Make your own folding stools from wood boards! Free DIY plans to build folding camp stools.

Preparation

2 - 1x2 @ 8 feet long

1 - 5/16" dowel, 2 feet long

Fabric for sling (see last step)

Bolts: 2 - 1/4" x 2" long

Nuts: 2 - 1/4"

Washers: 6 - 1/4"

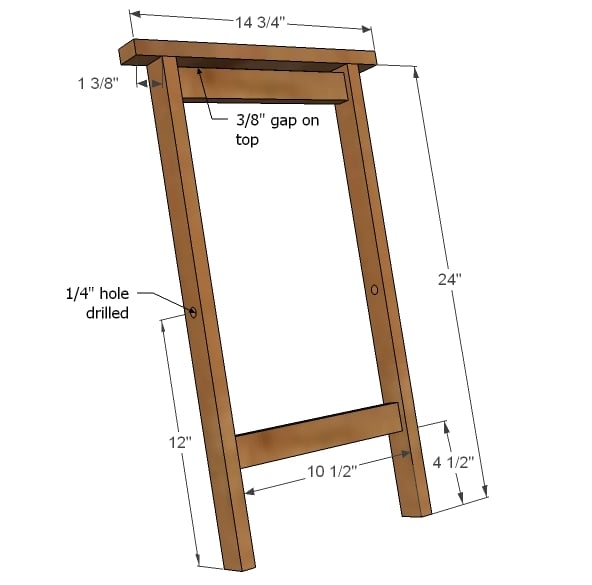

Assemble frames with either 2" screws or 1 1/4" pocket hole screws and glue

4 - 1x2 @ 24" (legs)

2 - 1x2 @ 15" (top sides)

2 - 1x2 @ 12.25" (outer stretcher top and bottom supports)

2 - 1x2 @ 10.5" (inner stretcher top and bottom supports)

1 - 5/16" dowel @ 13.5" (outer side fabric insert)

1 - 5/16" dowel @ 11.25" (inner side fabric insert)

Please read through the entire plan and all comments before beginning this project. It is also advisable to review the Getting Started Section. Take all necessary precautions to build safely and smartly. Work on a clean level surface, free of imperfections or debris. Always use straight boards. Check for square after each step. Always predrill holes before attaching with screws. Use glue with finish nails for a stronger hold. Wipe excess glue off bare wood for stained projects, as dried glue will not take stain. Be safe, have fun, and ask for help if you need it. Good luck!

Instructions

Step 1

Step 2

Step 3

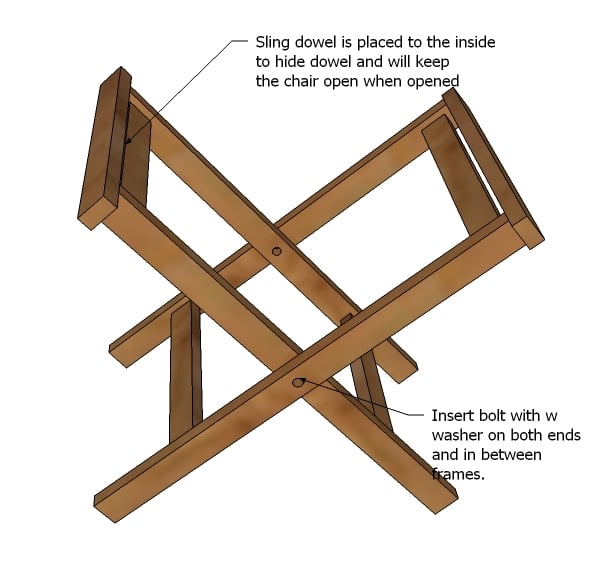

Now assemble the two frames by laying the smaller frame inside the larger and lining up the predrilled 1/4" holes. Insert a bolt, with a washer at the start, between frames, and end with nut through the predrilled holes. This will create a folding frame for you.

Next, you will need to make the sling, and then install with wood dowels.

It is always recommended to apply a test coat on a hidden area or scrap piece to ensure color evenness and adhesion. Use primer or wood conditioner as needed.

Comments

zarizi (not verified)

Mon, 01/16/2012 - 05:53

So great

Wow.. I like the chair. It so simple but my hands is not good enough to build thing like this. Just buy from supermarket.. HUhu

RichardMaretti

Mon, 01/16/2012 - 16:32

hi all

This is Babulerman.

Seven-Photogra… (not verified)

Mon, 04/09/2012 - 10:19

This is wonderful! I'm

This is wonderful! I'm thinking that these would be perfect additional seating in our small living room for those unexpected guests... & even for a little one's birthday party, they would be perfect! Thanks so much!!

Guinn (not verified)

Sat, 07/07/2012 - 14:37

camp stool

Very nice. I have looked for this site for some time but for some reason couldn't find it! Now I can finish the stool I am currently making, then make three more from your plans. Thank you so much.

Guinn

Guest AW (not verified)

Thu, 10/04/2012 - 19:49

camp stool

I think two of these stools would work for a wood & canvas canoe rest, either as a interum rest from car top to water-edge, or when doing some touch-up / refinishing work. canvas seat would cradle the canoe, but not damage paint or varnish finish. Comment?

Sehmket

Sun, 11/03/2013 - 15:43

Issues with seat?

I was working on this stool this weekend... I got the wooden parts completed without a problem, but I'm having some real issues with the seat. I first made it according to measurements, but it seems to be way too big... I tried pinning it smaller, and when I sat on it to figure it out, the pin broke, and I ended up crashing through and breaking the stool :(

Has anyone made this, and have any tips on how the seat goes together?

skyzen

Sat, 11/09/2013 - 15:55

splitting wood

1x2s split when joining them using 1 1/4" pocket screws. I drilled the pocket holes using 3/4 setting. Should i be using 1" screws instead?

Are there any other plans that use 1x2 strips only?