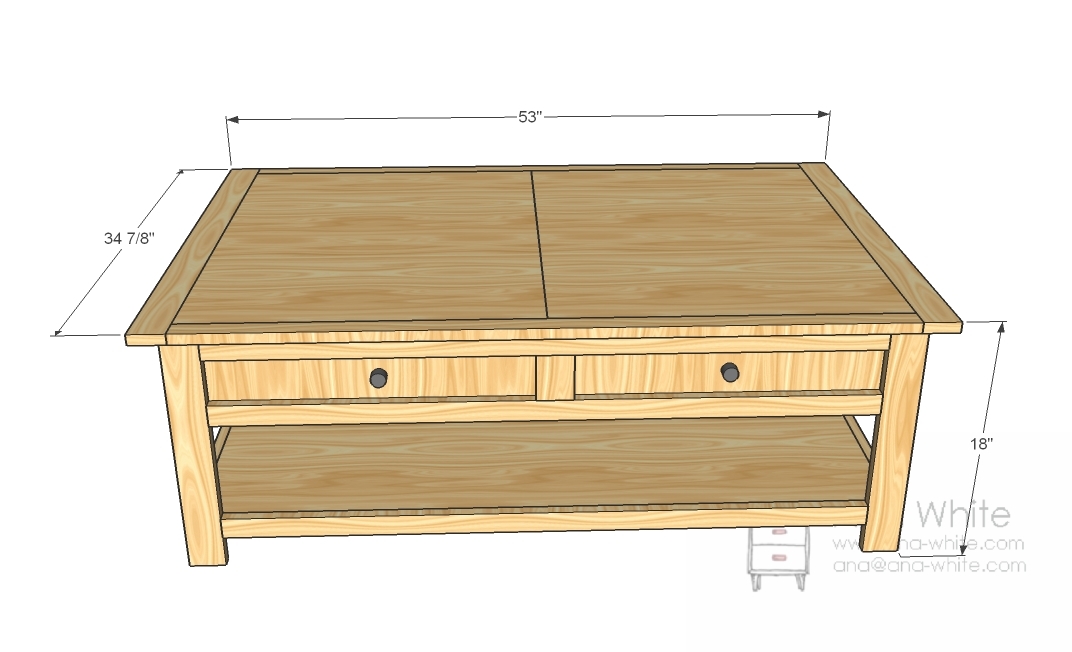

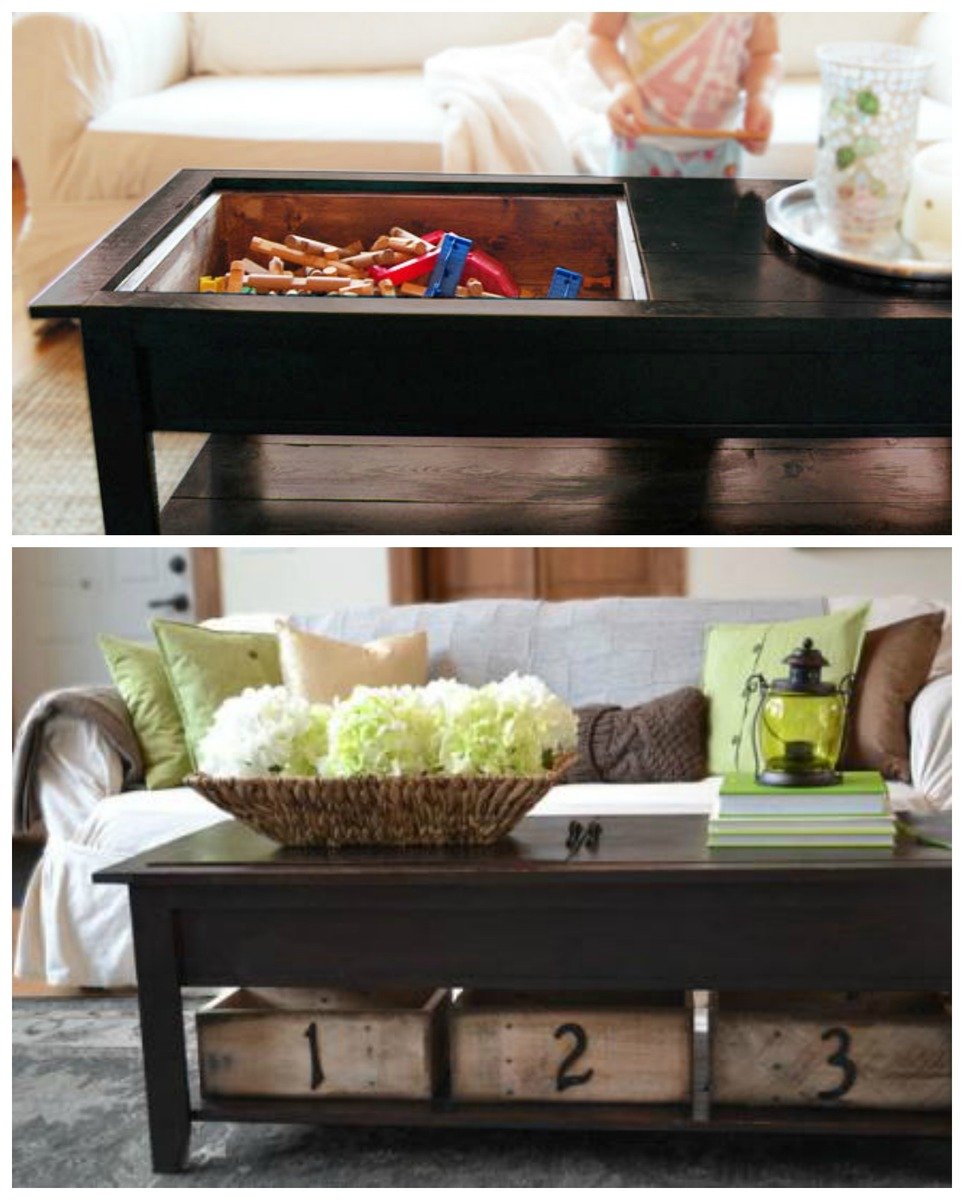

DIY Coffee Table with hidden train table storage inside. Special thanks to Christy for sharing her photos with us.

Thank you for your beautiful comments and positive feedback on our Lego Table. We all are special in our own unique way. But I am truly blessed because you are giving me an opportunity to follow my dreams, and I can't express how appreciative I am. Truly, thank you for your support.

After posting yesterdays Lego Table, I thought it only fair to then post the matching Train Table

The train table is double the width of the lego table. You just need more room for trains to make their tracks go round.

But you need that extra space for train tracks to wrap around. We tried a small track on Grace's Lego Table, and there's just not enough room.

But you need that extra space for train tracks to wrap around. We tried a small track on Grace's Lego Table, and there's just not enough room.

For this train table, you won't need a whole lot more supplies. Just a full sheet of plywood instead of a half, and a few extra feet of 1x6s and 1x3s and 1x2s.

Preparation

1 – sheet of 3/4″ plywood or MDF cut into strips 31 7/8″ wide x 48″ long (you will get exactly 3 strips) 1 – 1×6, 8 feet long 1 – 1×6, 6 feet long x – 1×3, 8 feet long x – 1×3, 8 feet long 2″ screws 1 1/4″ screws Finish nails Wood Glue Wood Filler Finishing Supplies All visible edges will be finished, so no need for edge banding on this one.

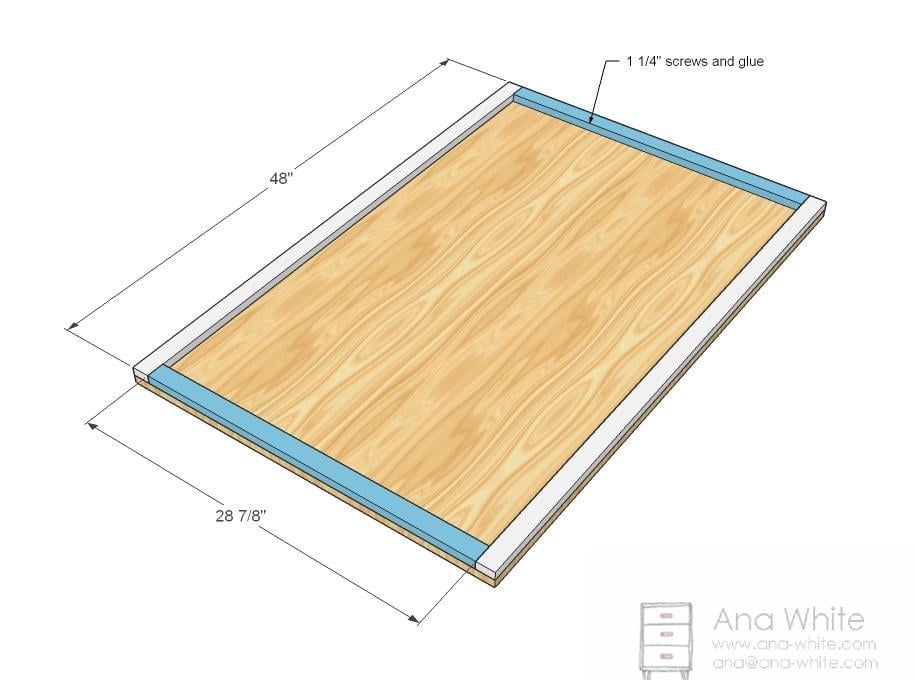

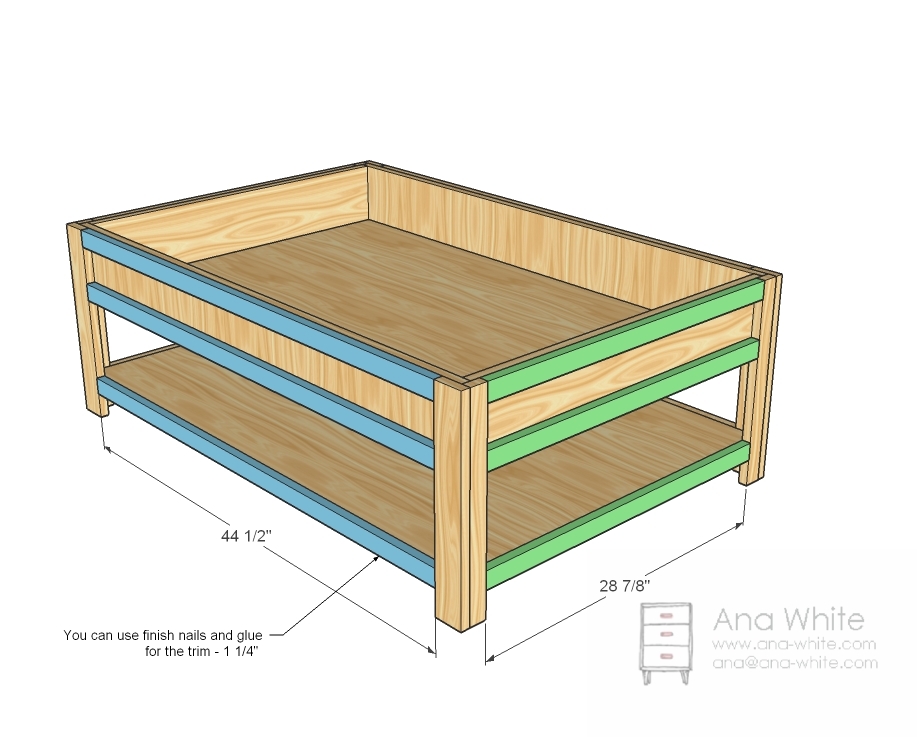

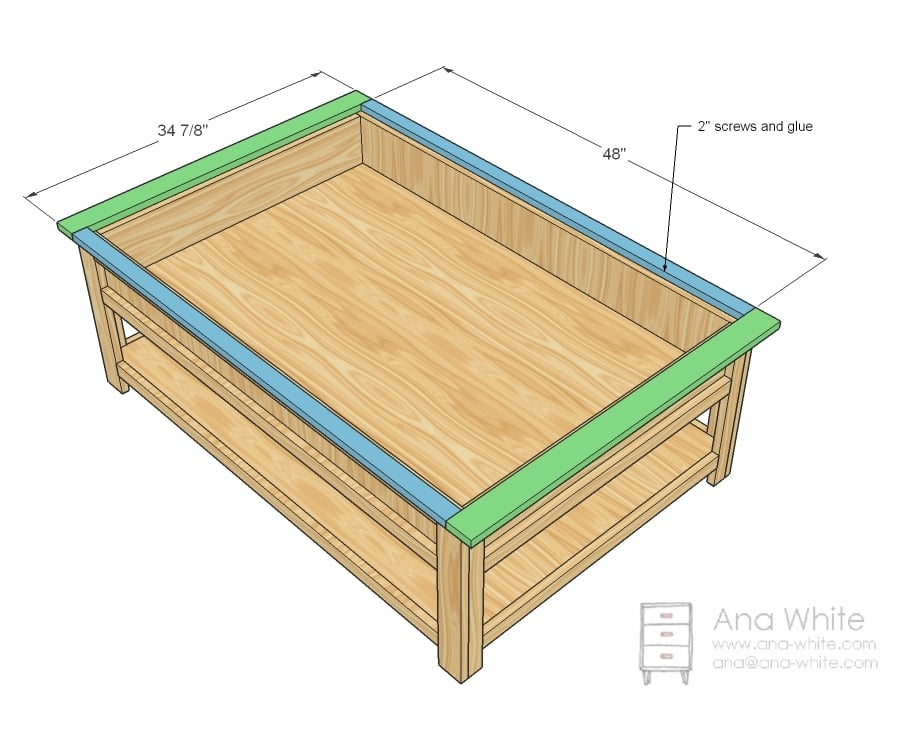

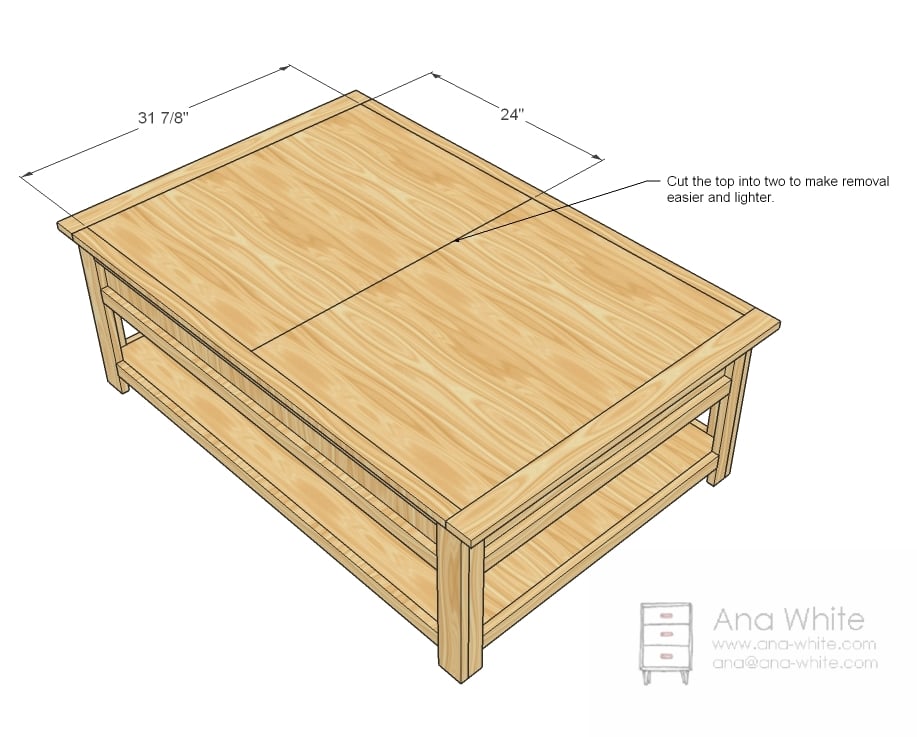

2 – 1×6 @ 48″ 2 – 1×6 @ 30 3/8″ 2 – 3/4″ Plywood or MDF @ 48″ x 31 7/8″ 4 – 1×2 @ 17 1/4″ (Side Legs) 4 – 1×3 @ 17 1/4″ (Front/Back Legs) 2 – 1×2 @48″ (bottom shelf supports) 2 – 1×2 @ 28 7/8″ (bottom shelf) 6 – 1×2 @ 28 7/8″ (trim) 6 – 1×2 @ 44 1/2″ (trim) 2 – 1×3 @ 34 7/8″ (top end) 2 – 1×2 @ 48″ (top sides)

Instructions

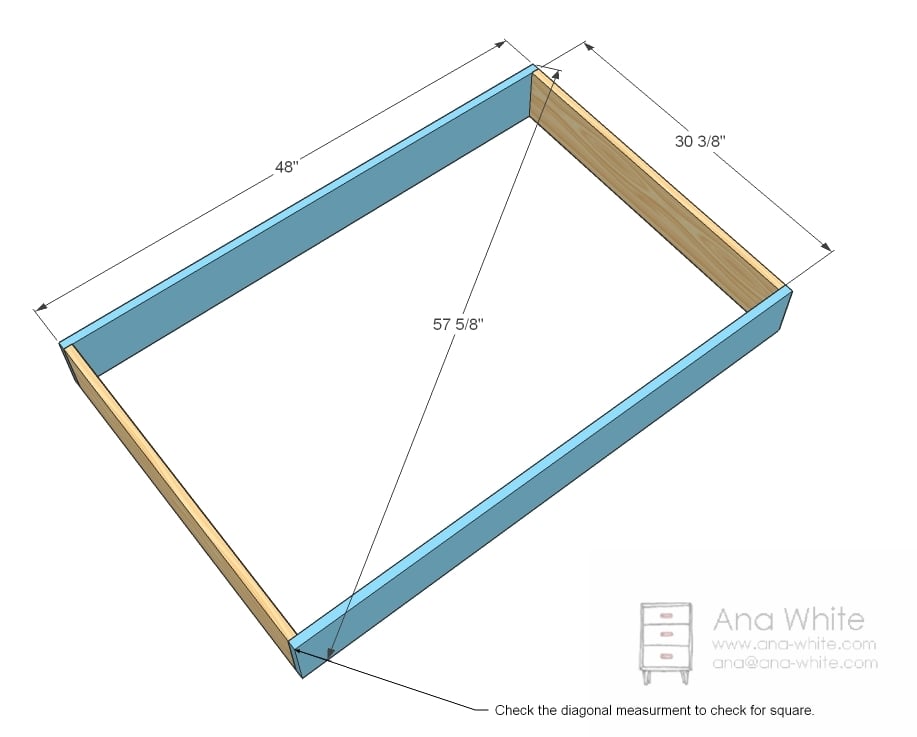

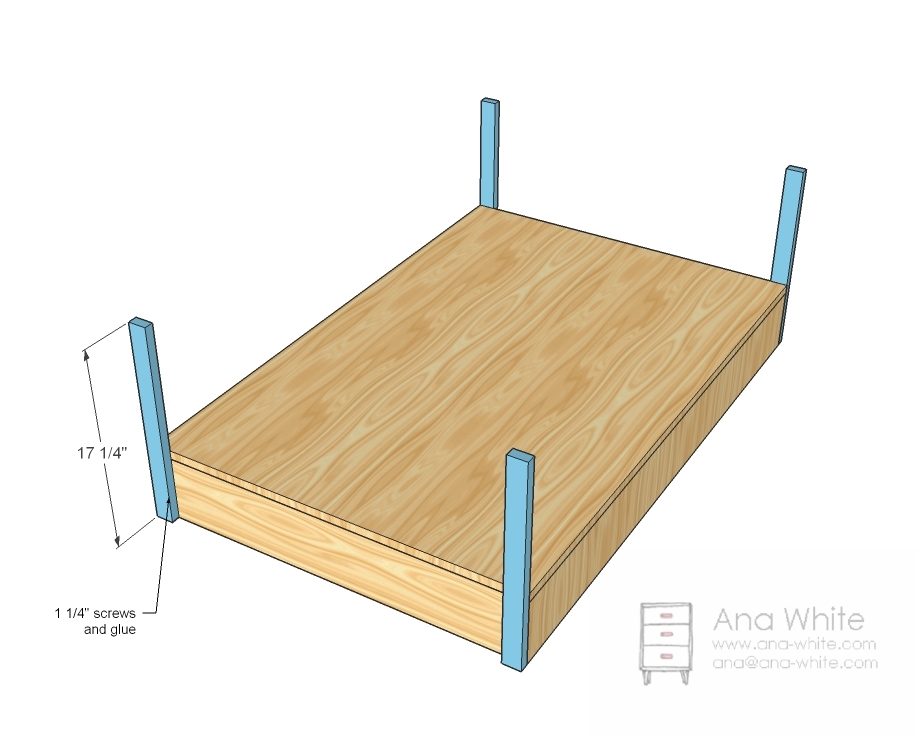

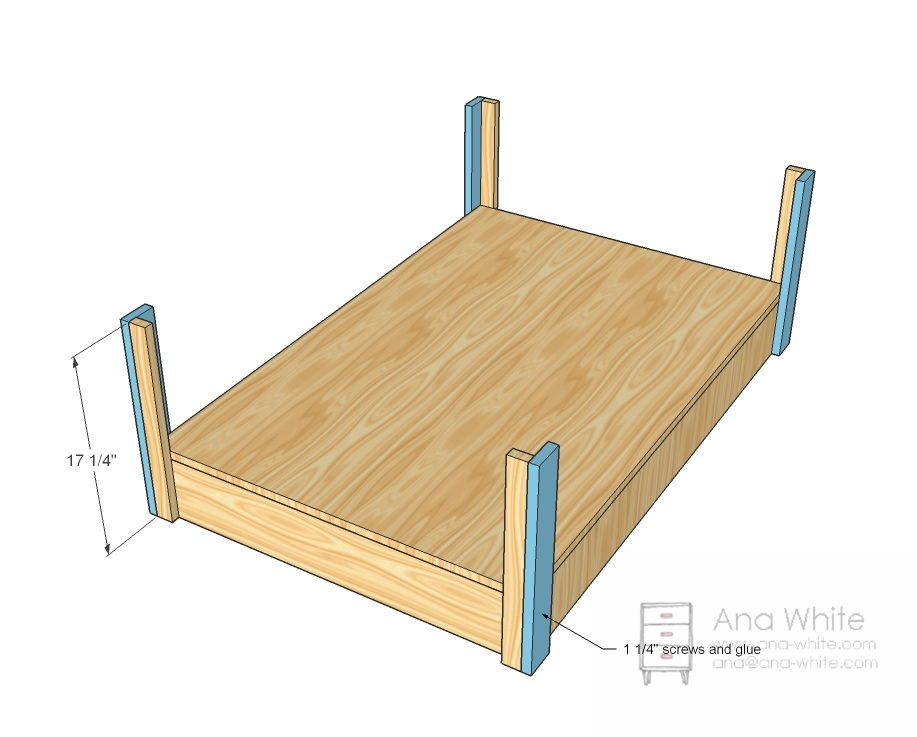

Step 1

Build the Box Screw the box together as shown above with 2″ screws and glue. The measure across diagonally, checking to see if the measurement matches the diagonal above. Measure the oppostite diagonal. One diagonal will be longer than the other. On the longer diagonal, push the two opposite corners together, decreasing the distance between the corners. This is how you adjust for square. When the diagonals match, you’ve got a square box!

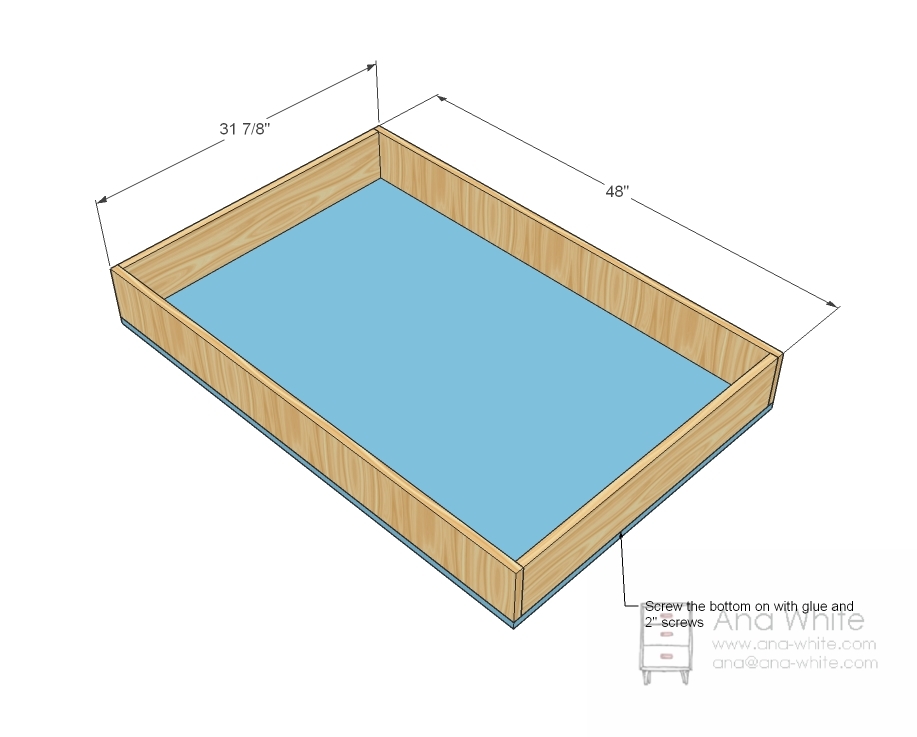

Step 2

Step 3

Step 4

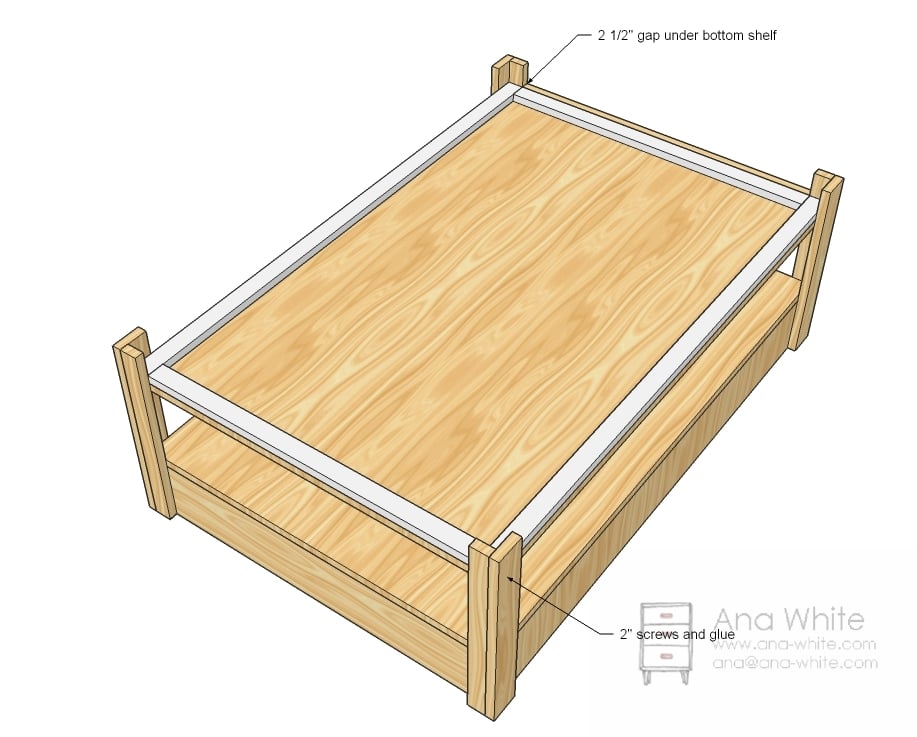

Step 6

Attach Bottom Shelf Get some help on this one or turn the table on it’s side. Predrill holes and attach the bottom shelf. What I would do is to cut 2 1/2″ long spacers and screw to the inside of the legs on the underside (with the shelf in place) flush with the bottom of the legs. Then let the bottom shelf rest on the tops of these spacers as you predrill holes and screw the bottom shelf on. You could even leave the spacers in.

Step 7

Step 8

Step 9

Top Inserts And those are the top inserts I was talking about. Sand them to get a nice fit. You may wish to drill a little hole in the center (half on each insert) to have a spot to pull the inserts up with. For those of you concerned about sagging, I checked the deflection and you should be able to put 70 pounds on each inset with no noticeable deflection – that’s as much as any preschooler would weigh. But if you are going to stand on it, make sure you put a foot on each insert

Comments

Spare time builder

Sat, 12/19/2015 - 22:25

No lip because plywood actual

No lip because plywood actual thickness is 23/32 and 1x whatever wood is 24/32. Difference of 1/32 is nothing and will disappear with sanding. Good luck I'm sure your table will be great!

Spare time builder

Sat, 12/19/2015 - 22:29

No lip

No lip because plywood actual thickness is 23/32 and 1x whatever wood is 24/32. Difference of 1/32 is nothing and will disappear with sanding. Good luck I'm sure your table will be great!

brat62387

Mon, 01/20/2020 - 22:20

Help

The shopping list and cut list don't add up. Is there an updated shopping list?