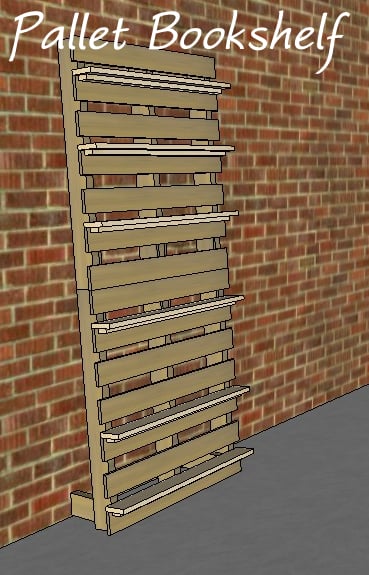

A simple bookcase made from pallets and a few 1x4's.

The measurements will vary based on the size of the pallets used. Be on the lookout for donor pallets to provide wood for the shelves and support pieces. If you don't have enough pallet wood to make the shelves you'll need to buy some 1x4's In sketchup the shelves are 36" long.

Preparation

1x2's approximately 36" per shelf, this will vary with the size of the pallets used.

As shown 2 10' 1x2's are needed

Please read through the entire plan and all comments before beginning this project. It is also advisable to review the Getting Started Section. Take all necessary precautions to build safely and smartly. Work on a clean level surface, free of imperfections or debris. Always use straight boards. Check for square after each step. Always predrill holes before attaching with screws. Use glue with finish nails for a stronger hold. Wipe excess glue off bare wood for stained projects, as dried glue will not take stain. Be safe, have fun, and ask for help if you need it. Good luck!

Instructions

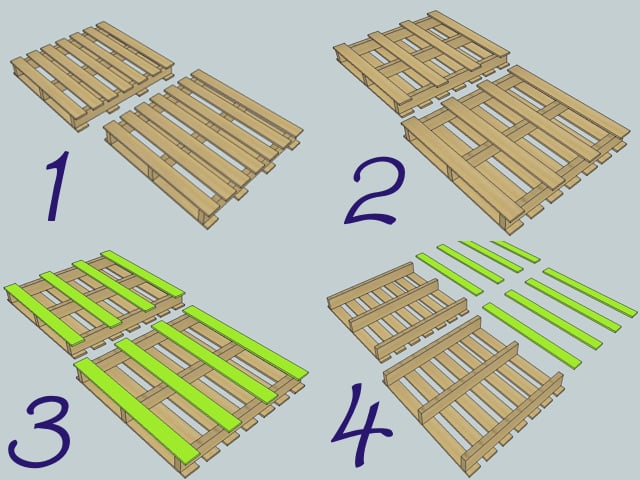

Step 1

1. Find two pallets of the same size in good condition. A third pallet can be used as a donor for shelf boards and support blocks.

2. Flip the pallets upside down

3. Remove the bottom boards as carefully as possible. This is the fun part. Cutting the nails with a reciprocating saw works well.

4. Save the boards to be reused

Step 2

5. Set the pallets end to end.

6. Cut 4 12" pieces of boards saved from the bottoms of the pallets. Sandwich the center runner with two pieces and put one piece on the inside of each outer runner. Drive 3 2" screws into each side of the joints. Each 12" board will have 6 screws in it.

7. Lean the attached pallets up against a wall. Adjust the angle until it looks right. In the sketchup the pallets are at a 5 degree angle from vertical.

8. When you are happy with the angle measure from the top edge of the bottom board back to the wall. Cut 2 pieces of 2x4 to this length. In the example it was 9.5 inches. Your measurement will probably differ.

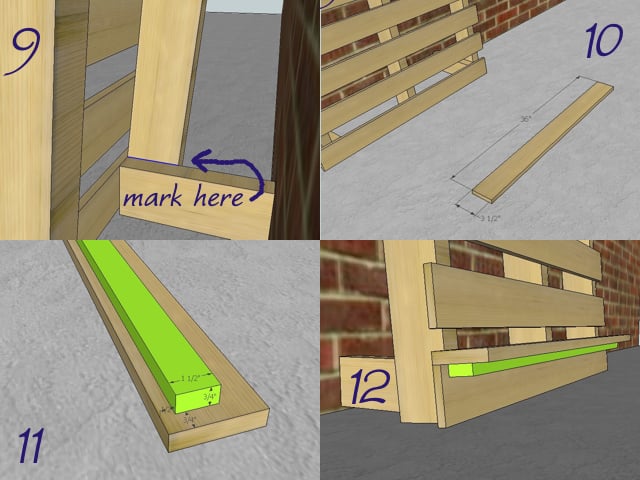

Step 3

9. Insert the 2x4 blocks in behind the pallets alongside the outer runners. Scribe a line across the top of the 2x4 on both sides. Flip the pallets back upside down on the floor. Align your 2x4 blocks with the line and fasten to the pallet with 4 2.5" wood screws. Screw from the inside so the holes will be hidden.

10. Stand the pallets back upright. Cut shelving to the width of your pallets. You will need one 1x4 or pallet board per shelf.

11. Cut 1x2 supports to the length of your shelf minus 1.5 inches. This will give you a 3/4" overhang on the ends.

12. Clamp the 1x4 in position on top of one of the pallet boards. Place the 1x2 support underneath and clamp it to the 1x4. Predrill 3-4 holes through the back of the pallet boards into the 1x2. Drive 2" wood screws to secure the 1x2 to the pallet. Then predrill holes up through the bottom of the 1x2 into the 1x4. Offset the holes so you don't hit the screws already in place. 3-4 holes with 1.5" screws per shelf should be plenty

Step 4

No illustration but this is an important step. The top of the bookshelf should be fastened to the wall to prevent it from accidentally tipping over.

Option 1:

Find a wall stud and drive a 3.5" screw through the top of the frame of the bookshelf into the wall. This works as long as you can align the piece with a stud.

Option 2: Attach a "earthquake strap" to the piece and drywall anchor it to the wall.

Option 3:

Attach a piece of 1x2 to the back of the shelf that spans across the three vertical runners and allows you to hit a stud somewhere in the wall. This is probably the best option as you will be able to hit 2 studs

It is always recommended to apply a test coat on a hidden area or scrap piece to ensure color evenness and adhesion. Use primer or wood conditioner as needed.

Comments

Irecreateit

Sat, 04/16/2011 - 07:34

Thanks!!

I have been looking for these plans. I got two 6 ft pallets, to cut out the attaching step. I look forward to building this. Thanks again!

texasjuju

Tue, 04/19/2011 - 01:59

Yes!

I've recently found myself on the look out for pallets by dumpsters all the time. I even made my husband stop and load up an old wood fence that someone tore down, which he later thanked me for when we saved a lot of money on the floor we made for our new shop and where we store our round bales of hay.

So your plan is just one more thing I get to build with my reclaimed wood from my pallets that I still get teased about.

We just made the grandkids a toddler picnic table, and once I get it all painted I'm posting it so others can see just one more thing you don't have to spend money on for your kids/grandkids to love.

Donald

Thu, 06/09/2011 - 01:10

Recycling

What an exellent way to recycle old pallets

rspence (not verified)

Thu, 01/19/2012 - 06:59

Picture

Does anyone have any picture of this book shelf. I was thinking about doing it in a kids room but I would like to see a finished product first. Thanks!

pam hope (not verified)

Mon, 07/16/2012 - 12:12

pallet bookshelf

Another good fact about reusing pallets: here in the US, about 50% of the used pallets you will find are made with oak slats...to withstand the weight of what is being shipped on it...OAK! for free!!!! doesn't get any better than that!

rasnas

Thu, 12/06/2012 - 12:18

awesome idea...but for me...I'm making a vertical garden

This is such an awesome idea!! I am going to modify it a bit & turn the shelf ledges into planter boxes! I don't know how long they will last outside but I'm going to enjoy lettuce, strawberries, and maybe broccoli vertically.