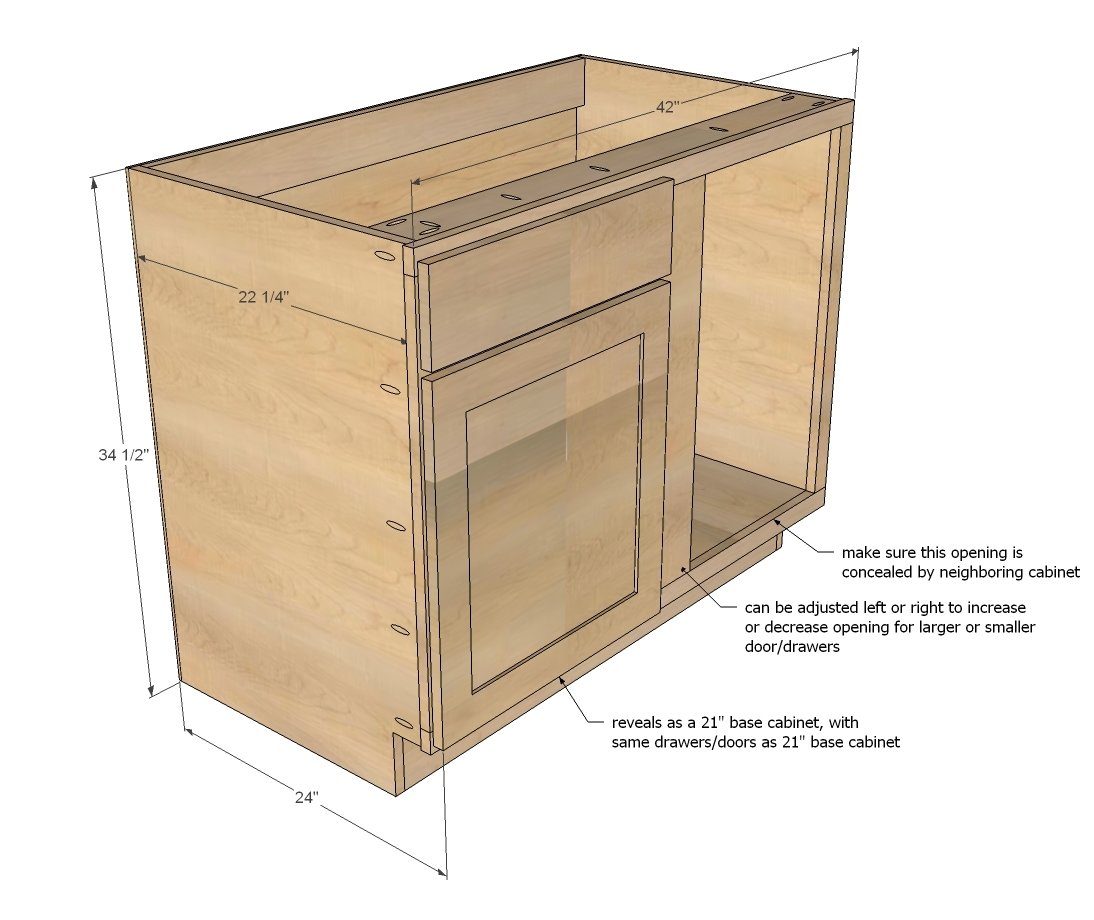

How to build a blind corner base kitchen cabinet - step by step plans from Ana-White.com

Preparation

3/4" plywood ripped into strips 22 1/4" long (for sides and shelves) 3/4" plywood scrap from ripping sides and shelves (for top supports) 3/4" plywood ripped into strips 5" long (for base supports - use cheaper plywood here) 1x2s for face frames 1x6 (or other wide width board) for the center stile (27" length) 1/4" plywood (for backs) 1-1/4" pocket hole screws 3/4" finish nails edge banding for shelves

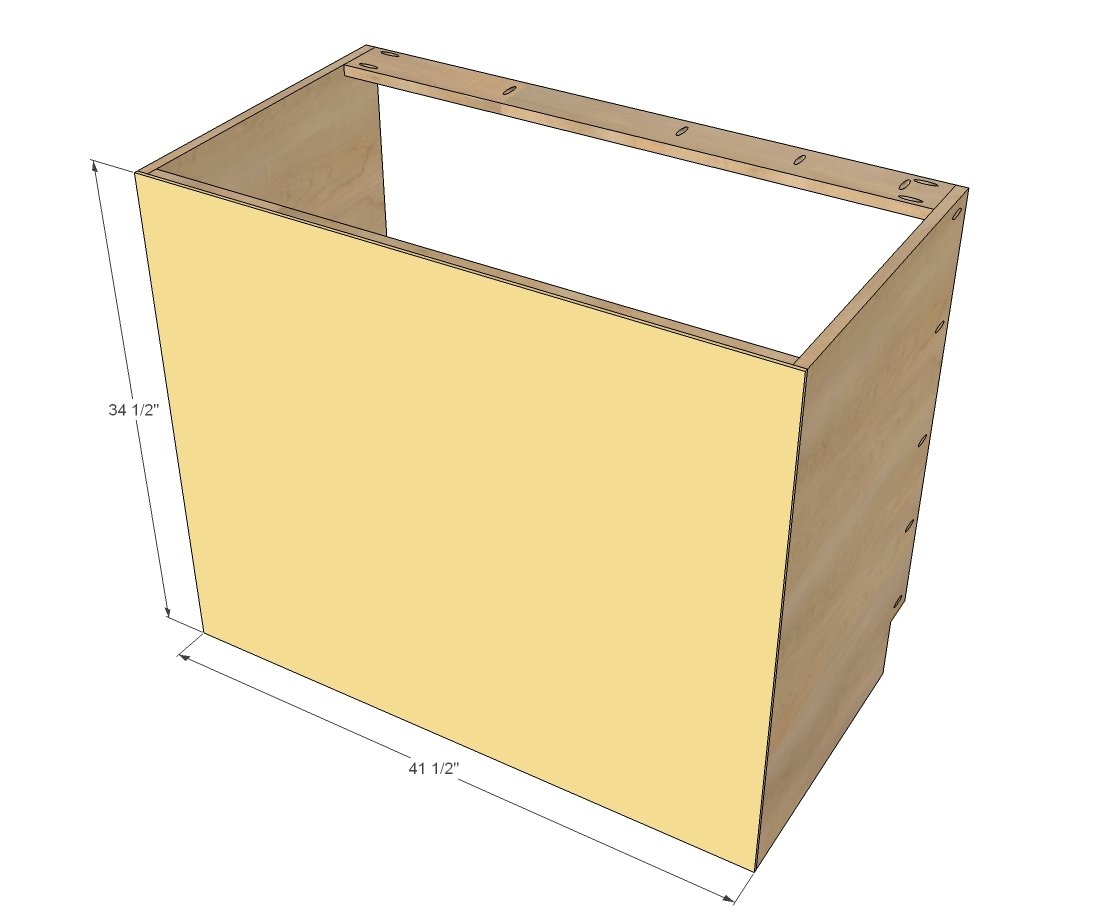

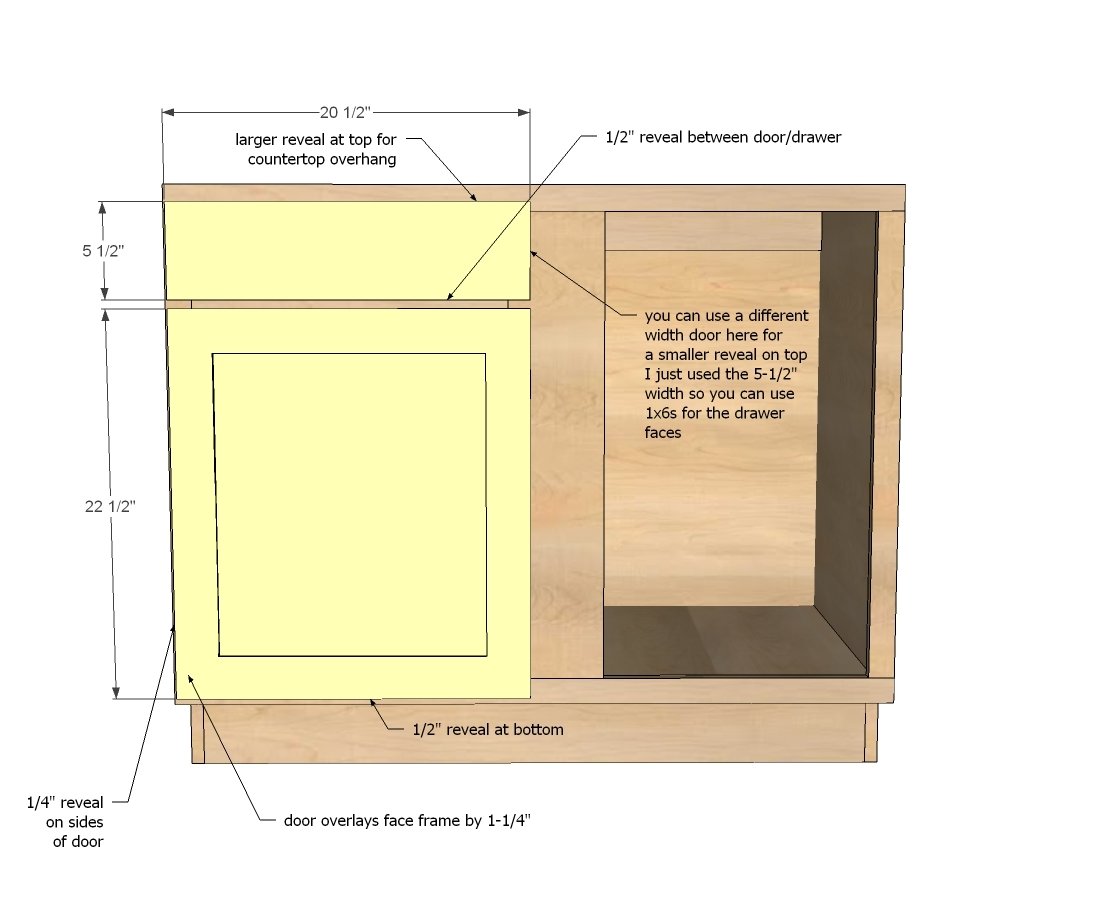

CARCASS 2 - 3/4" plywood @ 22-1/4" x 34 1/2" (side panels - same on ALL BASES) 1 - 3/4" plywood @ 22-1/4" x 40" (bottom shelf) 2 - 3/4" plywood @ 5" x 40" (bottom supports) 2 - 3/4" plywood @ 3-1/2" (can vary in rip width) x 40" (top supports) 1 - 1/4" plywood @ 32" x 41-1/2" (back) FACE FRAME 2 - 1x2 @ 27" (side stile - same on ALL BASES) 1 - 1x6 @ 27" (center stile) 2 - 1x2 @ 42" (top/bottom rails - always overall width of cabinet) 1 - 1x2 @ 18" (drawer/door rail) SHELVES 3/4" plywood @ 22" x 39-3/4" (measure and adjust to fit shelf pins) DOOR/DRAWER FACE for FULL OVERLAY (1-1/4") 5 1/2" x 20-1/2" (drawer face) 22-1/2" x 20-1/2" (door)

Please read through the entire plan and all comments before beginning this project. It is also advisable to review the Getting Started Section. Take all necessary precautions to build safely and smartly. Work on a clean level surface, free of imperfections or debris. Always use straight boards. Check for square after each step. Always predrill holes before attaching with screws. Use glue with finish nails for a stronger hold. Wipe excess glue off bare wood for stained projects, as dried glue will not take stain. Be safe, have fun, and ask for help if you need it. Good luck!

Instructions

Step 1

For all the base cabinets, make sure the side panels are cut exactly the same as the other cabinets. Make sure you create the two sides for each cabinet in mirror - meaning the toekicks are on the bottoms, pocket holes for attaching face frames are on the outsides, and shelf pin holes are on the inside for adjustable shelves.

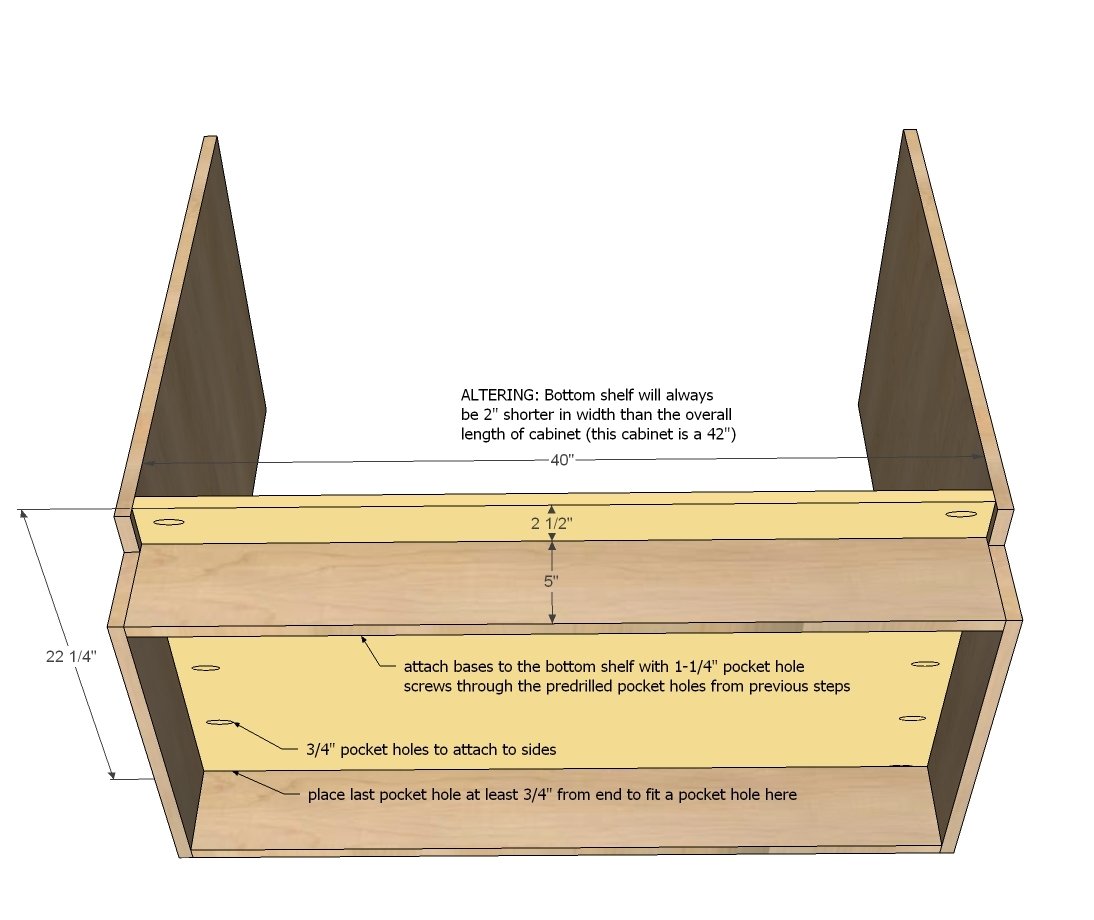

Step 2

We used cheaper plywood (unfinished off the shelf oak) for these pieces because they are hidden underneath the cabinet. We ripped a bunch at 5" widths. All pocket holes are drilled on the 3/4" setting, and we used fine threaded pocket hole screws. Note that the toekick is cut 1/2" less than the front - see next diagram.

Step 4

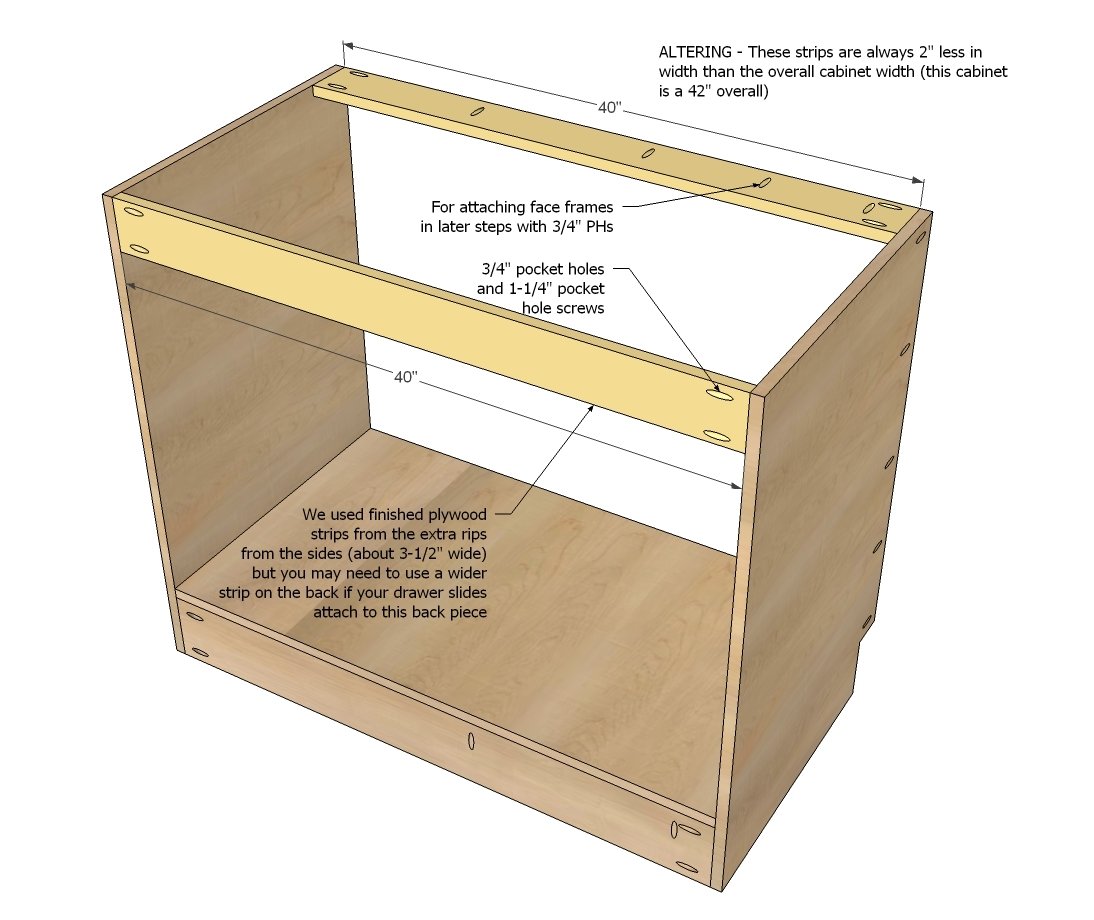

Step 6

The face frame overextends the sides by 1/4", but is flush to top and bottom (of toekick cutout) but overextends bottom shelf by 1/2". This leaves a 1/4" lip on inside of cabinet. I recommend building the face frame first with 3/4" pocket holes and 1-1/4" pocket hole screws, and then attaching the whole face frame to front with 1-1/4" pocket hole screws through holes predrilled on outsides of sides and top. On the bottom, you won't be able to get a drill in between the face frame and the bottom support board, so we nailed on the bottom with glue.

It is always recommended to apply a test coat on a hidden area or scrap piece to ensure color evenness and adhesion. Use primer or wood conditioner as needed.

Comments

Mrs B

Wed, 12/04/2013 - 15:42

Blind Cupboard hardware

Thanks for all of the kitchen cupboard plans. When I do my work room I will be using this piece of hardware to make that hard to reach back a little better.

http://www.leevalley.com/en/hardware/page.aspx?p=43657&cat=3,43722,43723

JoanneS

Thu, 12/05/2013 - 16:25

Vanilla kitchen :)

Love the title you gave this kitchen! When we use these colors in our home we call them “ice cream” colors, because they make you think about ice cream sundaes – white (appliances) for the whipped cream, creamy white (cabinets) for the vanilla ice cream, and browns and blacks (floor and hardware) as the toppings. The whole room is yummy! :)