Build your own modern dollhouse with free plans from Ana-White.com Cost was about $30 for materials. It's a joy to build and a joy to give!

Pin For Later!

Preparation

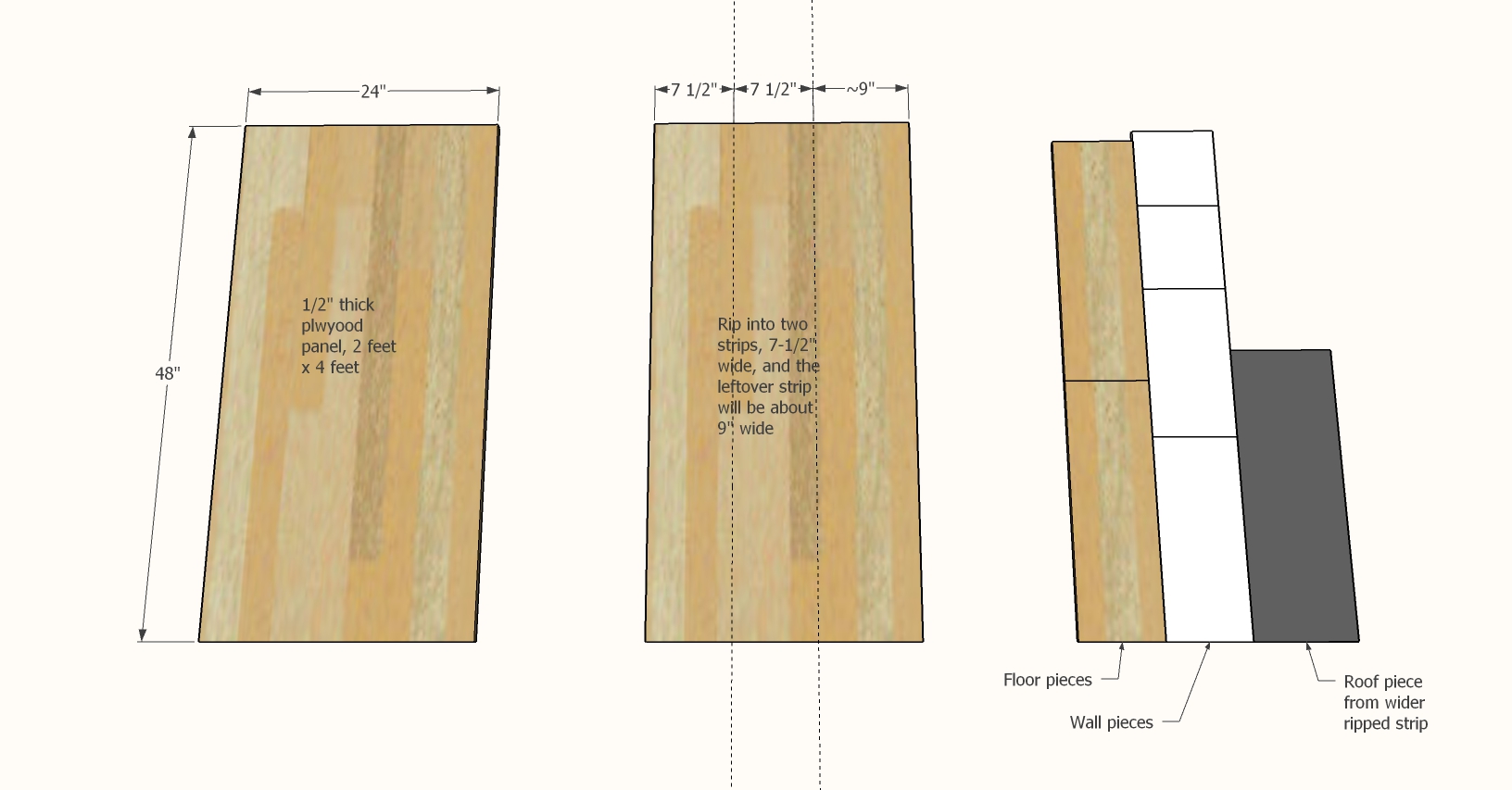

1 - 1/2" plywood panel, 2 feet x 4 feet in dimension

1 - 1/4" plywood panel, 1 foot x 2 feet in dimension

1-1/4" and 5/8" brad nails

Instructions

Step 1

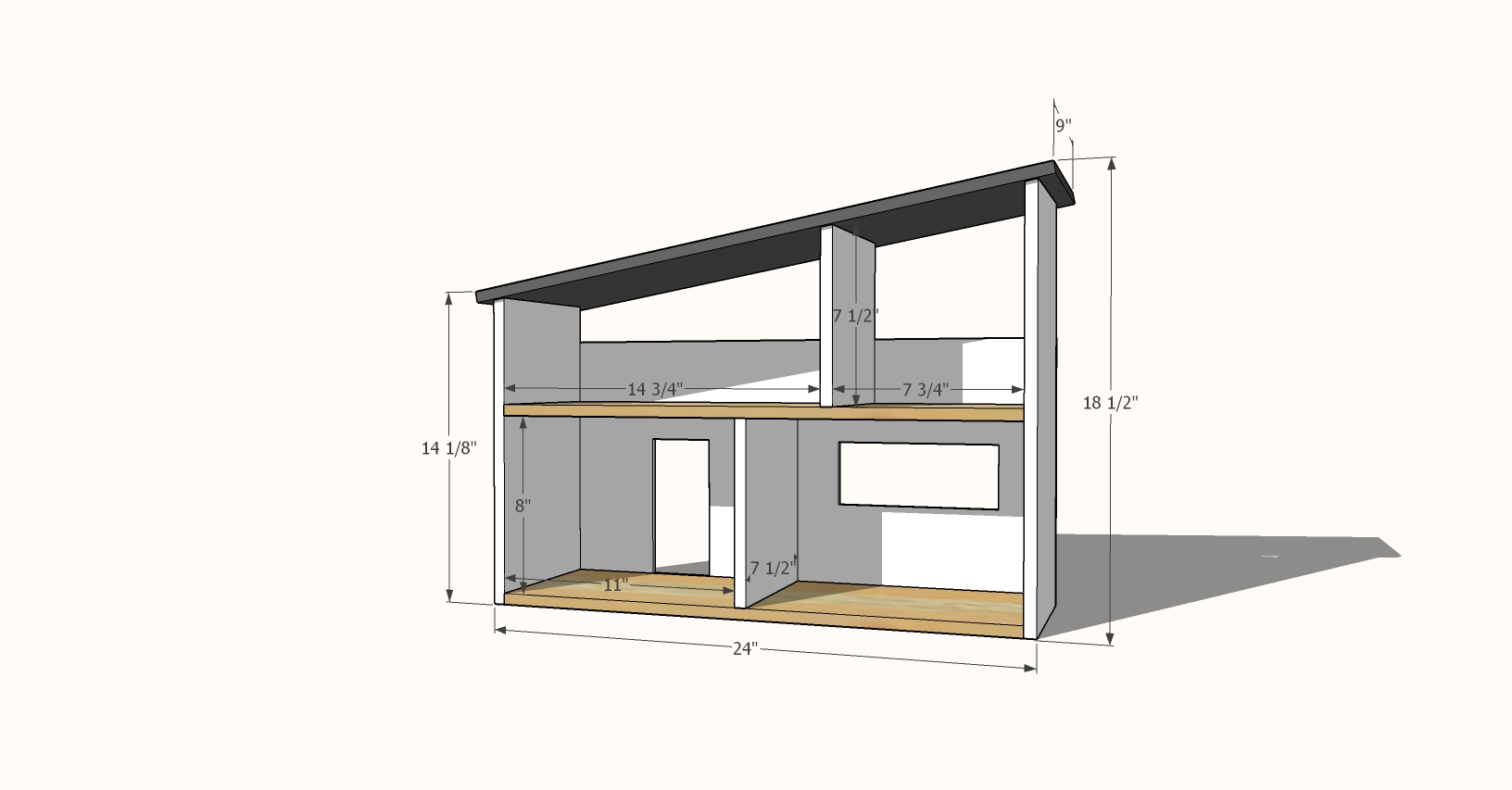

From the 1/2" piece of plywood measuring 2 feet x 4 feet, rip into two strips that are each 7-1/2" wide x 48" long. Save the remaining strips (about 9" wide) for the roof panel. Rip using either a table saw, a circular saw with a straight edge, or have your home improvement store make the cuts for you.

Then cut from those pieces the following:

From the 7-1/2" wide rips:

- 2 @ 23" - floors

- 1 @ 8" - bottom floor interior wall

- 1 @ 13-3/4" - top end cut at 10 degrees off square, long point measurement (short outside wall)

- 1 @ 18" - top end cut at 10 degrees off square, long point measurement (long outside wall)

- 1 @ 7-1/2" - top end cut at 10 degrees off square, long point measurement (upper floor interior wall)

From the 9" wide strip

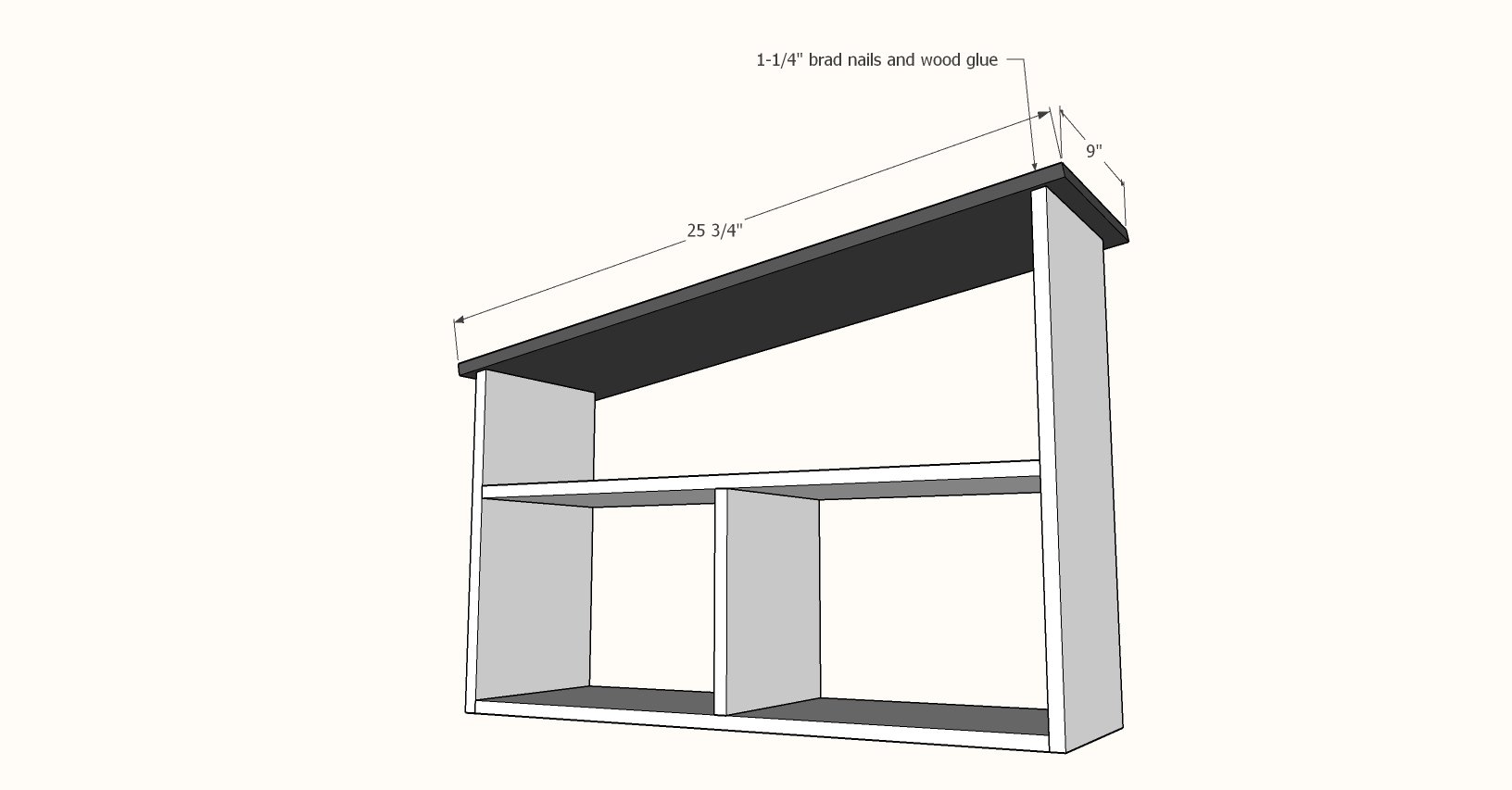

- 1 @ 25-3/4" - roof

For the back

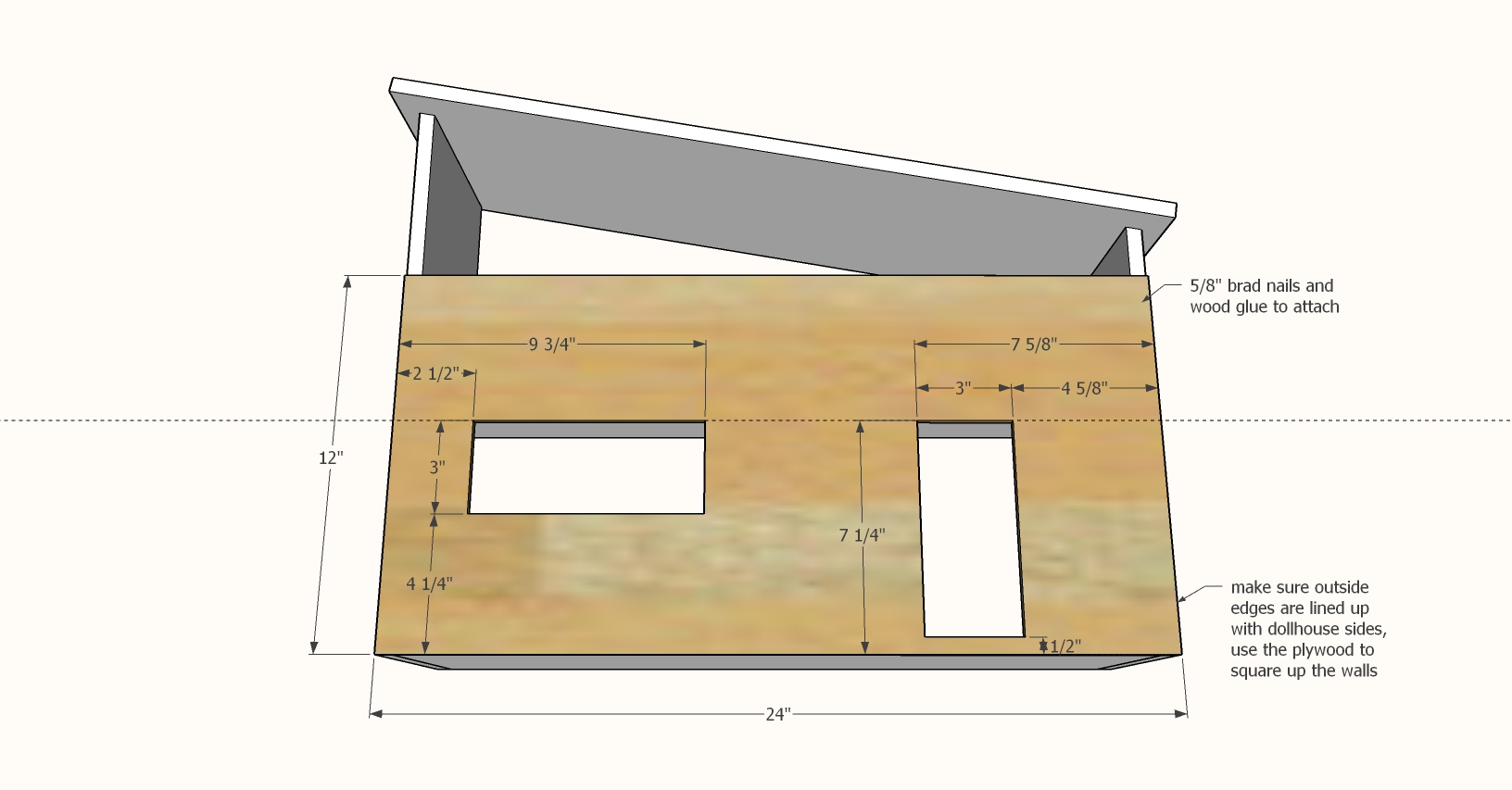

- 1/4" plywood @ 12" x 24" (may not need to cut at all)

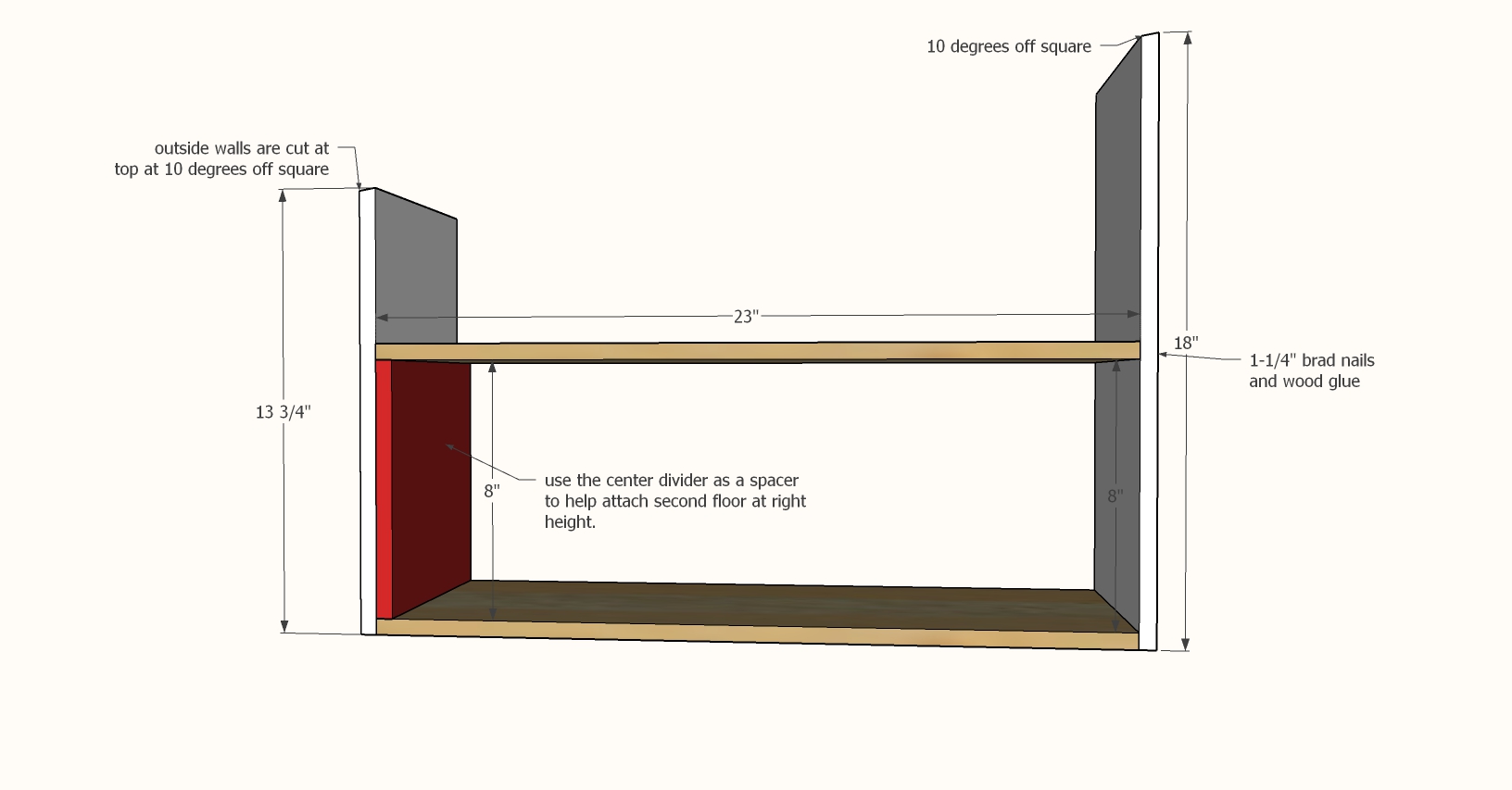

Step 2

Attach the bottom floor to the side walls, making sure the side walls are orientated correctly, so the top angles angle in the same direction.

Use 1-1/4" brad nails and wood glue.

Then set the bottom floor interior wall (shown in red in the diagram) inside the dollhouse and place the middle floor on top.

Attach with 1-1/4" brad nails. Repeat for the second side of the middle floor.

Step 3

Step 5

Switch nails to 5/8" nails.

Apply glue to the back edges and place the 1/4" plywood on top.

Force the dollhouse walls square to the 1/4" plywood panel and nail on.

Cut holes out with a jigsaw. You'll need to use a drill and drill bit to start the jigsaw in the centers of the windows/doors. I used a Kreg Jig bit.

Vacuum off sanding residue before finishing.

Clear coat over top is recommended for longer durability.

Comments

Sb1212

Tue, 11/23/2021 - 19:37

Love!

Hi, love this! Any plans for the furniture? 😊