Build your own sideboard with free plans from Ana-White.com. Features three large drawers and three large cupboards behind doors, inspired by Restoration Hardware Printermaker Sideboard, there's plenty of style and storage in this project plan!

Preparation

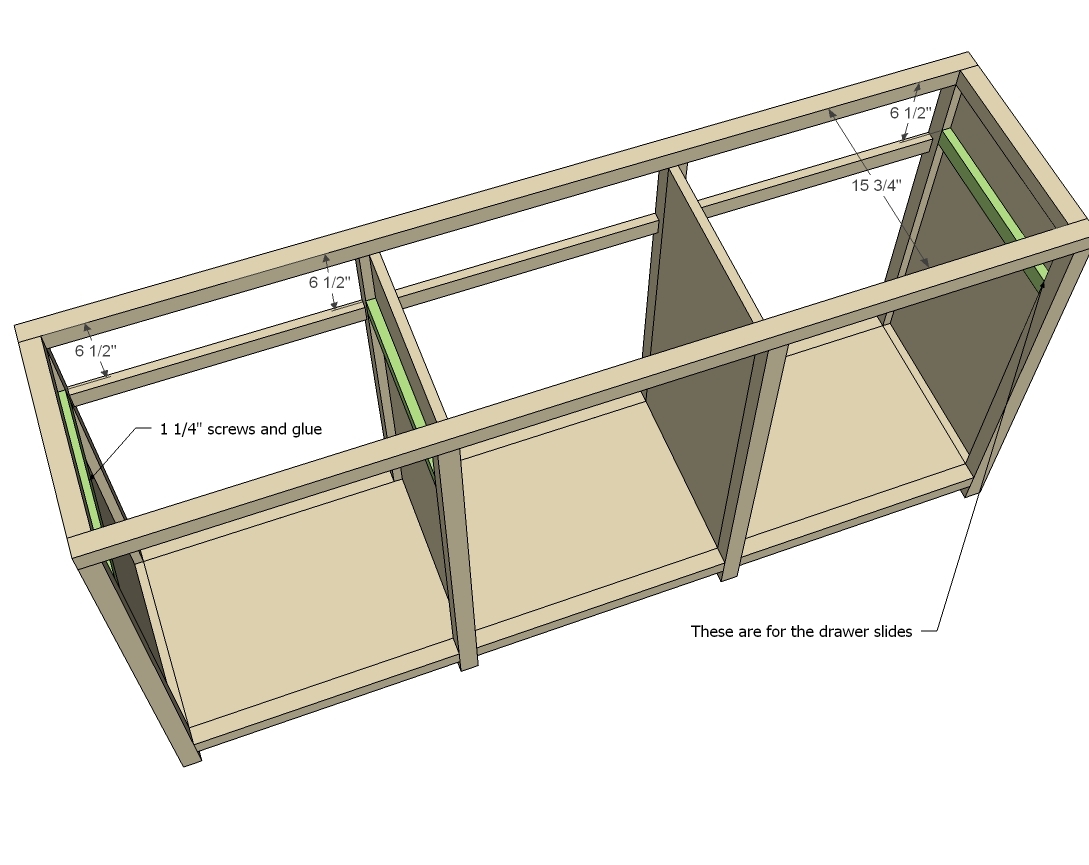

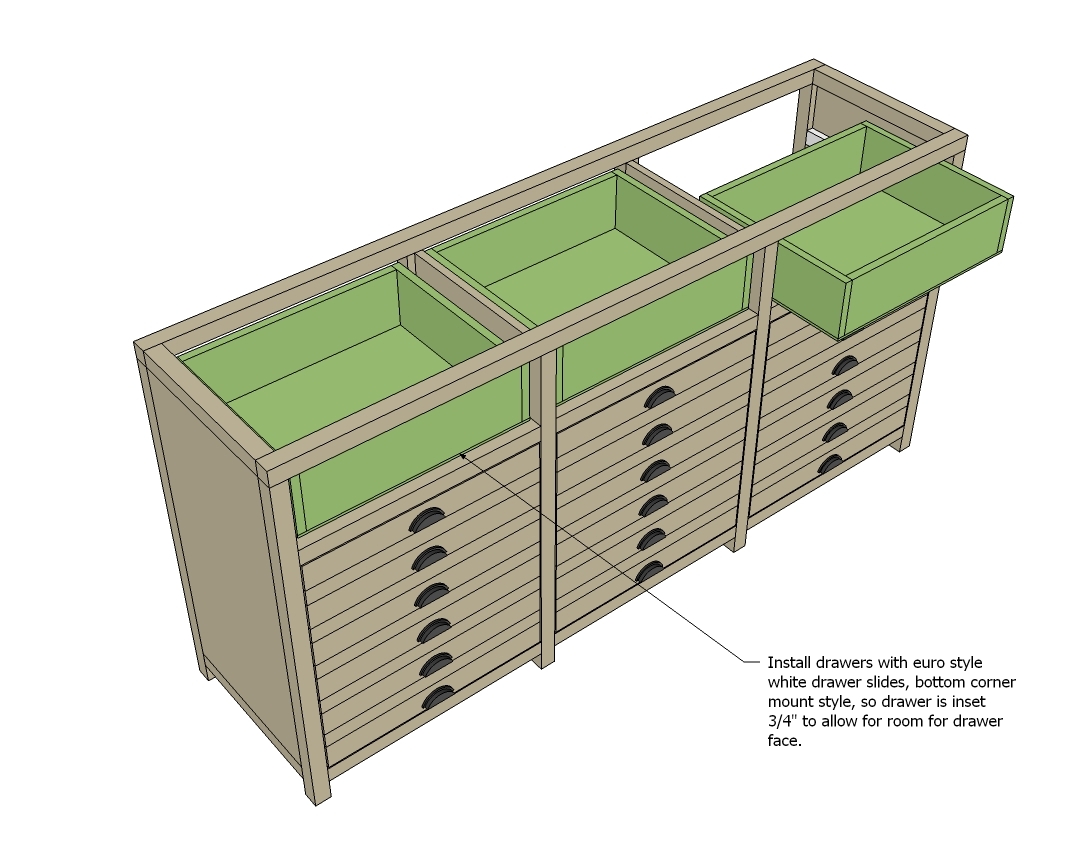

3 sets euro style bottom corner mount drawer slides, 16” length

3 – sets inset hinges

24 – cup style handles

8 – 2x2 @ 8 feet long

6 – 1x3 @ 8 feet long

6 – 1x2 @ 8 feet long

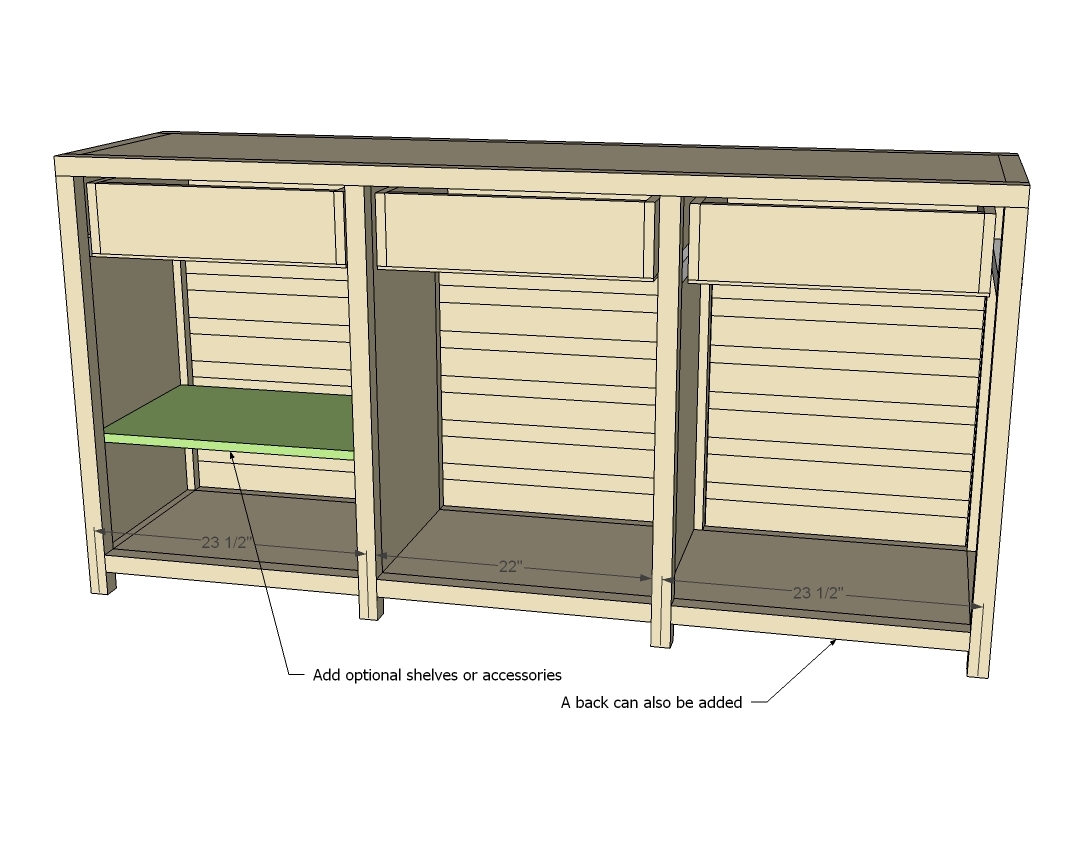

1 sheet ¾” plywood (get 1 ½” sheets if you want shelves)

2 – 1x6 @ 10 feet long

1 ¼” and 2 ½” PH screws

Wood glue

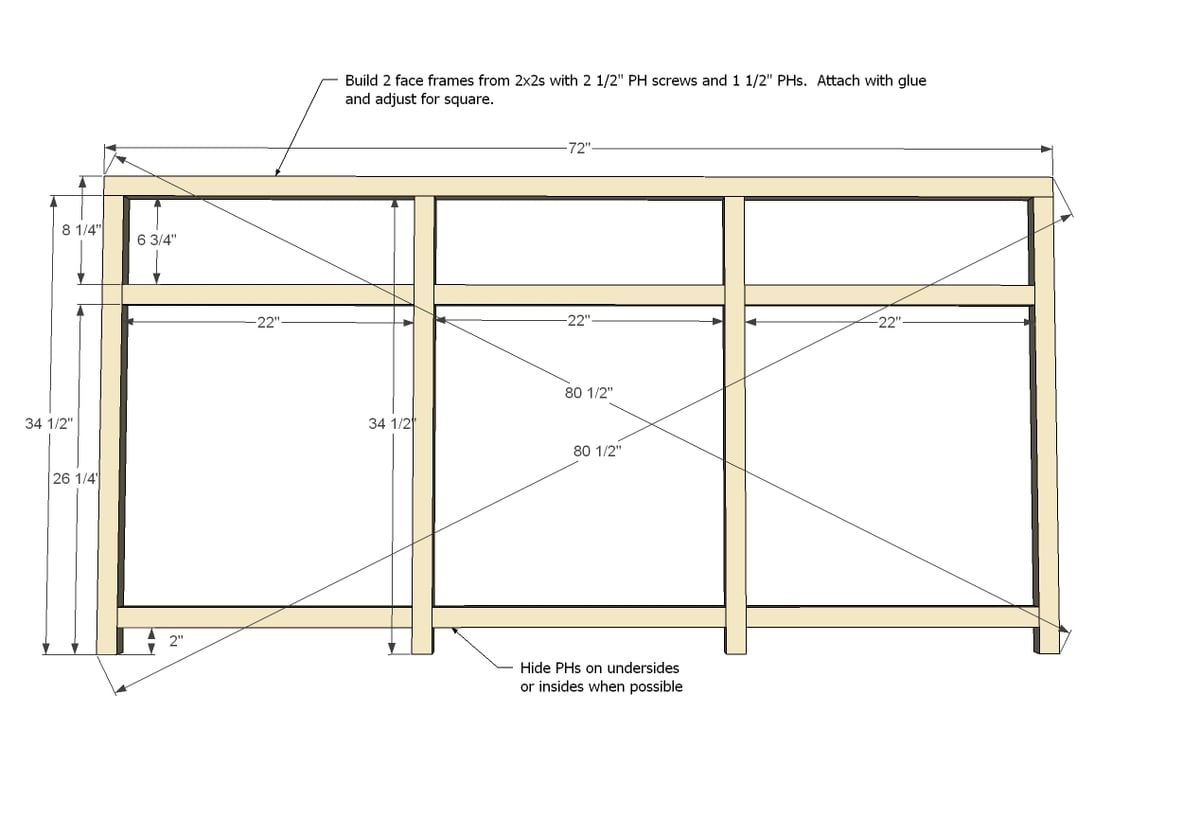

FACE FRAMES

2 – 2x2 @ 72”

8 – 2x2 @ 34 ½”

9 – 2x2 @ 22”

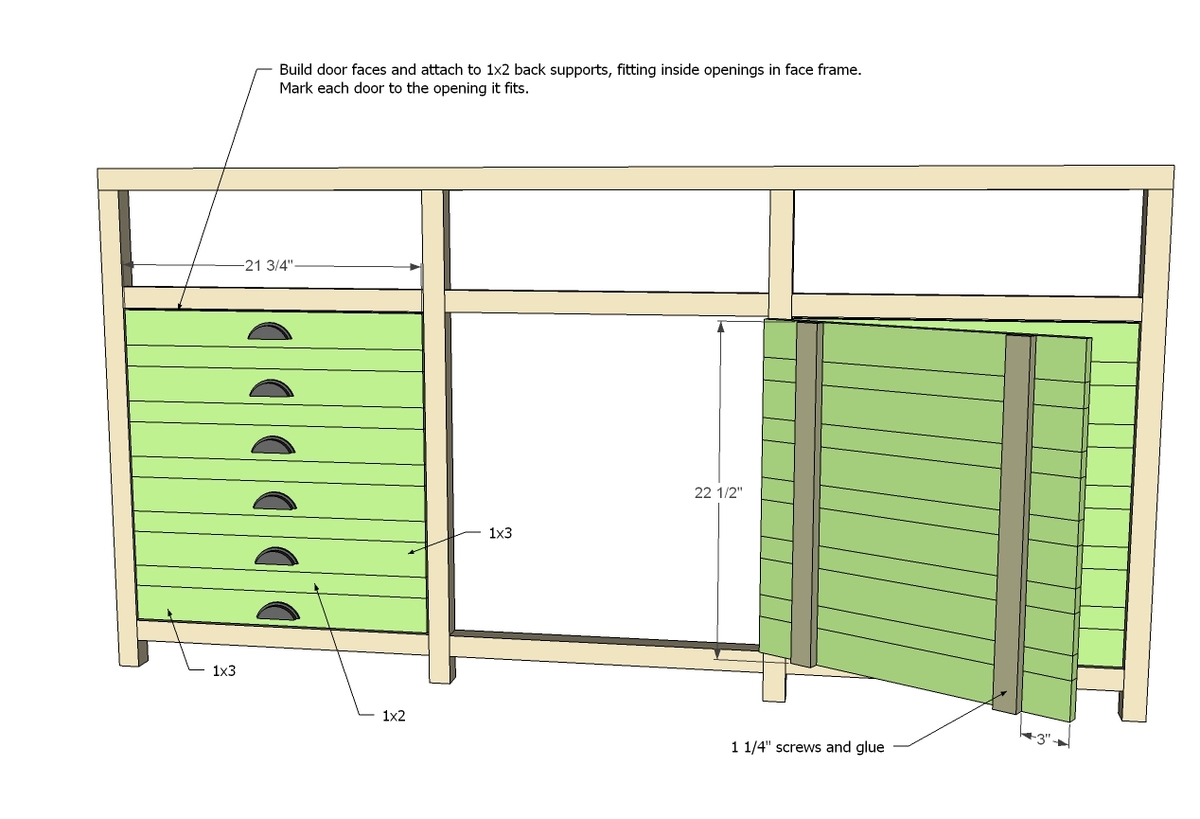

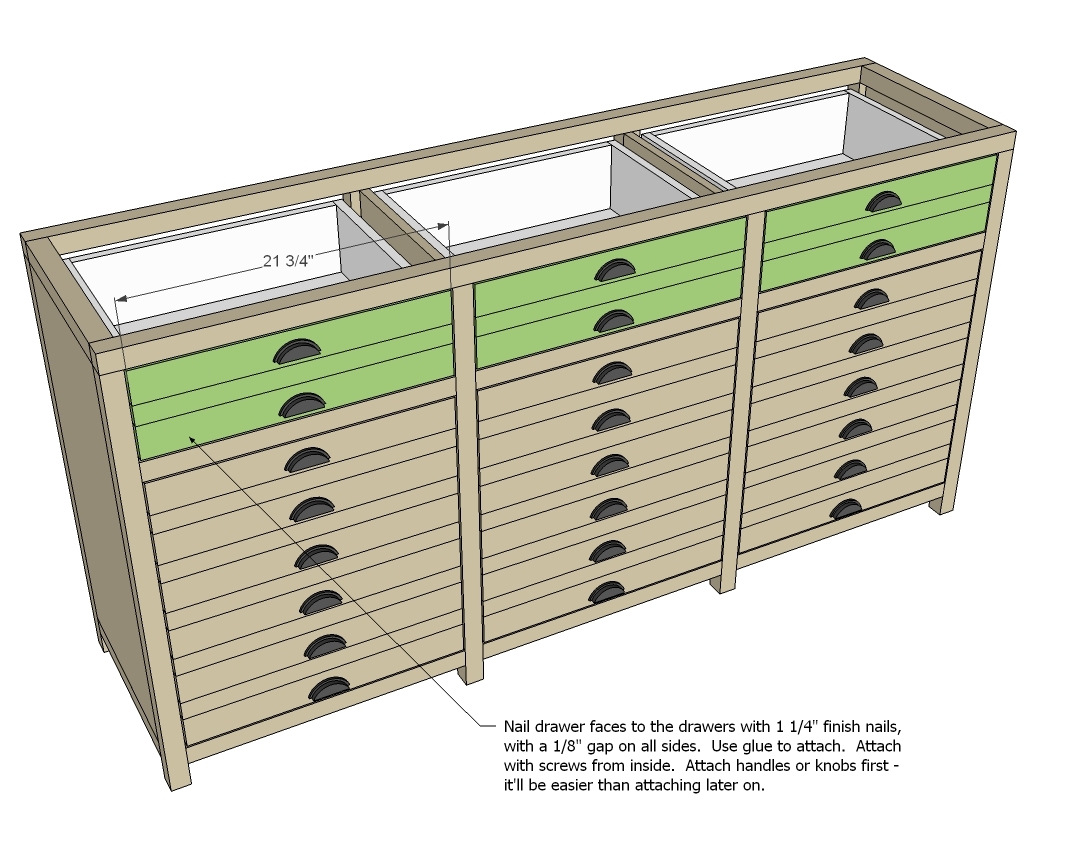

DOOR/DRAWER FACES

24 – 1x3 @ 21 ¾”

18 – 1x2 @ 21 ¾”

6 – 1x2 @ 22 ½”

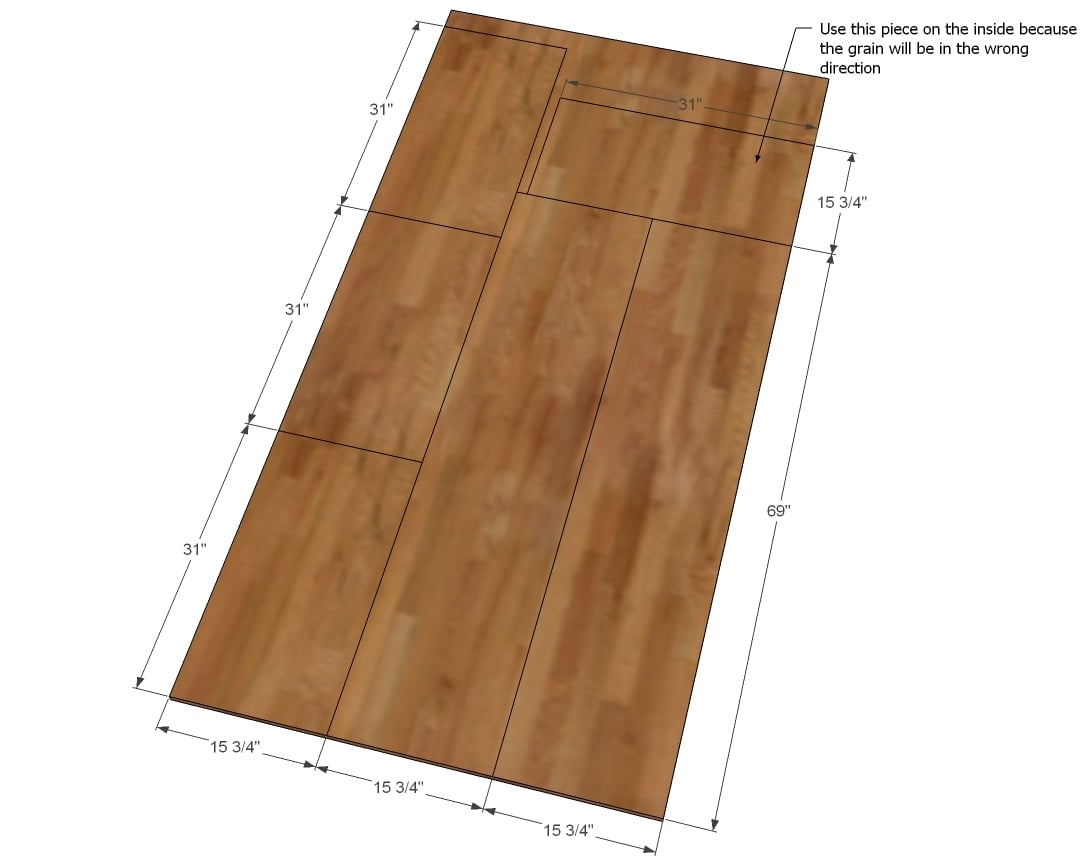

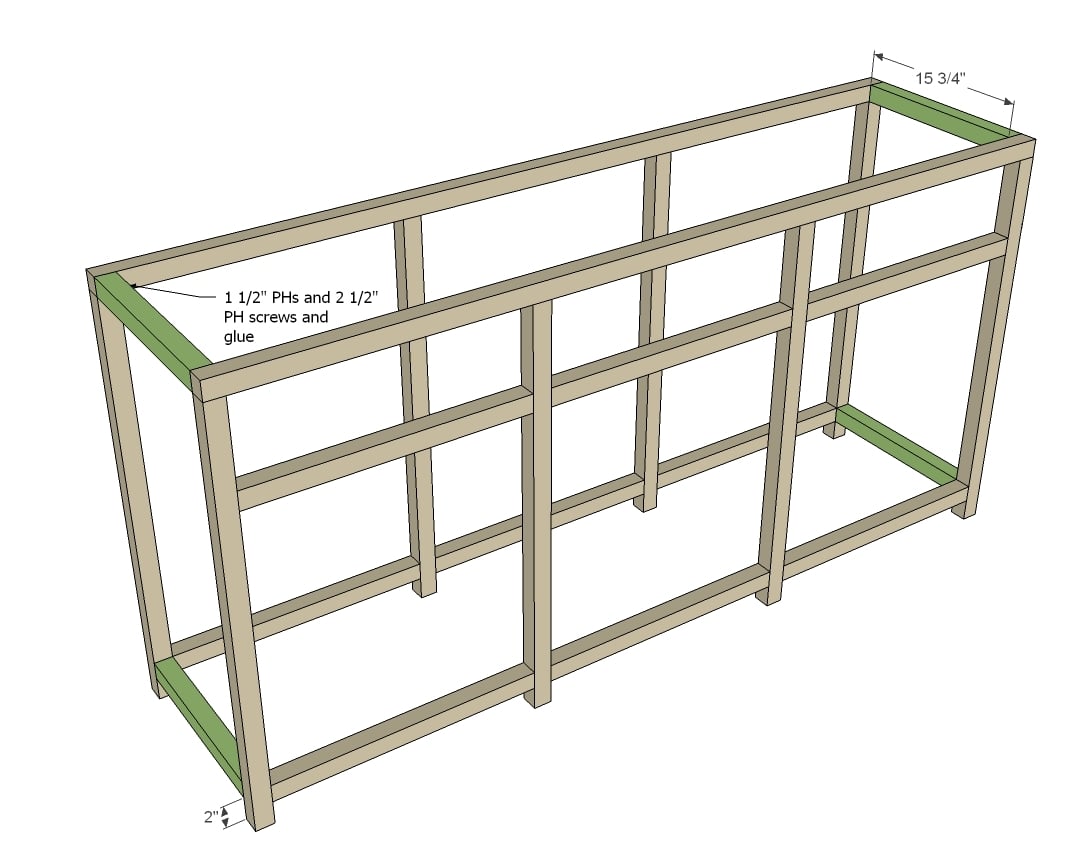

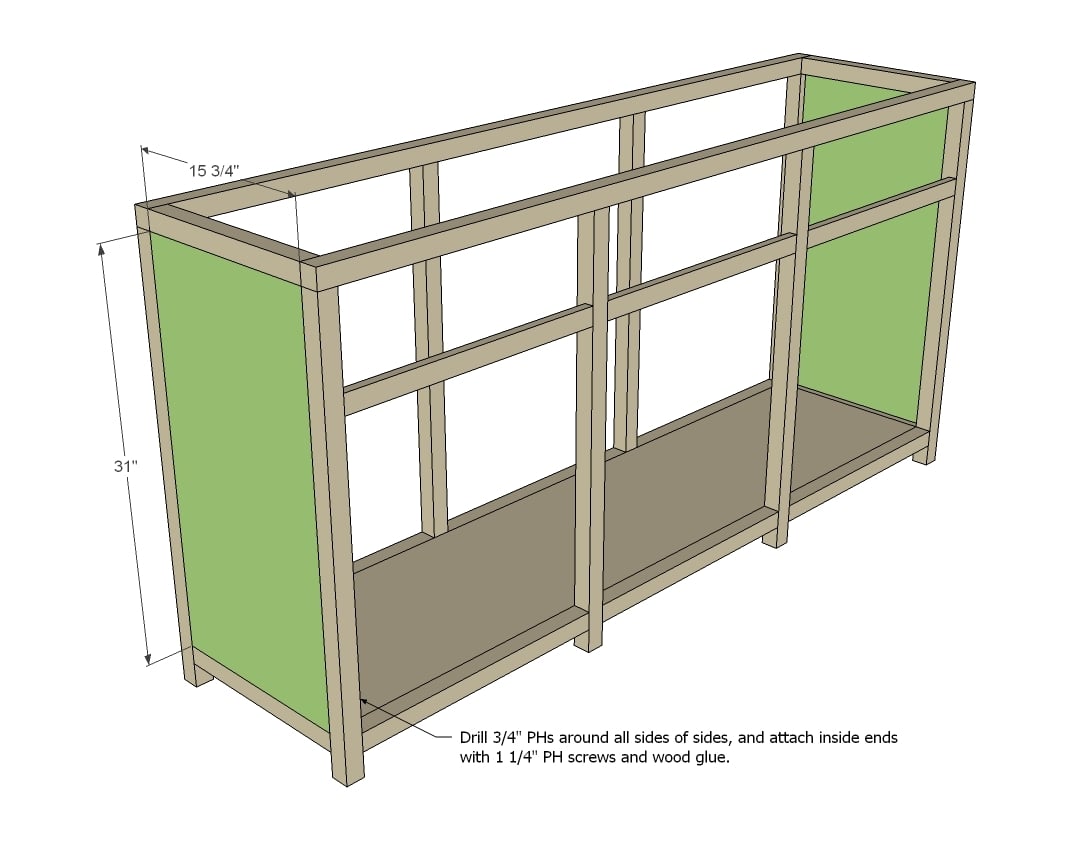

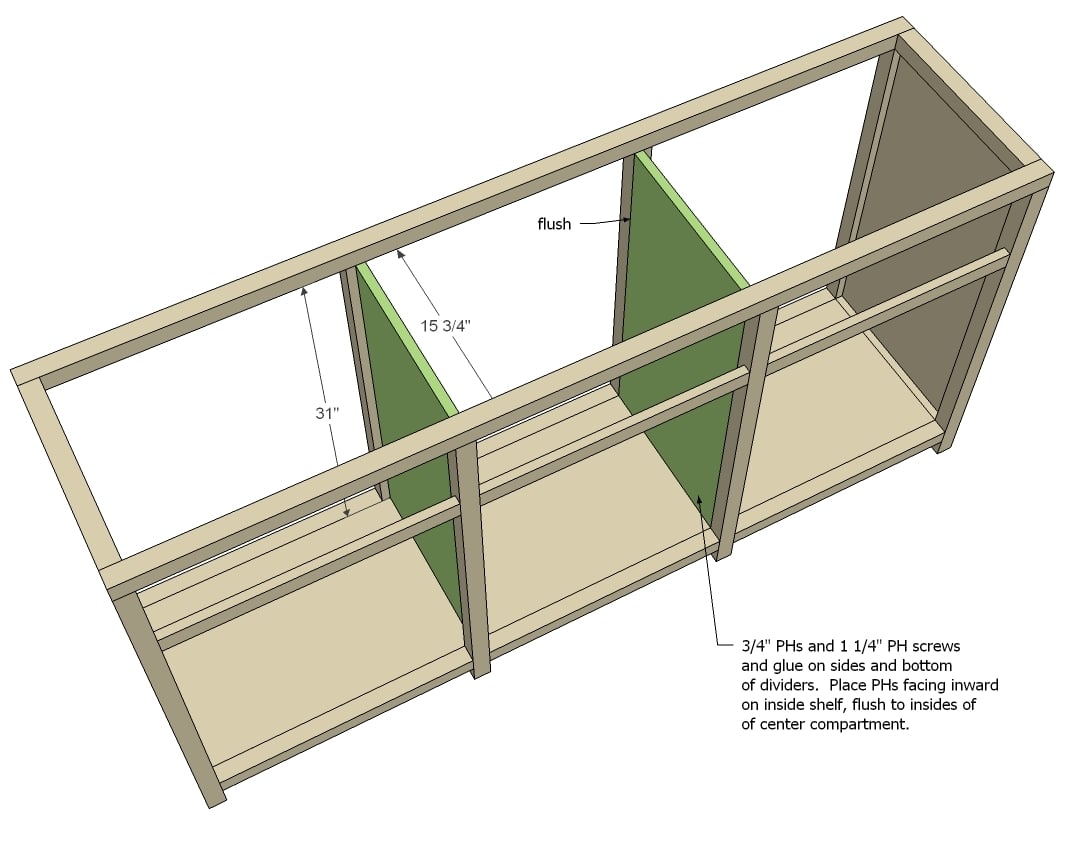

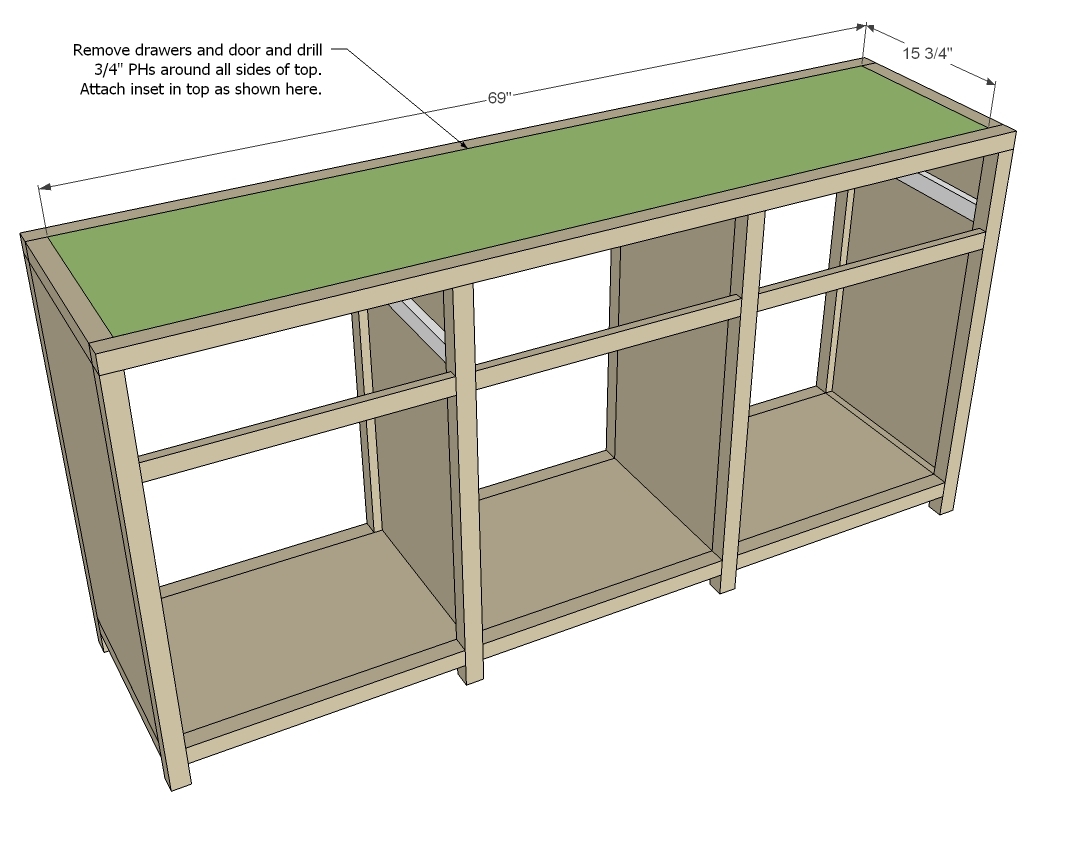

MAIN BOX

4 – 2x2 @ 15 ¾”

2 – 1x16 @ 69”

4 – 1x16 @ 31”

DRAWERS - CUT TO FIT YOUR CABINET!!!!

4 – 1x2 @ 15 ¾” (slide supports)

6 – 1x6 @ 19 ½”

6 – 1x6 @ 17”

Please read through the entire plan and all comments before beginning this project. It is also advisable to review the Getting Started Section. Take all necessary precautions to build safely and smartly. Work on a clean level surface, free of imperfections or debris. Always use straight boards. Check for square after each step. Always predrill holes before attaching with screws. Use glue with finish nails for a stronger hold. Wipe excess glue off bare wood for stained projects, as dried glue will not take stain. Be safe, have fun, and ask for help if you need it. Good luck!

Instructions

Step 1

You’ll probably want shelves, so go ahead and get the extra sheet of plywood, and just have all the plywood ripped into 15 ¾” wide strips, referred to as 1x16s throughout this plan. BUT if you don’t want shelves, or have some scraps to use up, here’s how you can get all the pieces on a single sheet.

Step 3

You'll want to build your doors now to fit the frame. Trust me on this one, lining up 11 boards and getting them all square is going to be a trick. Use the frame to help you build the door faces now.

On second thought – I’d recommend a 1x3 here on the back but a 1x2 will do the trick. Just a little more to bite into.

Once your doors are done, you can put aside.

TIP: Test your drawer face boards for fit at this step too - everything is easier to do when your frame is laying flat down.

Step 8

Step 9

Step 10

Step 11

It is always recommended to apply a test coat on a hidden area or scrap piece to ensure color evenness and adhesion. Use primer or wood conditioner as needed.

Comments

MichelleC

Mon, 10/01/2012 - 14:16

In Love!!!

This is going on "the list"! It is GORGEOUS!!!!!

birdsandsoap

Mon, 10/01/2012 - 15:29

Talk about taking advantage

Talk about taking advantage of those "nesting" instincts! This turned out beautiful. I love the pulls and the illusion of all those drawers. Such a timeless piece. Well done! I was planning on building a dresser and painting it white, but you are lulling me over to the "dark side" with your beautifully stained finish!

spiceylg

Tue, 10/02/2012 - 07:39

Wow

What a beautiful build and 9 months pregnant? Holy moly, that's impressive!

bhoppy

Tue, 10/02/2012 - 08:21

Beautiful!

This turned out absolutely gorgous! Never underestimate the power of nesting instincts:-)

Kate (not verified)

Tue, 10/02/2012 - 08:35

I can't believe she did that

I can't believe she did that 9 months pregnant! I'm only 5 and a half months and struggling just to finish my simple changing table (I found I just couldn't work on it as long every night as I'm used to). It looks gorgeous, and I love the plans!

Mindy (not verified)

Wed, 10/10/2012 - 18:36

Drop fronts?

Do you think this could be revamped with drop fronts instead of drawers to hide tv components?

Gloria (not verified)

Fri, 12/07/2012 - 14:26

My daughter loves this chest.

My daughter loves this chest. My husband is making it for her for Christmas but we cannot read the measurements that are with the photos. I cannot find wnywhere to make them bigger to see the numbers. Do you have a suffstion>

Linnie B (not verified)

Tue, 12/25/2012 - 16:32

Click on the photo to

Click on the photo to enlarge:)

Gloria (not verified)

Fri, 12/07/2012 - 14:34

My daughter loves this

My daughter loves this console. My husband is building it for her for Christmas. We cannot read the dimensions that are on the photos. Any suggestions.

Gloria (not verified)

Fri, 12/07/2012 - 14:39

printer's console

My daughter loves this console. My husband is building it for her for Christmas. We cannot read the dimensions on the photos. Any suggestions

leeannraye

Tue, 02/09/2016 - 18:25

Hinges

Can someone please direct me to the type of hinges to use? I bought some inset hinges but they don't appear to work. I've never felt so confused about hinges.

CassieM

Tue, 01/12/2021 - 08:24

Hinges for this cabinet

For those of you who have made this, where did you get hinges and what kind? I can’t find inset face frame hidden hinges that work.