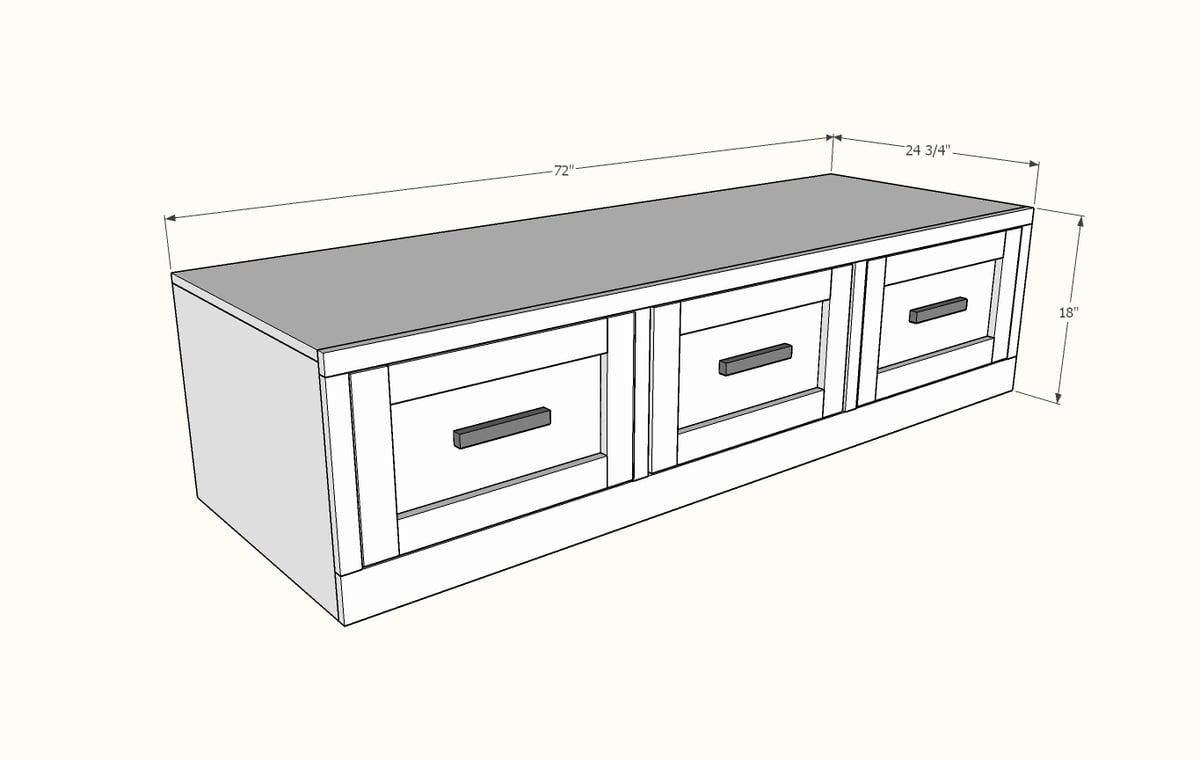

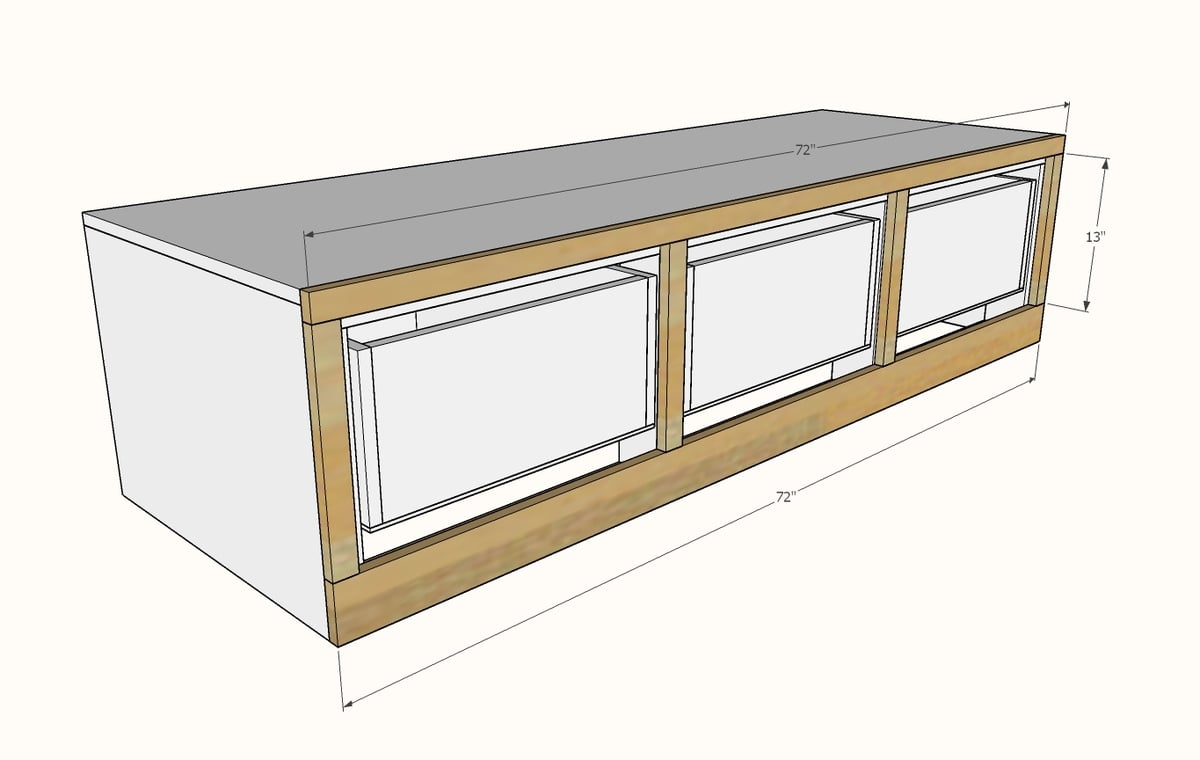

The easiest way to build a drawer bench. Free step by step plans by ANA-WHITE.com

Preparation

1 -sheet of 3/4" plywood cabinet grade, 48" x 96" - ripped into two strips, 96" x 23-7/8"

5 - 2x4 @ 8 feet long

3 - 1x10 @ 8 feet long

48" x 48" sheet of 1/4" plywood (for drawer bottoms)

12 feet of 1x2 boards

6 feet of 1x4 board

2 - 1x3 @ 8 feet long

3 - full extension side mount drawer slides

3 knobs or handles

3" screws (about 40)

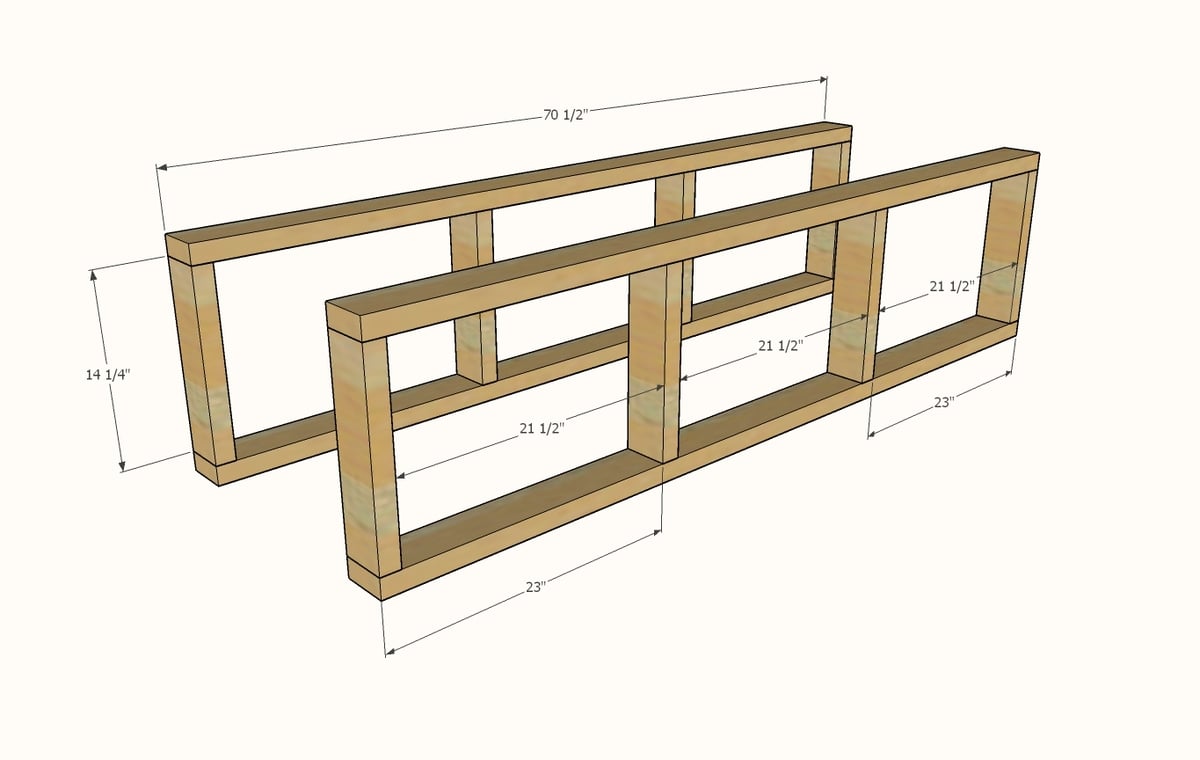

FRAMES

4 - 2x4 @ 70-1/2"

8 - 2x4 @ 14-1/4"

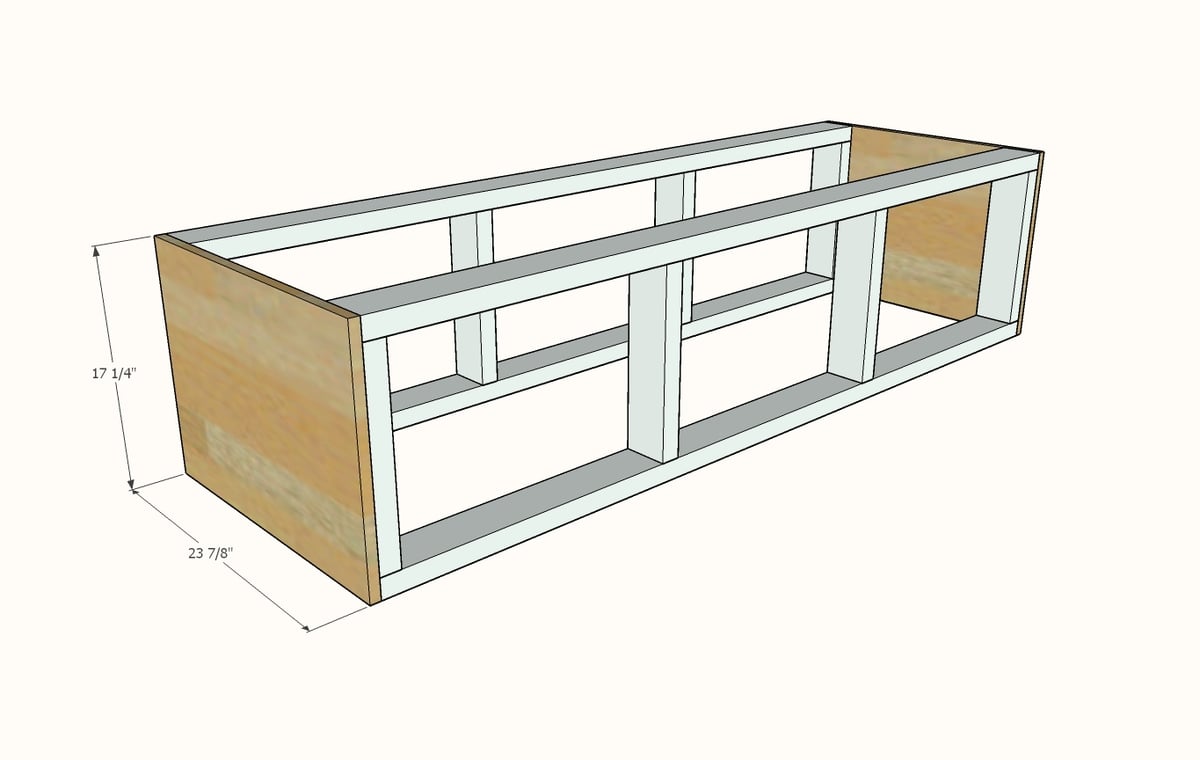

SIDES/TOP

2 - 3/4" plywood @ 23-7/8" x 17-1/4"

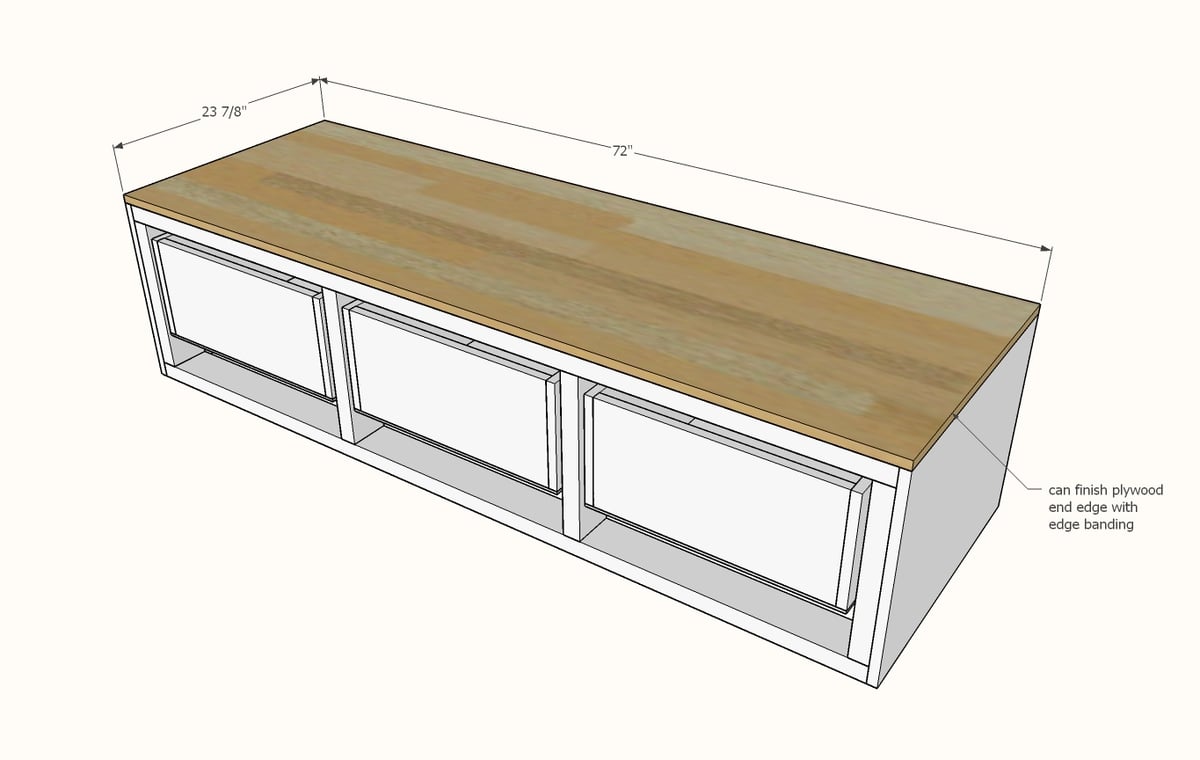

1 - 3/4" plywood @ 23-7/8" x 72"

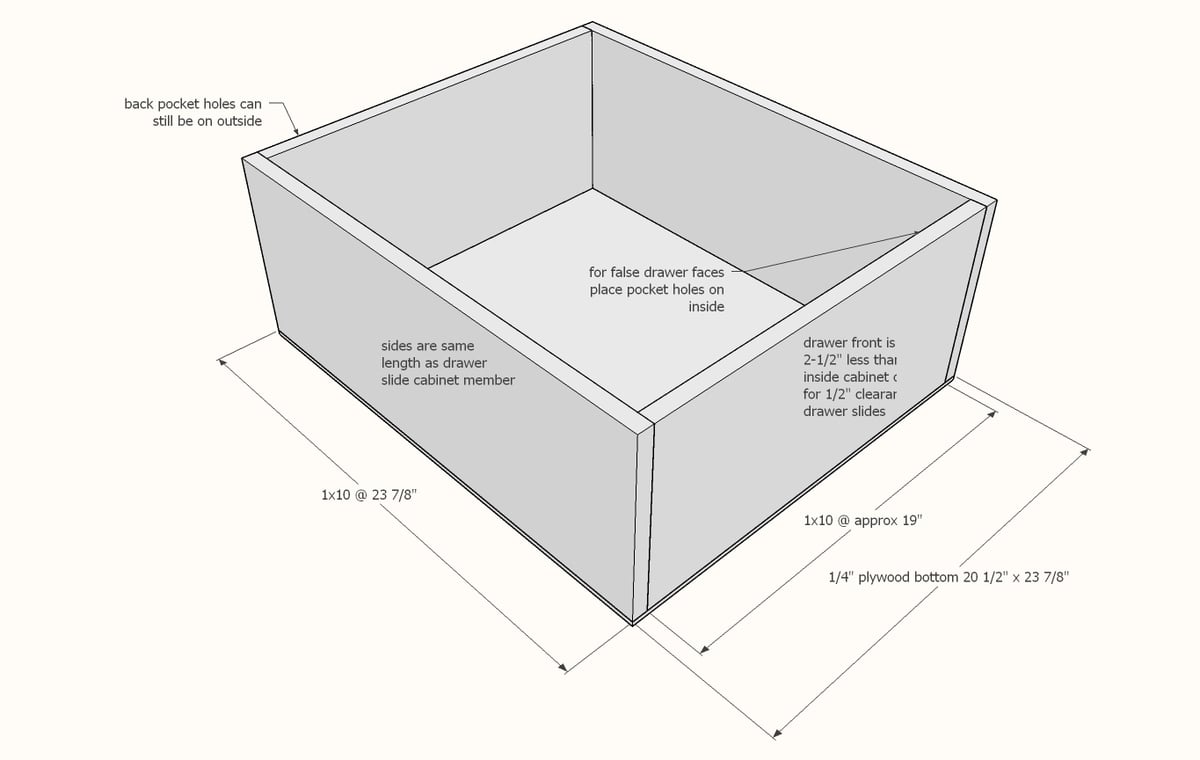

DRAWERS - CUT TO FIT!!!

6 - 1x10 @ 23-7/8"

6 - 1x10 @ 19"

3 - 1/4" plywood @ 23-7/8" x 20-1/2"

FACE FRAME

1 - 1x2 @ 72"

1 - 1x4 @ 72"

4 - 1x2 @ 13"

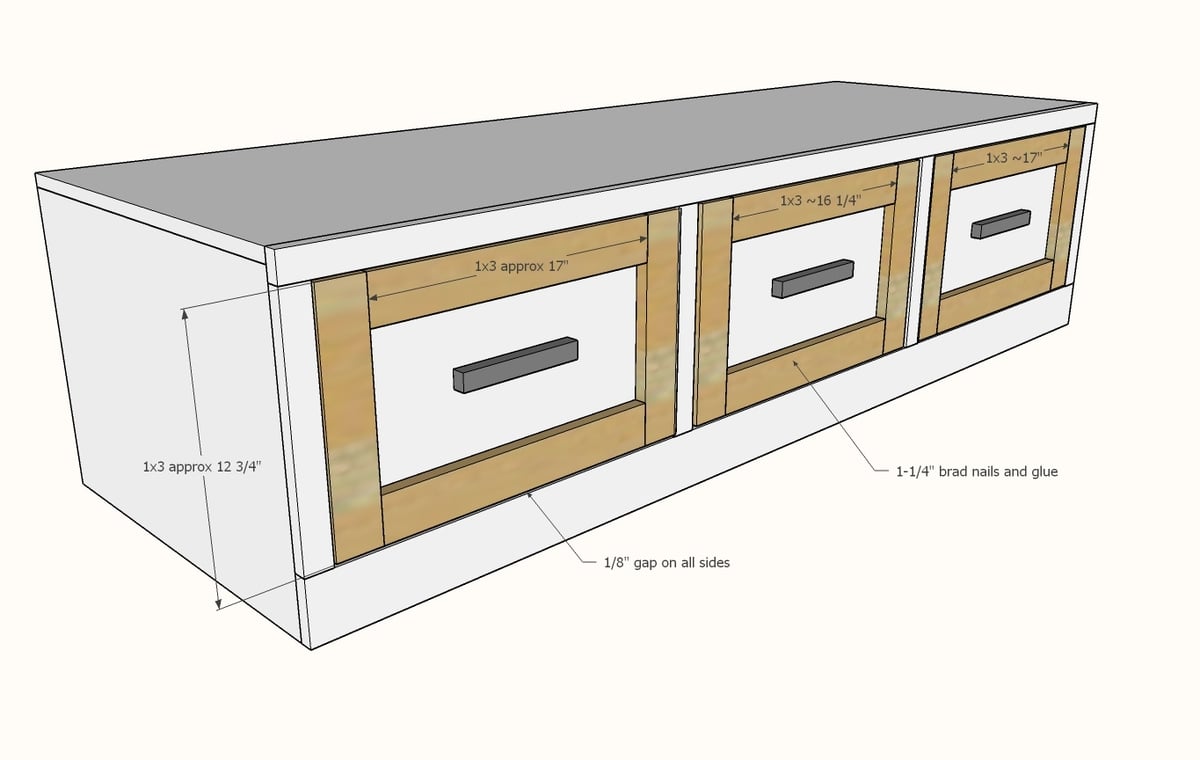

DOOR FACE FRAMES

6 - 1x3 @ approx 12-3/4"

4 - 1x3 @ approx 17" - end drawers

2 - 1x3 @ approx 16-1/4" - middle drawer

For the 3/4" plywood - first rip the plywood into two pieces, 96" long x 23-7/8" wide. Then cross cut to get the pieces in the cut list.

Instructions

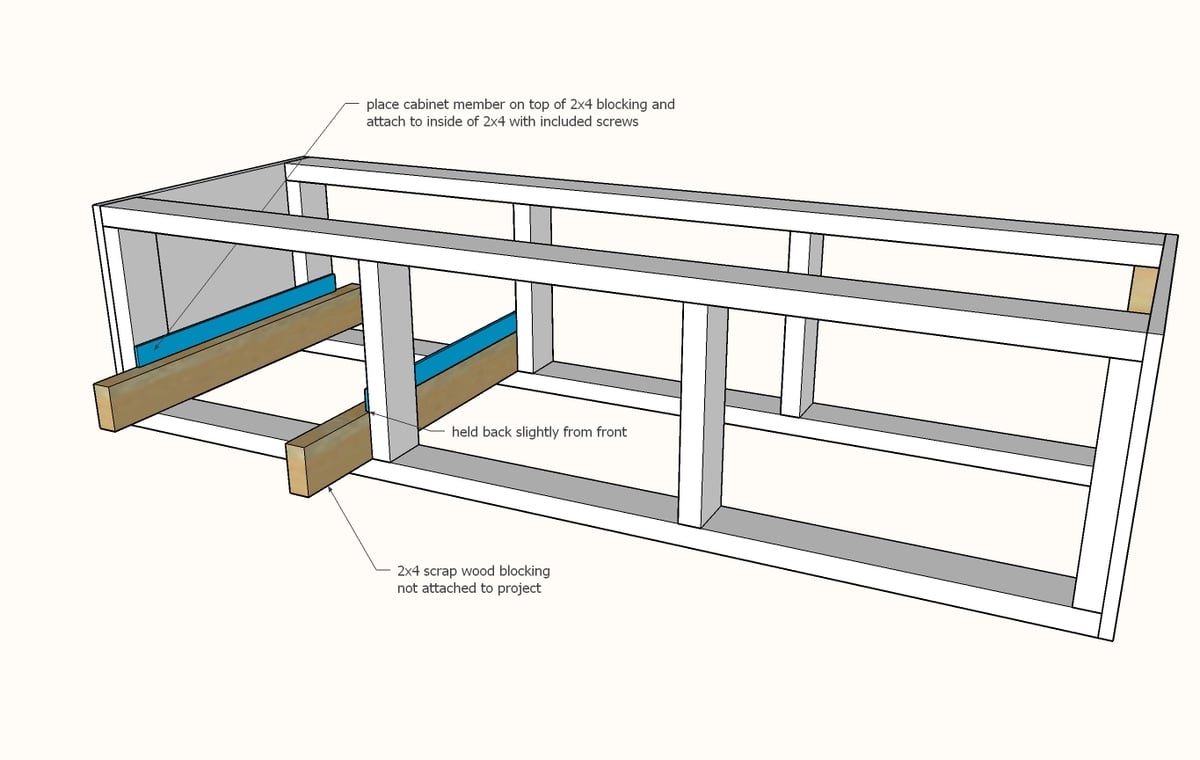

Step 1

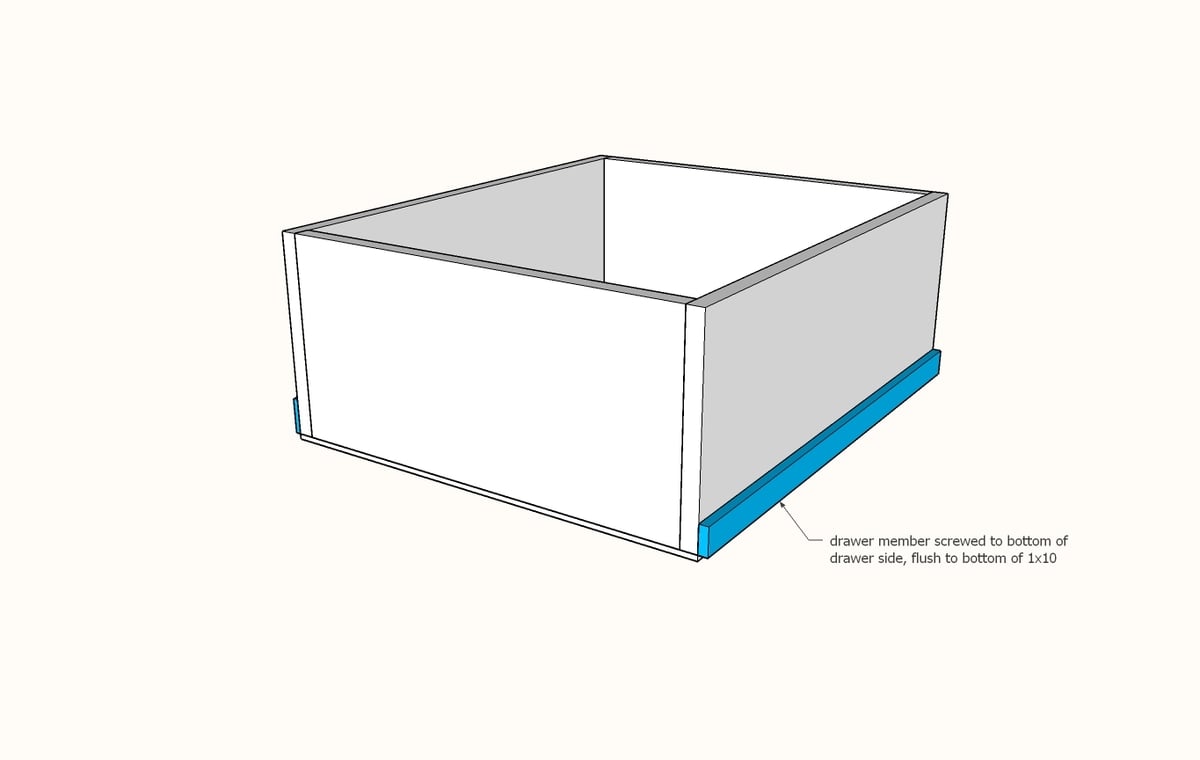

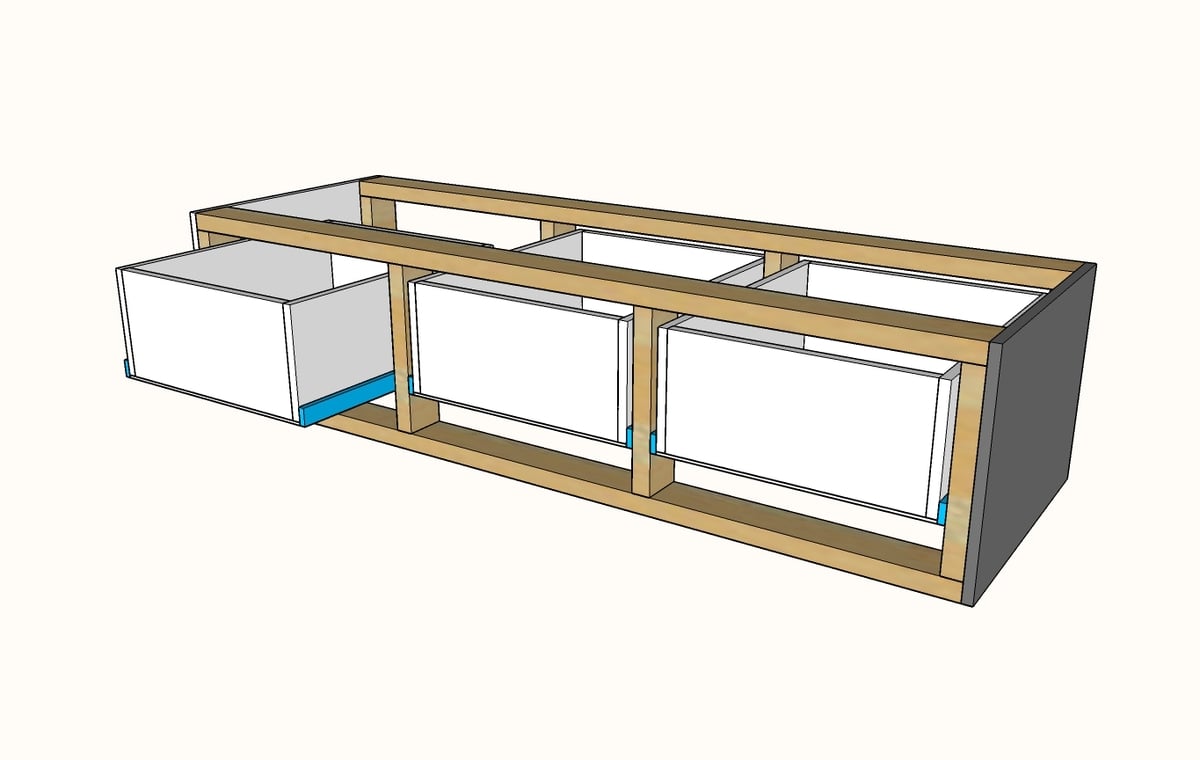

Step 2

Step 3

Read the instructions with your drawer slides and build drawers to fit your slides and opening. The measurements show are for standard 1/2" clearance drawer slides with 3/4" thick 1x10s.

If using a Kreg Jig to build the drawer box, place pocket holes on the inside of the front of the drawer. You can still place on the outside on the back. I used a Kreg Jig set for 3/4" thick material and 1-1/4" pocket hole screws.

I used a stapler with 3/4" narrow crown staples to attach the bottom with glue. You can also use a brad nailer with 3/4" brad nails and glue.

Comments

Pjrichar

Mon, 11/26/2018 - 05:20

Size of drawer slides?

Would you be able to share what size drawer slides you used?

In reply to Size of drawer slides? by Pjrichar

Ana White

Wed, 11/28/2018 - 18:25

Yes of course, 24"

Yes of course, 24"

jenbunn

Mon, 03/22/2021 - 09:38

If the drawers are only 23 7…

If the drawers are only 23 7/8” in deep, the slides are still 24”not 22”?

rachelowe

Fri, 06/28/2019 - 10:03

Adjusting Dimensions

I LOVE this plan! And I'm really hoping to accomplish this look in my mud room. My only problem is, I don't have as much room lengthwise as you do and I'm having trouble adjusting some of the dimensions. Any way you can help me out with this? I'm REALLY good at following directions and and DIY projects but math is not my strong suit haha

Chrismmalone405

Sun, 12/01/2019 - 17:49

Me too. I am looking to make…

Me too. I am looking to make this 2 feet smaller and am gonna have to figure out the dimensions. Would love support!

LandOfOzArts

Sat, 11/02/2019 - 17:17

Can this bench be used under a mattress?

Could this bench be used to make a storage bed? I like the queen & king storage bed plans, but want 3 drawers on the side benches. Would this design style (the 2x4 frame) be sturdy enough to use for a bed frame? Thanks.

Sananasir1

Mon, 11/18/2019 - 12:47

Hi Ana, Love your simple…

Hi Ana,

Love your simple designs and videos....you and your family are an inspiration for us!!

We bought all the basic tools...now unsure about the kind of wood to buy (in terms of 2x4's and the plywood). We went to Home Depot (I'm in Canada) and got confused with the curved woods! Can you please give us some pointers dear.

Thanks a million

miked1108

Fri, 01/24/2020 - 16:29

Mudroom bench with easy drawers question

Hello. Just curious what grade of plywood do you recommend for this project?

EliG

Tue, 05/19/2020 - 15:40

Two Drawer Size

Great bench the wife will love it. I'm a novice at building things and since we have time on our hands I figured I try something new. I am trying to figure out how to duplicate this, but for 2 drawers instead of 3 drawers. The length of the bench would be 46" 3/16, the height is 18" and the depth 15" 3/4. I was looking for any assistance as to what the sizes of the drawers should be, and what size the drawer slides I should use? Any help will be greatly appreciated.

Momof7Dragons

Wed, 02/09/2022 - 12:08

Help with cut list and measurements

I have a bar-height table that I want to build built-in seating for. What dimensions or cut list would I need to use to make 2ft tall by 4 ft wide with approx 18 inch seat width? How big would the drawers be then?

Lcoccetti

Fri, 01/06/2023 - 09:49

Maximum drawer width?

Hi Ana, my son and I are planning to build this for his new apartment. The space between walls under the three windows is very wide (10' 10"). What is the widest size drawer you recommend?