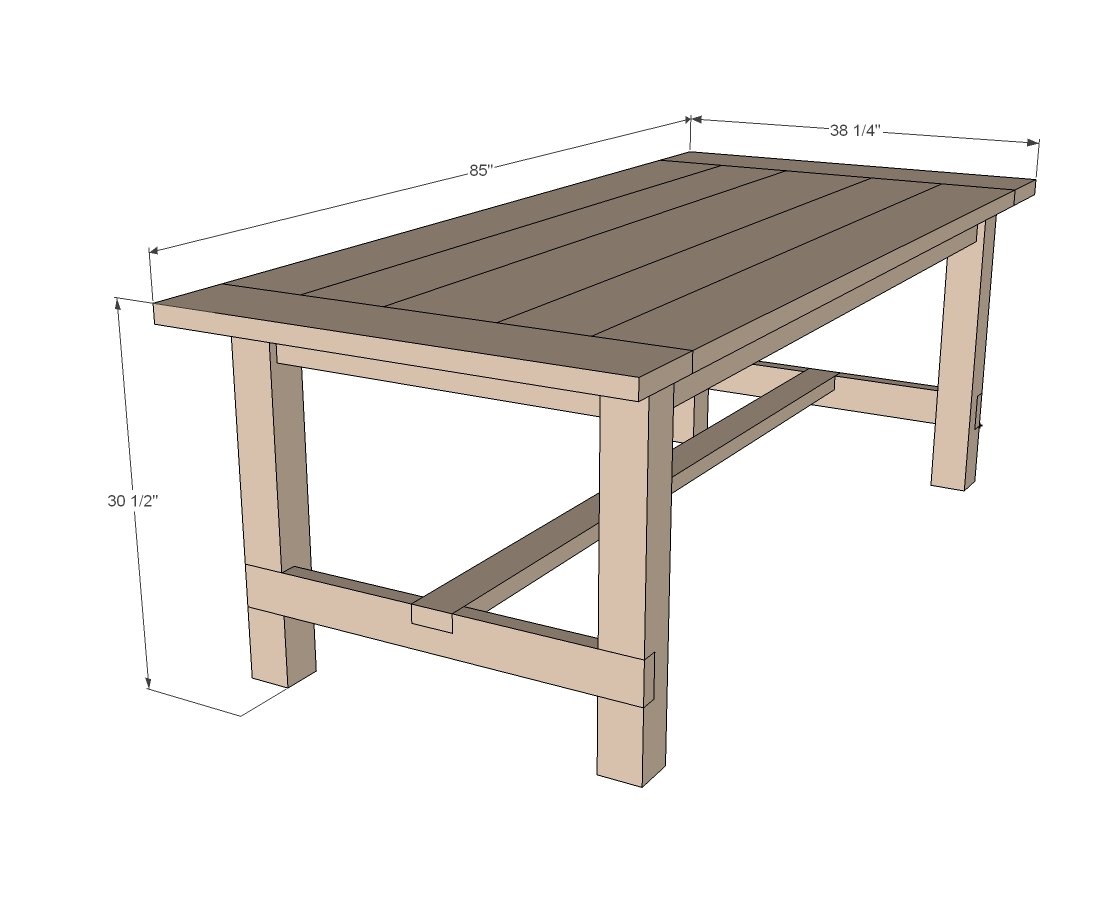

Free plans to build a Farmhouse Table. This table has been built tens of thousands of times and is loved the world over for it's basic material composition, simple clean lines, easy to build steps, and sturdy, functional size. Our step by step plans with diagrams make it easy.

This plan uses pocket holes and is the updated plan. We also have this plan available to build without pocket holes.

Preparation

- 4 - 2x4 @ 8 feet long

- 1 - 4x4 @ 10 feet long

- 4 - 2x8 @ 6 feet long

- 1 - 2x8 @ 8 feet long (breadboard ends)

- 1 - 2x10 @ 6 feet long

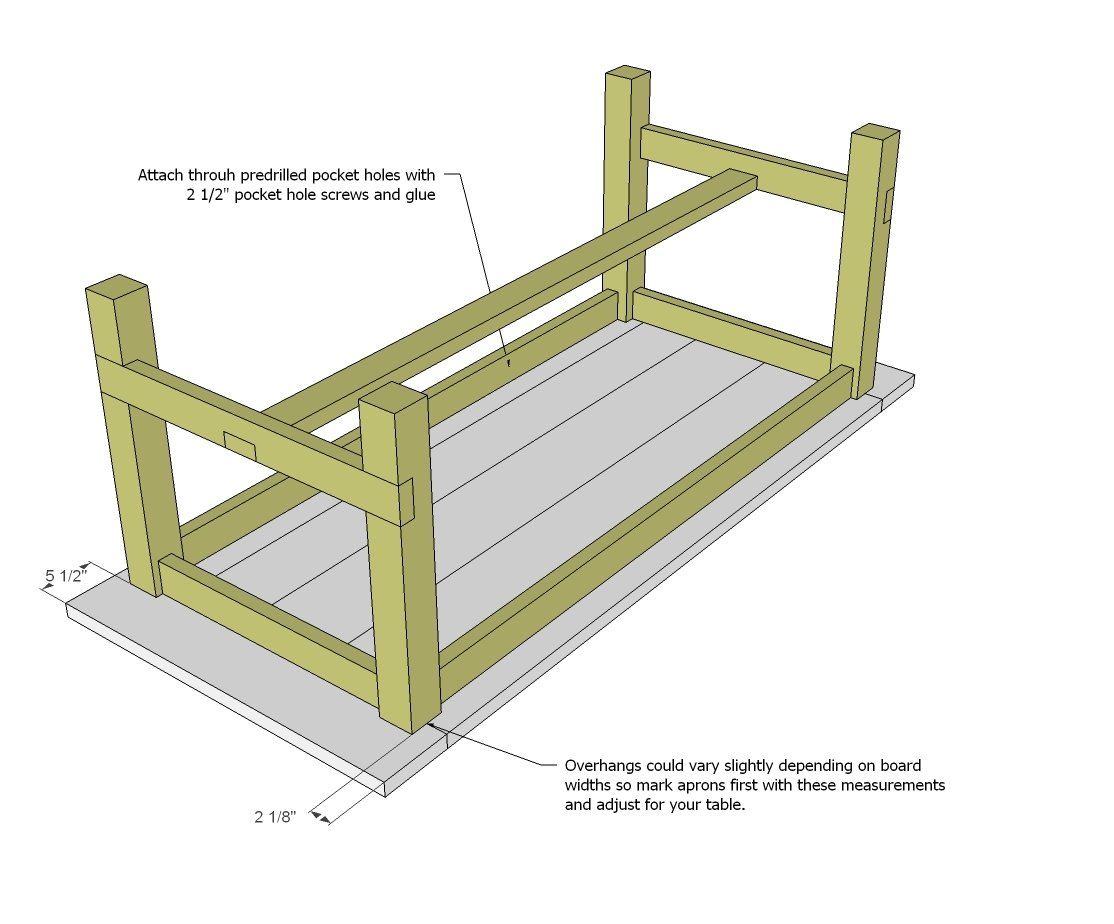

- 4 - 4x4 posts @ 29" (legs)

- 2 - 2x4 @ 67" (long aprons)

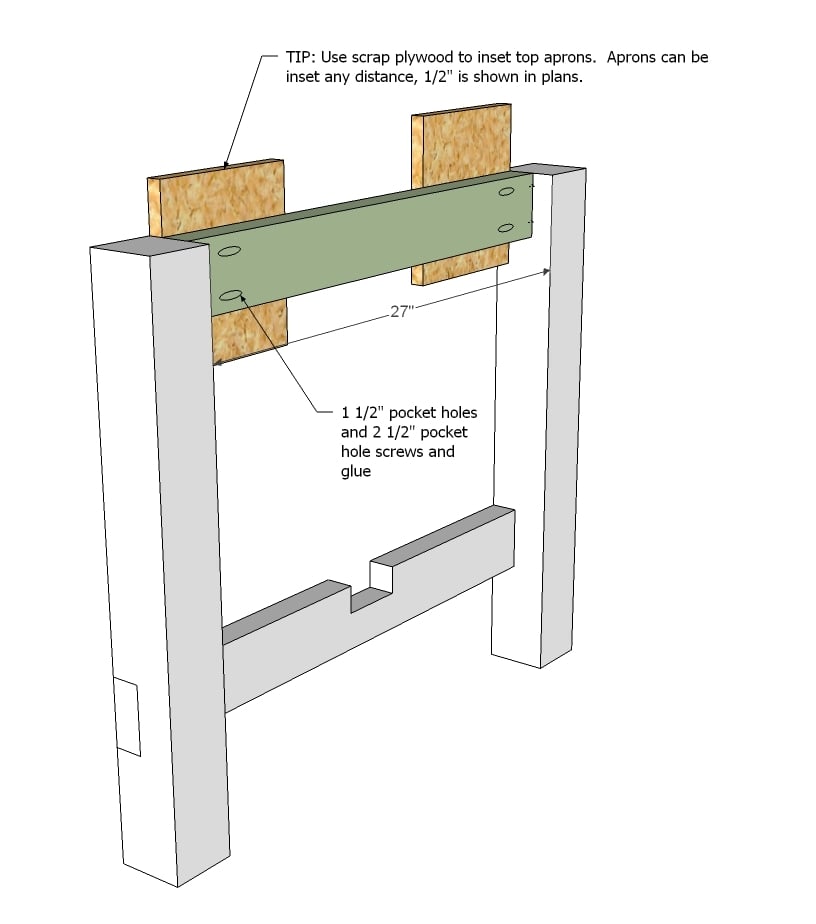

- 2 - 2x4 @ 27" (short aprons)

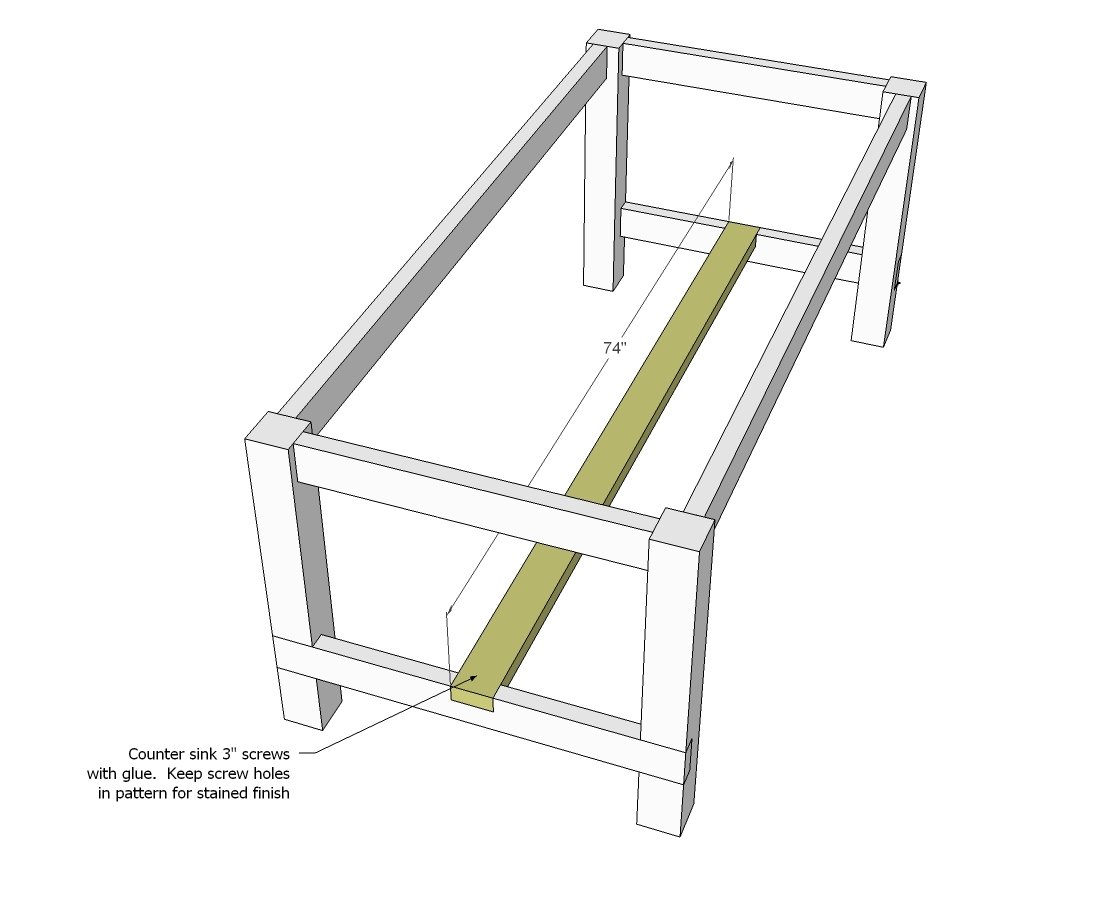

- 1 - 2x4 @ 74" (stretcher)

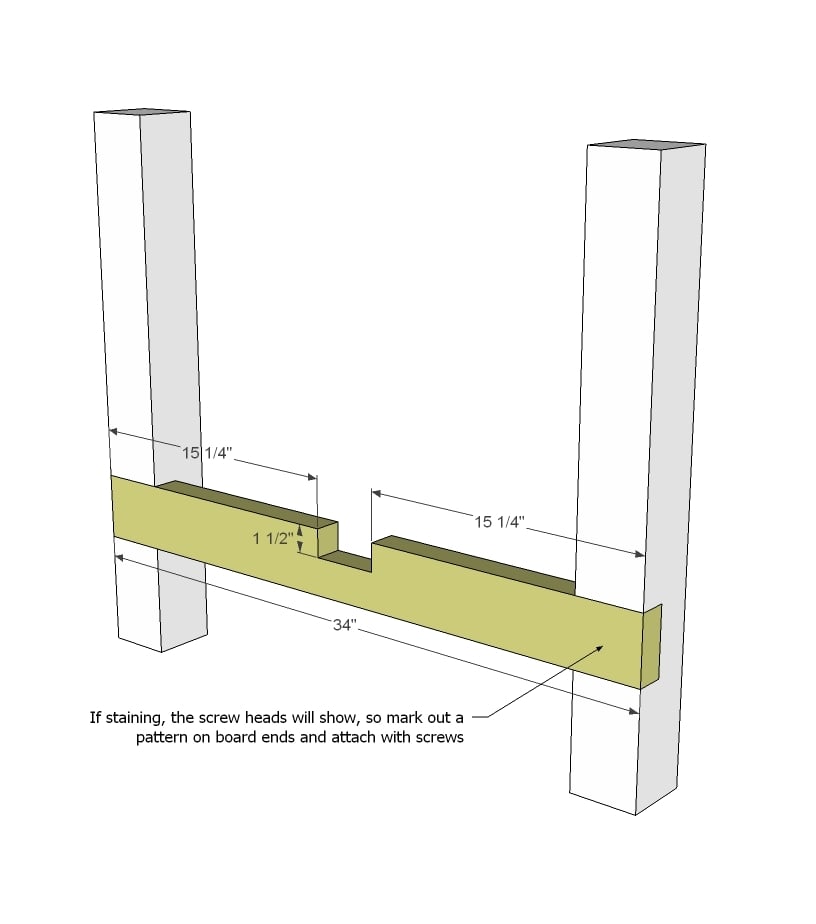

- 2 - 2x4 @ 34" (stretcher supports)

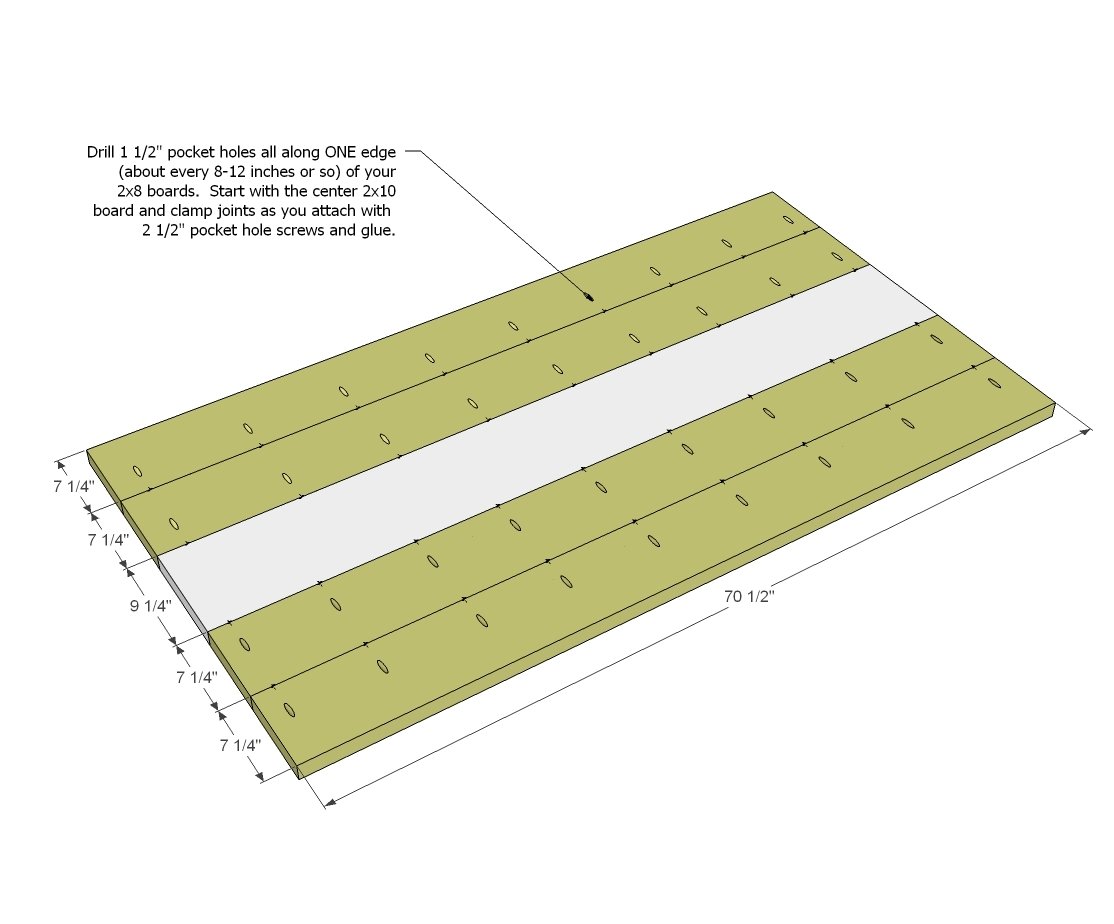

- 4 - 2x8 @ 70.5" (table top planks)

- 1 - 2x10@ 70-1/2" (center table top plank -- I had to use one 2x10 to get the right overall width)

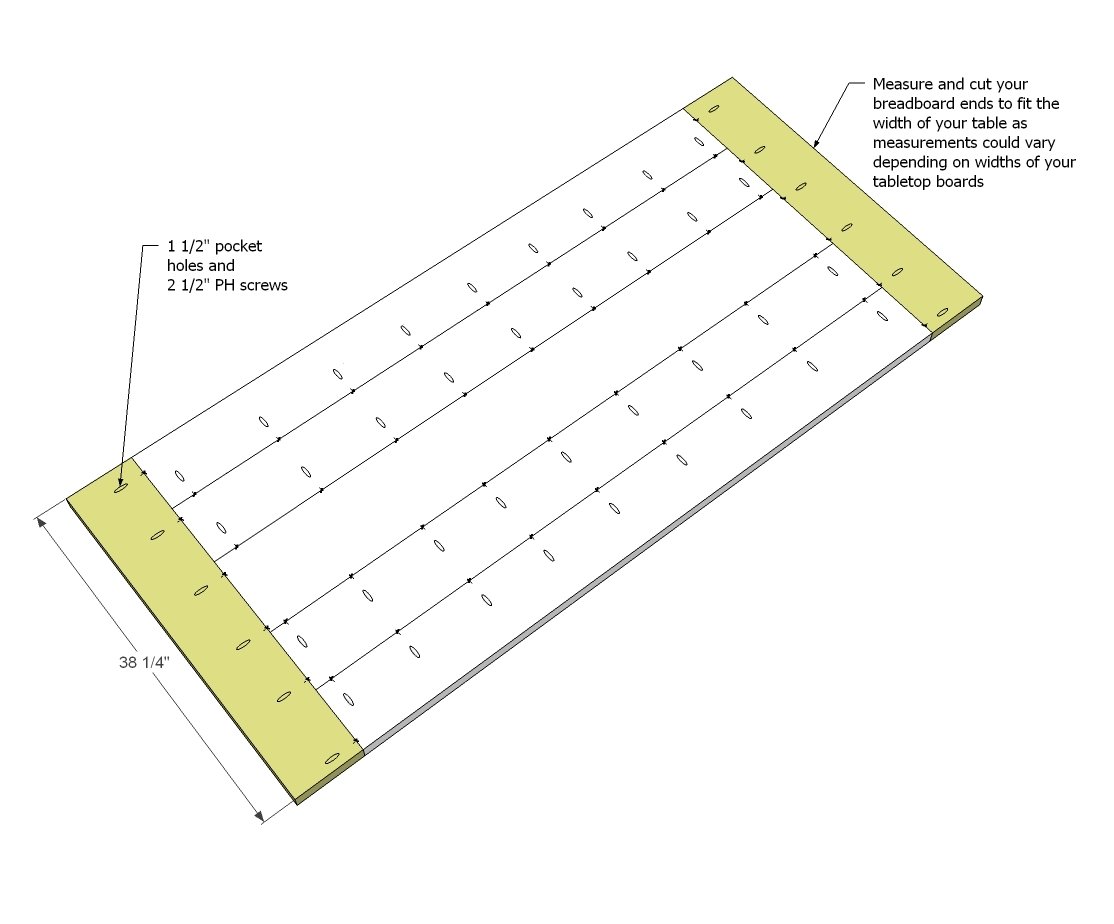

- 2 - 2x8 ~38" (breadboard ends -- measure your joined tabletop before cutting these)

Please read through the entire plan and all comments before beginning this project. It is also advisable to review the Getting Started Section. Take all necessary precautions to build safely and smartly. Work on a clean level surface, free of imperfections or debris. Always use straight boards. Check for square after each step. Always predrill holes before attaching with screws. Use glue with finish nails for a stronger hold. Wipe excess glue off bare wood for stained projects, as dried glue will not take stain. Be safe, have fun, and ask for help if you need it. Good luck!

Instructions

Step 1

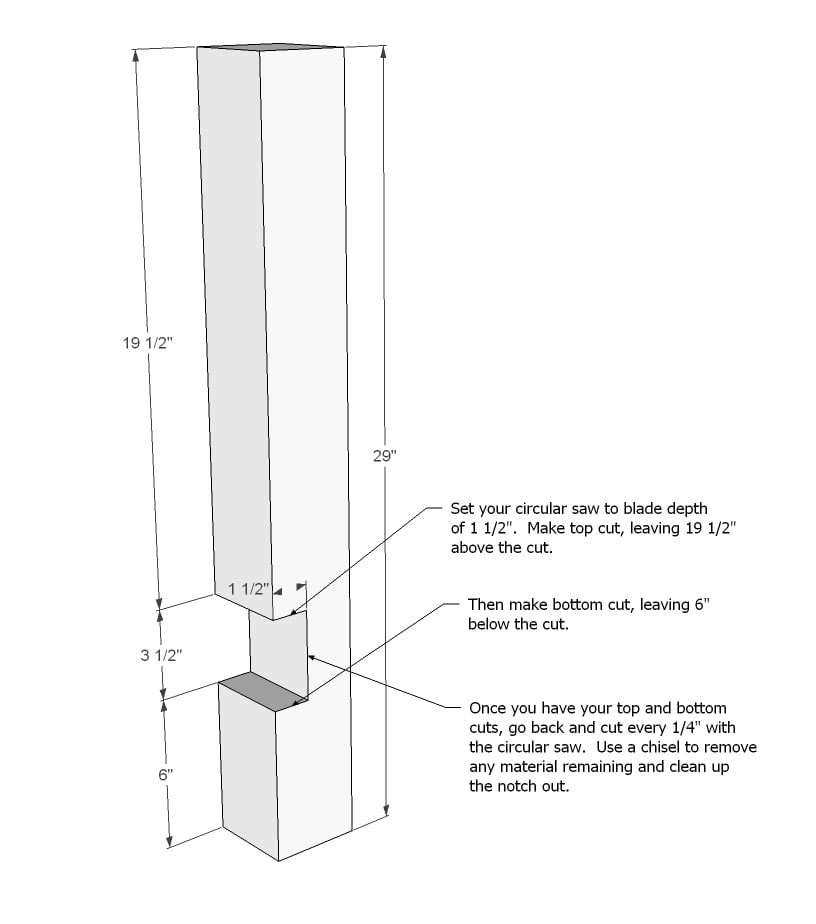

First, cut and notch out the 4x4s. If you can get your home improvement store to make square cuts, ask them to cut your 4x4s. Otherwise, you'll need a 12" (maybe a 10" will work too) miter saw or set your circular saw to the deepest possible cut. Cut one side, flip the 4x4 and finish the cut on the bottom side. Sand until cut is smooth. You'll probably add cork or felt pads under the legs later on to level table up and protect your floor.

Then notch out the stretcher joint as shown in diagram. Definitely practice first on a scrap if you can. This is easier to do than it looks - just be sure to get the top and bottom cut right, and it will all work out!

Step 2

Step 3

Step 4

It is always recommended to apply a test coat on a hidden area or scrap piece to ensure color evenness and adhesion. Use primer or wood conditioner as needed.

Comments

Felindre1

Sun, 03/21/2021 - 07:32

Farmhouse table

I think the plans look admirably simple and will be making a table for an imminent move. However, I may be being very thick but the cut list and plans don’t seem to match. The support wood is shown as 2x4 and jet joints 2x3 1/2? Also cut list says 7x 6x2 (=42) but measurements show a width of 38 1/2 for breadboard??

Or is the difference that cut list is rough timber and construction is planed I.e. 4x2 becomes 3 1/2 and 1 3/4?

Lauren Small

Wed, 05/05/2021 - 20:17

Lumber has the name its…

Lumber has the name its called and then an actual measurement which is a little bit smaller. So a 2x4 is actually smaller that 2x4".

trainer999

Tue, 08/31/2021 - 12:06

Yes, a 2x4 is actually 1.5x3…

Yes, a 2x4 is actually 1.5x3.5