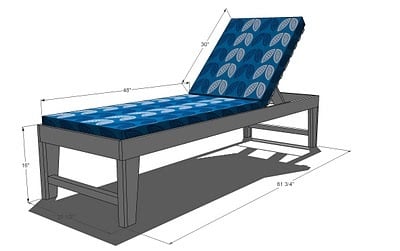

Plans are for a single lounger, but can be easily modified, as one of our readers did, to a double. Featuring no special hardware, slatted wood design, adjustable back angles, and optional wheels.

Preparation

Shopping List

1 – 2×2 8′ Long

10 – 1×2 8′ Long

5 – 1×4, 8′ Long

2″ Screws

1 1/4″ Screws

5 Hinges

1 – 24″ 3/4″ Dowel

4 – 3/4″ Pipe Straps

Wood Glue

Wood Filler

Finishing Supplies

24″ Wide Foam, 48″ and 30″ long for Cushions

Fabric for Cushions, 2 1/2″ yards (approximately)

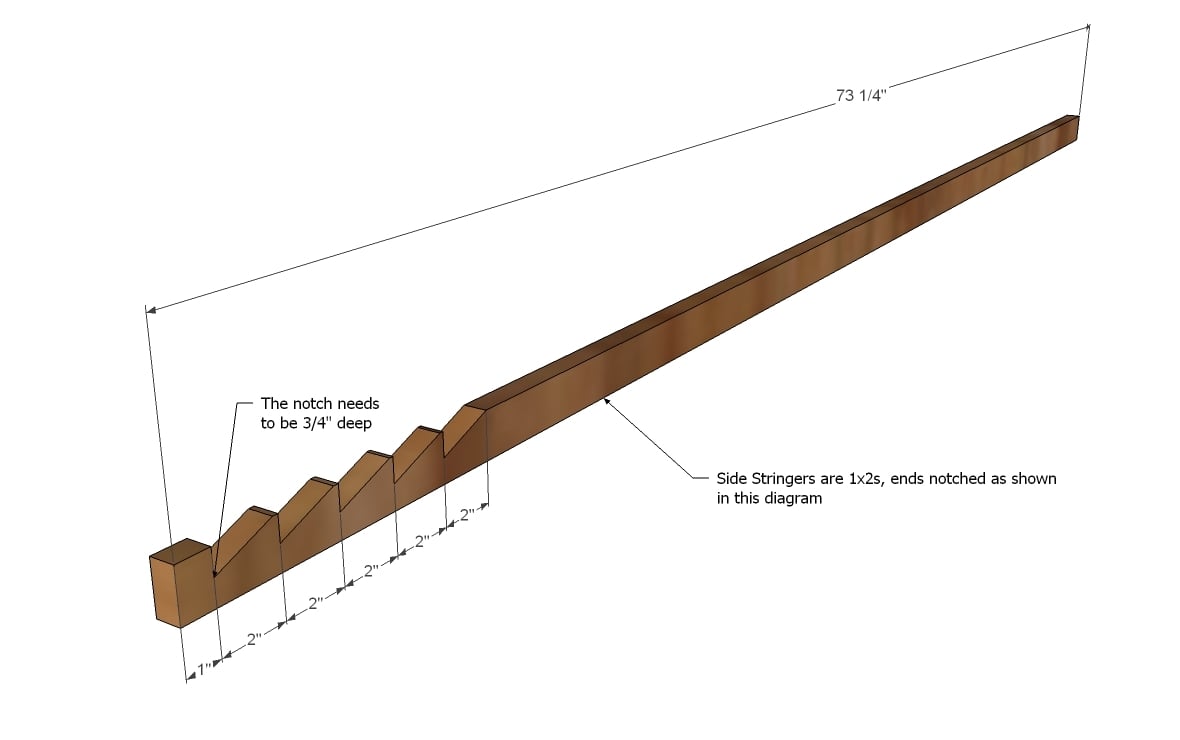

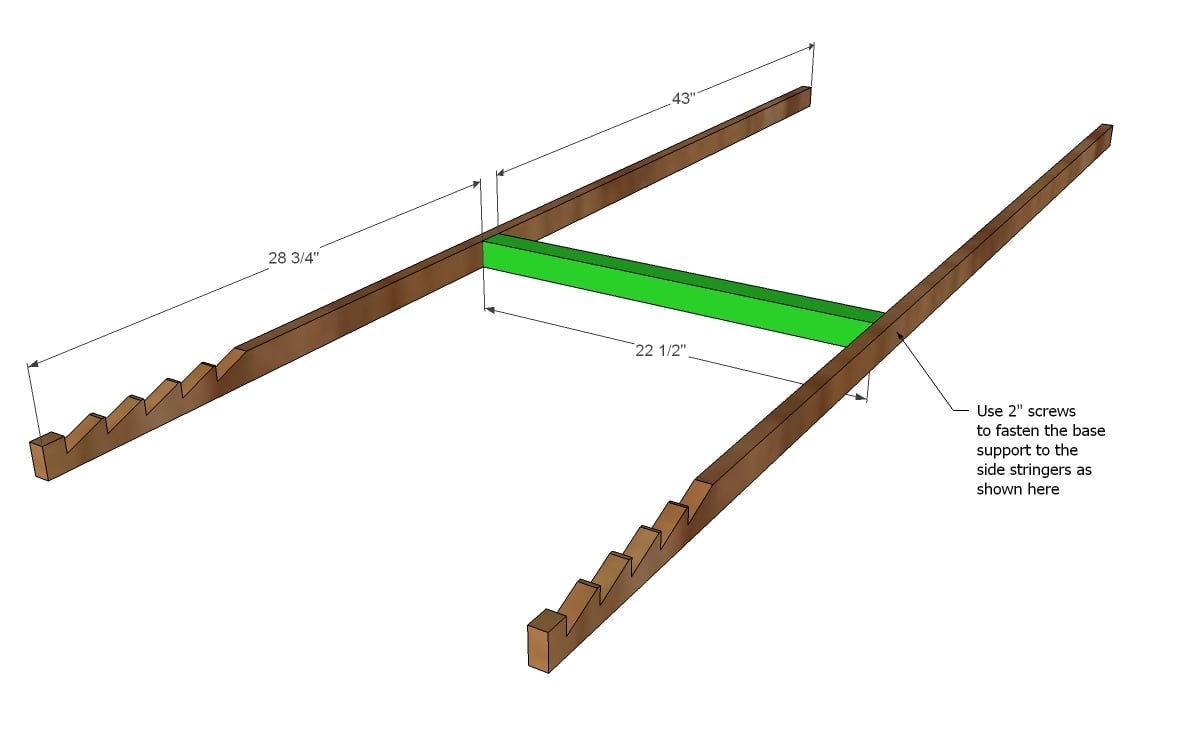

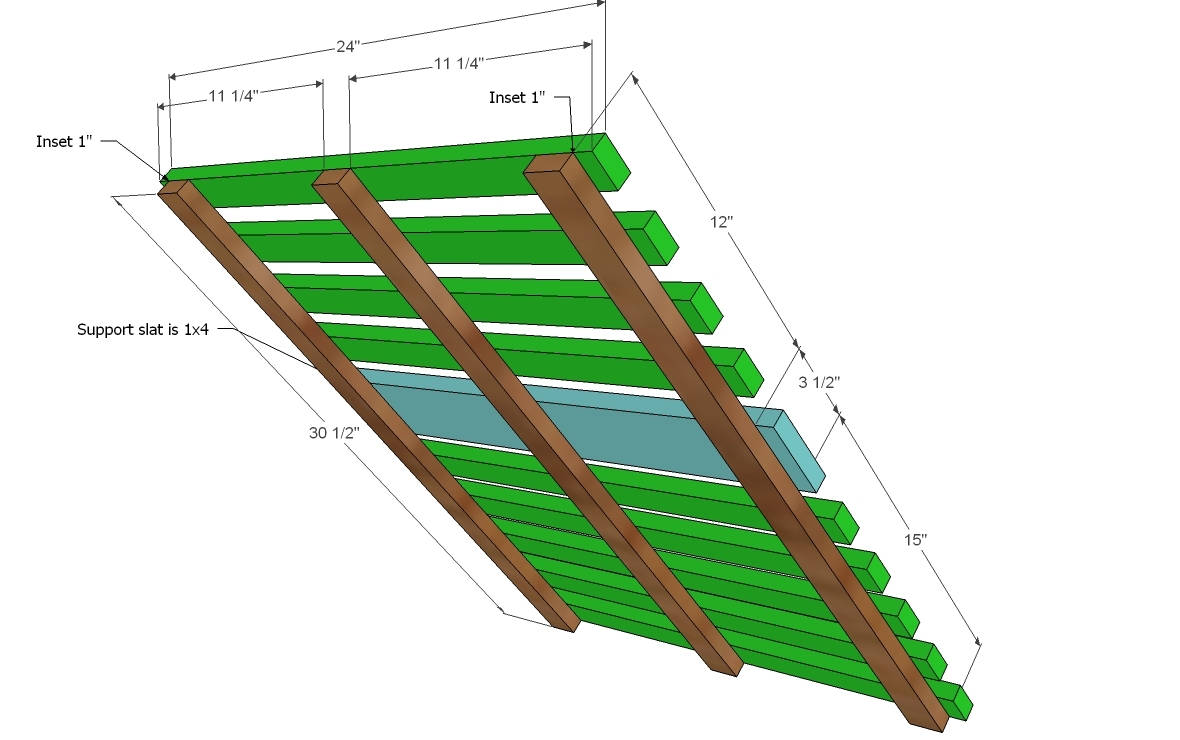

2 – 1×2 @ 73 1/4″ (Side Stringers)

1 – 2×2 @ 22 1/2″ (Base Support)

2 – 1×4 @ 81 3/4″ (Sides)

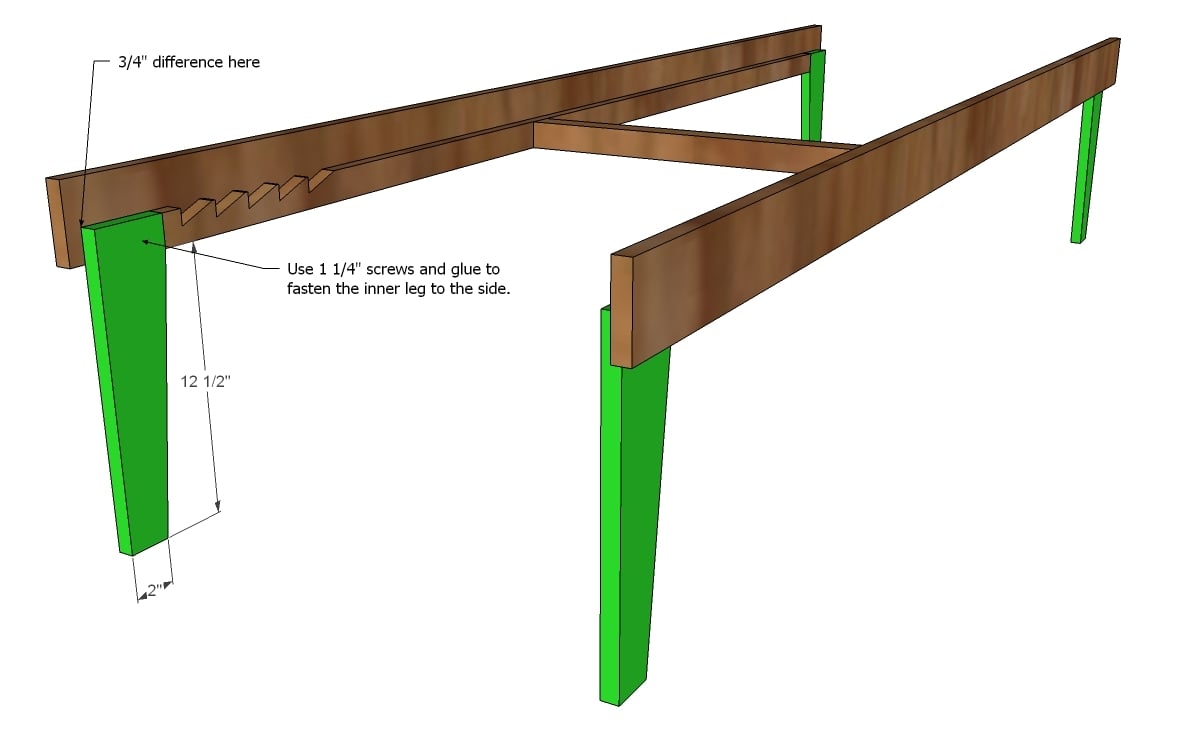

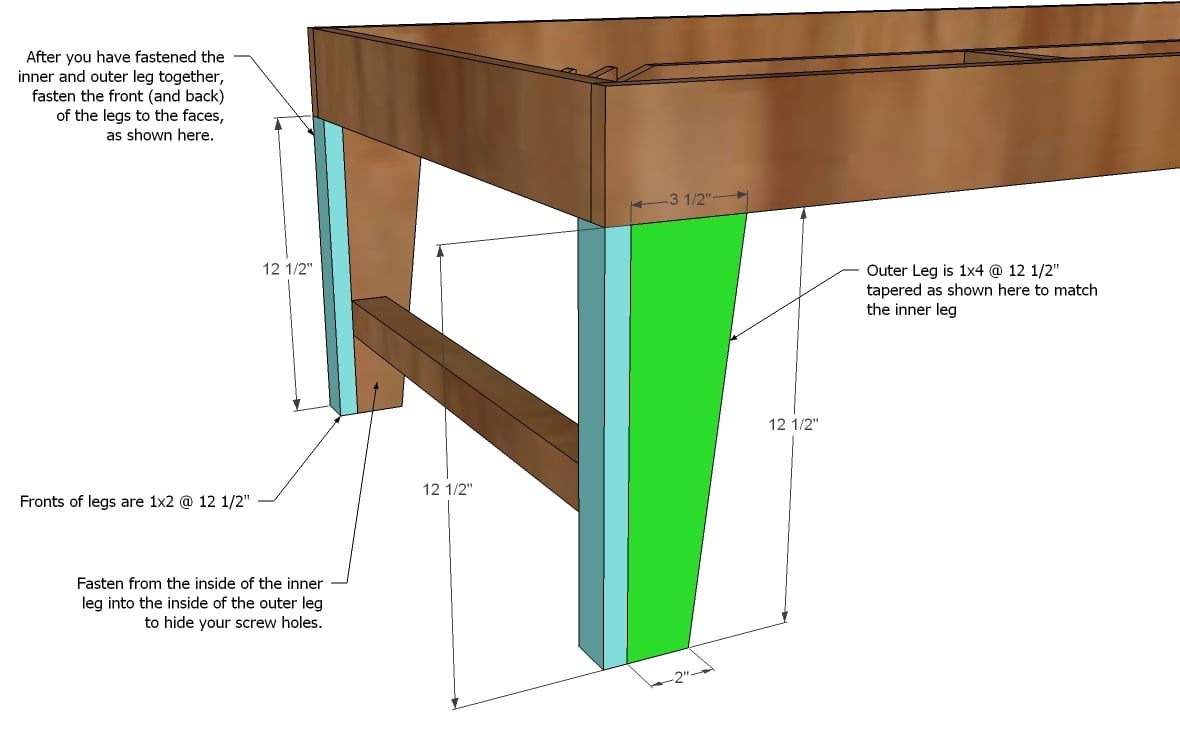

4 – 1×4 @ 14″ (Inside Leg Piece)

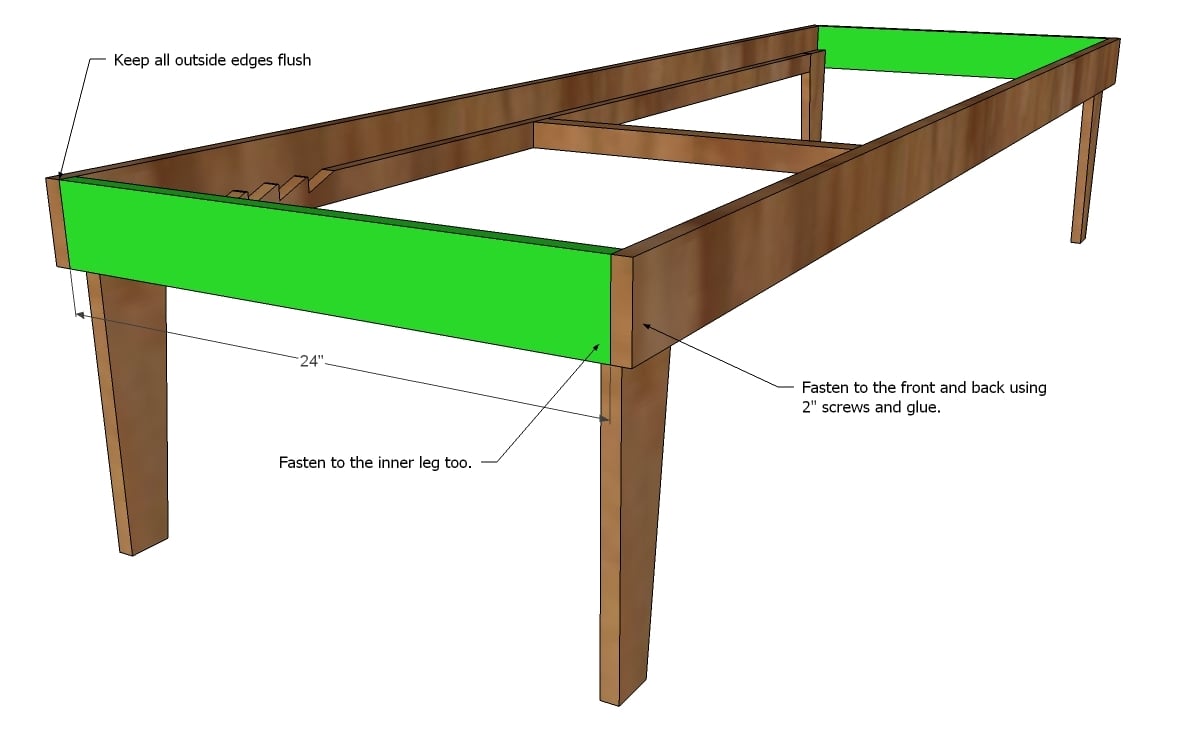

2 – 1×4 @ 24″ (Front and Back)

2 – 2×2 @ 22 1/2″ (Stretchers)

4 – 1×4 @ 12 1/2″ (Outer Leg)

4 – 1×2 @ 12 1/2″ (Fronts and Backs of Legs)

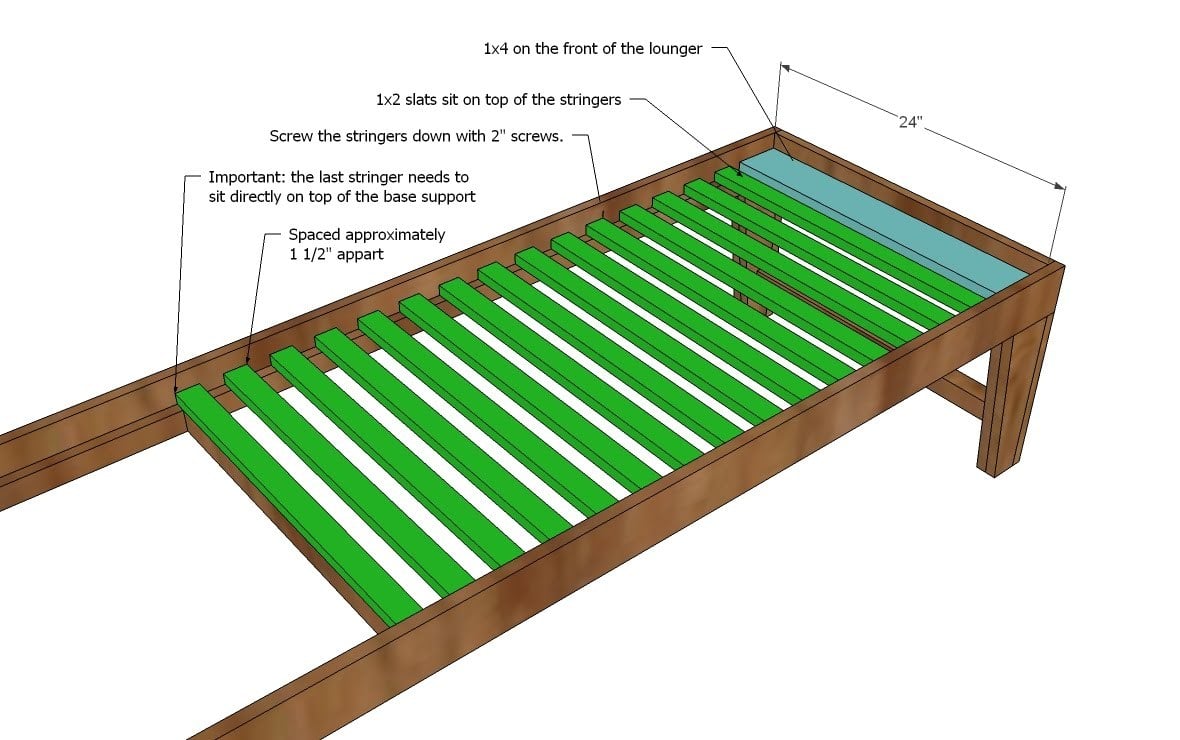

24 – 1×2 @ 24″ (Main Slats)

2 – 1×4 @ 24″ (Support Slats)

3 – 1×2 @ 30 1/2″ (Back Stringers)

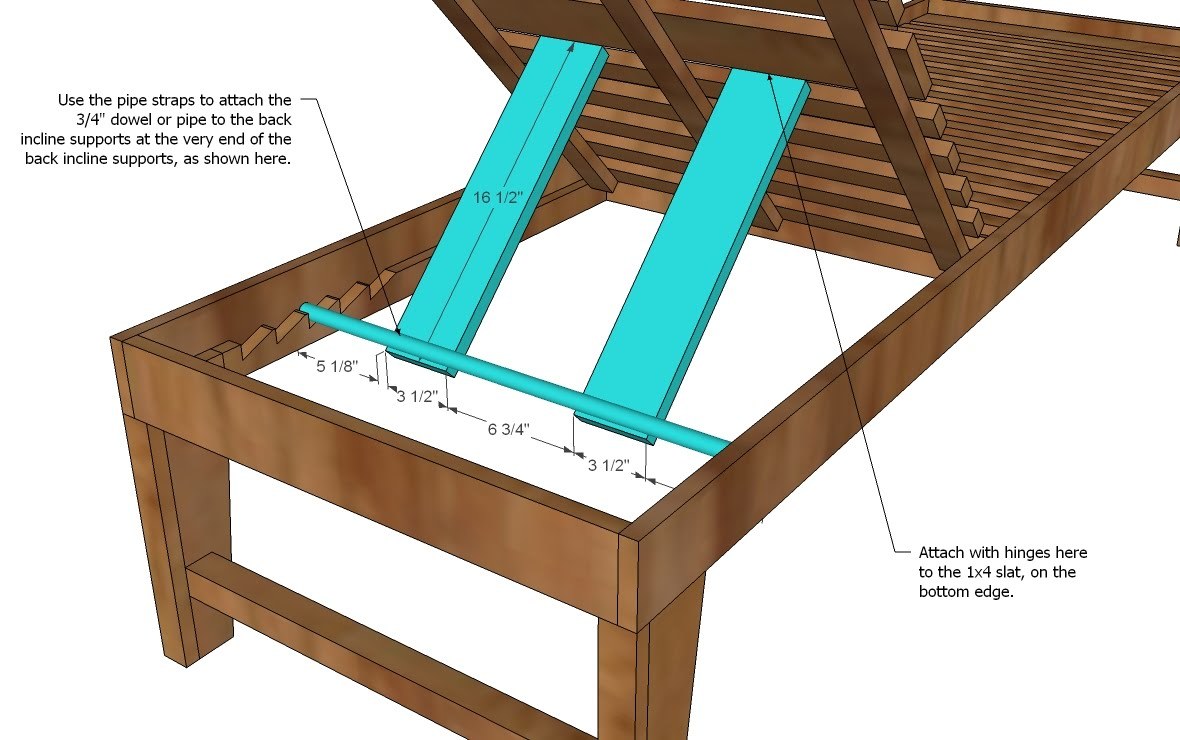

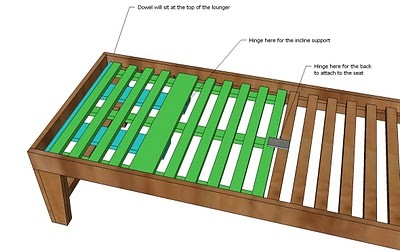

2 – 1×4 @ 16 1/2″ (Back Incline Support)

1 – 3/4″ Hardwood Dowel or Pipe @ 24″ (Back Incline Catch)

This is an advanced project, make sure you fully understand how this lounger works before beginning. Work on a clean level surface. Check for square after each step. Predrill and countersink your screws. Use necessary safety precautions and equipment.

Instructions

Step 1

Step 3

Step 4

Step 7

Step 8

Step 9

Step 10

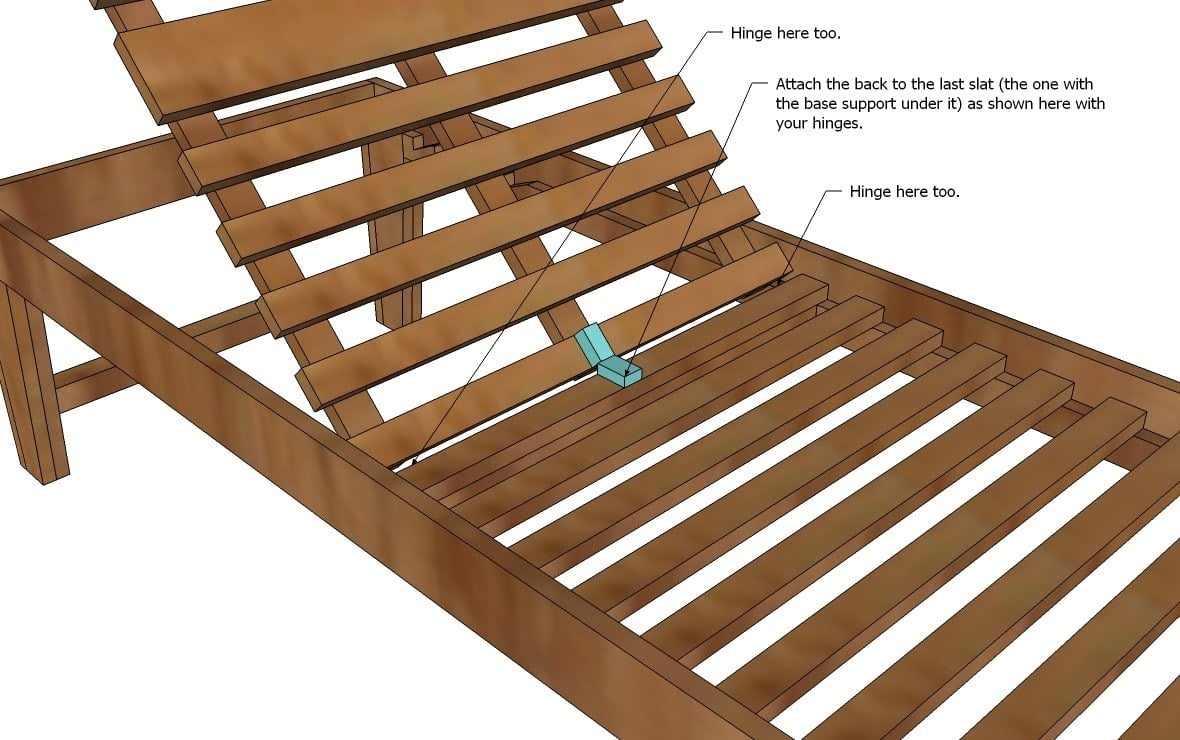

Attaching the Back. Lay the back in the lounger, and attach the last slat of the back to the last slat on the lounger. Simply lay the hinges flat on top of the slats and screw in place. Position the hinges so that the pin rests in a gap between the back slat and the seat slat. Use three hinges, all positioned over the back stringers.

Comments

Viola (not verified)

Fri, 04/02/2010 - 09:29

Thank you so much Ana. You

Thank you so much Ana. You truly are amazing. I so appreciate your hard work and dedication. I hope things are working out better for you.

JessA (not verified)

Fri, 04/02/2010 - 09:33

This is stunning! I am

This is stunning! I am always in awe of your talent!

Serena (not verified)

Fri, 04/02/2010 - 09:40

Wow! I am amazed that you

Wow! I am amazed that you know how to draw up plans for something so complicated. Thanks for taking the time and thought to put this together. This will be great for the summertime!

TheSimplePoppy (not verified)

Fri, 04/02/2010 - 09:45

I have always loved these

I have always loved these loungers - and the cost is always so prohibitive. I wonder how hard it would be to double them, but still have each side fold individually? Awesome plans!

jill g (not verified)

Fri, 04/02/2010 - 09:58

YAY! I am sooo excited. I'm

YAY! I am sooo excited. I'm in the process of purchasing a second hand table saw and then this project is MINE! I plan to build two of these. THANKS ANA!

Regina (not verified)

Fri, 04/02/2010 - 11:38

These plans look fantastic!

These plans look fantastic! I'm not quite at this level yet, but I fully intend to give these a shot towards the end of the summer!

Cricket (not verified)

Fri, 04/02/2010 - 11:54

You are amazing. Not only do

You are amazing. Not only do you make a mean lounger, I am consistently amazed at the way you make woodworking accessible to everyone. And that means making up your plans so we can actually afford to put foam on the lounger after we build it. Awesome. I love your site, and it has me eying the large pile of old barn wood in my backyard.

Lacking Productivity (not verified)

Fri, 04/02/2010 - 12:15

This makes me so so so

This makes me so so so excited to get to where I feel advanced enough to do this! I have wanted chairs like this for year...but the price tag was always WAY out of my price range.

You rock my socks off!

Spencer & Lori… (not verified)

Fri, 04/02/2010 - 12:35

Are you kidding me! This is

Are you kidding me! This is amazing! Especially after I looked and saw how much they are to buy! Yikes!

About Us (not verified)

Fri, 04/02/2010 - 12:53

First, I have 5 kids and one

First, I have 5 kids and one of them is a 4 month old. My weekly trip to the grocery store is pure trauma! So I laughed as I read the first part of this. I was so hoping you would do one like this. We are going to build 2 of these!

sophie, Inzaburbs (not verified)

Fri, 04/02/2010 - 13:05

Ana, just last night I was

Ana, just last night I was looking at the WE website and sighing, wishing you had plans for the modern farmhouse table. I must have missed it first time round, because when I went back to look for something else to make - there it was!

I still resolved to write to you one day and ask you to make those modern outdoor loungers. Did you read my mind ??????

I am going to have to practice practice practice though- since you put it in the advanced section I will just have to get advanced :-)

Anonymous (not verified)

Fri, 04/02/2010 - 13:08

You ROCK~!!!!! I've been

You ROCK~!!!!! I've been spending hours on your site for weeks but haven't yet said anything. I'm shocked because I've been looking this whole week for chaise loungers or plans to build them myself, and now you all of a sudden have one. It's like you read minds!!! THANKS SO MUCH! You are amazing! I wish we had more time in a day so you could blog constantly for us and still spend time with your children. =)

Shanon Ridenour (not verified)

Fri, 04/02/2010 - 14:31

I was lusting over chaises

I was lusting over chaises just like this last summer! Yet another project I'm itching to try out. Thank you for sharing your talents with all of us.

Annalea (not verified)

Fri, 04/02/2010 - 15:12

I'll chime in:Ana, your rock!

I'll chime in:

Ana, your rock! I love how you deconstructed the mechanics of a chaise lounge, and made them accessible. I can't wait to see what folks come up with!

Sleep well . . .

Janey (not verified)

Fri, 04/02/2010 - 15:45

Yay! Thank you! I can't wait

Yay! Thank you! I can't wait to get started on them.

Kaybi (not verified)

Fri, 04/02/2010 - 17:27

You are so smart! Thank you,

You are so smart! Thank you, thank you, thank you!!!

Jenny @ Anythi… (not verified)

Fri, 04/02/2010 - 17:39

Oh I have been so hoping that

Oh I have been so hoping that you would post these plans and you totally made my Friday! I can't wait to get started!

Pacific NW Blogfan (not verified)

Fri, 04/02/2010 - 21:46

I'm diggin' it. Great job.

I'm diggin' it. Great job.

Work at Home Dad (not verified)

Fri, 04/02/2010 - 23:29

Wow that is so nice. Thank

Wow that is so nice. Thank you for sharing it.

Anonymous (not verified)

Sat, 04/03/2010 - 00:43

Ana, I had a look at the RH

Ana, I had a look at the RH website from your link. That Belvedere Loveseat is divine.

Stephanie (not verified)

Sat, 04/03/2010 - 04:04

Wonder if this cold be done

Wonder if this cold be done in Azek or other similiar material so it is weather proof, Perhaps one day try some thing in Knock off Azek, so it's a new arena for you!!!!

KRISTINA CIPOL… (not verified)

Sat, 04/03/2010 - 06:00

Thank you SO much for

Thank you SO much for sharing! The fact that you take the time out to post plans etc is SO nice of you! I've always loved these chairs but they are usually expensive...so making them a project may just be more doable! Thanks again! :)

Chrissy Jordan (not verified)

Sat, 04/03/2010 - 09:48

You are uh-mazing! Thank you

You are uh-mazing! Thank you for sharing your life with us! I am going to make two of these and join them with an attached umbrella for a cabana feel. But first we're making the picnic table for our son, can't wait. :)

Melissa (not verified)

Sun, 04/04/2010 - 19:08

Just a suggestion for anyone

Just a suggestion for anyone who is going to make this. When you make your padding, cover it with Sunbrella or some similar type of fabric that will not fade in the sun. We got the PB one (at a discount store, of course, and about the same price you could build it for), but it did not have the Sunbrella fabric, and what used to be red is now light orange. We have to recover it, and we only got it about a year ago.

Kristi (not verified)

Mon, 04/05/2010 - 11:58

You are incredible! And

You are incredible! And psychic- I was thinking of these yesterday as I planted my umbrella holder. I have a HUGE pot that I put a pvc pipe in and then surround with flowers. Rainy days, it sits outside and holds sunny flowers. On bright days, I push aside a few leaves and slide in the umbrella.

Swear to goodness, I was standing there yesterday thinking, "I wonder when she's going to put up the plans for those gorgeous wood lounges? They would be perfect here..."

THANK YOU!

Remodelaholic (not verified)

Mon, 04/05/2010 - 16:20

This is so perfect I have

This is so perfect I have been wanting some of these for ages! Thank you!

JackieSue (not verified)

Mon, 04/12/2010 - 20:19

HELP!! =) I just wanted to

HELP!! =) I just wanted to ask... (first of all, I'm the anonymous quoter from April 2nd...I guess I didn't log on that day.) Anyhow, I'm in the middle of this project but was a little confused about the front legs because there's not a detailed diagram of that portion. I figured it was just assumed to be close to the same as the back legs, but there is much more space up there than in the back so I was hoping you could clarify to help me. THANKS SOOOOO MUCH, I'm so excited to be doing this project!

JackieSue (not verified)

Mon, 04/12/2010 - 21:11

Ok so I kept going and

Ok so I kept going and according to my measurements, I'm thinking maybe the sides are supposed to be 76 1/4 rather than 73 1/4. Could that be true? You tell me. =) Thanks again! I just love you and your plans~!!!

Ana White (not verified)

Tue, 04/13/2010 - 03:51

Hmmmm . .. . The cleat

Hmmmm . .. . The cleat should be centered on the sides so that there is 4 1/4" space on both the front and the back. 73 1/3 + 4 1/4 + 4 1/4 = 81 3/4.

Hope this helps. Ana

JackieSue (not verified)

Tue, 04/13/2010 - 08:13

Thank you!!! So you might

Thank you!!! So you might want to change the plans to say 81 1/4 rather than 83 3/4. ? Pictures to come... =)

Ana White (not verified)

Tue, 04/13/2010 - 08:20

oh, thanks for being patient

oh, thanks for being patient with me! All fixed!

Jennifer (not verified)

Thu, 04/15/2010 - 01:56

We just threw out our old

We just threw out our old ones, so this will be great! I'll have to get Hubbie on it right away....I keep thinking that I need to learn to use these tools and get it done myself. You are VERY inspiring.

charlotteannette (not verified)

Mon, 04/19/2010 - 06:57

Oh man I totally should have

Oh man I totally should have read the comments before I started, but I also noticed the 84 vs 81 discrepancy, and just hacked off the last 3 inches of the sides. I am not done yet, but I have a question--do you think I made a mistake trying to do this in cedar?? ANA help! Its a really soft wood, is it going to hold up?

I am going to make a second one, but should i do it in some harder wood?

Ana White (not verified)

Mon, 04/19/2010 - 06:59

Cedar works, will hold up to

Cedar works, will hold up to weather. Can't wait to see your finished chair!

Alberta Mama (not verified)

Mon, 05/03/2010 - 12:46

Hey Ana,I was at Pottery Barn

Hey Ana,

I was at Pottery Barn last week looking at these really closely as I really, really want to build one and they have just used a piece of 1x3 (I think) wood instead of a dowel. I am going to try it. Also, they only had three height settings, so your plan is much more custom!

marabama (not verified)

Sat, 07/03/2010 - 18:42

Like many others I have

Like many others I have become addicted to your website and to woodworking.Last year I made my first project ever, a pair of basic adirondack chairs that my daughter decided would make her an excellant birthday present. Still wanting a pair of my own, this year I decided to make another set and a friend of mine decided they would look really good on his pool deck. So now I'm working on the chaise and I love it. This one's mine all mine! Just remember folks if you don't go ahead and try an advanced project like I did you will always think of yourself as a beginner

Doug (not verified)

Mon, 08/16/2010 - 14:00

Ana - I gotta tell you the

Ana - I gotta tell you the plans are great! The colors that focus on the steps to be performed are excellent. Looks like maybe your using Google SketchUp? I am building now and using 8" side boards and all in cedar. So far its looking great. Its the first time I've worked with cedar and a nice wood to work with. Not really that much more $ than finished pine either. I did have trouble finding 1x2's so just bought 1x4's and ripped them in half.

peter oa sullivan (not verified)

Thu, 10/07/2010 - 23:50

im doing my leaving cert in

im doing my leaving cert in killarney and u have no idea how much u have helped me u have saved me sume amount of work with this cutting list when im finished i will send u a picture tnks

Cale (not verified)

Wed, 12/01/2010 - 17:02

i recently (like today) found

i recently (like today) found your website... and i have to say "Thank You"... After shopping around, scouring the Internet, pricing out the budget, and realizing how expensive buy four of these lounge chair would be. I realized it couldnt be that hard just to make it myself. One problem the plans; i can see the basic shapes, but i couldnt figure out the measurements, nor did i think about countersinking the screws, or wood-filler, etc. So "Thank You" your site is enormous help.

Anna (not verified)

Fri, 02/18/2011 - 08:29

Brilliant!

Brilliant!

helpme (not verified)

Mon, 02/21/2011 - 13:36

help! i'm in the process of

help! i'm in the process of building this chaise and i am using white pine that i purchased from home depot since it was the only wood available. every time i screw two pieces together, the wood is splitting at the screw. the wood is very soft and very light, but i bought it because the only other option was pressure treated. is the problem with the wood, the screws, or am i just an idiot?

In reply to help! i'm in the process of by helpme (not verified)

claydowling

Wed, 04/06/2011 - 12:02

Pre-drilling

There are a couple of tricks to using screws with 1x material.

First, always pre-drill a pilot hole. Use a drill bit the same size as or slightly smaller than the shaft of the screw (i.e. thinner than the threads). Just hold them up next to each other, it's not precision measurement. If in doubt, go smaller.

The second is to countersink the screws. You can buy a countersink that includes a drill bit for the pilot hole at and of the big box stores. Or you can buy a hand countersink at Harbor Freight. I prefer the later, but either works quite well.

Also, never use a self-taping screw like a drywall screw in 1x material. Sometimes you'll get away with it, but it's more likely that the wood will split. If not right away, then the first time the joint is stressed. Proper wood screws are always what you should use. The angled base on the head is less likely to cause splitting than the curved base of a drywall or deck screw. It should just nestle snugly into the countersunk hole. A properly countersunk screw has a certain elegance to its appearance.

Ryan (not verified)

Wed, 04/06/2011 - 09:48

Measurement issue

Maybe someone who has done this before can help me because i can't seem to comprehend the measurements lol. so I am looking at the plan and it say to leave 4 and 1/4 inch at each end of the stringers and then attach legs to leave 3/4 of an inch. That all makes sense but then how can you attach a 1x4 to the front and back and make everything flush. Won't there be an extra 1/4 inch overhang???? Help Pleasseeee

In reply to Measurement issue by Ryan (not verified)

claydowling

Wed, 04/06/2011 - 12:45

Easy mistake

A 1x4 is nominally 3/4" thick. It was 1" before surfacing, which is how lumber is priced.

Ryan (not verified)

Wed, 04/06/2011 - 13:15

I feel dumb....thank you so

I feel dumb....thank you so much...i've been dying to try this but didn't want to screw up

constantia

Tue, 05/03/2011 - 11:18

Wheels

Did anyone attach the wheels? I think I know how the West Elm wheels are attached (which I really like that look). Just trying to get ideas from someone who's already done it.

kent (not verified)

Mon, 05/30/2011 - 20:33

chaise lounge plans

Thank you Anna for your free internet lounge plans. I made a few modifications to the back. One can reach through and read a book on their stomach. I also added rear wheels. Cheers! Kent

Guest (not verified)

Thu, 06/23/2011 - 13:38

Love these plans. I am in the

Love these plans. I am in the middle of making two with douglas fir but i have a question... So do I use a one hole pipe strap so that the dowel can get to the end of the supports? I bought a two hole and in order to screw it to the supports, the dowel will be almost an inch from the end. Also, the 3/4" pipe straps do not attach the dowel snug. there is enough room for the dowel to slip out. Is that right? Thanks.

Double Chaise? (not verified)

Tue, 01/10/2012 - 10:48

Double Chaise

I'm hoping that someone would be able to post the specifications for the double chaise? Any help?

Thanks.

npalacios281

Mon, 01/16/2012 - 11:33

I look forward to this project

I have been wanting pool furniture for the longest. However, I am a bit confused between the shop list and the cut list. The first couple items on the shop list are wood cuts right?