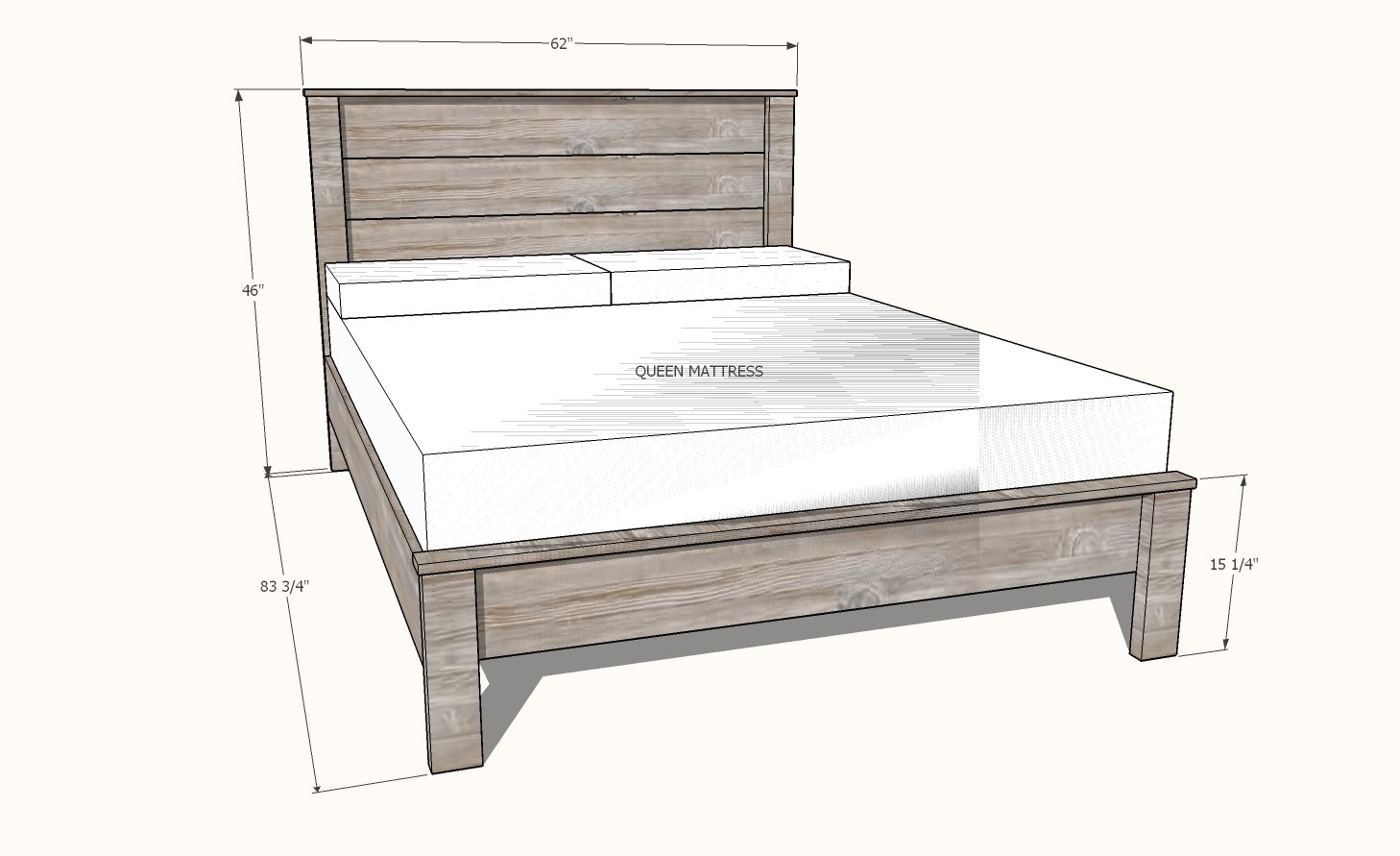

You can build this simple panel bed frame (or just the headboard) with just a circular saw and a drill for about $120 in materials. This free tutorial includes video, step by step diagrams, shopping list and a cut list for Twin, Full, Queen, King and California king mattress sizes.

Also check out our nightstand plans, browse other bed plans, and read our wood finishing post.

Preparation

SHOPPING LIST FOR QUEEN - for other sizes, see the downloaded PDFs above

2 - 1x8 @ 10 feet long (can cut in half for transport)

2 - 1x8 @ 8 feet long (use on siderails)

2 - 1x3 @ 6 feet long

11 - 2x4 @ 8 feet long (includes 6 2x4s used for the bed slats)

50 - 1-1/4" brad nails OR 2" self tapping wood screws

40 - 3" self tapping wood screws (can substitute for 2-1/2" or 2-3/4" lengths)

CUT LIST FOR QUEEN - for other sizes, see the downloaded PDFs above

4 - 1x8 @ 57" - panel boards

2 - 2x4 @ 45-1/4" - headboard legs

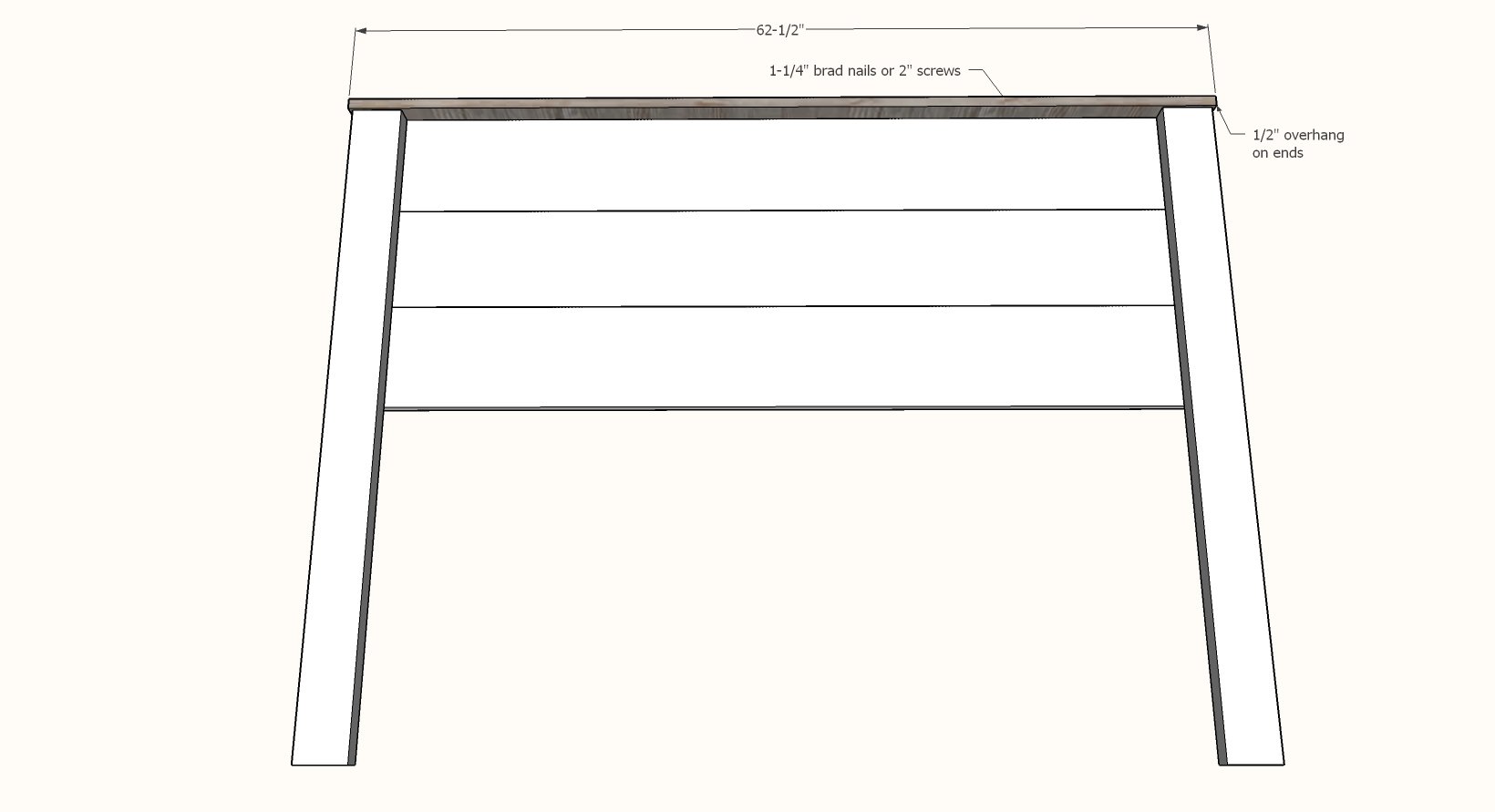

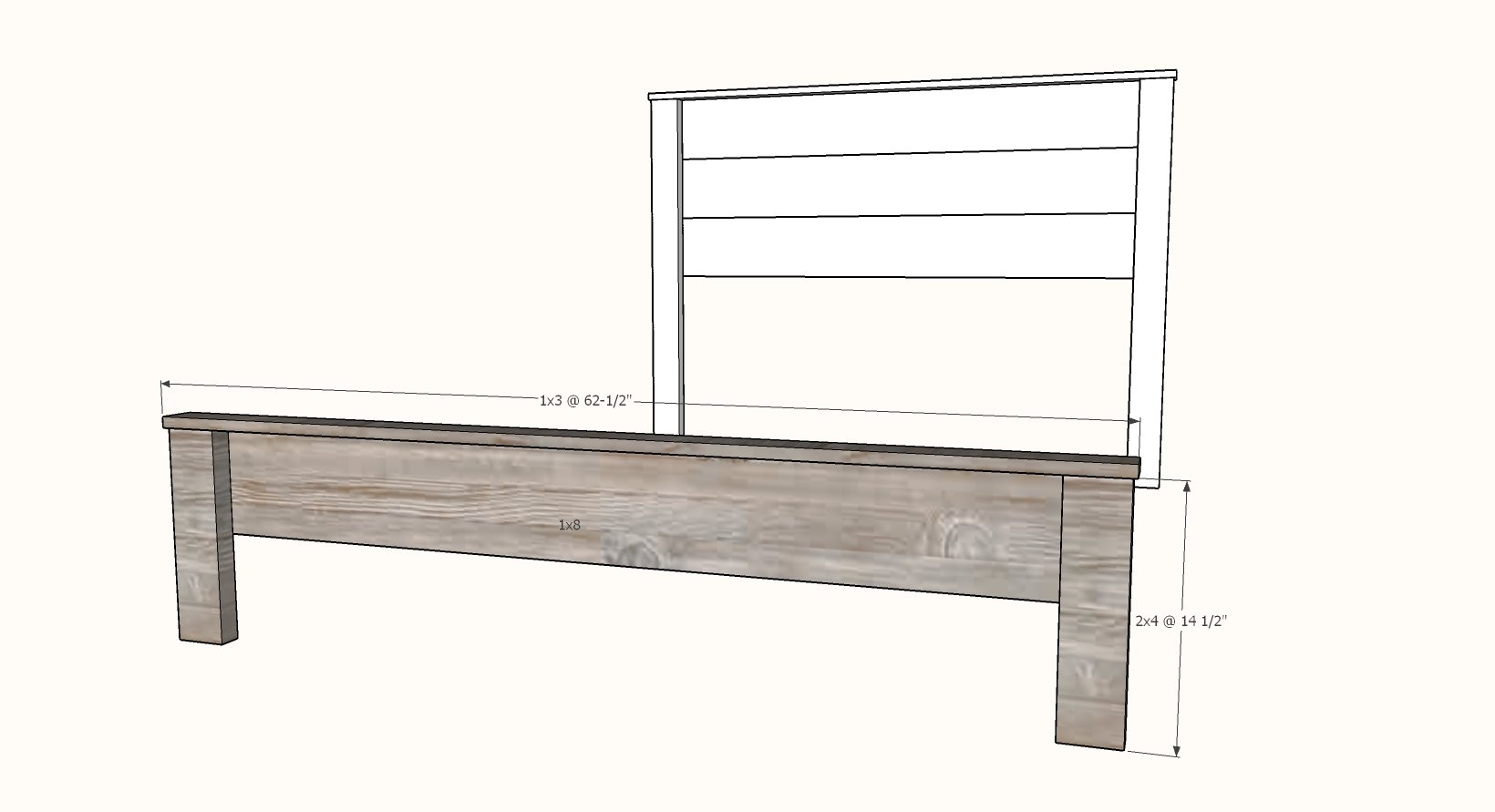

2 - 1x3 @ 62-1/2" - tops

2 - 2x4 @ 14-1/2" - footboard legs

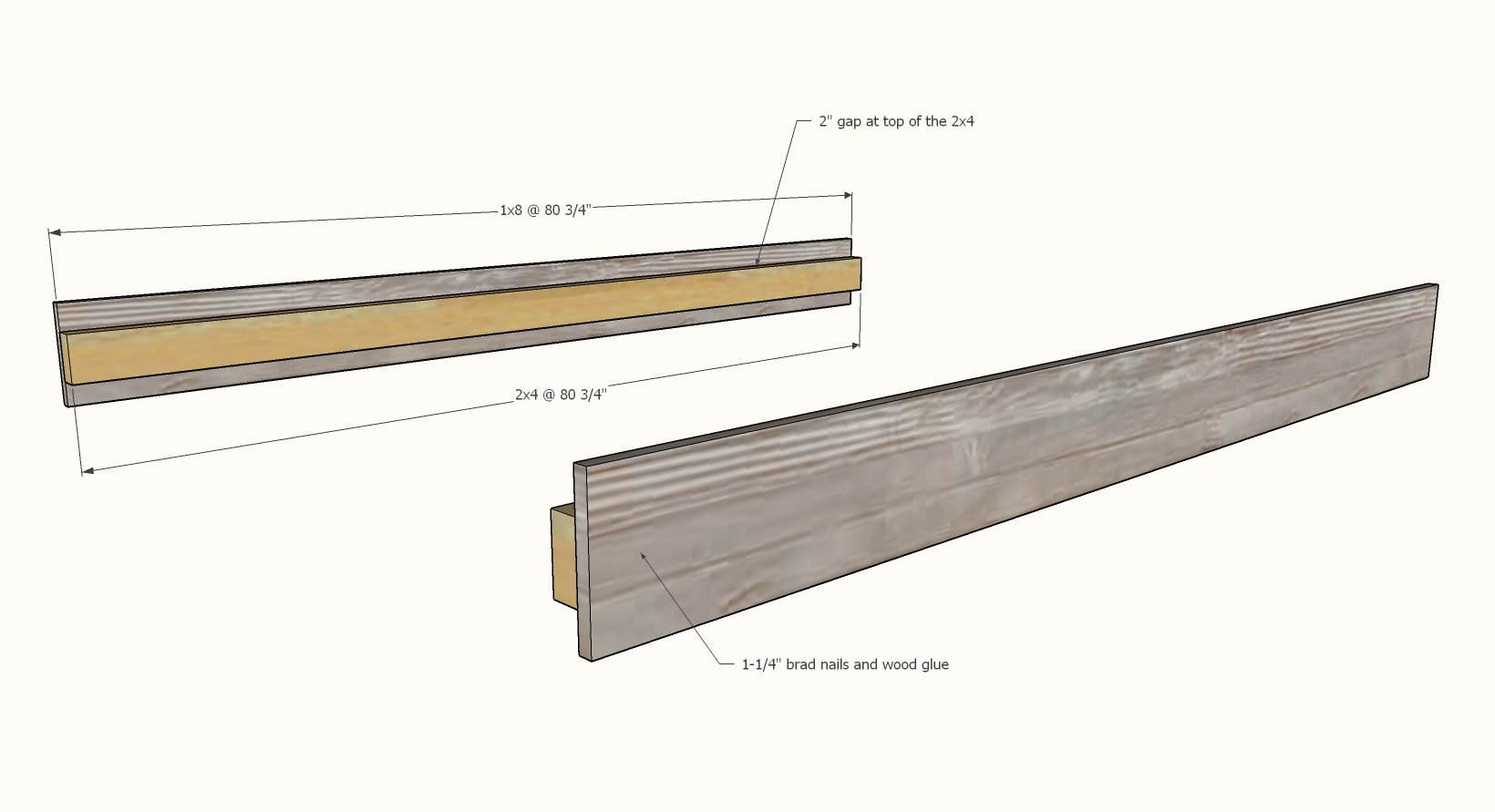

2 - 1x8 @ 80-3/4" - sidrails

2 - 2x4 @ 80-3/4" - siderail cleats

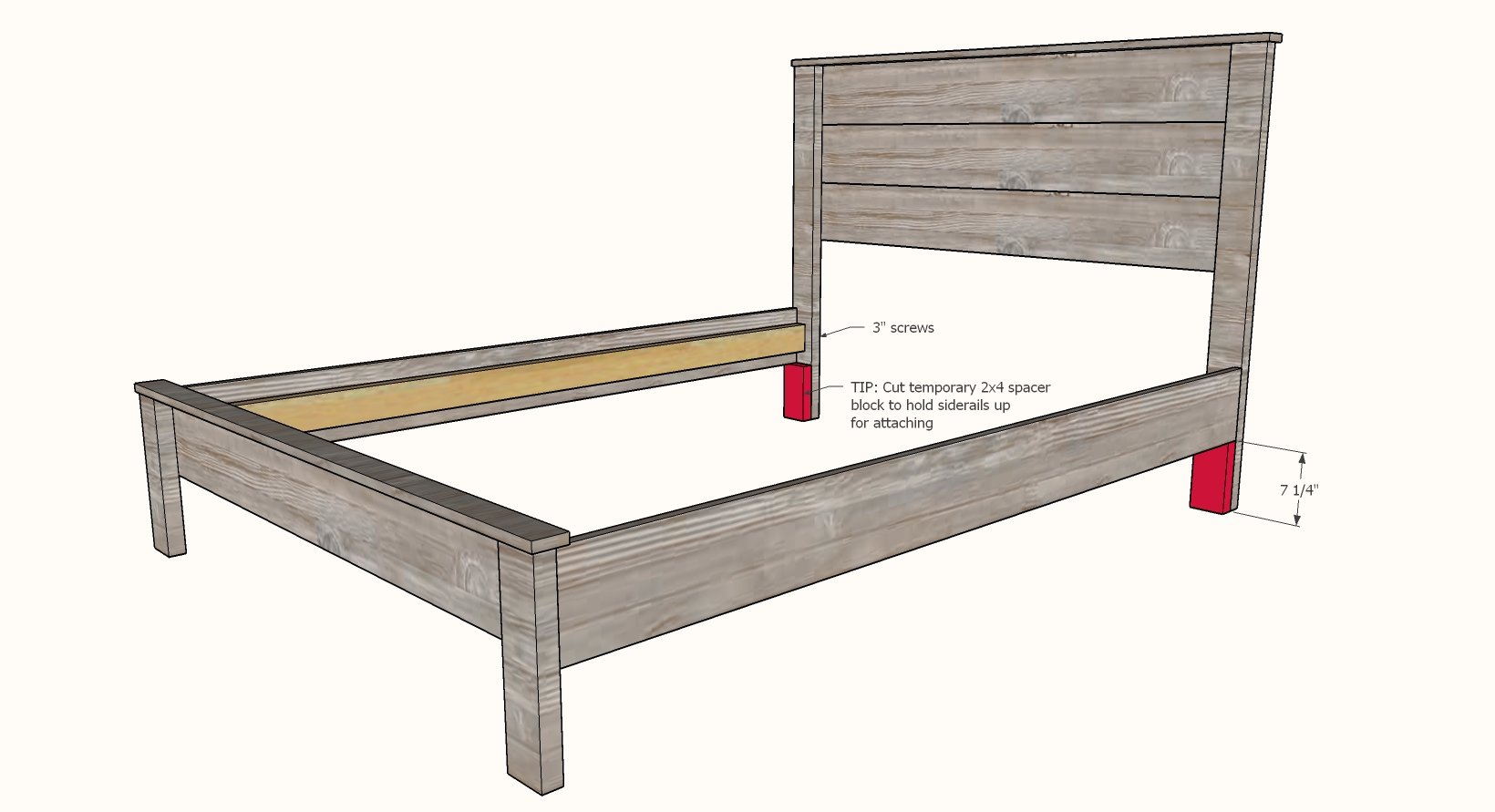

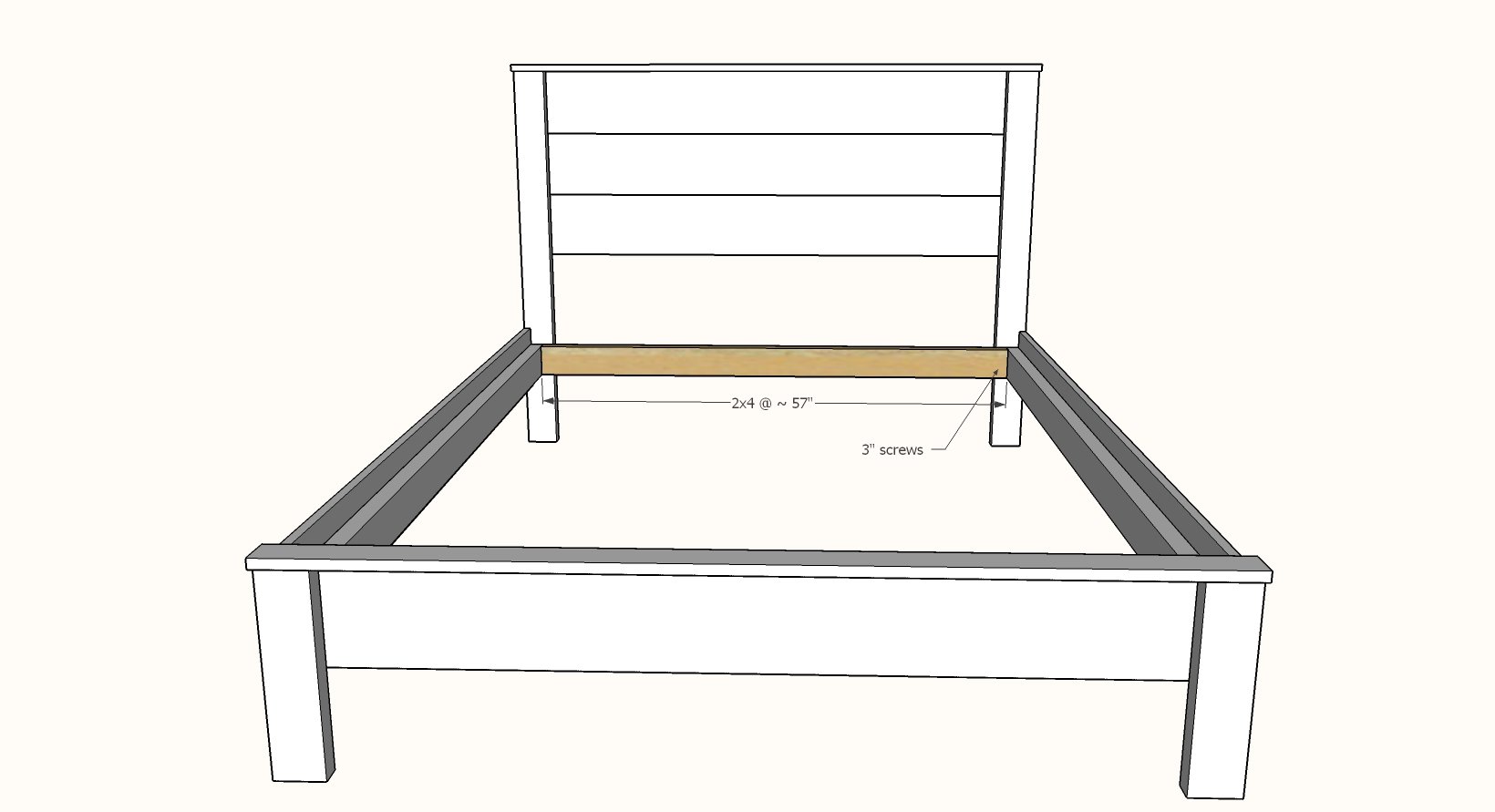

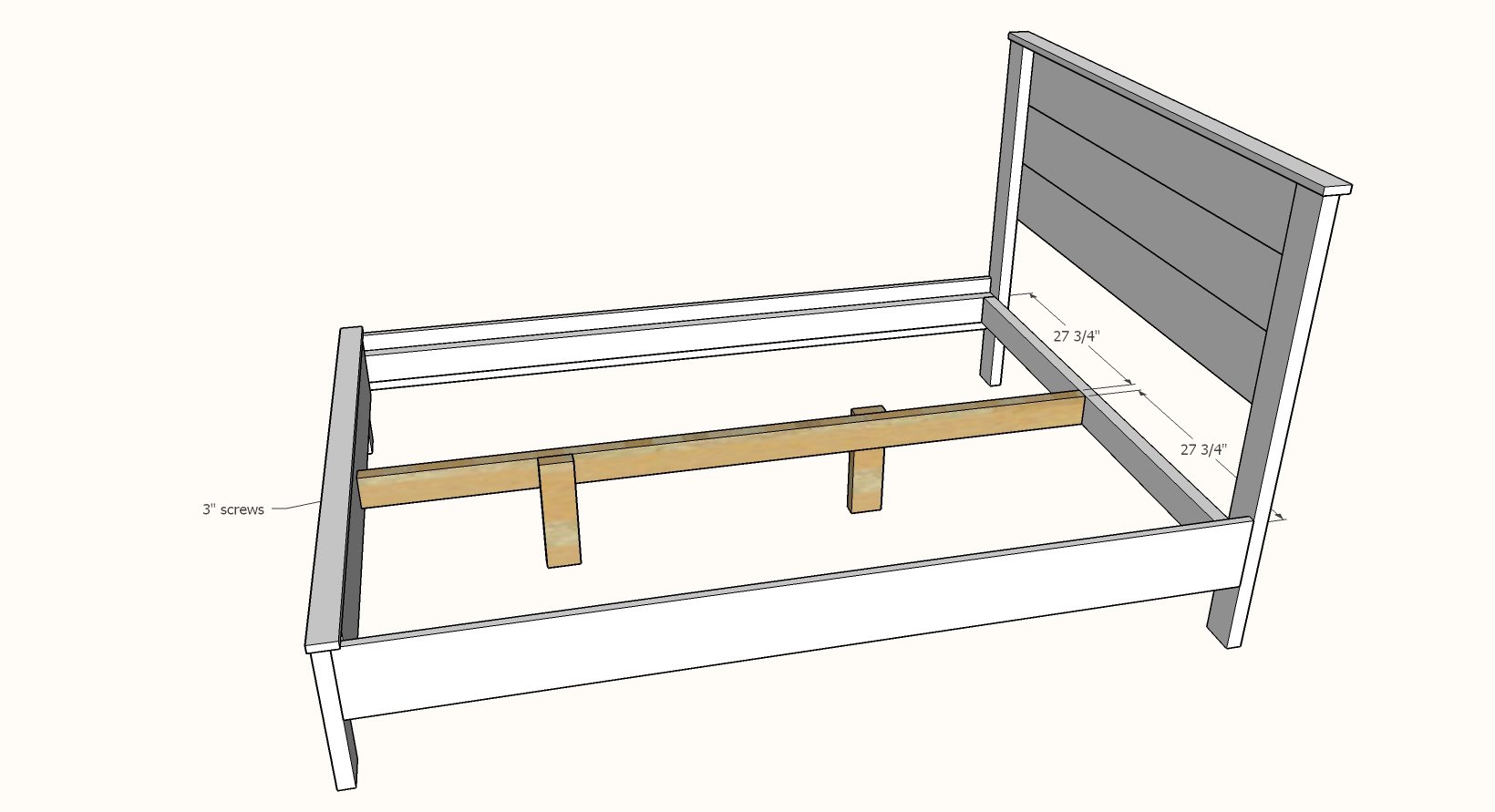

1 - 2x4 @ ~57" - cut to fit - headboard bed frame

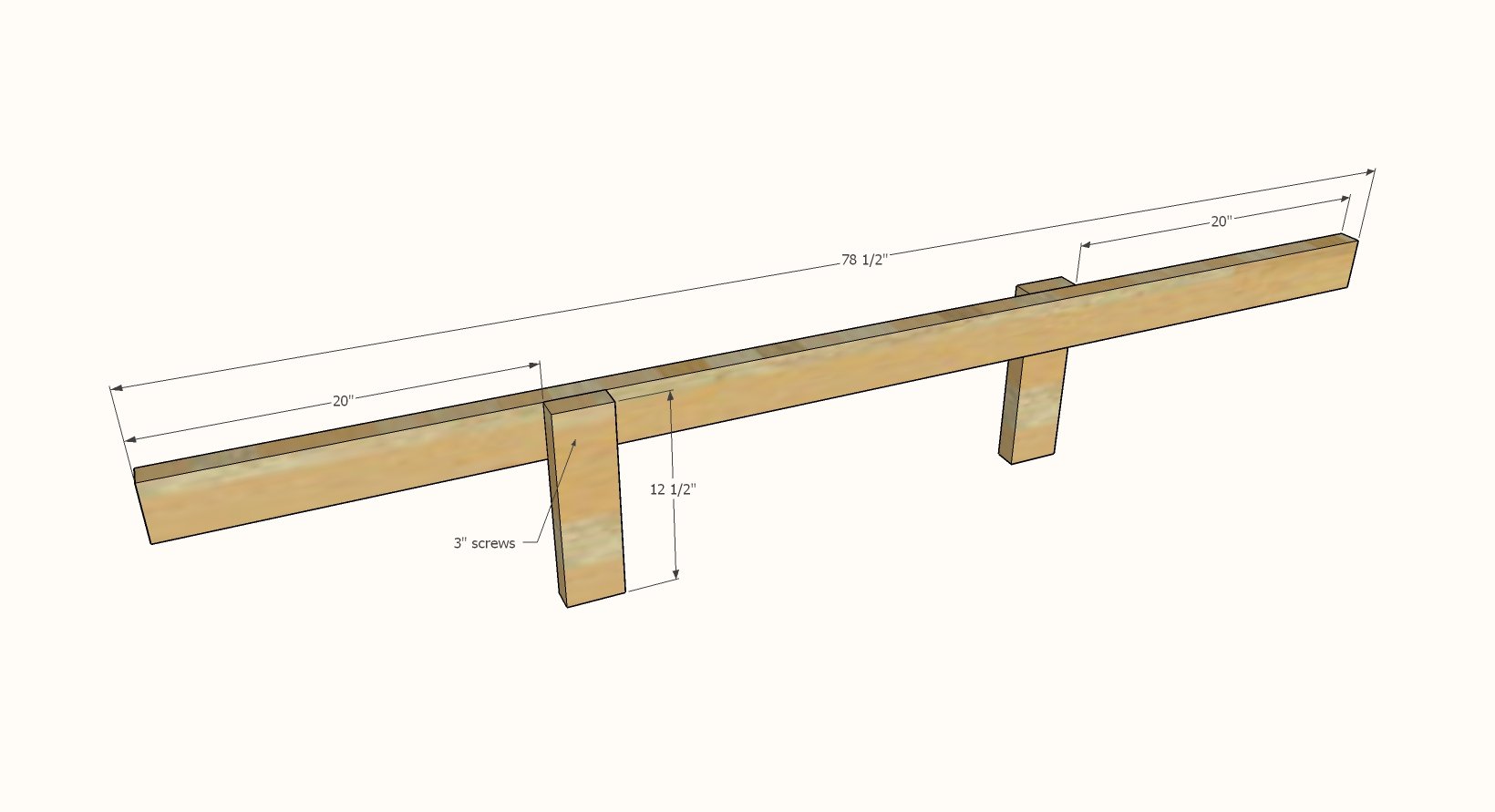

1 - 2x4 @ 78-1/2" - bed frame center

2 - 2x4 @ 12-1/2" - bed frame legs

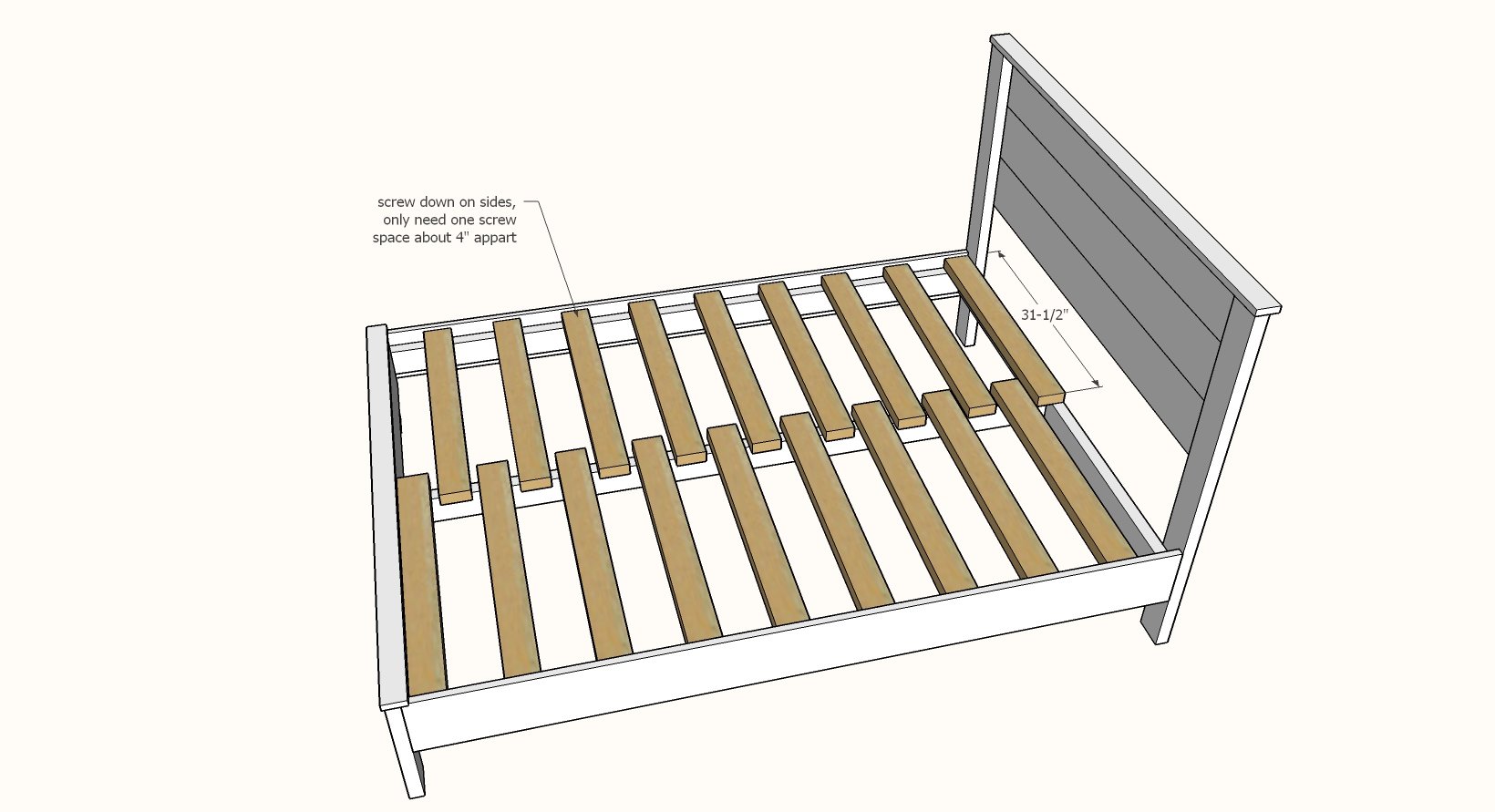

18 - 2x4 @ 31-1/2" - bed frame slats (can also use 1x4s or 1x3s or other materials if less expensive/have on hand)

This bed plan does not require a brad nailer, but having a brad nailer will make building this project easier. You can substitute screws for nails throughout this plan.

Instructions

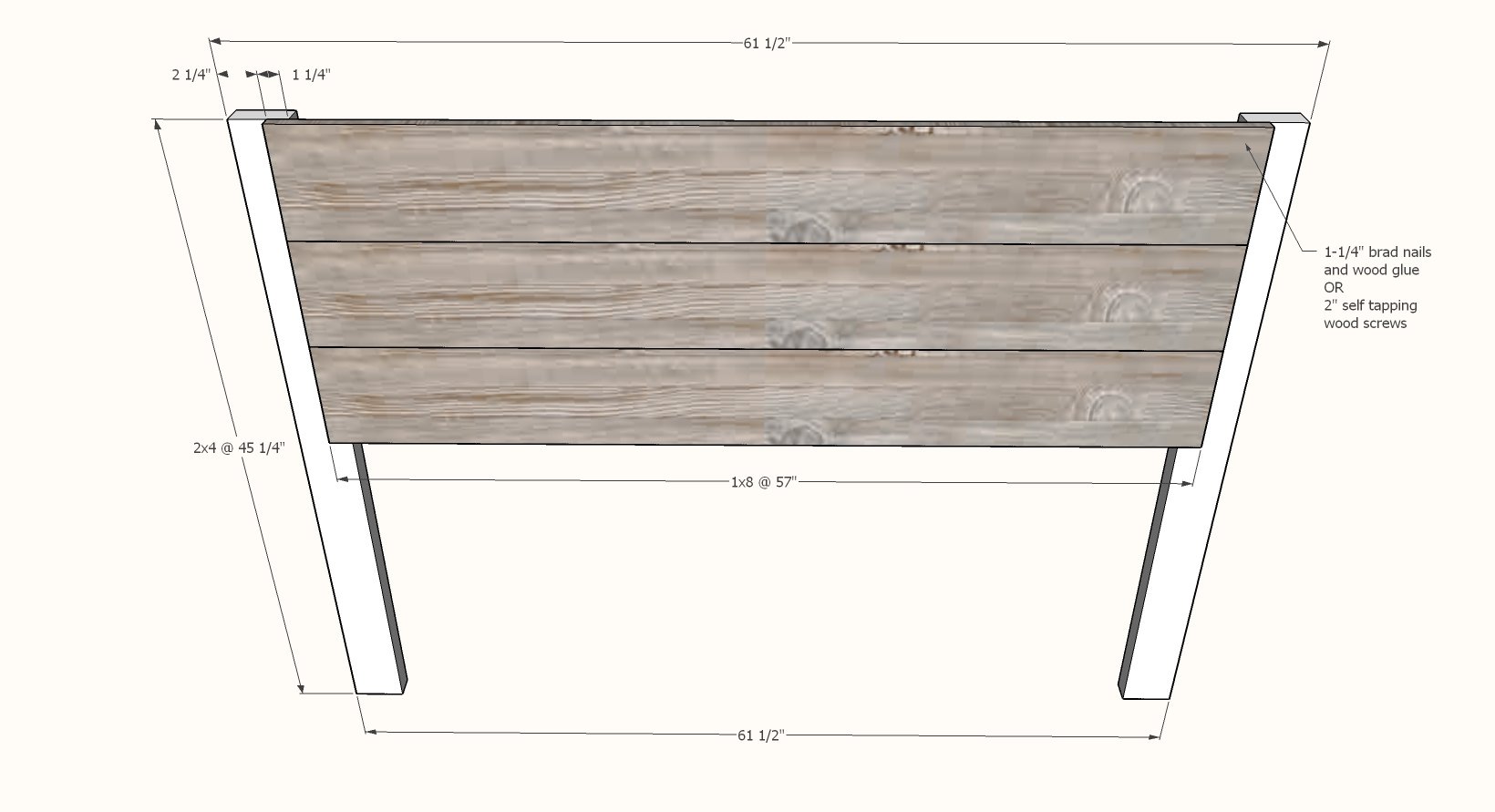

Step 1

Layout the two headboard legs.

Mark a line all the way down each 2x4 leg, 2-1/4" in from the outsides.

Dryfit the panel boards for the headboard on the legs.

Then attach the top 1x8 to the legs, with glue and screws or nails.

Repeat, working downward, for all the 1x8s - just make sure you apply a bead of glue between the 1x8 boards as you go.

Comments

Chantcaps

Sun, 05/26/2019 - 13:47

Hi there! would there be a…

Hi there! would there be a cut list availible for a king size bed? Thank you!

In reply to Hi there! would there be a… by Chantcaps

Ana White

Sun, 05/26/2019 - 16:40

Yes of course I’d love to do…

Yes of course I’d love to do a king version for you

Standard or California?

thegirlwiththebook

Sun, 05/26/2019 - 18:26

May I request California…

May I request California King please? Where I live no one carries bed frames in this awesome size : )

In reply to May I request California… by thegirlwiththebook

Ana White

Tue, 05/28/2019 - 13:36

No problem! I updated the…

No problem! I updated the plans for a California King modification above

Nor

Mon, 05/27/2019 - 03:44

Please make a standard king…

Please make a standard king too

In reply to Please make a standard king… by Nor

Ana White

Tue, 05/28/2019 - 13:55

Here's the standard king…

Here's the standard king modification https://www.ana-white.com/sites/default/files/Untitled%20document%20%28…

Chantcaps

Tue, 05/28/2019 - 04:18

Just a standard for me would…

Just a standard for me would be great! Thanks so much

In reply to Just a standard for me would… by Chantcaps

Ana White

Tue, 05/28/2019 - 13:55

No problem! here's the…

No problem! here's the standard king modification https://www.ana-white.com/sites/default/files/Untitled%20document%20%28…

jwright88

Sun, 05/26/2019 - 17:02

Full size

Love this so much! Looks so easy. I’d love a plan for a full size bed.

In reply to Full size by jwright88

Ana White

Tue, 05/28/2019 - 14:09

No problem - here's the full…

No problem - here's the full size cut list and shopping list https://www.ana-white.com/sites/default/files/full%20simple%20panel%20b…

Wonderfullymad…

Sun, 05/26/2019 - 18:14

King plsns

Ooooh! I would love KING plans!

In reply to King plsns by Wonderfullymad…

Ana White

Tue, 05/28/2019 - 13:55

Thanks for asking - here's…

Thanks for asking - here's the king modification https://www.ana-white.com/sites/default/files/Untitled%20document%20%28…

mbelli

Sun, 05/26/2019 - 20:58

I would love this in a twin…

I would love this in a twin size bed! Is this possible?

In reply to I would love this in a twin… by mbelli

Ana White

Tue, 05/28/2019 - 14:09

No problem, here's the twin…

No problem, here's the twin mods https://www.ana-white.com/sites/default/files/twin%20simple%20panel%20b…

mbelli

Tue, 05/28/2019 - 22:02

Thank you!!!

Thank you!!!

[email protected]

Tue, 02/15/2022 - 18:57

Gap between mattress and headboard

I’ve almost completed this plan but I’m wondering if I should cut the legs off the headboard by about 6”, I won’t be using a box spring and I don’t want a gap between the headboard and mattress, does that sound reasonable?

I don’t want my toddler to fall through the gap or think crawling through there is a good idea lol

freakinhilarious

Sun, 05/26/2019 - 21:00

I would loooove plans for aa…

I would loooove plans for aa Ca King!

In reply to I would loooove plans for aa… by freakinhilarious

Ana White

Tue, 05/28/2019 - 14:10

Here's the California King…

Here's the California King Mods https://www.ana-white.com/sites/default/files/california%20king%20simpl…

lkepich

Mon, 05/27/2019 - 05:51

King

I would love King size as well!

In reply to King by lkepich

Ana White

Tue, 05/28/2019 - 14:07

Here you go! Here's the…

Here you go!

Here's the standard king size modification https://www.ana-white.com/sites/default/files/Untitled%20document%20%28…

Premorgan

Mon, 05/27/2019 - 06:51

I would love plans for a…

I would love plans for a twin size!

In reply to I would love plans for a… by Premorgan

Ana White

Tue, 05/28/2019 - 14:10

Of course, here's the twin…

Of course, here's the twin mods https://www.ana-white.com/sites/default/files/twin%20simple%20panel%20b…

Premorgan

Wed, 05/29/2019 - 12:40

Thank you so much!

Thank you so much!

mombuilds1123

Mon, 01/27/2020 - 07:36

Could you tell me what type…

Could you tell me what type of wood you used for this bed and the stain? I love it!

shellcrab75

Mon, 05/27/2019 - 07:11

Can I get the plans for a…

Can I get the plans for a standard king size please?

In reply to Can I get the plans for a… by shellcrab75

Ana White

Tue, 05/28/2019 - 14:07

Here's the standard king…

Here's the standard king size modification https://www.ana-white.com/sites/default/files/Untitled%20document%20%28…

rcamacho7

Mon, 05/27/2019 - 10:29

What color are the walls…

What color are the walls painted ?

In reply to What color are the walls… by rcamacho7

Ana White

Tue, 05/28/2019 - 13:56

The wall color is "grey…

The wall color is "grey screen" by Sherwin Williams

MaddyND

Mon, 05/27/2019 - 12:31

We too would love to see plans in TWIN size!

Great bed! We too would love to see plans in TWIN size!

In reply to We too would love to see plans in TWIN size! by MaddyND

Ana White

Tue, 05/28/2019 - 14:11

Thank you! Here's the twin…

Thank you! Here's the twin mods https://www.ana-white.com/sites/default/files/twin%20simple%20panel%20b…

cstephens

Mon, 05/27/2019 - 18:19

Can I get plans for a twin…

Can I get plans for a twin please?!

In reply to Can I get plans for a twin… by cstephens

Ana White

Tue, 05/28/2019 - 14:11

Yes, here you go https://www…

Yes, here you go https://www.ana-white.com/sites/default/files/twin%20simple%20panel%20b…

asl

Mon, 05/27/2019 - 19:25

Can I get the King size…

Can I get the King size plans as well? Thanks so much!

In reply to Can I get the King size… by asl

Ana White

Tue, 05/28/2019 - 14:07

Yep! Here's the standard…

Yep! Here's the standard king size modification https://www.ana-white.com/sites/default/files/Untitled%20document%20%28…

Smalltownbigdreams

Mon, 05/27/2019 - 20:48

Yes a Standard King size…

Yes a Standard King size plan please :)

In reply to Yes a Standard King size… by Smalltownbigdreams

Ana White

Tue, 05/28/2019 - 14:07

Here's the standard king…

Here's the standard king size modification https://www.ana-white.com/sites/default/files/Untitled%20document%20%28…

Sonoma47

Tue, 05/28/2019 - 08:51

king size bed

May I get the plans for a standard King size bed please.

Thanks so much!

In reply to king size bed by Sonoma47

Ana White

Tue, 05/28/2019 - 14:06

Here's the standard king…

Here's the standard king size modification https://www.ana-white.com/sites/default/files/Untitled%20document%20%28…

cabushey

Wed, 05/29/2019 - 20:08

Beautiful room and so…

Beautiful room and so functional! What color stain did you use on the bed? Thank you!

acnettles

Thu, 05/30/2019 - 14:24

Tall bed

Hi Ana - would it be possible to raise the bed? I want to make myself a bed, but I want to make it so I can get rid of the risers I need to store my sewing/quilting stuff under my bed. I would need about 9.25" clearance from the base of the bed to the floor. I'm thinking if I add a piece of wood as a brace would make that possible, but I'm not sure.

Jennifer823

Fri, 05/31/2019 - 05:00

How long will this build take

What is an approximate time frame for this project?

Jennifer823

Fri, 05/31/2019 - 05:04

ALSO could you use a…

ALSO could you use a boxspring with it?

nz231

Mon, 06/03/2019 - 10:45

I am wondering the same…

I am wondering the same thing. My bed has to have a box spring. Could you include the modifications to make a queen bed like this but with a box spring mattress? Thank you so much!! :)

Ralphyoder

Tue, 06/04/2019 - 03:43

Farmhouse bed color

Hi! Love the stain color. Would you mind sharing what brand and color was used for this bed? I am working on building one for our Air BNB. Thanks!

RubyJ15

Thu, 10/17/2019 - 13:34

Thanks so much for these…

Thanks so much for these plans! I'm excited to build this the bed. I have one question, are the 3 inch screws that attach the footboard to the bed frame center go through the footboard so that that are seen from the outside?

Thanks!

itrytodoitupnice

Thu, 01/02/2020 - 12:00

Cedar instead?

Our local hardware store has cedar on sale, the only cut they don't have is the 1x3. They do have a 1x4, do you think it would make an ok substitute? Would cedar even be a good idea?

marcalejo

Sat, 01/18/2020 - 11:51

Type of wood

Hi Ana. I would like to know what kind of wood do I use? Douglas fir? I want to build this for my son.

WoodworkingRachel

Mon, 01/20/2020 - 13:50

Type of wood

This is a beautiful bed! What type of wood are you using? Whatever it is I would like to use the same type of wood!

cwilks13

Thu, 03/05/2020 - 19:36

What colour stain did you…

What colour stain did you use on this bed?

i love it!

SEB11

Fri, 05/29/2020 - 05:22

Matching nightstands

Awesome bed!

Do you have the plan for the "Modern Simple Nightstand Plans" as well?

Thanks :)