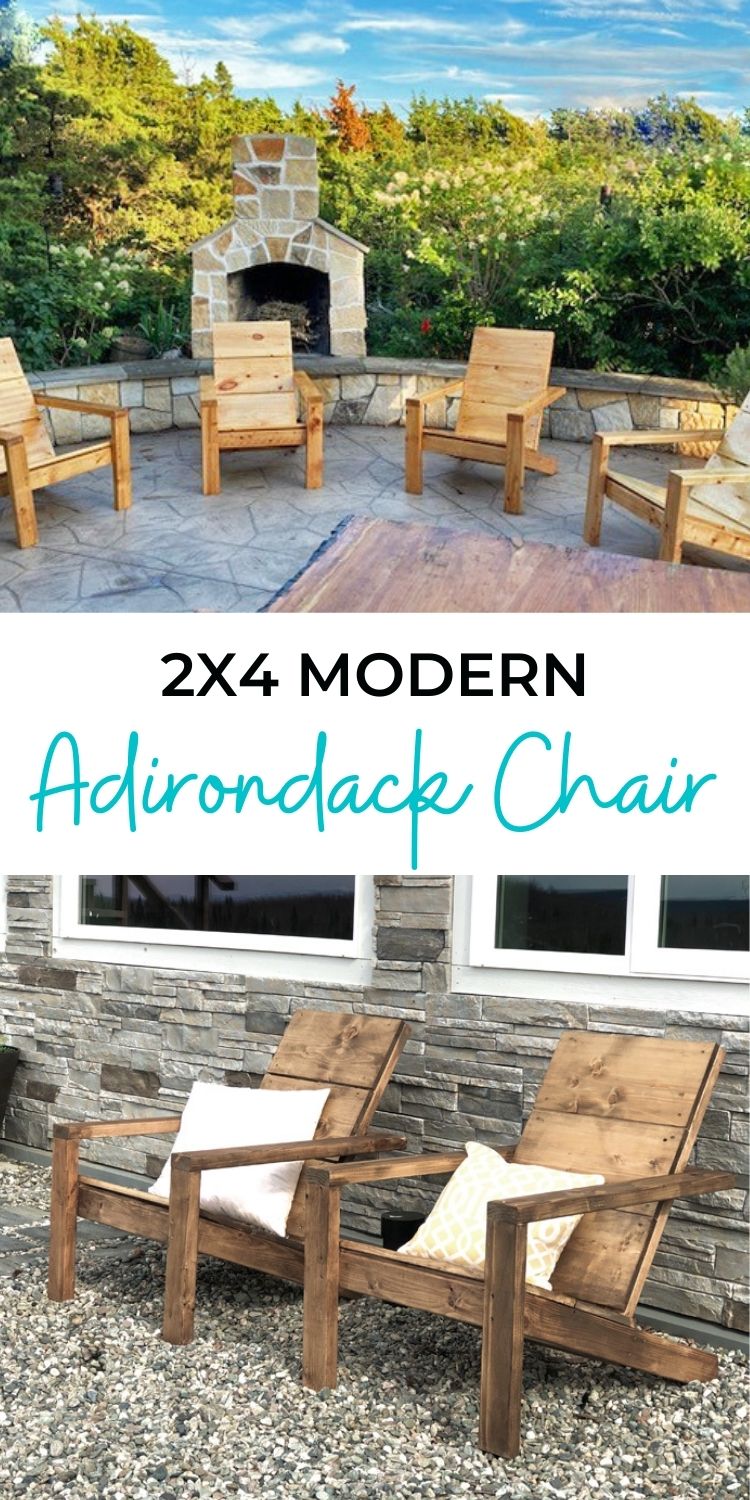

The MOST POPULAR Adirondack Chairs plans! This is an easy build that shouldn't take too long, and the chair is super comfortable and sturdy! Free plans by Ana-White.com

Here's Some Tips to Build Better Outdoor Furniture

Want to build better outdoor furniture? Over the twenty years I've been building, maintaining, and enjoying my own outdoor furniture, I've learned a few tips that can help build longer lasting furniture.

Preparation

- 3 - 2x4 @ 104-5/8" long (OR 4 - 2x4 @ 8 feet long or 92-5/9" long)

- 1 - 1x10 @ 10 feet long*

- 4 - 2-1/2" Kreg Pocket Hole Screws

- 24 - 2-1/2" long self tapping exterior screws (look for the screws with the star bit heads, can be up to 3" long)

- 30 - 1-1/2" long self tapping exterior screws (same type as the longer screws, can be slightly shorter or longer (up to 2"), these screws are just used to attach the seat boards to the frame)

*If building more than one chair, you only need 9 feet of 1x10 boards per chair. So for two chairs, you could purchase one 8' long 1x10 and one 10' long 1x10.

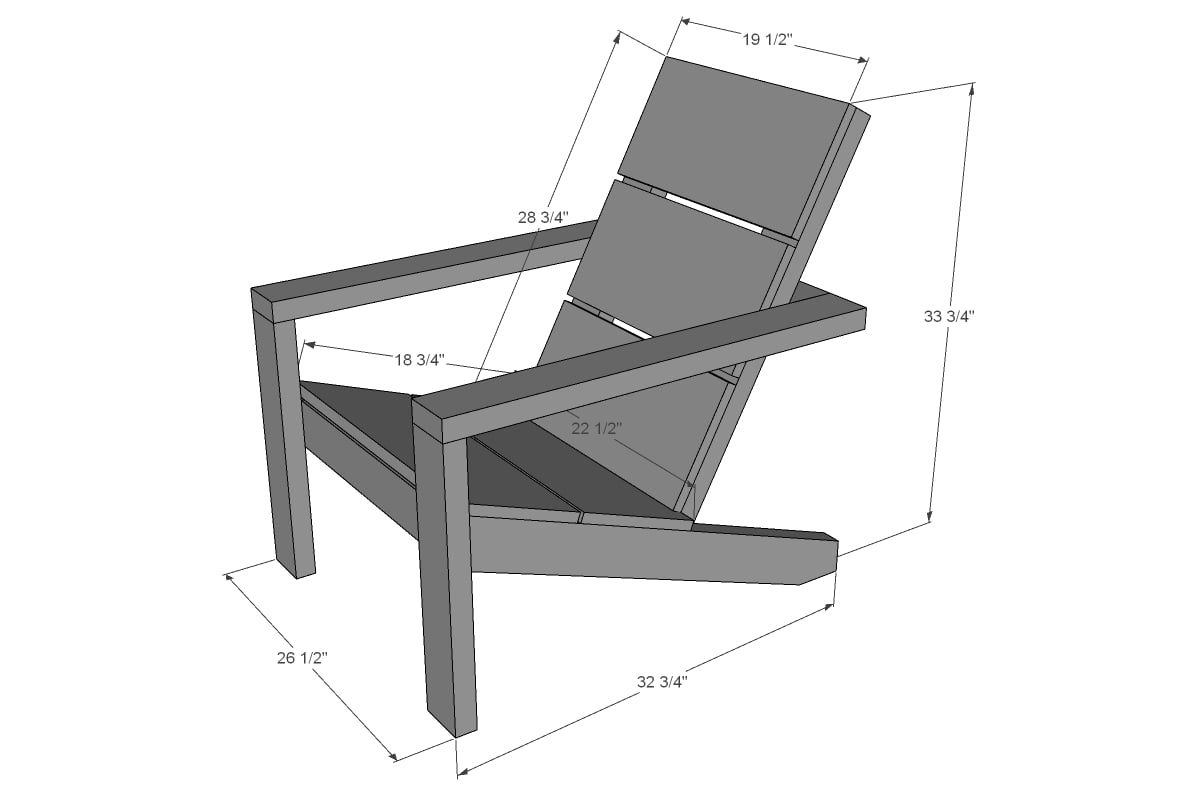

- 5 - 2x4 @ 19-1/2" - legs and horizontal supports

- 2 - 2x4 @ 31-3/4" - arms

- 2 - 2x4 @ 33-1/4" - both ends cut at 20 degrees off square, ends ARE parallel, long point to short point measurement

- 2 - 2x4 @ 32-3/4" - back supports

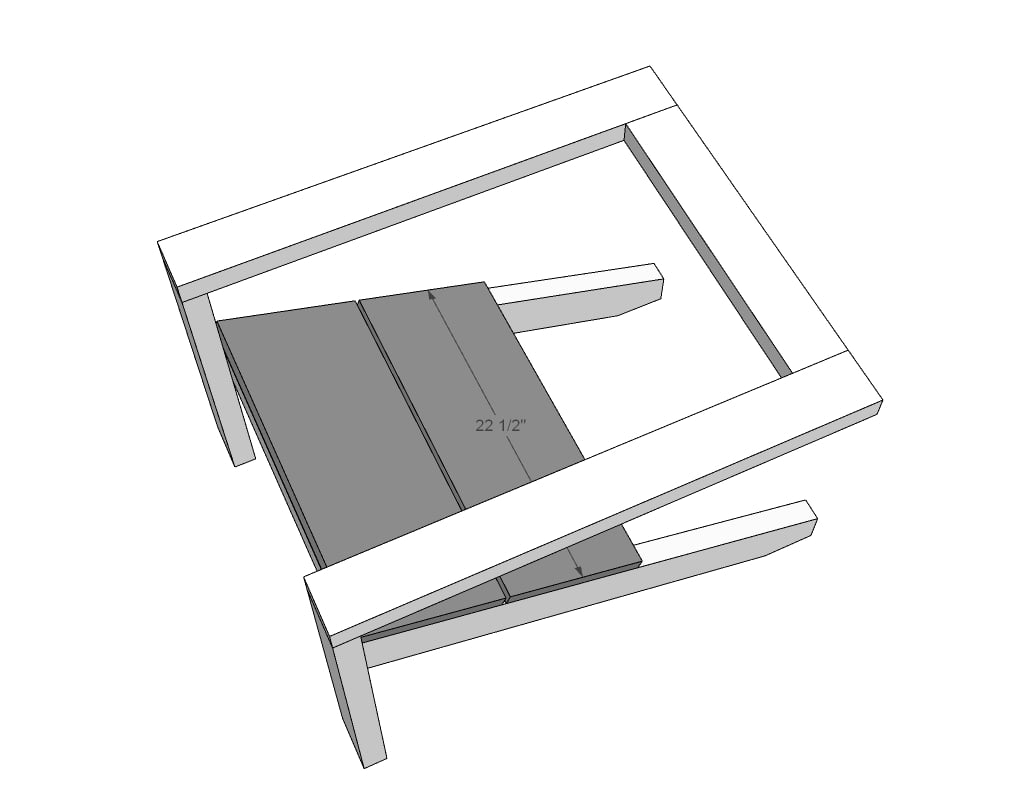

- 2 - 1x10 @ 22-1/2" - seat

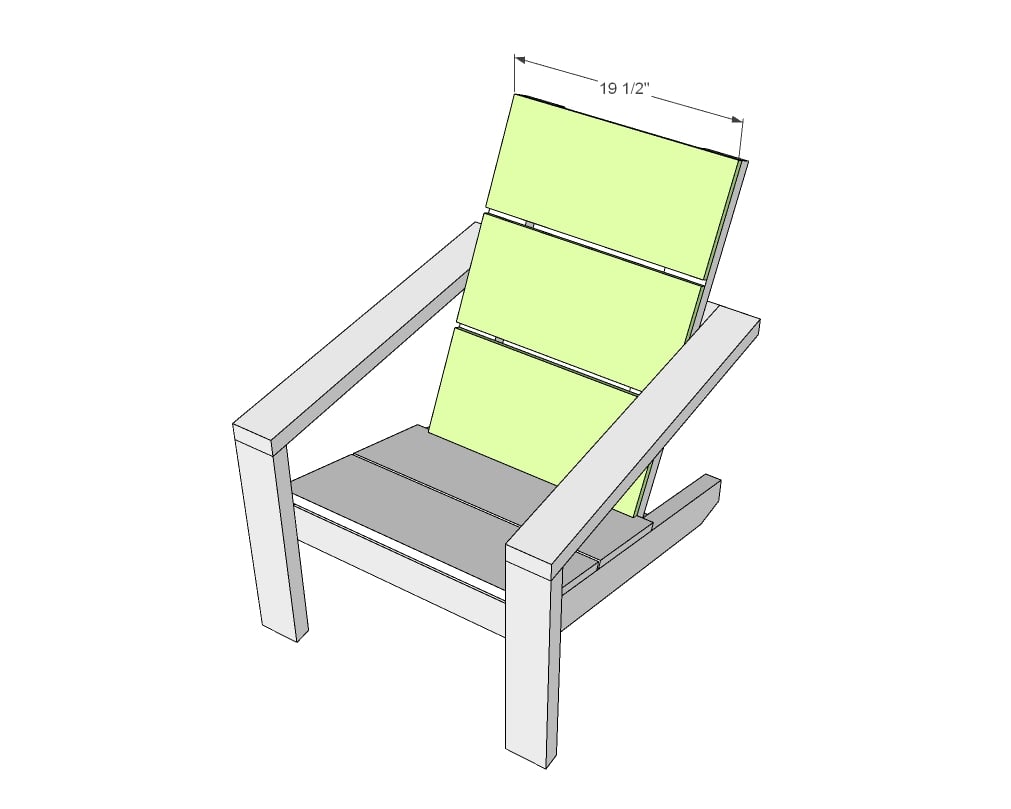

- 3 - 1x10 @ 19-1/2" - back

It may be easier to pre-finish your boards before cutting.

Work on a flat level surface.

Instructions

Step 1

Step 2

Step 3

Step 4

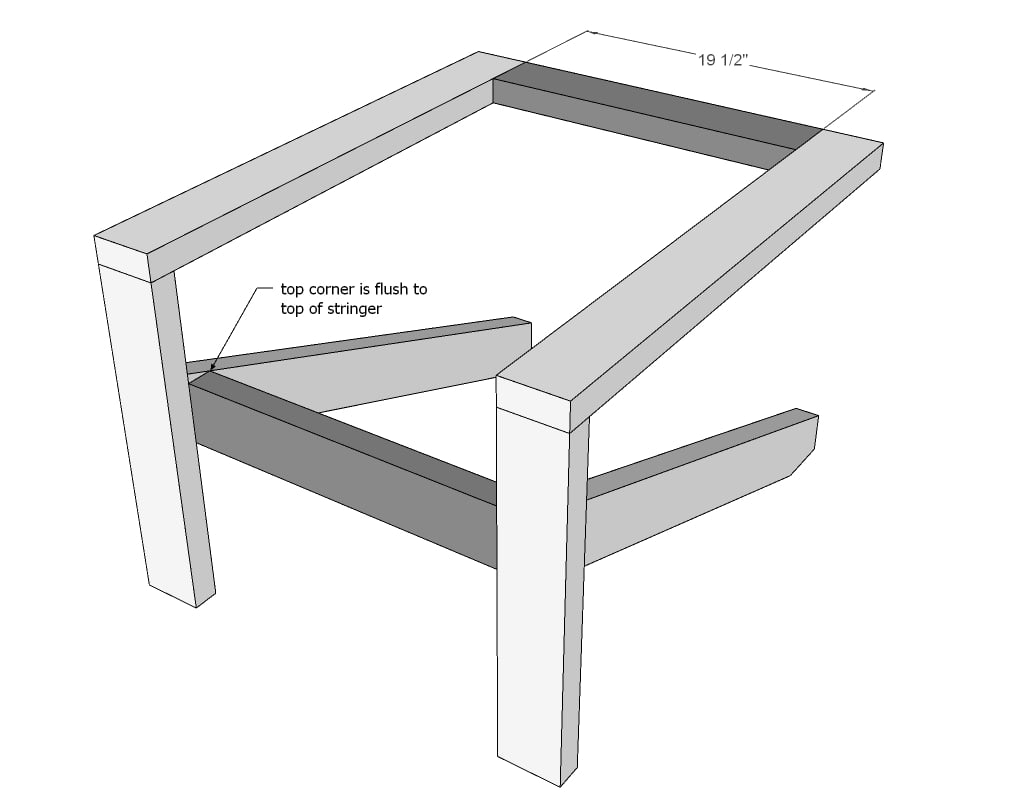

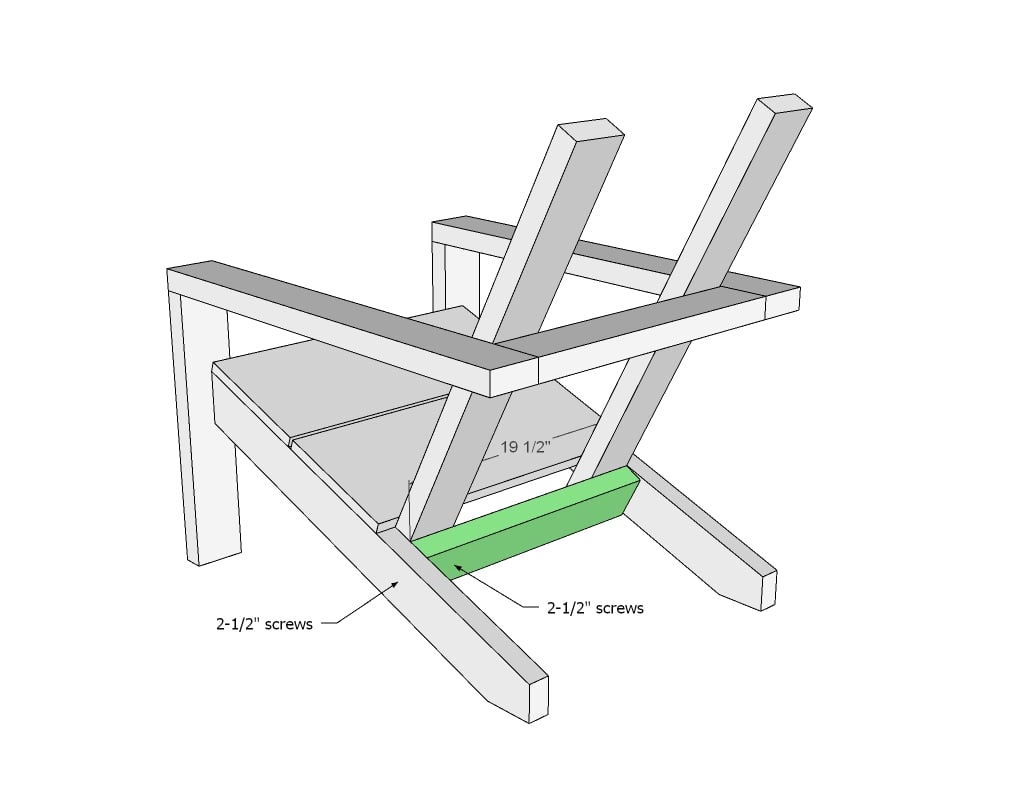

Place the remaining 2x4 @ 19-1/2" long under the back of the chair as shown in the diagram.

Place one seat support in the chair and hold flush to the bottom of the stringer.

Attach with screws to the stringer and to the back support.

Move to the other side of the chair and repeat with the second back support.

Remove the 2x4 @ 19-1/2" long.

Comments

tp_clough

Sat, 07/04/2020 - 16:10

I used pressure treated pine…

I used pressure treated pine to build this chair , wasn’t to hard for me, a beginner . Did you use regular pine ? Seems to cost more then what you said . I couldn’t find 1x10s so used 1x4s. , going to try to build another but make the back a bit longer , would like something to rest my head on. Thx for sharing T.

trentonstanley

Mon, 07/13/2020 - 19:00

I built these using 1x6s for…

I built these using 1x6s for the seat and back because that's all the lumberyard had in cedar. The seat ends up being 1 inch shorter so the angle on the back is just a little shallower but they still work and look great. And because I used cedar mine cost a little more than double Ana's estimate, but it was worth it. They're beautiful and comfortable and way more solid than I expected. Thanks for a great plan, Ana!

rajasaab

Thu, 07/16/2020 - 07:56

Need a suggestion

So i built these and they are awesome. The only problem i have is that the arms are not staying stable as you sit on it and rest your arms and lean back the back support slides. Any thoughts on shoring up that back support piece?

zaremba111

Thu, 07/16/2020 - 14:45

Drive 2 3" Screws through…

Drive 2 3" Screws through the front side of each back support. Drive them parallel to and lined up in the middle of the armrests stright into the back support. It should add additional strength and prevent the sliding you are getting. I would suggest you use another board under the back support to make sure you are level. See step 4 again. You most likely missed the screw to the back step.

Adiban

Sun, 07/19/2020 - 16:58

Awesome

Wonderful plan. Made 4 chairs this weekend.

gajakannan

Tue, 09/22/2020 - 21:40

Help

Hello,

I'm new to wood working. I can't seem to follow the cut ana made using circular saw and speed square. Can you please explain?

Thanks

Chris_PerthWA

Tue, 07/21/2020 - 05:52

Love it

This chair is perfect. Check out mine at https://www.ana-white.com/community-projects/thanks-ana-adirondack-chai…

gajakannan

Wed, 09/23/2020 - 14:43

Hello, I'm new to wood…

Hello,

I'm new to wood working. I can't seem to follow the cut ana made using circular saw and speed square. Can you please explain?

Thanks

BPJacobs

Mon, 07/27/2020 - 06:30

Very comfortable

These chairs are awesome! I have built 6 so far with 2 as gifts. I modified them slightly because I did not have a pocket hole jig so I added another 2x4 to attach those pieces. The plans were very good and the chairs were simple to build. Very Happy!

brendacloer

Fri, 08/14/2020 - 05:45

Modified Plan

Is there a plan for vertical slats on the back instead of horizontal?

1john3

Mon, 08/31/2020 - 08:41

Your helpers made that video…

Your helpers made that video!! Oh yeah, awesome chair. I need to add some seating spaces for my new fire pit. These will work. Thanks for sharing.

gajakannan

Sun, 09/20/2020 - 19:03

The seat and back is 1x10…

The seat and back is 1x10 lumber? i cant seem to find 1x10 in any of the big box store in my area... is there a modified plan for 1x6 or 1x8?

gajakannan

Sun, 09/20/2020 - 19:10

clarification, since this is…

clarification, since this is gonna be outdoor i am looking for a pressure treated outdoor lumber not a regular pine wood, unless someone tells me i can use the regular pinewood and put oil based coat?

davidcschneider

Sun, 11/15/2020 - 18:34

Advice on changing the width size of the main leg support

Hi Ana,

I love this website. I feel like there is nothing I can't make.

I just built this chair. Really easy and I want to make more. But I wanted to change the main support legs to a 2X6 and I was wondering if I had to make any adjustments to the 20 degree cuts that need to be made. My gut says no but I thought I would ask just in case.

I am going to fire them so that the groves in the wood show. I sand the groves smooth and then stain it. It comes out really cool. I don't think I can post a photo but I you look at my photo, I posted some shelving I made.

Anyway, thanks for this awesome website and if You have that information thanks in advance.

David

GooseUK

Sun, 02/28/2021 - 10:38

Amazing post.

Thank you so much for sharing this amazing project, video and instructions.

Me and my wife did a double sized one.

Hagrid

Sat, 06/12/2021 - 17:32

Great idea. I’m going to try…

Great idea. I’m going to try that as well.

Pargie

Thu, 03/04/2021 - 12:35

Folding Options

Love the design, only thing that would make this look better is if it was foldable for winter storage in the garage. Anyone have any ideas on small tweaks or hardware (door hinges?) to make this compact?

Greg T.

Tue, 03/23/2021 - 05:48

Scaled Down Plans For Toddler

Great project. I wanted to make two for my 3 and 4 year old kids so i halved all the measurements and the chair came out tiny. Any suggestions on adjusting plans to smaller scale would be great. thanks.

sdmspringer

Mon, 04/26/2021 - 13:34

In love!!!

This was my second ever building project, and I so much enjoyed the process and the end product! The chairs are also sooooo comfortable!

karenpine

Thu, 05/13/2021 - 08:28

Wood Recommendations

What type of wood, would you recommend for this project? Pine, Whitewood, or cedar?

npselvan84

Fri, 05/28/2021 - 23:38

Love the plan

I like the plan and I was looking for such a plan for a long time. But one quick question, I see the lumber price 1x10 10 feet as $28. Where do you get the lumber cheaper than Lowes or HomeDepot?

Hagrid

Sat, 06/12/2021 - 17:13

Awesomeness

This was fun. Took 1hr 30 minutes to build using only 2x4’s. It’s heavy but that’s ok with me. I may add wheels to either front or back legs for mobility. I tweaked it for another hour and 30 minutes from feedback from my wife and daughter. I ended up increasing the recline but then cut 3” off front legs ( and bottom of back support ) to get it where we all liked it. Now we just need to decide on paint, stain, etc. thanks for sharing this plan. Keep Crushing!

jendon

Tue, 07/06/2021 - 08:31

Amazing chairs!

I built two of them and they are so comfortable. I am now going to add the 2x4 outdoor side table to go between them or as a foot rest. My parents even enjoyed them and you can get out of them very easily do to the strength. I did study the video and plans for those angle cuts, just to make sure I was doing them correctly. Thank you, Ana for those helpful tools for is beginners.

Carrie8020

Mon, 07/19/2021 - 05:21

Modifying Adirondack chair plans.

The back supports are 32-3/4" - back supports and the seat is 22-1/2" - seat, how can I modify these to fit my son Inlaw who is 6’4 and 280. He love the design I actually made a set following the plans, but the chair was not wide enough for him. Suggestions

[email protected]

WesleyY

Tue, 10/19/2021 - 07:27

Recommendation

Just built these last weekend. I'd recommend that when attaching the 2 boards to the seat in step 3, take the 19.5" board and put it between the two back legs to maintain the distance. This will ensure that the spacing is correct when attaching that board in step 5.

michael.shima

Thu, 04/07/2022 - 08:27

Nice plans. I was looking…

Nice plans. I was looking for something to do with treated lumber I had from tearing out an old deck. This was perfect. I used the decking boards instead of 1x10s for the seat and the back. For the 2x4s I had several 2x10s that I ripped in half then down to 4". It worked out great. For finish, I used fire. Fire is good! Then several coats of clear.