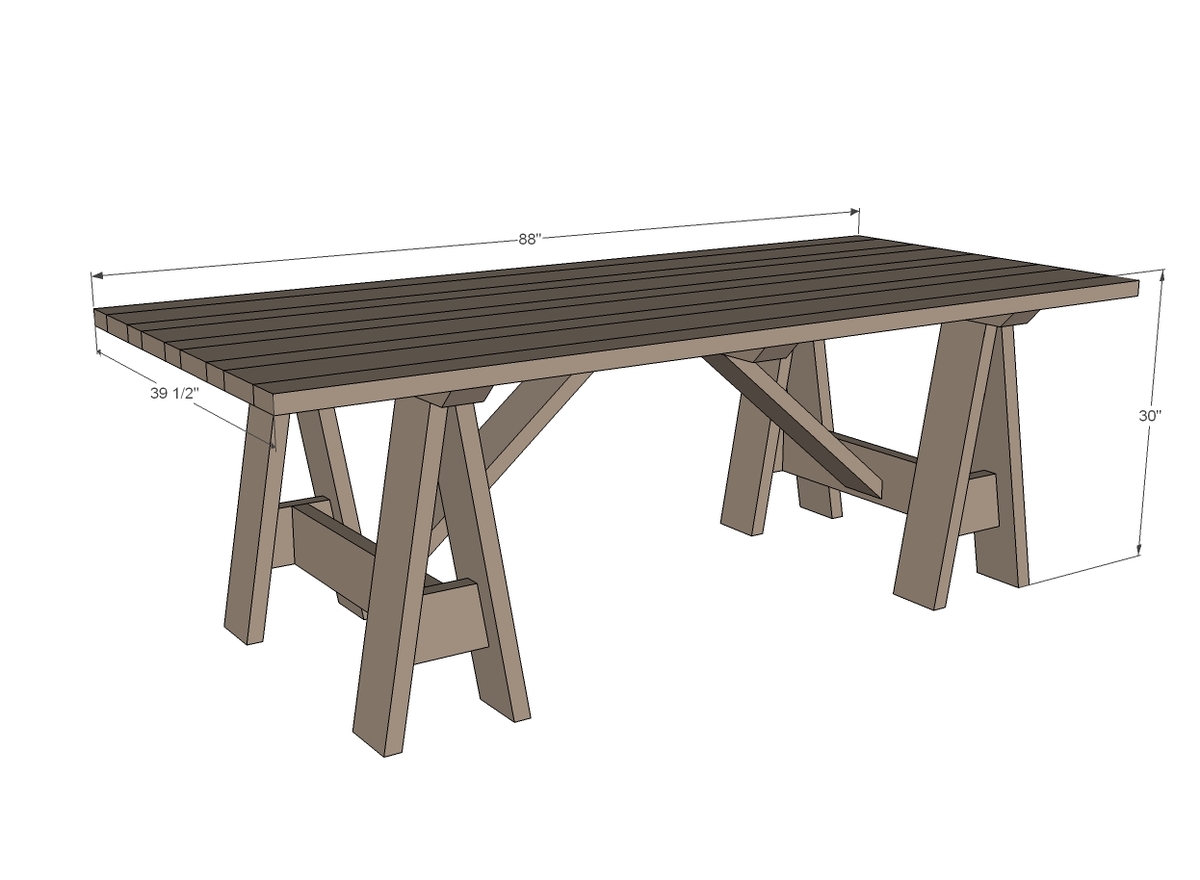

Build your own stylish and substantial outdoor table! This easy to build design features a modern sawhorse style base and a thick top.

Free step by step plans for outdoor table from Ana-White.com, include lots of detailed diagrams. Build using 2x4s and 2x6s.

See also: Matching Sawhorse Outdoor Bench Plans

Preparation

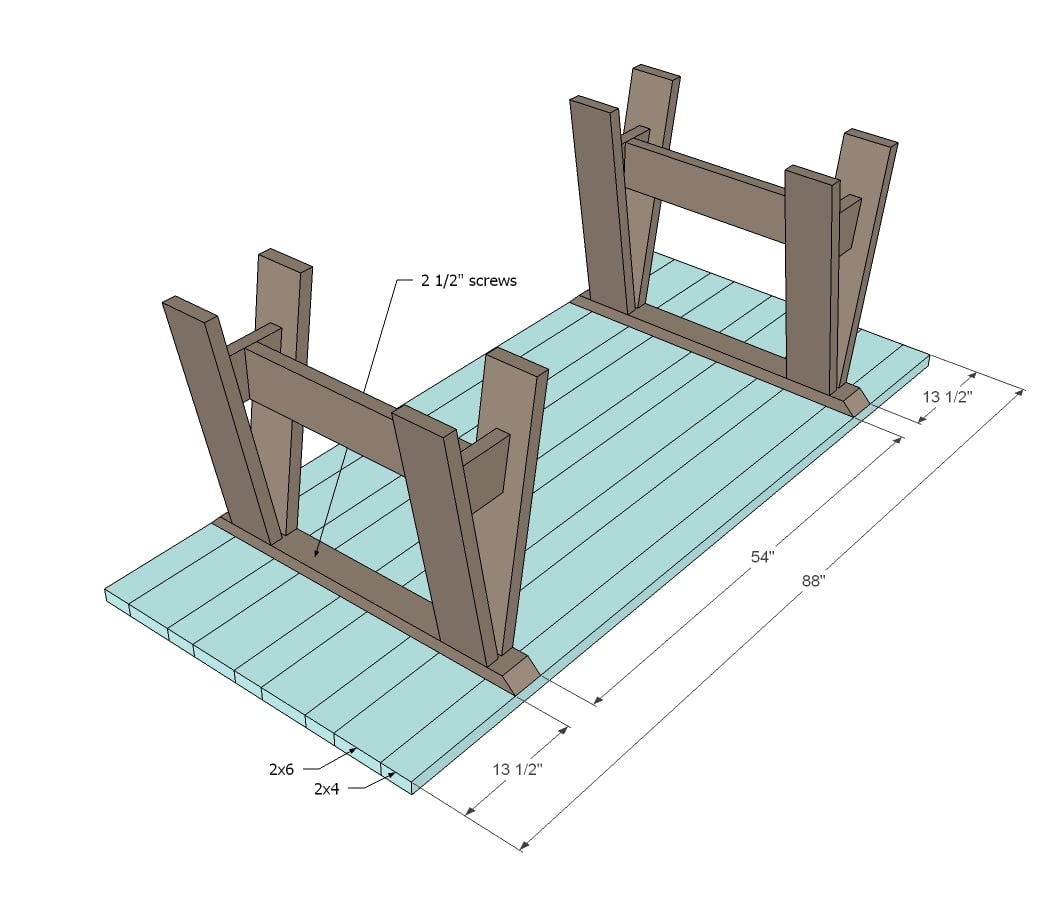

- 9 - 2x6 @ 8 feet long

- 7 - 2x4 @ 8 feet long

- - to frame the outside of the top, need 3 more 2x4x8s

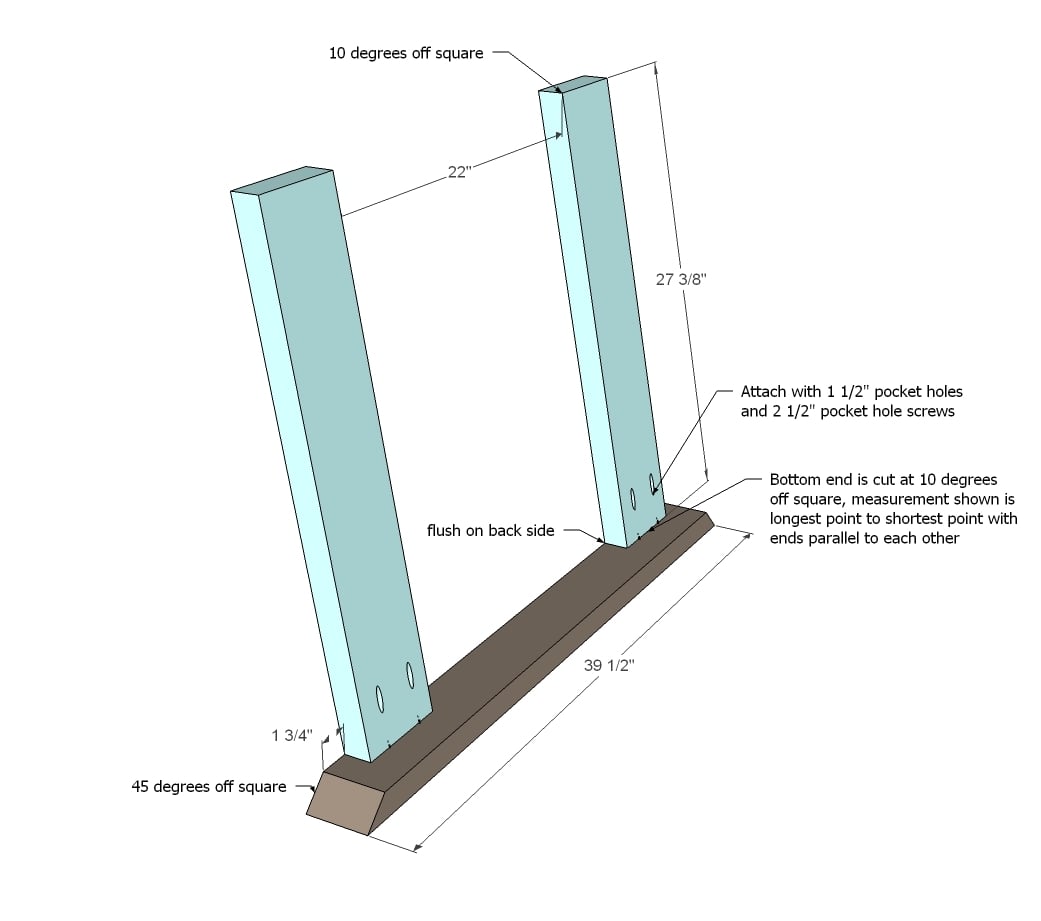

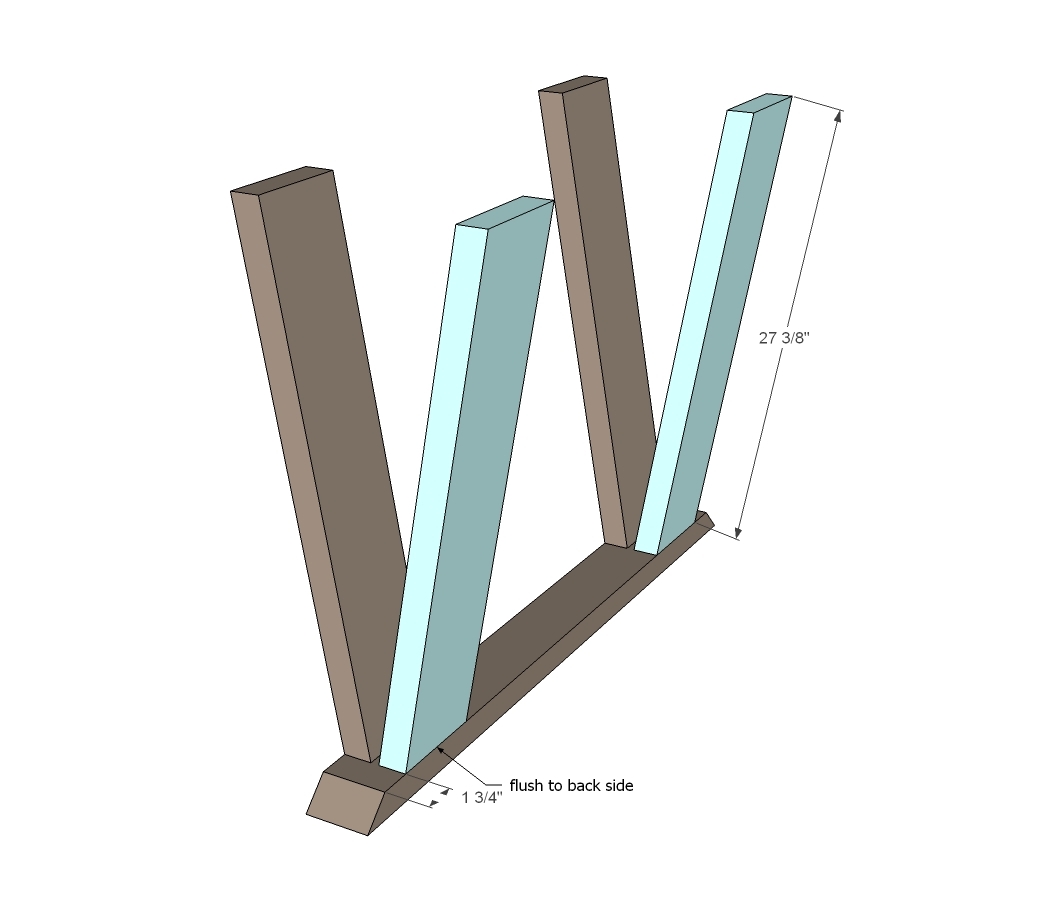

- 8 - 2x6 @ 27 3/8" (long point to short point, both ends cut at 10 degrees BEVEL)

- 3 - 2x4 @ 39 1/2" ( long point to long point, both ends cut NOT parallel at 45 degree BEVEL)

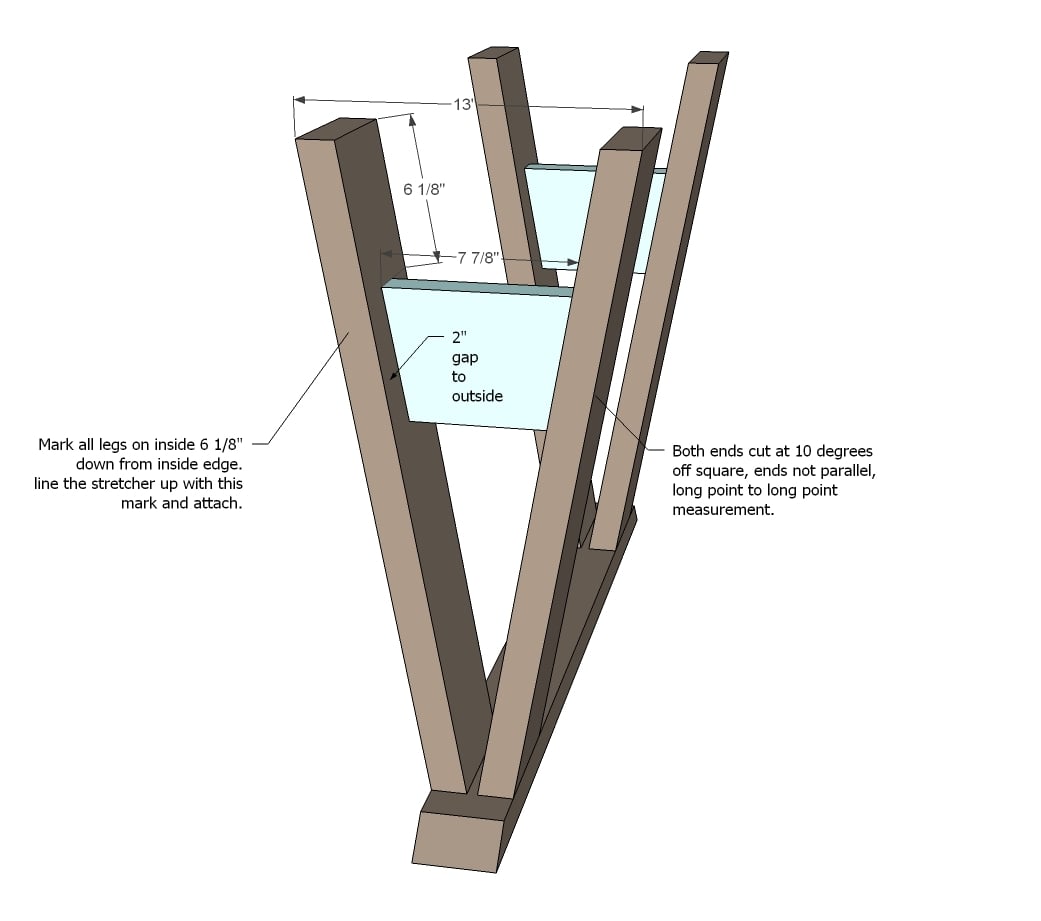

- 4 - 2x6 @ 7 7/8" (long point to long point both ends cut NOT parallel at 10 degrees off square)

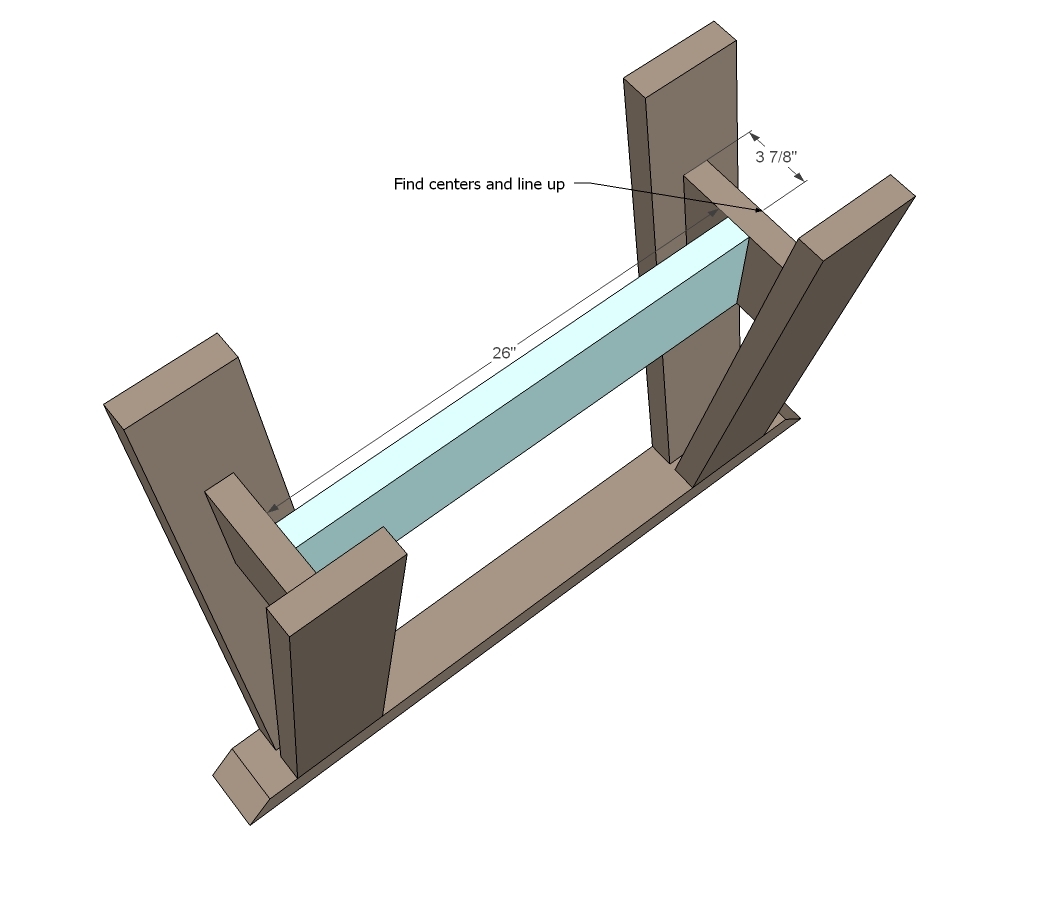

- 2 - 2x6 @ 26"

- 4 - 2x6 @ 88"

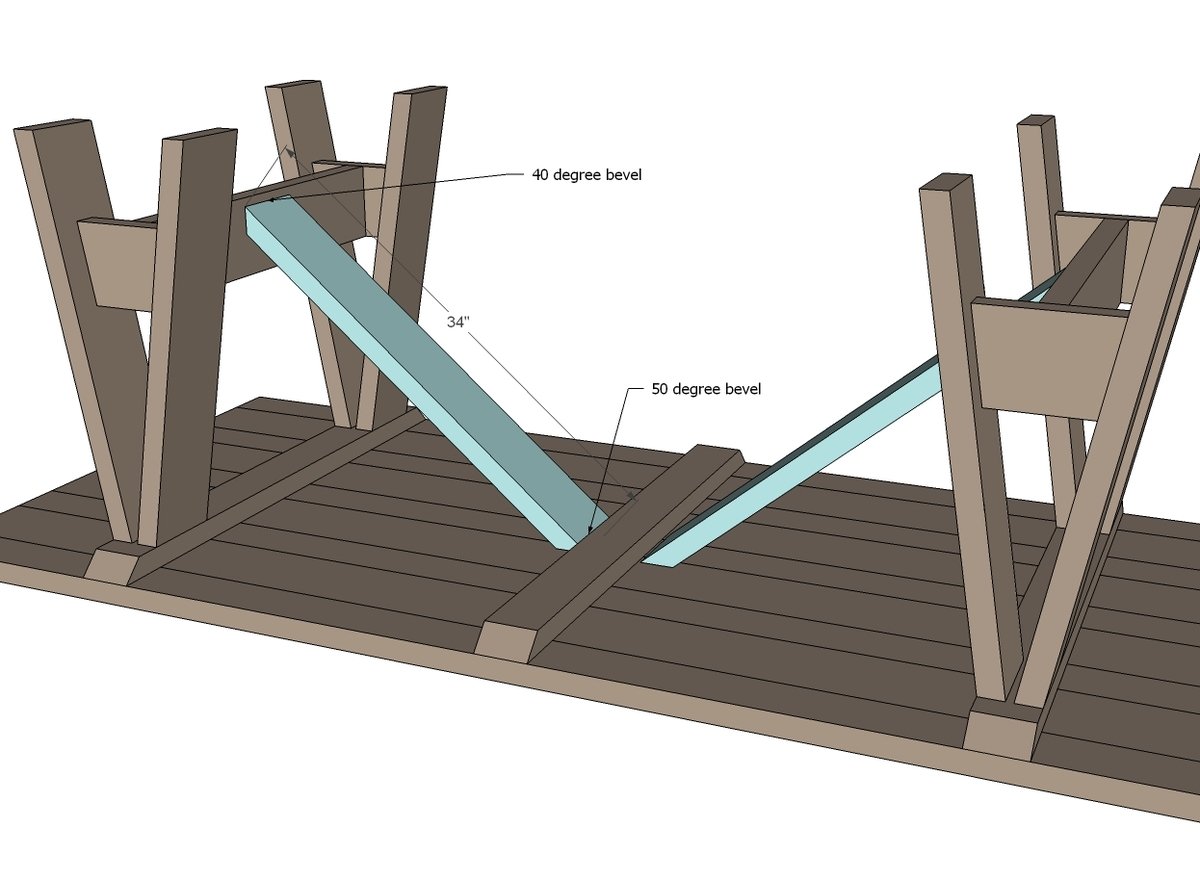

- 5 - 2x4 @ 88" cross supports 34" long - both ends beveled - one at 40 and one at 50 (you may be able to get away with both at 45 to make things easier)

Please read through the entire plan and all comments before beginning this project. It is also advisable to review the Getting Started Section. Take all necessary precautions to build safely and smartly. Work on a clean level surface, free of imperfections or debris. Always use straight boards. Check for square after each step. Always predrill holes before attaching with screws. Use glue with finish nails for a stronger hold. Wipe excess glue off bare wood for stained projects, as dried glue will not take stain. Be safe, have fun, and ask for help if you need it. Good luck!

Instructions

Step 1

Step 4

Step 6

Step 7

It is always recommended to apply a test coat on a hidden area or scrap piece to ensure color evenness and adhesion. Use primer or wood conditioner as needed.

Comments

Angie Overton

Fri, 05/31/2013 - 14:23

Question about STep 5

I LOVE this table. And I love the cost too. I saw it over on Shanty 2 Chic. Your plans make it look so easy to do. I do have a question about step 5 though. With the shims in place... do you use the pocket hole screws to attach them to each other? Or is it the cross pieces that are holding them together? I know this is simple... I just cant seem to picture it.

And what did you mean by ditching the 2x4 in that step?

LOVE LOVE LOVE IT!!! Thanks!

In reply to Question about STep 5 by Angie Overton

Lady Goats

Fri, 05/31/2013 - 15:19

Step 5

If you space the boards 1/2" apart, you can use one less 2x4 for the top. I'm not sure what you mean about the shims? I didn't head over to shanty2chic's site yet, but I wouldn't use pocket holes with shims (you'd be able to see the screws).

Natascha Ribeiro

Mon, 06/03/2013 - 07:41

Best Regards from Brazil

Hi Ana!! i was searching trough the internet (sorry for my horrible english)...and i found your website...i just paid someone to make me a simple door...and cost me 1.400, the cheapest here cost around $80... everything that's handmade is too expensive...people here buy tables made out of metal and some type of stone on top...but still not cheap at all...i live at a farm and i love hand works...and your website is an inspiration!!! keep doing this amazing work you do...you have an amazing gift!!!

Best regards from Brazil

Natty

Tmilz

Mon, 06/10/2013 - 11:45

Modification

I am planning to build this table very soon, but I am having an issue. I plan to shorten the table to 5' and I am having trouble figuring out the new length and angles needed for the ( 2 ) Cross braces. Any help would be greatly appreciated. I can do the math and determine the angle, but I need the length of the opposite side of the triangle. By my calculations the adjacent side would be 15" long. If I know the length of the opposite side I can determine the length and angle of the hypotenuse side... Sorry I feel like I am asking everyone to go back to algebra class.

logansam54

Sun, 07/07/2013 - 10:58

Can this be made longer?

To make this table seat 8 would any additional supports be needed underneath or can I just use longer boards. At 3 feet per seat I need it 9 feet long.

-Elise

adambc

Thu, 05/15/2014 - 17:49

2x4 edge

hi ana

Love the site and projects are so simple. Question on the edge around this table though, would it work better with a 45 degree cut to square each corner? Or just cut them flush for a square corner?

-a

Marsha036

Sat, 07/19/2014 - 21:59

Sawhorse outdoor table legs

Help just completed my legs but they wobble. How do I fix this. So far have one sawhorse done. Has anyone had this happen and how did they fix it?

liamtoh1

Fri, 03/27/2015 - 16:31

Wood type

Will the dimensional lumber (white wood) available at big box stores (Menards, Lowes, HD) work outdoors in all the elements (snow, rain, sun)? I was under the impression that this type of wood will rot / fungus / etc. very easily, even if you stain with wood protector.

If you use Cedar (which is an excellent choice for outdoor furniture), the cost will triple. Any other options.

stsoso44

Fri, 04/03/2015 - 16:18

wood type

I would like to know if we need pressure treated wood or is white kiln dry wood ok for screened in porch in North Carolina climate

Thank you very much and the ideas are great

Steven