Some dining spaces (or even work spaces) require a long thin table. This rustic simple table is easy to build, yet sturdy and stylish.

Special thanks to Deux Maison for sharing their amazing photos. Make sure you stop over to see more photos and read about their building experience.

Preparation

2 – 2×2 Boards, 8′ Long ($2 Each for pine)

4 – 1×8 Boards, 8′ Long ($7 Each for pine)

2 – 1×3 Boards, 8′ Long ($1.50 Each for pine)

1 – 1×4 Board, 10′ Long ($4 Each for pine)

2 – 1×6 Boards, 10′ Long ($6 Each for pine)

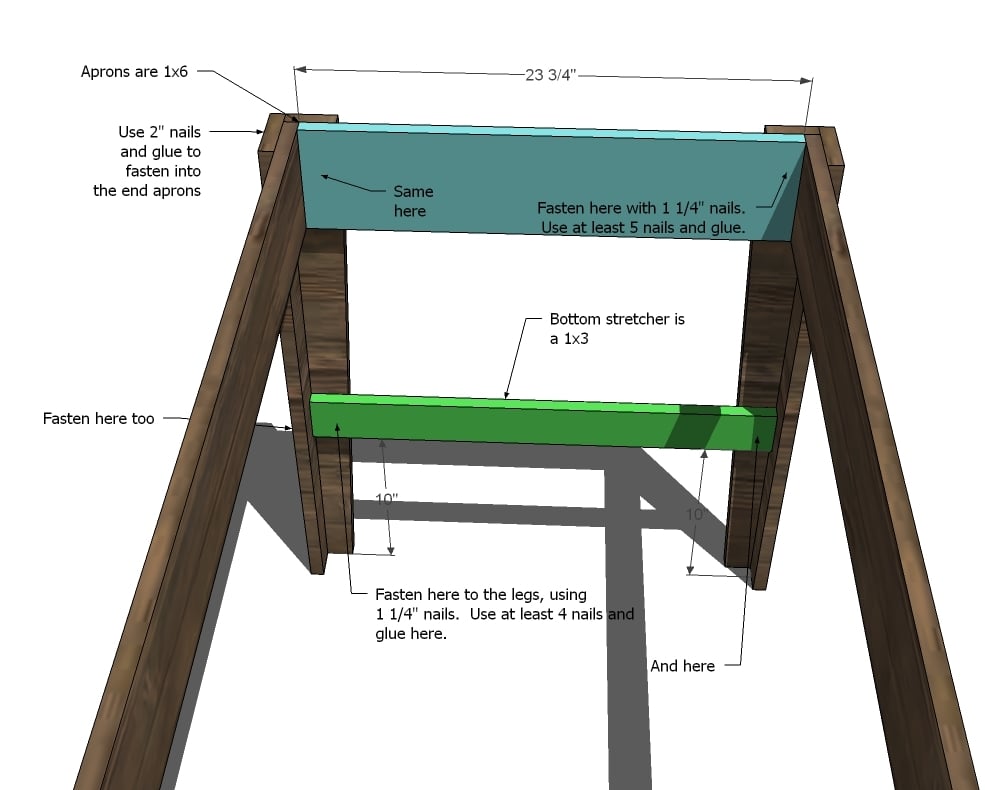

1 1/4″ and 2″ Finish Nails

2″ Wood Screws (about 100)

2 1/2″ Wood Screws (about 20 screws)

Wood Glue

Wood Filler

Sandpaper

Finishing Supplies

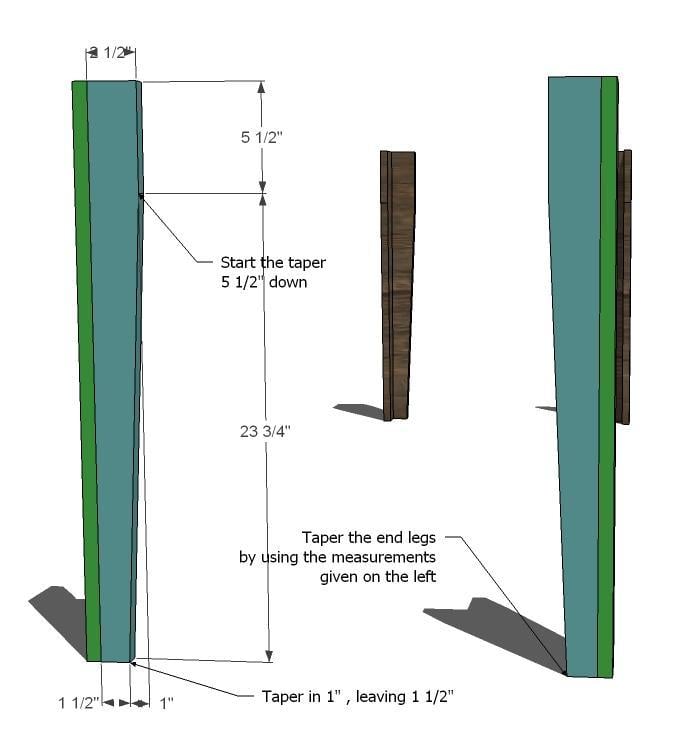

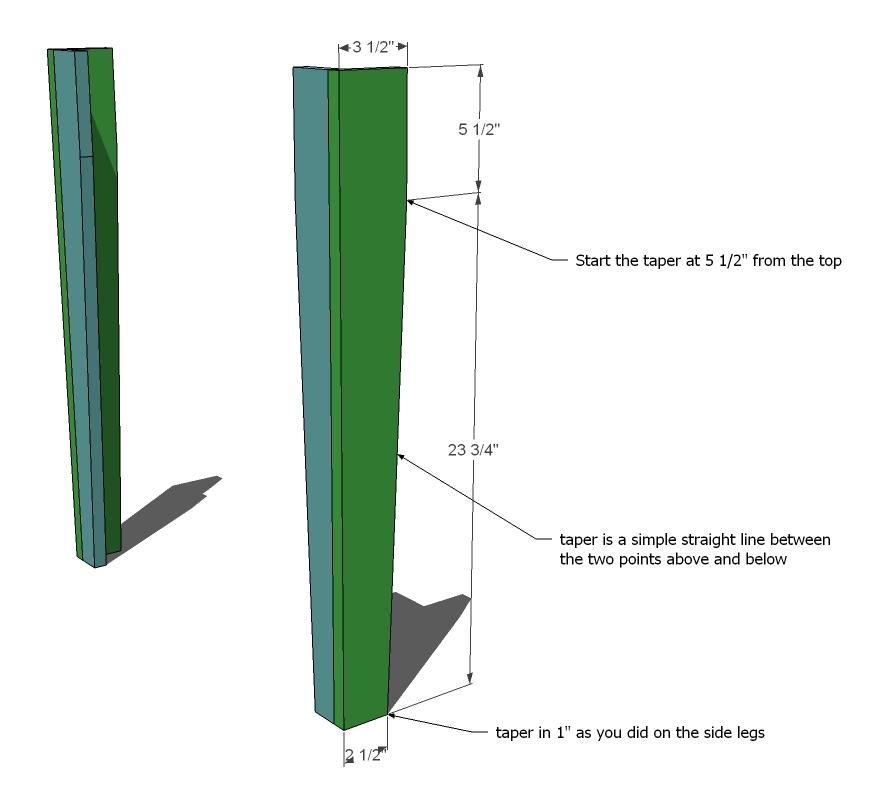

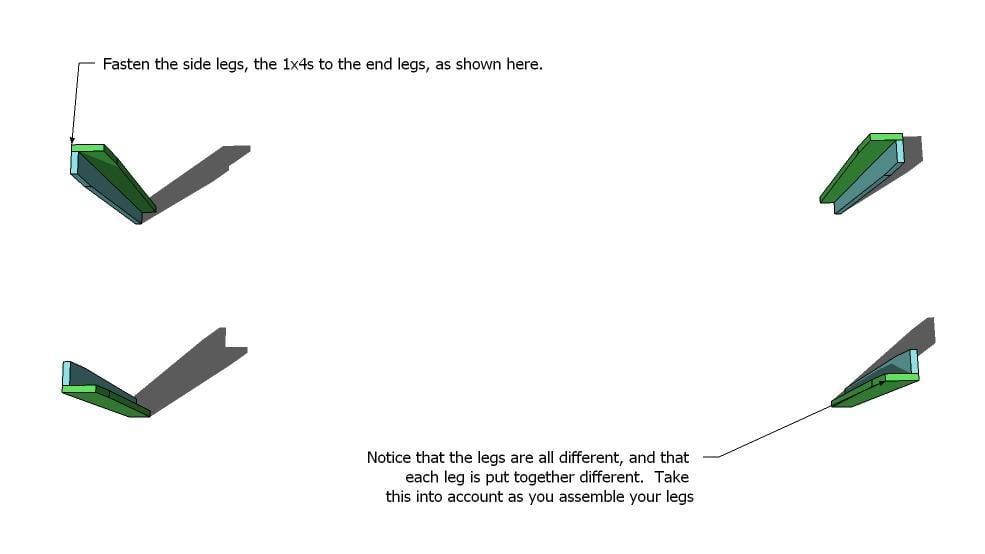

4 – 1×3 @ 29 1/4″ (Table End Legs)

4 – 1×4 @ 29 1/4″ (Table Side Legs)

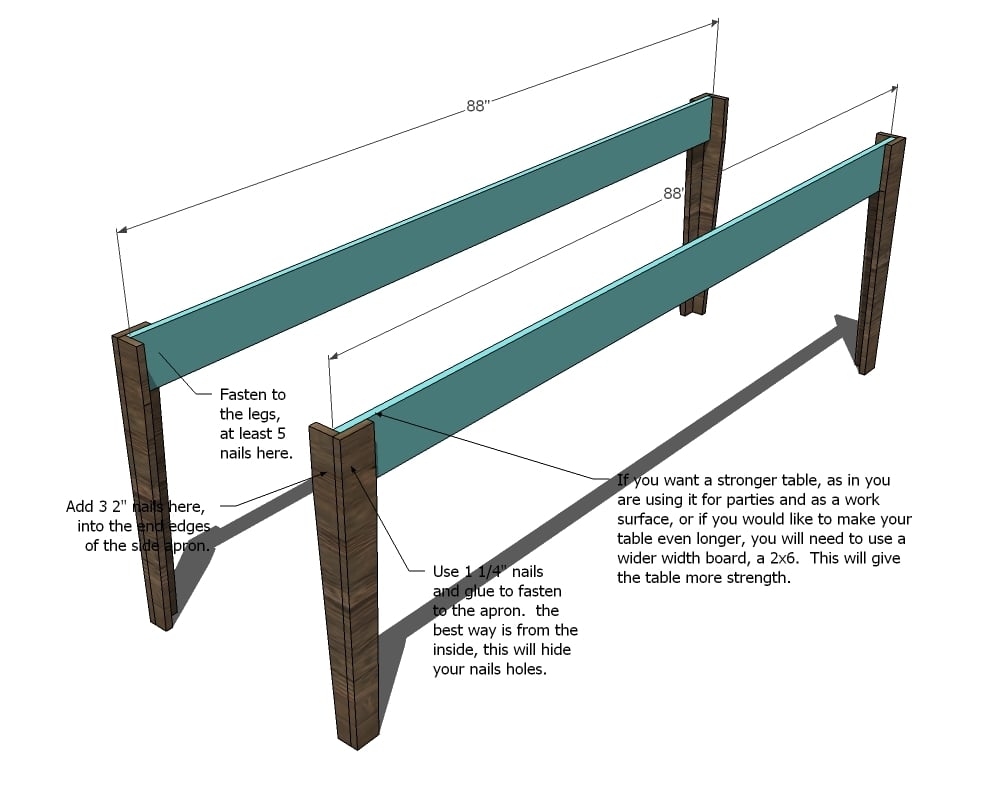

2- 1×6 @ 88″ (Side Aprons)

2 – 1×6 @ 23 3/4″ (End Aprons)

2 – 1×3 @ 23 3/4″ (End Stretcher)

8 – 2×2 @ 23 3/4″ (Under Tabletop Supports)

This table is highly customizeable to fit your needs. Note that the tabletop expects your tabletop boards (the 1x8s) to be 7 1/2" wide. If your 1x8s are not 7 1/2" wide, adjust accordingly.

Work on a clean level surface. Check for square after each step. Use straight lumber. Measure and confirm your cuts before cutting. Dryfit your boards before fastening. Always use glue. Predrill and countersink screws. Use saftey precautions and protective eye and hearing gear.

Instructions

Step 1

Step 2

Step 3

Step 4

Step 6

Step 7

Step 8

Tabletop Pieces. From the underside, fasten through the under tabletop support pieces into the tabletop pieces. Start with the middle boards and work your way out. Minimize any gaps between the boards. Predrill and countersink your screws. To further strengthen the table, you can add simpson strong tie corner brackets to the corners.

Comments

StevestonSurfer

Tue, 03/03/2015 - 20:16

Chunky

Hi. My wife likes chunky. I am not, but I was wondering if these plans would work if everything was switched from 1" to 2". I am a carpentry noob by the way, but have done a lot of other practical handywork so think I will pick it up fast. Picked this for my first project, to use as a breakfast table in our new home.

Ana White Admin

Wed, 03/04/2015 - 10:45

Modification

Sure! Be sure to plan based on new lumber dimensions for your space. Take a look at this for added inspiration http://ana-white.com/2013/02/plans/casual-2x4-desk

keepgrowing2

Sun, 01/14/2018 - 14:05

Narrow Farm House Table

Ana,

Can this table be made without the stretchers (and be structurally sound)? I'm looking to build a table that is about 7' long by 30" and want to be able to push chairs in at the ends. Thanks for your expertise!