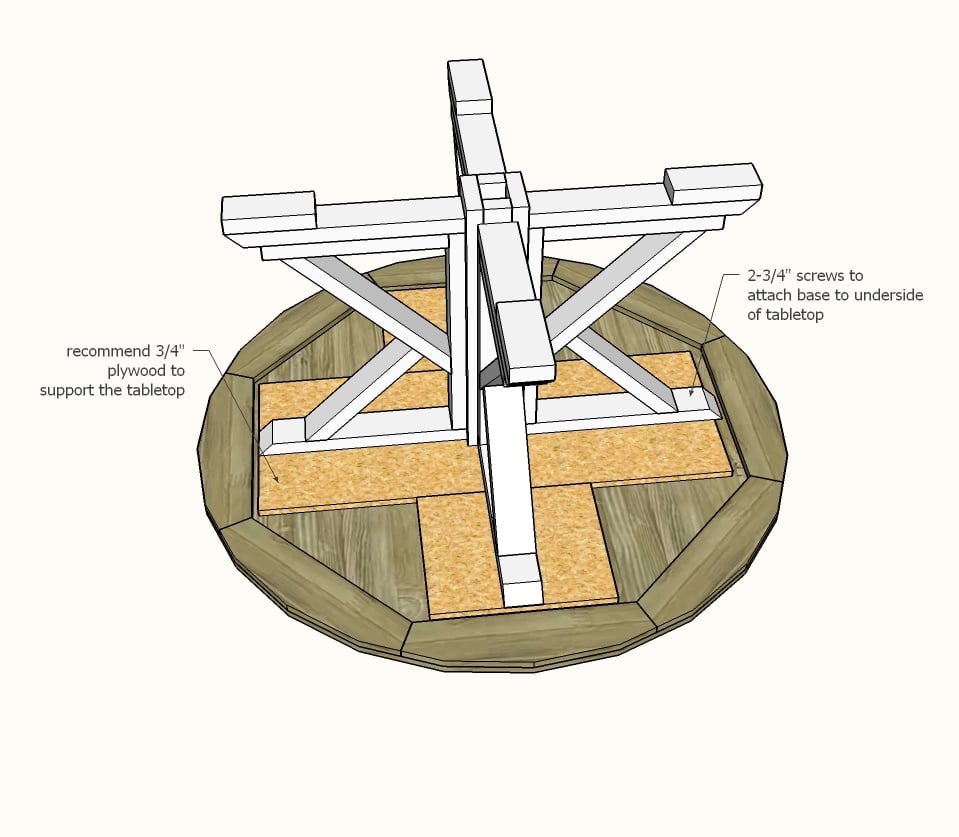

3/4" plywood scraps (recommended)

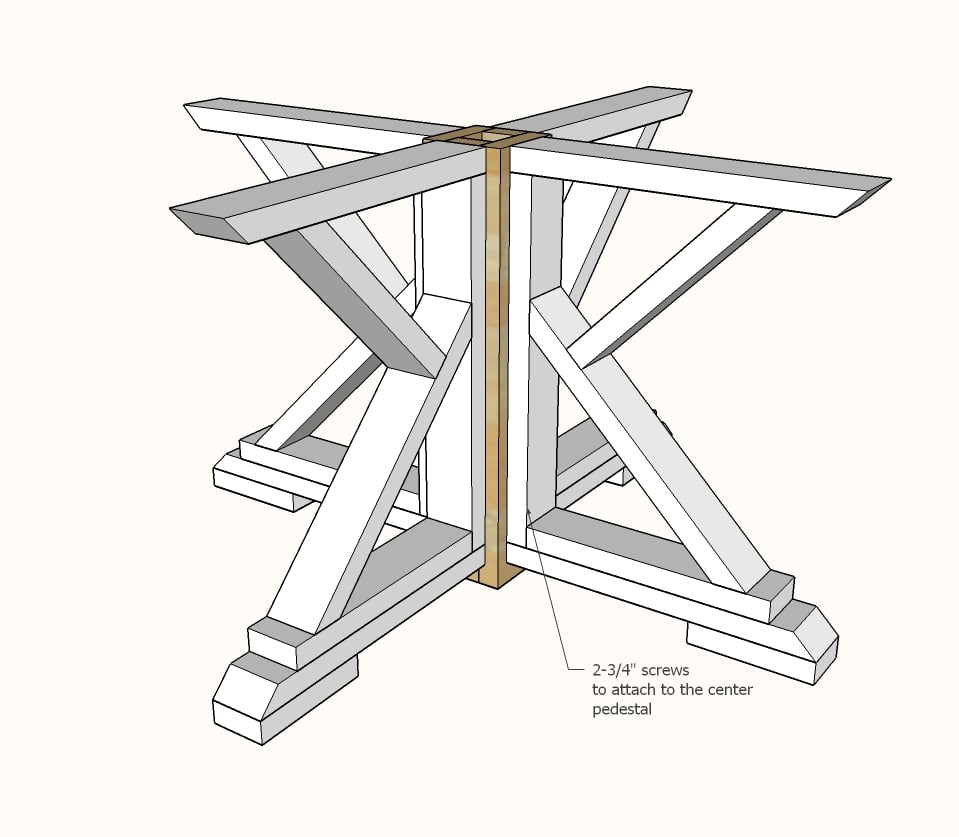

Center

2 - 2x6 @ 28-1/2"

2 - 2x4 or 2x6 @ 2-1/2"

Legs

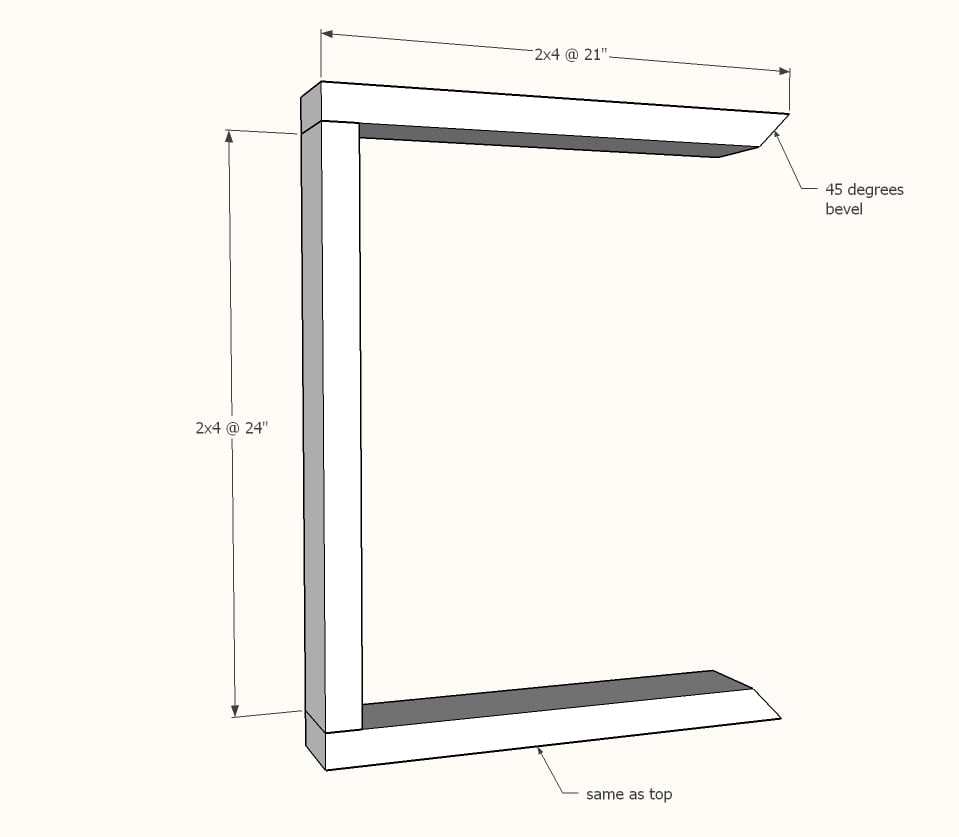

4 - 2x4 @ 24"

8 - 2x4 @ 21" - long point measurement, one end cut at 45 degree bevel

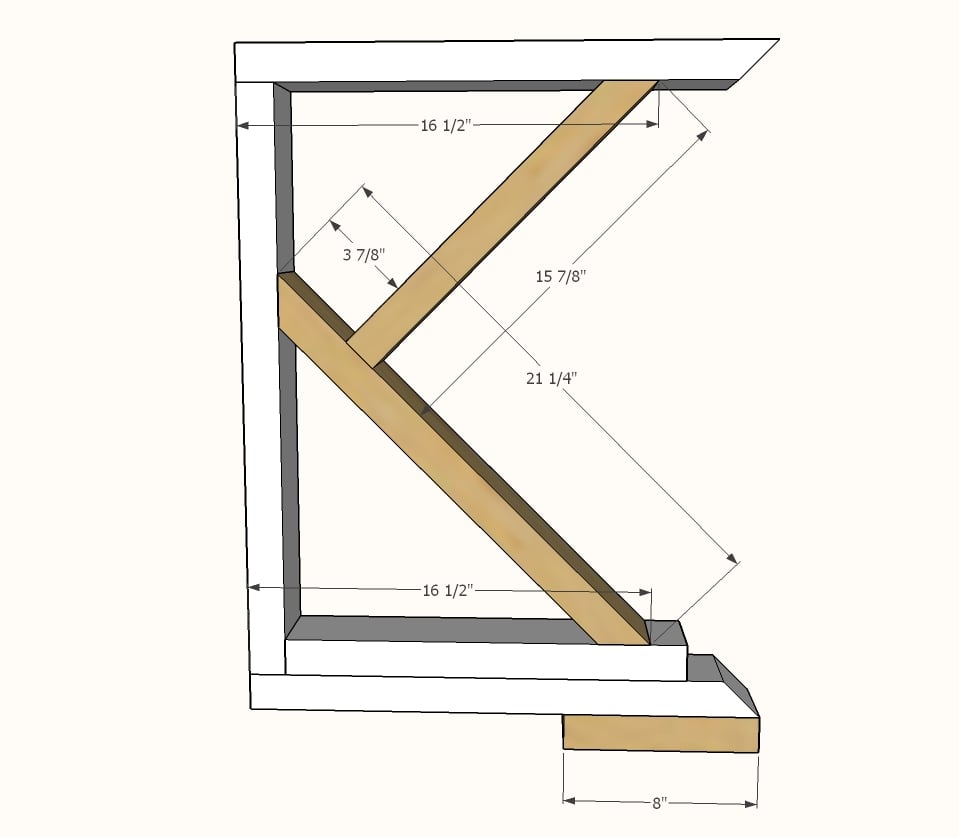

4 - 2x4 @ 16-1/2"

4 - 2x4 @ 8"

4 - 2x4 @ 21-1/4" - long point to long point measurement, both ends cut at a 45 degree bevel, ends NOT parallel

4 - 2x4 @ 15-7/8" - long point measurement, one end cut at 45 degree bevel

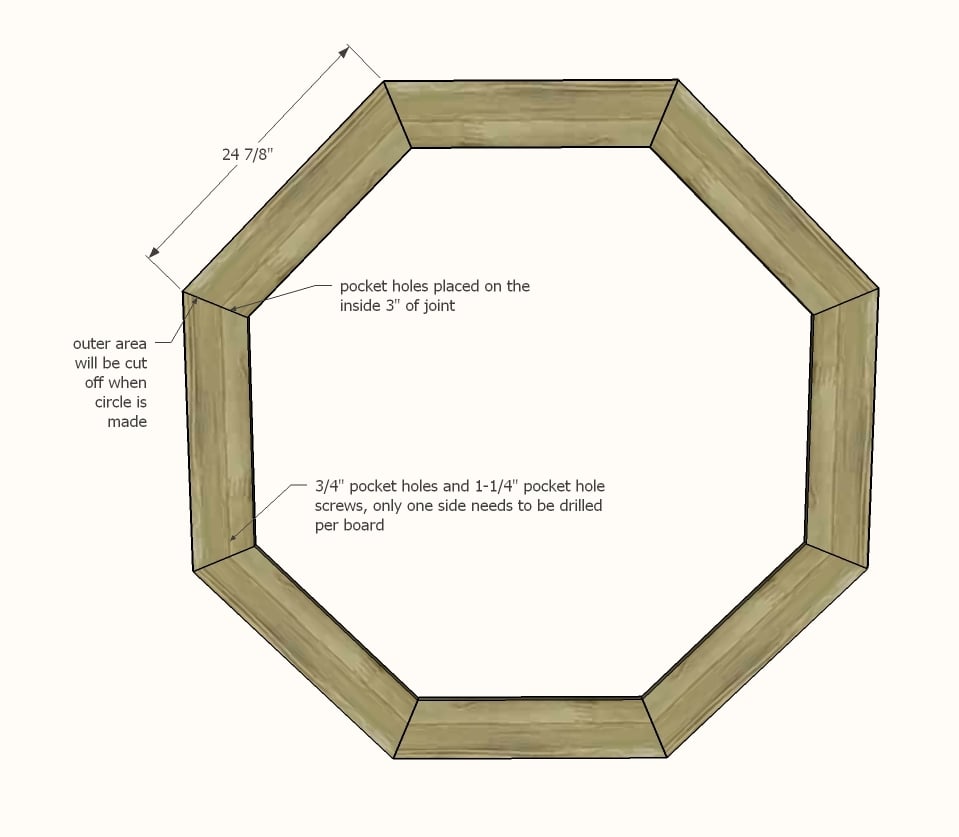

Top

8 1x6 @ 24-7/8" - Longest point measurement, both ends cut at 22.5 degrees, ends NOT parallel

5 - 1x6 @ 60"

2 - 1x6 @ 57"

2 - 1x6 @ 47"

2 - 1x6 @ 35"

Instructions

Step 1

Step 2

Step 3

Step 4

Step 6

Step 7

Attach the octogon ring to the tabletop with glue and 1-1/4" screws.

Cut the circle out (see video for detail).

Comments

kwaltons

Fri, 01/25/2019 - 06:26

Making Smaller

Does anyone have suggestions for making this smaller? I LOVE the design, but my space won't allow for a 60" table. I'd like to make it 48"-50", but I'm getting flummoxed by the octagon and how to transfer the measurements. Does anyone know of an online calculator that would help with the process?

Thanks in advance!

In reply to Making Smaller by kwaltons

Brian Famous

Sat, 02/02/2019 - 08:59

48" round table top

kwaltons,

if you want the table top to be 48" in diameter instead of the current measurements, you actually just need to knock 5" off of each of the 1x6 boards. So instead of 24 7/8", you need to cut them to 19 7/8". That should allow a 48" diameter circles to be cut if you ensure your fulcrum is dead smack in the middle.

Hope this helps!

keithdeith10

Tue, 07/14/2020 - 14:28

What wood would you use for…

What wood would you use for the top.

49rPhan

Thu, 07/16/2020 - 19:41

I'm following too just to…

I'm following too just to know. Don't want to use too soft of a wood for the table.

Vintage-Farm-Wife

Sat, 06/08/2019 - 13:08

Am I looking at this wrong? …

Am I looking at this wrong? Doesn't the center part need 4 of the 2-1/2" blocks?

devlinfa

Sun, 03/21/2021 - 03:24

I have been studying the…

I have been studying the design and I agree it must be 4 of the 2-1/2"

ashleyncsu

Sun, 09/08/2019 - 18:33

In the picture and video it…

In the picture and video it looks like the table top is beveled. If so, did you use a router for this? Which type/size bit?

JMac2474

Sun, 12/15/2019 - 02:52

Jig specs

Great design and tutorial! One fine detail, what was the dimension of the jig for the first pass around? 60’ inch table 30’ from the attached point? Or did you start out longer and then finished at 30’?

KyleG.

Sat, 12/28/2019 - 11:49

Great design but I'm also…

Great design but I'm also looking to make it a bit smaller (48"-50"). What should the angles of the pieces for the octagon ring be cut at?

lumberboy13

Sun, 01/12/2020 - 07:35

To make the octagon 48" in…

To make the octagon 48" in diameter, the segment length needs to be 1' 7-7/8" like Brian said above. No matter what size you make the ring, the angle of each cut needs to be 22-1/2 degrees.

steve4christ

Wed, 04/21/2021 - 14:29

Measurement rookie

I been struggling with the numbers😳 could you share what the octagon measurements would be for a 42” round table and the formula you used.

jasoncsmith1979

Mon, 06/08/2020 - 22:00

Base

If the table is 60” with the base being 48” what would be a stable base size be? Don’t think with the top being 48” that the base should be 48”.

jasoncsmith1979

Mon, 06/08/2020 - 22:01

Apologies for the grammar.

Apologies for the grammar.

ezjensen

Wed, 06/17/2020 - 11:03

Base

@jasoncsmith1979 I am looking to make this top at 48" as well. Thinking I'm going to make the bottom at 36".

The plans have the base 12" shorter, so I'll make is 12" shorter with the smaller top as well. I'm guessing there is most likely some mathematical equation for this, but that is not my strong suit.

keithdeith10

Wed, 07/08/2020 - 17:57

What type of wood did you…

What type of wood did you use. Looking to start this project this weekend.

mlbest1

Thu, 09/10/2020 - 12:39

Jig Length

Can you tell me what the length of the jig is? I'm guessing that it is a little longer than 30 inches due to the off set for the hole used to attach to bottom of table top? Also, did you use a router to make the groove around the edge of the top?

Thanks,

Mike

BAPoppe

Thu, 12/24/2020 - 10:31

Making a 72" table.

To make the table larger to 72" in diameter. What length do the 8 pieces cut at 22.5 degrees need to be, and do I have to extend the base dimensions out farther?

jbarcher13

Fri, 06/18/2021 - 12:12

Modifying the base of the circular farmhouse table

Those of you that want a smaller tabletop. (48" to 50"), would you keep the base the same as this plan or make modifications to that too?

Many thanks, Jan

williamsjamesridge

Sat, 12/25/2021 - 19:07

Wood types

What were the 2 types of wood (tabletop and base) used in this project?

kmg671983

Wed, 02/09/2022 - 13:05

Question

How hard would it be to alter this to be an oval table with this base?

KBrochu

Wed, 02/23/2022 - 14:46

Round Farmhouse Table Jig Sizes?

To make the 60" Round Farmhouse Table does anyone know what the jig sizes are?