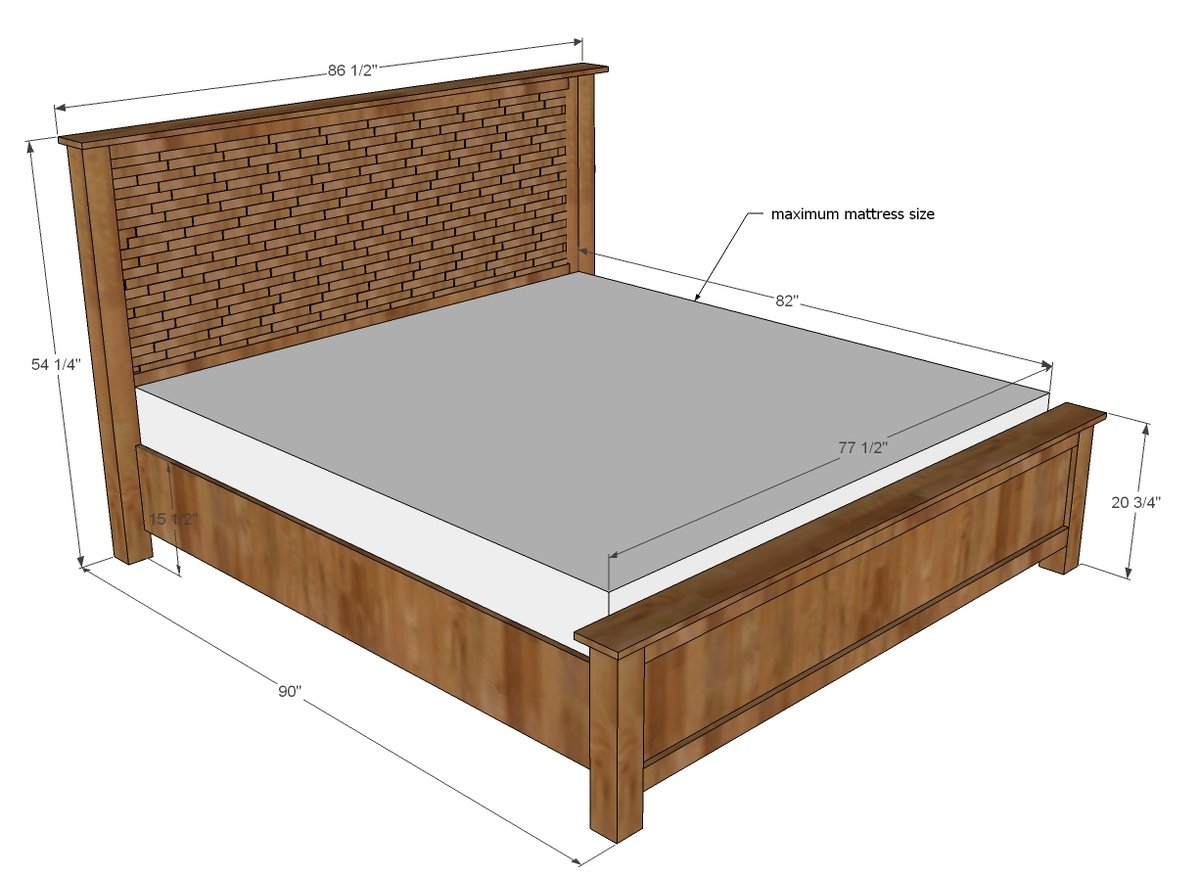

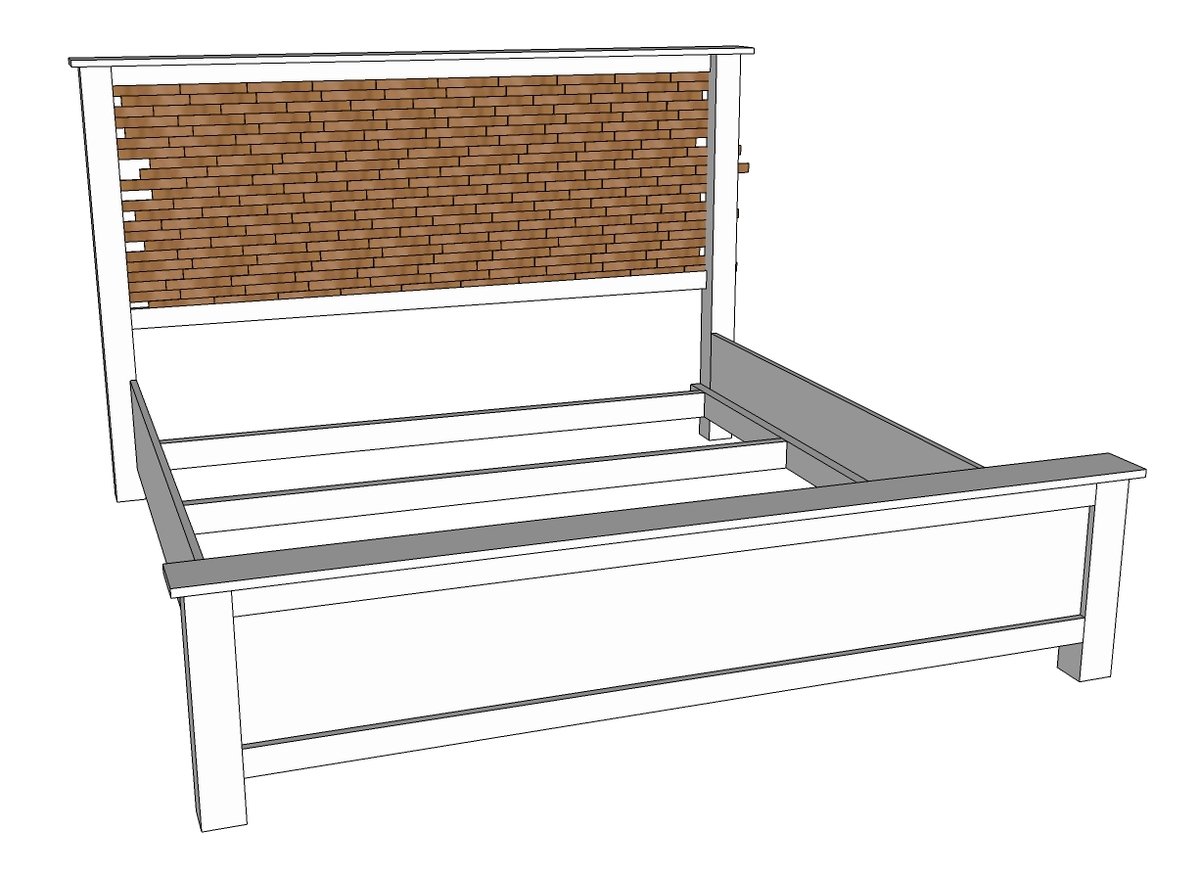

Wood shims fancy up this headboard! Free DIY bed plans (king) from Ana-White.com

Preparation

- 1 - sheet 3/4" plywood (full 4x8 sheet, hardwood preferred)

- 2 - 4x4 posts, 8 feet long each

- 4 - 1x3 @ 8 feet long

- 6 - 2x4 @ 8 feet long

- 2 - 1x12 @ 8 feet long

- 2 - 1x6 @ 8 feet long

- Approximately 13-15 packs wood shims (for headboard)

- 4 - 1x3 @ 77 1/2" (panel trim boards)

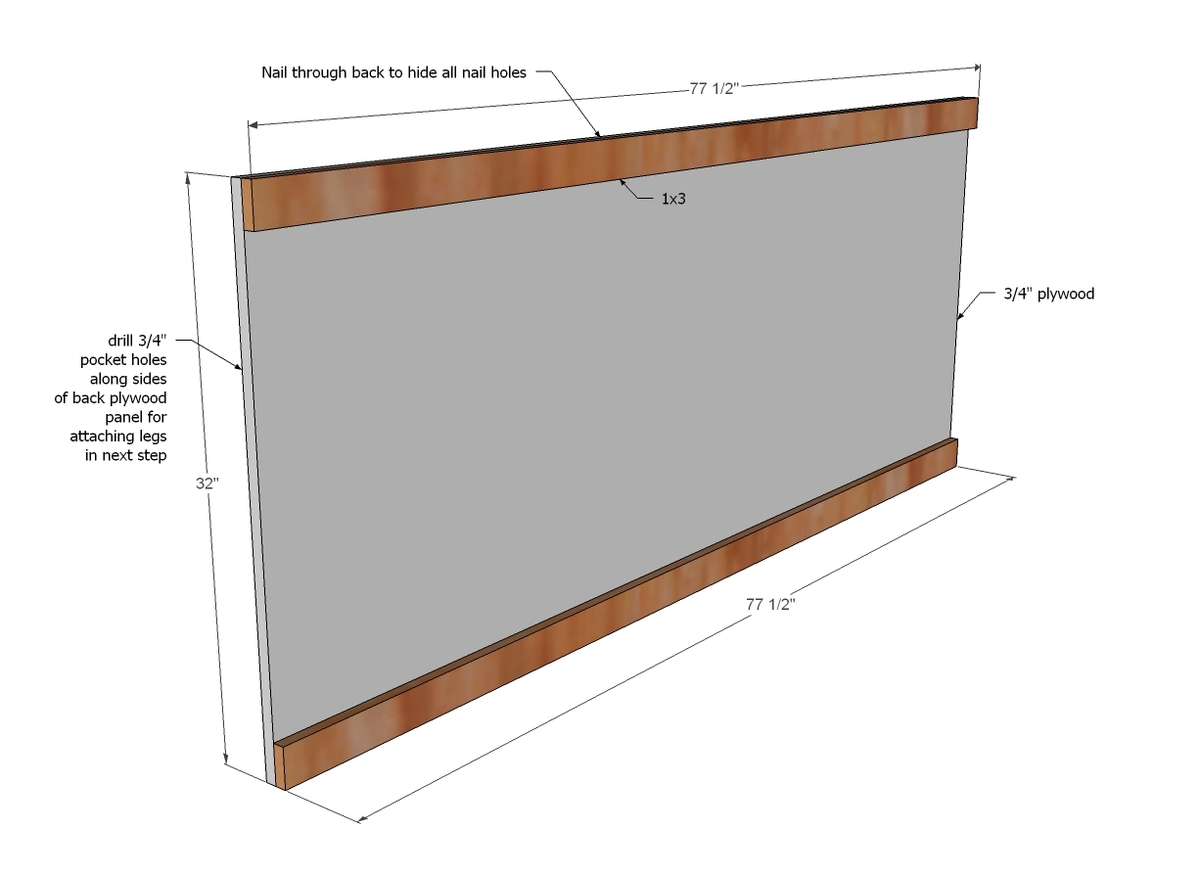

- 1 - 3/4" plywood @ 77 1/2" x 32" (headboard panel)

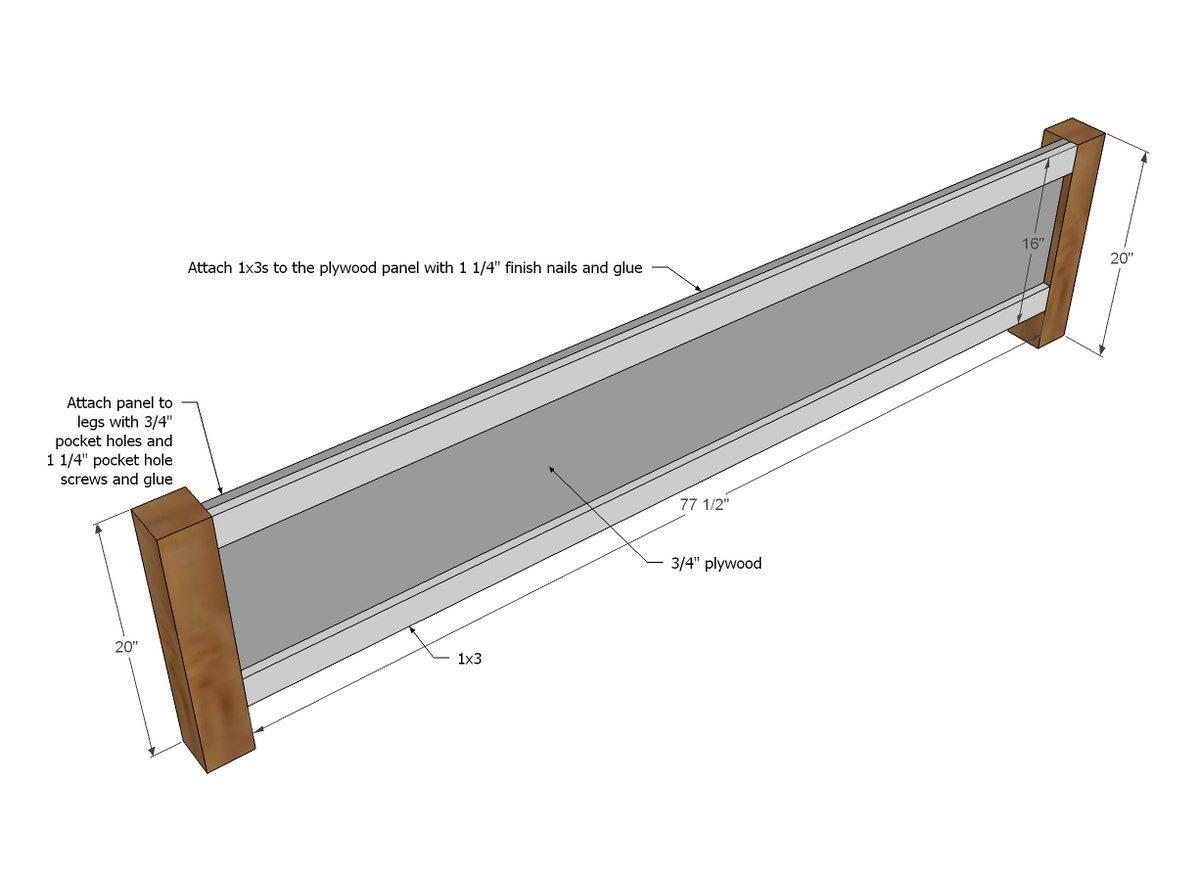

- 1 - 3/4" plywood @ 77 1/2" x 16" (footboard panel)

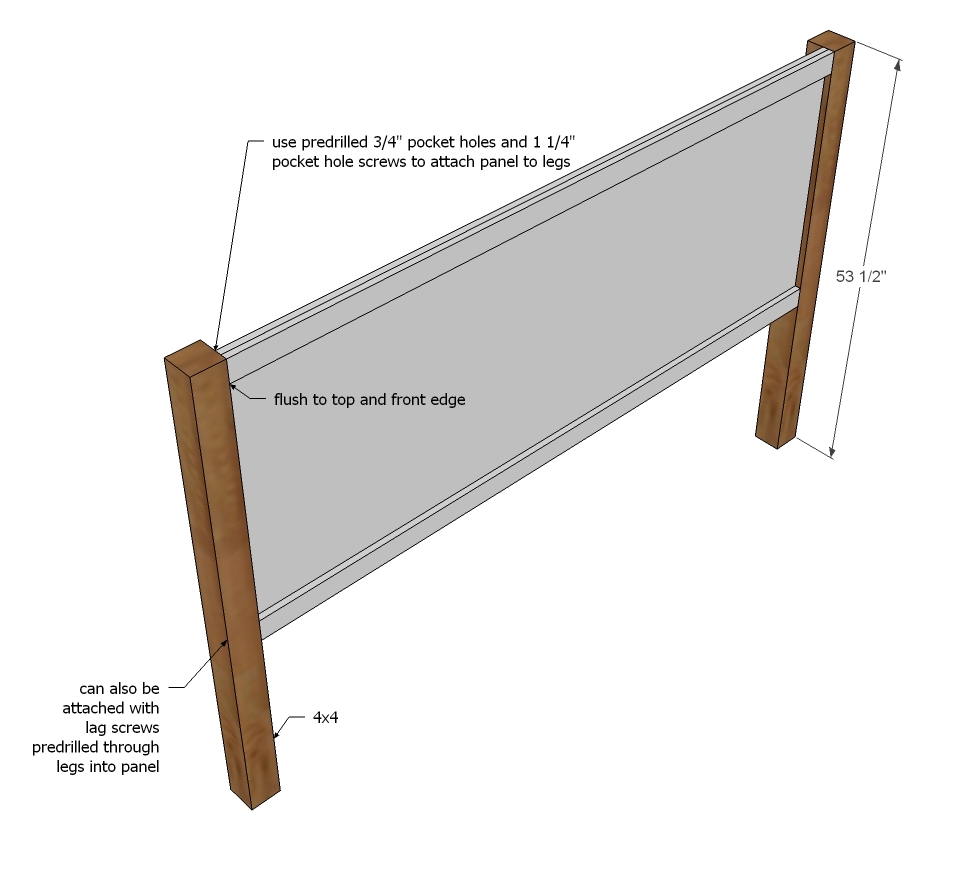

- 2 - 4x4 @ 53 1/2" (headboard legs)

- 2 - 4x4 @ 20" (footboard legs)

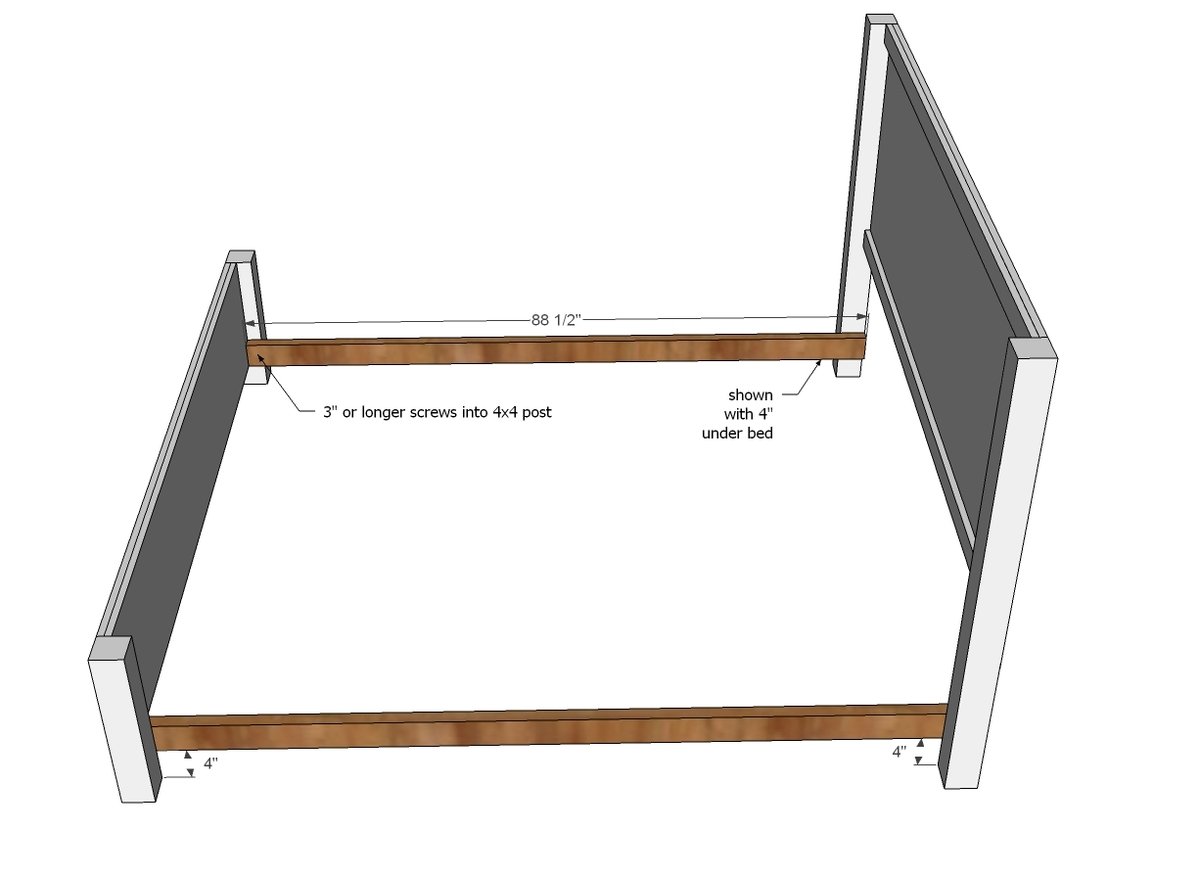

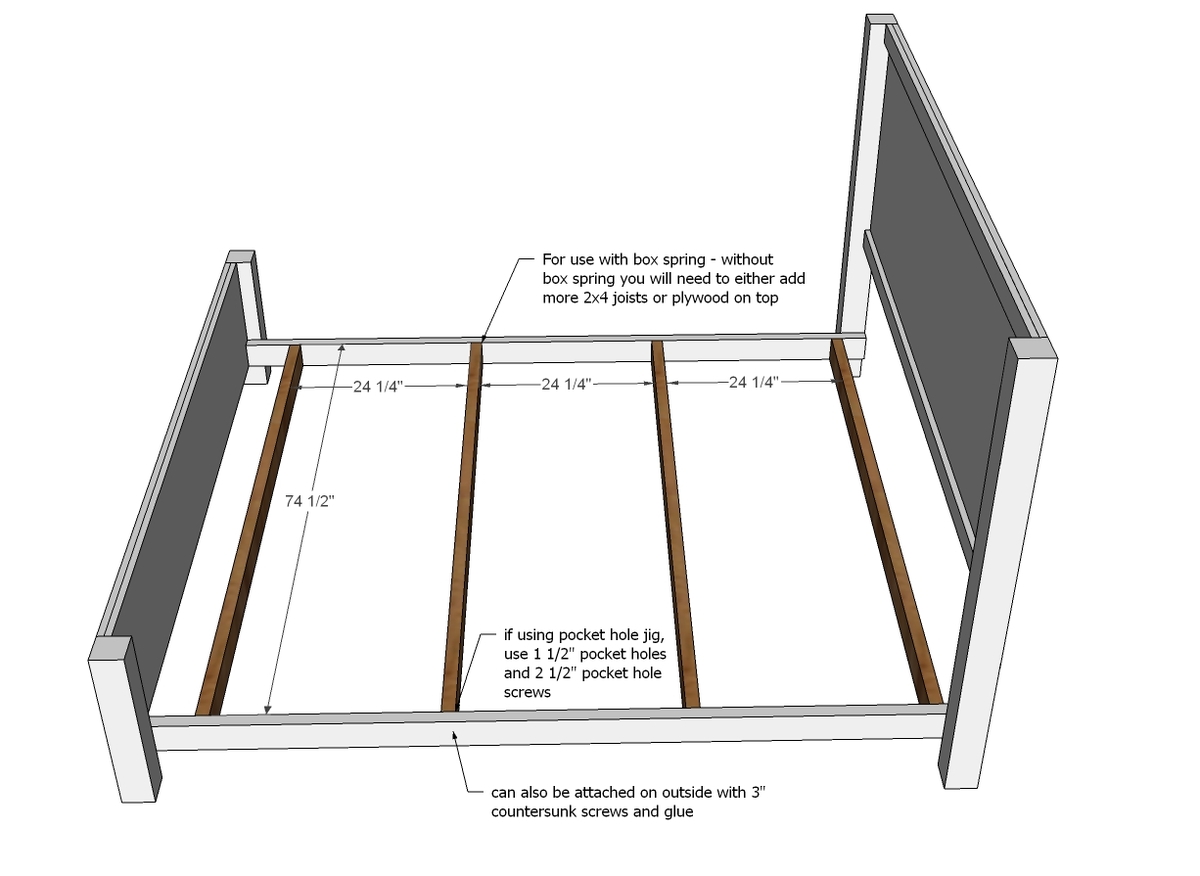

- 2 - 2x4 @ 88 1/2" (inner siderails)

- 4 - 2x4 @ 74 1/2" (frame supports - for extra support, add addtional 2x4 supports)

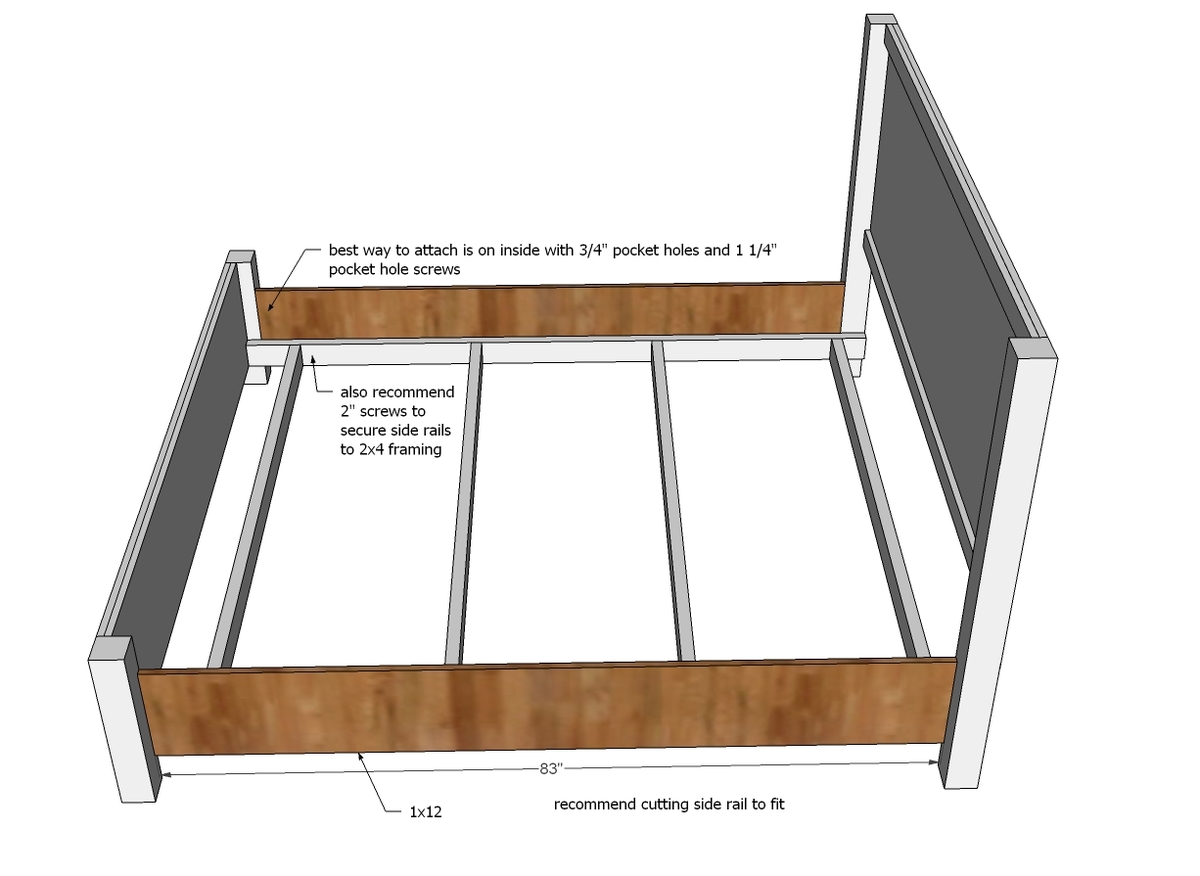

- 2 - 1x12 @ 83" long (siderails - can also use 2x12s for extra support)

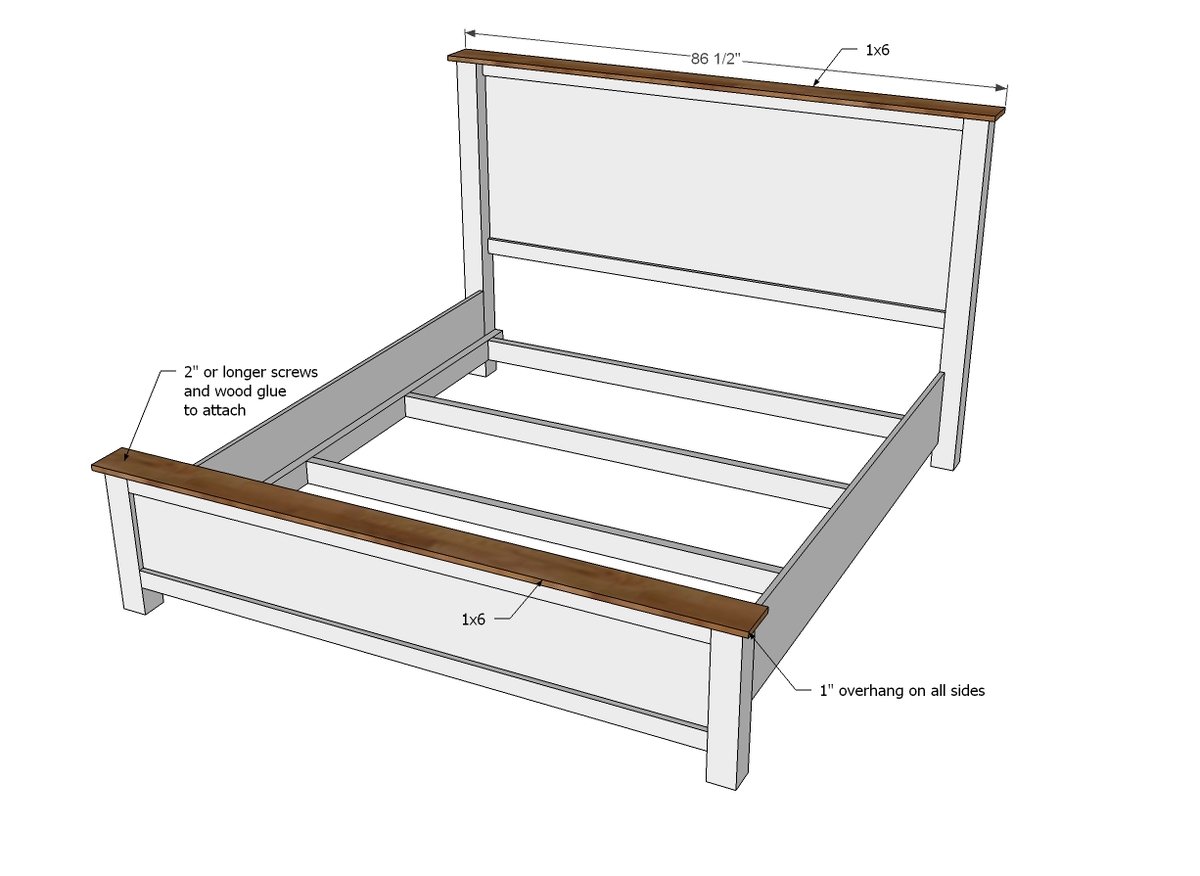

- 2 - 1x6 @ 86 1/2" long (headers)

To cut the plywood, first cut the plywood to 77 1/2" x 48". Then cut the remaining piece into a 32" and 16" wide piece.

Please read through the entire plan and all comments before beginning this project. It is also advisable to review the Getting Started Section. Take all necessary precautions to build safely and smartly. Work on a clean level surface, free of imperfections or debris. Always use straight boards. Check for square after each step. Always predrill holes before attaching with screws. Use glue with finish nails for a stronger hold. Wipe excess glue off bare wood for stained projects, as dried glue will not take stain. Be safe, have fun, and ask for help if you need it. Good luck!

Instructions

Step 1

Attach 1x3s to the headboard panel. You can also do the same with the footboard panel.

If you are using pocket holes, drill 3/4" pocket holes along side and top edges every 6"-8" of plywood pieces for attaching legs and headers in later step prior to attaching the 1x3s.

Rebecca also added the wood shims to the headboard at this step rather than waiting until the end - it's up to you.

From Rebecca:

"I attached my shims before the side 4x4's so I could sand the sides down and make sure they were even. I suppose you could even run a circular saw along he edge to make it easy. I did not run my 4x4's through the table saw first to make them more square and a flush to the front. So there is a little disconnect between my headboard and the legs. That is a personal decision though. My husband brought it up. "

Step 2

Step 4

Step 7

Attach headers to the footboard/headboard. If you drilled pocket holes facing upward in your panels, attach with 1 1/4" pocket hole screws. I recommend screws to attach headers just because they may try to come up over time. Try trim screws - they have a tiny screw head that will be much easier to hide.

It is always recommended to apply a test coat on a hidden area or scrap piece to ensure color evenness and adhesion. Use primer or wood conditioner as needed.

Comments

bullitt453

Thu, 08/08/2013 - 13:01

Awesome!

Very cool. May modify this to a full size and use it in my son's room. Only I would paint the shims a mix of black, white, vintage gray, and orange (the colors used in his room).

Marie320

Thu, 08/08/2013 - 16:50

how can you modify to a queen

how can you modify to a queen size ?? what would be the cut list?? I love this one but don't know how to modify

ffsangel1

Thu, 08/08/2013 - 19:06

Love this plan!

Showed this plan to my daughter who is getting married soon. She loved it so much that this is what she asked me to make for her wedding gift from me. Will have to figure out how to modify to a queen, but she is so very excited. Thank You so much Ana and Rebecca for the plans.

darkjuan

Fri, 08/09/2013 - 13:42

wood shims

Ana,

i have a couple question regarding the wood shims, what is the length size?

11-7/8 or 7-7/8

and also, do you stain them before install them on the headboard or after?

In reply to wood shims by darkjuan

redhead_61

Fri, 08/09/2013 - 18:00

I used 7 7/8" shims on this

I used 7 7/8" shims on this headboard. I stained after I glued them on. You could use the hot glue glue idea Ana had and then you might want to stain before. Not sure what would be easier.

michelle_newbie

Mon, 08/12/2013 - 13:02

Type of Wood

This is a very newbie question. What type of wood is normally used on these projects? Cedar? Pine? Other?

Thank you. I LOVE this plan and LOVE this website.

elslap1

Sat, 12/28/2013 - 08:03

project order

after completing this project I have one major recommendation for the order of the project. It came out beautiful in the end but was a heck of a lot of work. I thought of a few changes that may help make the project easier and quicker. I highly recommend the headboard in this order

1. frame the headboard

2. Stain the headboard (if this is not done before placing shims than you spend an increcible amount of time trying to stain between the shims evenly vs a very easy coating before "shimming")

3. sand each shim on all sides except the back (I can't begin to tell how difficult it was to sand the tops and especially edges of each shim with the limited space due to surrounding shims) I found that the backs of the shims were particularly rough and wound have been much easier to have pre-sanded.

4. attach shims to headboard (I layed the headboard flat on the ground and attached the shims with glue, never even to use my pin nailer)

5. stain when you stain the rest of the project.

Hope this helps save some people some time!

Elliot

In reply to project order by elslap1

MsKirstenChute

Wed, 03/19/2014 - 20:12

Thanks for the Tip :)

Your advice will definitely be used when i start this project this weekend! Thanks again for the VERY helpful tip!

dgahunia

Sat, 03/15/2014 - 11:54

Strengh of the rails

Hey everyone,

to the people who have already built this bed.... how strong did you find the bed to be with the rails installed as shown in the plan... did the bed squeak... or could the rails split or crack over time because they are just being held up by screws.

Its definitely a beautiful looking bed

dmozer74

Thu, 12/24/2015 - 13:31

I realize I'm answering a

I realize I'm answering a rather old question here, and even then I'm not really answering...Next week I will build this bed and intend to add 2x4 blocks below the mounting point at the headboard and footboard for the side rails to rest on. I will also add 2x4s below the center support 2x4s at exactly 4 inches in height. That should keep the squeaks to a minimum. I'll report on the success in my brag upon completion.

efischer

Sat, 08/16/2014 - 06:36

strength of rails

I am wondering if anyone answered dgahunia's question about the rails? Are the screws strong enough. If so, what size screw did you use and can you take them apart to move the bed? Are their any other options for the rail attachment? Thank you. I am just about done with my bed and want to double check I attach the rails correctly.

ga_stone

Sat, 11/01/2014 - 19:32

Stain Colors and Brand, plus question on Step 3

This is a great plan but and I really like the color of the stain in the pictures at the beginning of these plans. Can you please let me know the stain brand, color, and whether you did a coat of poly on top of the stain?

Also, in the diagram for Step 3, it seems like the panel for the headboard if flush with the back of the posts instead of the front of the posts (as all the other pictures of the finished be seem to be). Was this just an oversight?

Thanks again. Great design!

hwinger

Tue, 12/23/2014 - 21:37

We made this bed in the king

We made this bed in the king size. DEFINITELY sand each shim prior to gluing it down. It is definitely no fun rolling over in the night and hurting my hand on the rough shims. I would also recommend staining the headboard (the base for the shims) prior to gluing down shims so that any holes between shims blend in with the stain color underneath. We did not and there are a couple spots that you can see the plain wood under the shims. Also, we did what they recommended in the plans to secure the side rails. The bed is not very stable and squeaks. We keep talking about altering it somewhat, but it's so dang heavy that we have been putting it off. One other thing that I wish we had done would have been to sand off the corners of the end of the footboard. We've gotten a few bruises from walking into the ends. It cost more than we expected and it took longer. But overall, we love it and are very happy with it. Just wish we had known now to do some things differently.

smithknk

Thu, 05/28/2015 - 13:22

using existing rails?

Would using an existing mattress frame work for this and just attach the headboard and footer to the frame? Love the headboard and all the hints people have given to make it easier!

elslap1

Sat, 03/05/2016 - 08:17

using existing rails

I ended up doing this. I planned to build the bed as depicted but I already had a king frame that we had been using. I ended up drilling holes in the metal frame and screwing from the metal frame to the 4x4's attached to the side pieces (1x12's). I used 1.5" screws as the width of a 2x4 is roughly 1.5". It is important to factor in the width of the bed frame, as it may be different than the official plans, so you may need to make the headboard and footboard slightly narrower to attach to the side rails in the original fashion. I hope this helps, please let me know if anybody needs specific advice on how I modified the measurements or adapted the different widths and I will be happy to help.

-Elliot

Trauberman

Sun, 08/23/2015 - 16:39

Master Bedroom - Frame

Potential Idea

dmozer74

Wed, 12/16/2015 - 13:13

Build Price

Can you give some guidance on how you had such low costs on this project? I can't seem to get the costs below ~$250 for the wood alone, plus stain.

Hollymomof4

Fri, 02/26/2016 - 19:31

Assistance Needed

I love this bed and am going to make it! Instead of a foot board I need to build some steps up so that our elderly little pup can make it up onto the bed. I want to make them the full width of the bed but am not sure how to plan this out, can someone suggest an easy way to do this?