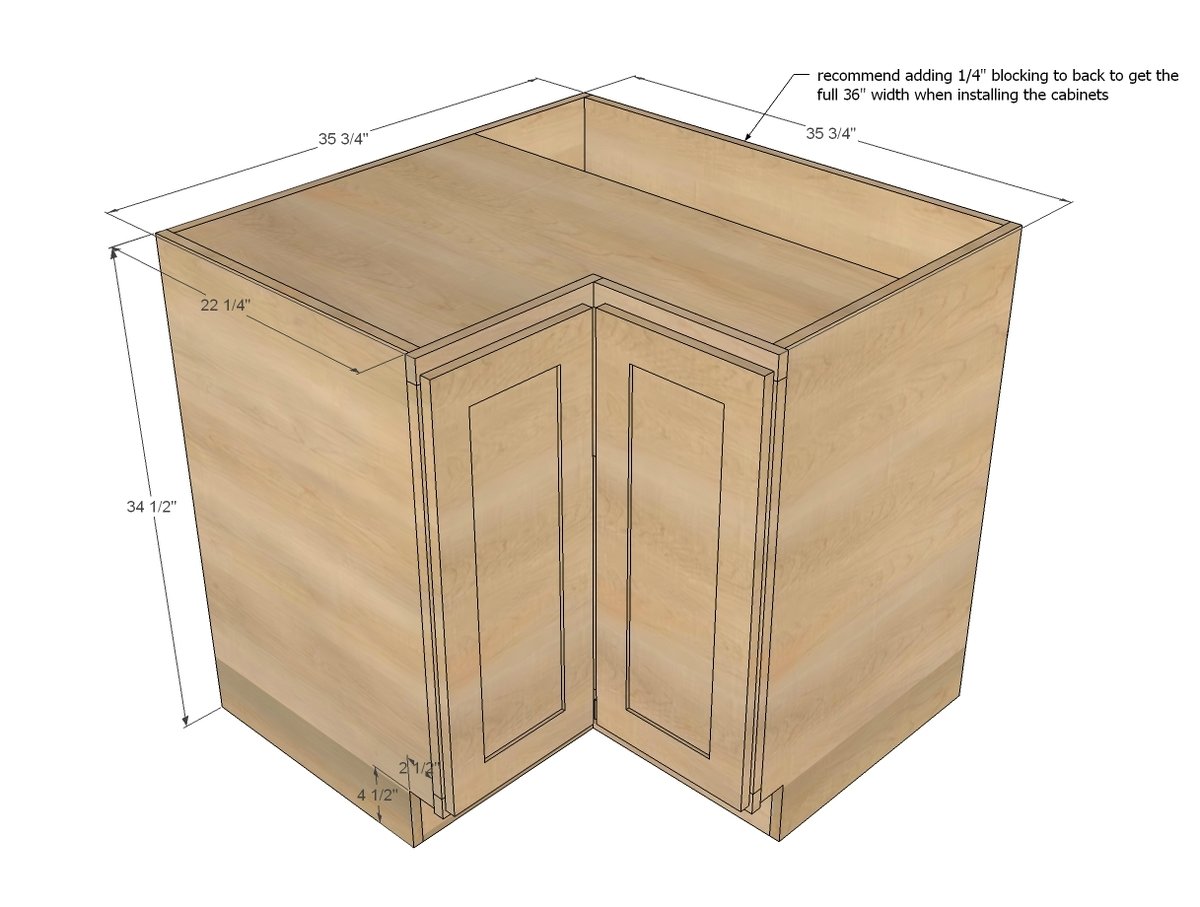

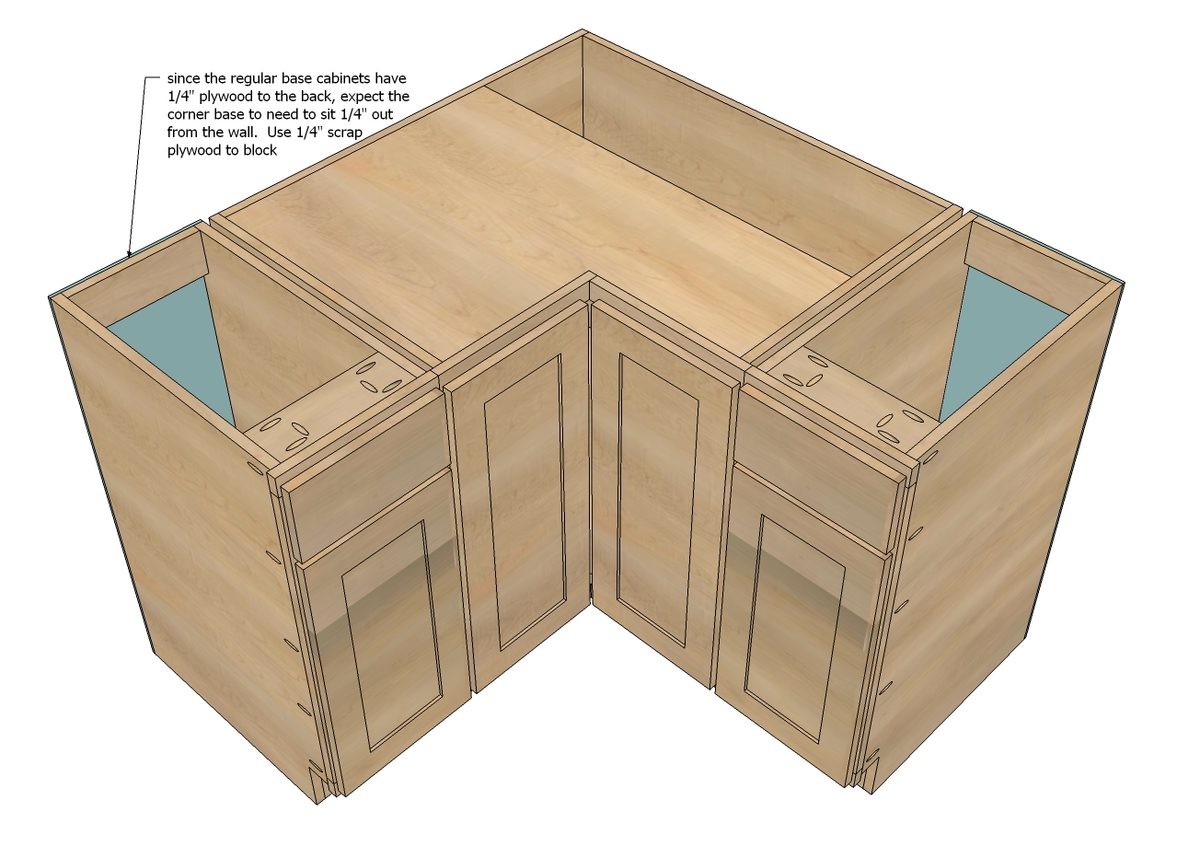

Plans for 36" base pie cut corner cabinet with lazy susan from Ana-White.com

Preparation

2 sheets of 3/4" plywood (we used one sheet of prefinished plywood and one sheet of cheaper hardwood plywood in oak)

10 feet of hardwood 1x2s for the face frames

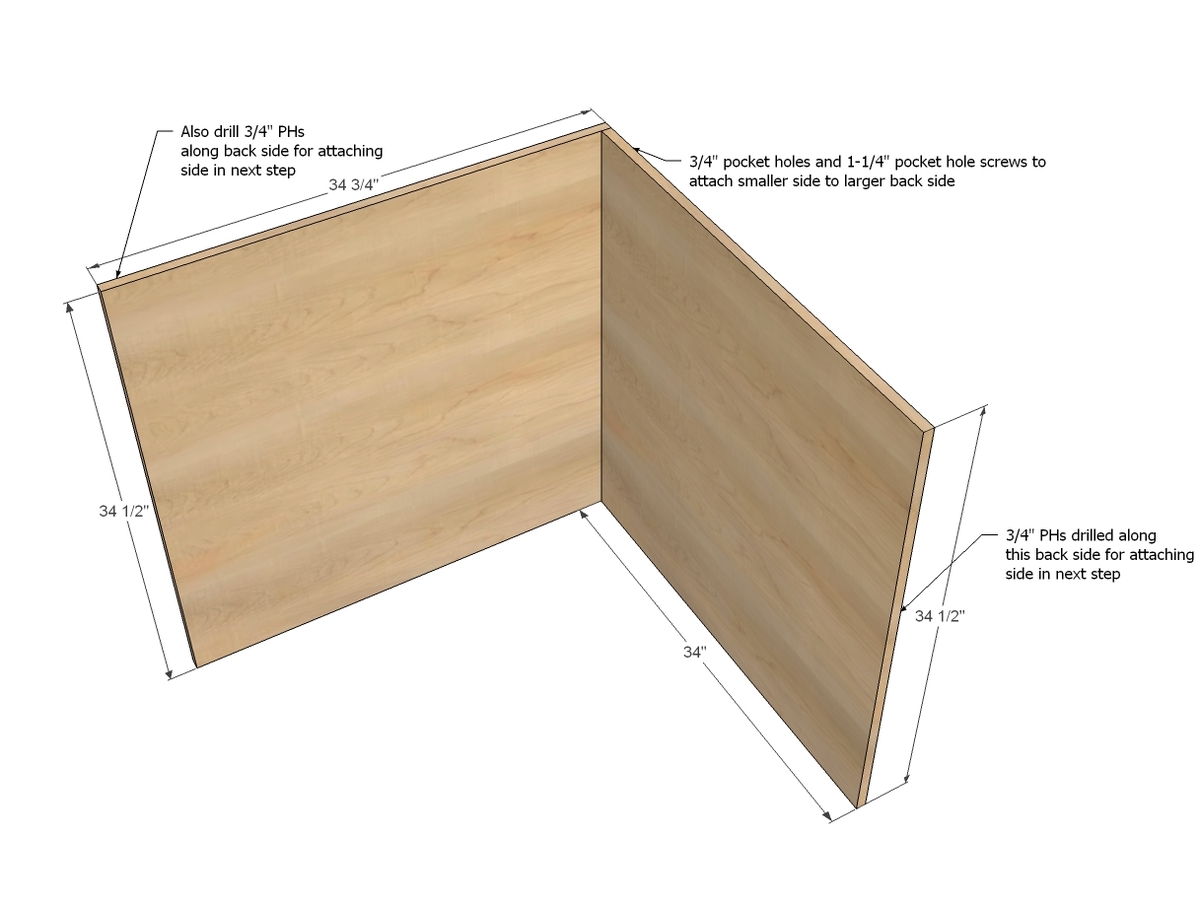

1 - 3/4" plywood @ 34-1/2" x 34-3/4" (larger back piece) (we used cheaper plywood here)

1 - 3/4" plywood @ 34 1/2" x 34" (smaller back piece) (we used cheaper plywood here)

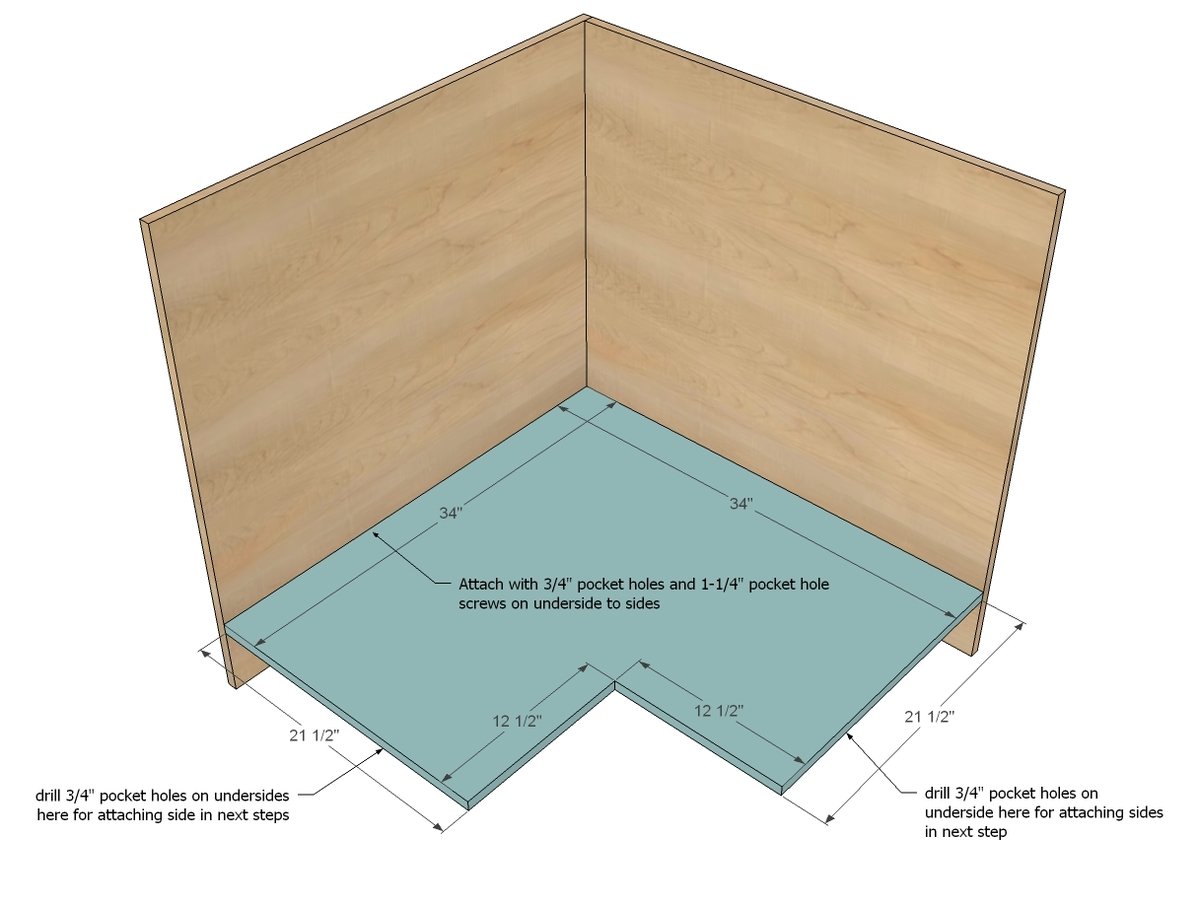

1 - 3/4" plywood @ 34" x 34" (bottom shelf)

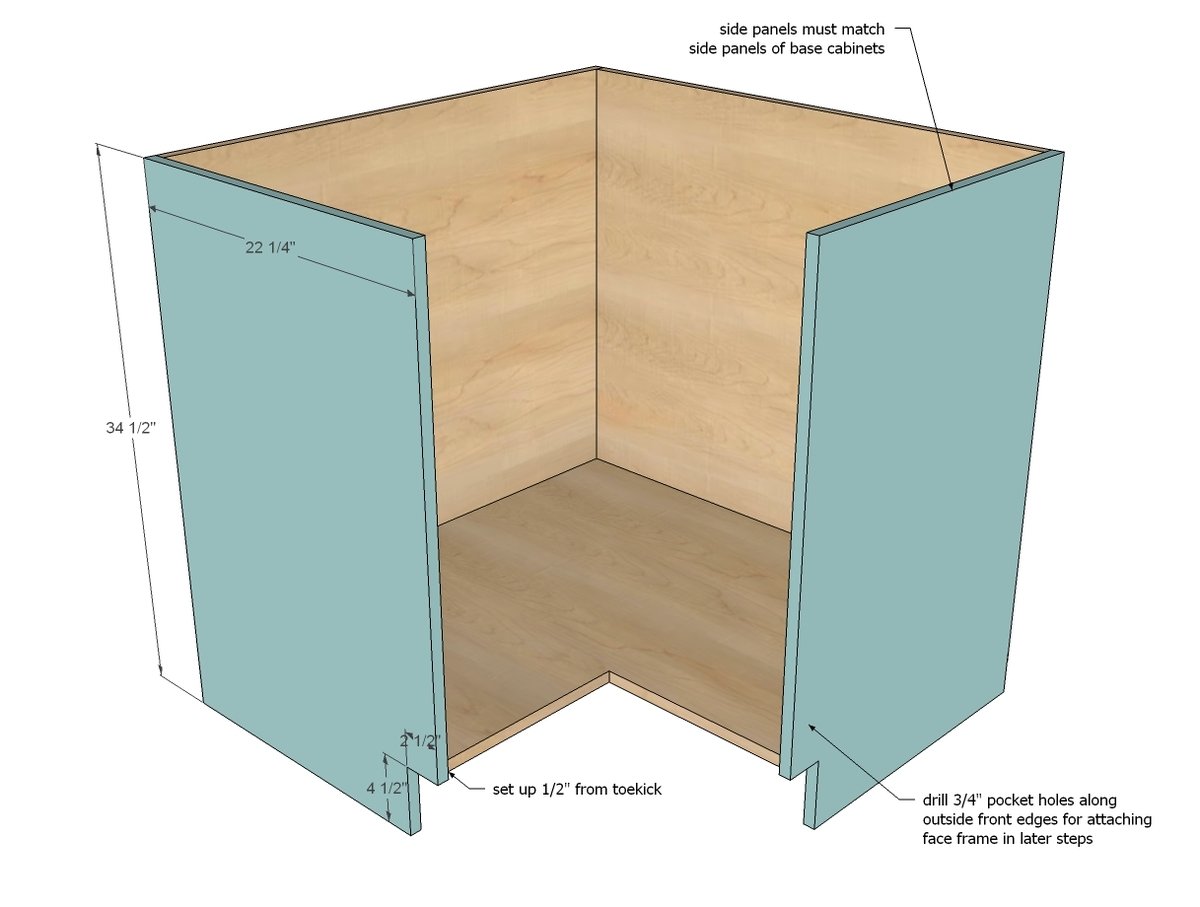

2 - 3/4" plywood @ 34 1/2" x 22 1/4" (sides - must match other base cabinets)

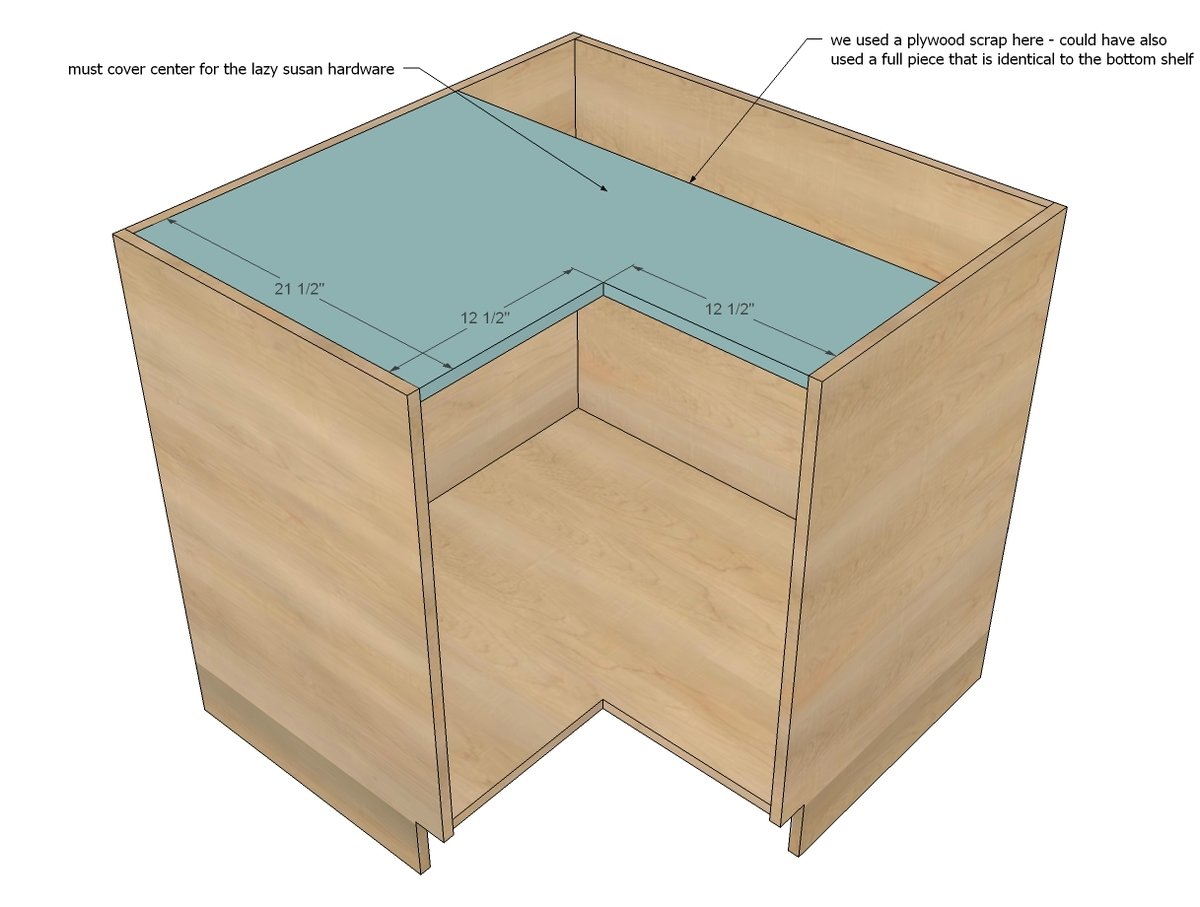

1 - 3/4" plywood @ 34" x 20" or more (top - we used cheaper plywood here)

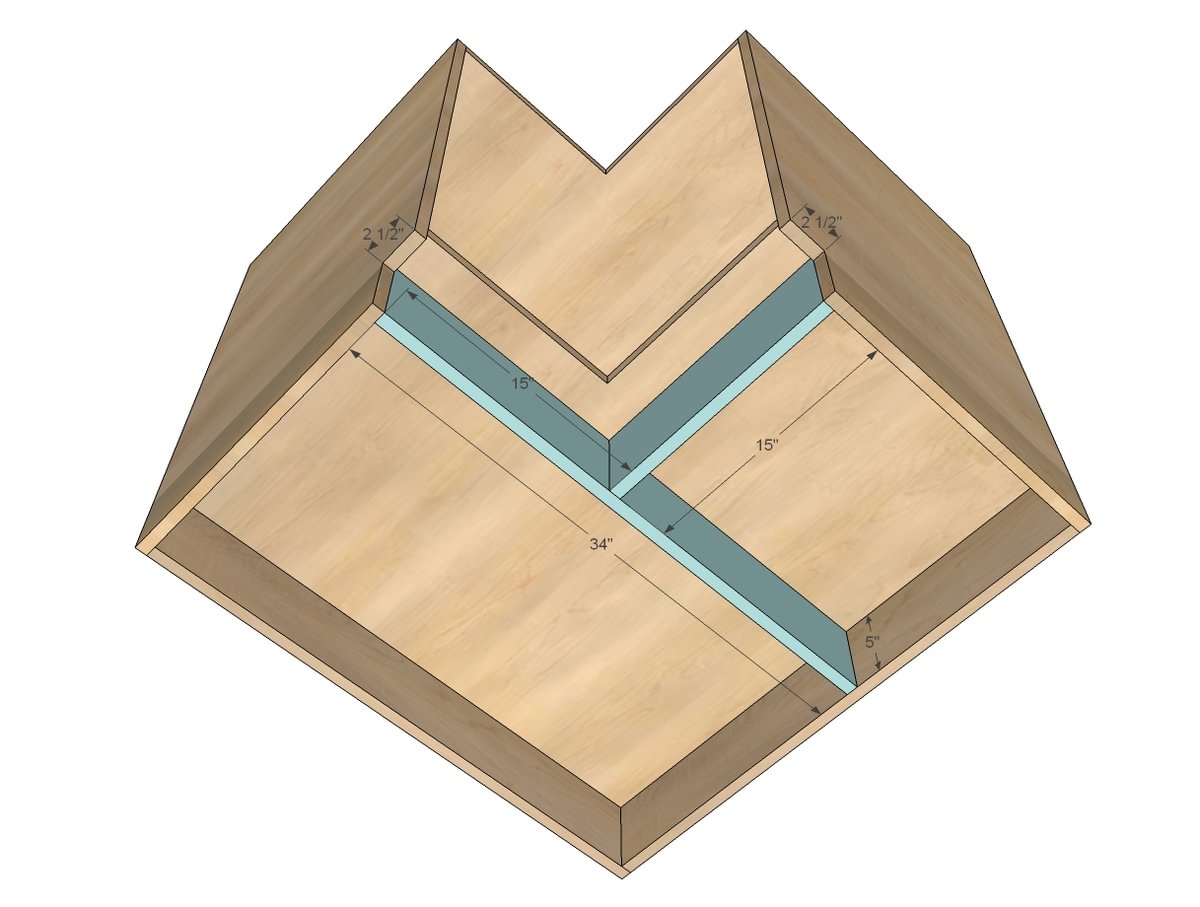

1 - 3/4" plywood @ 34" x 5" (base support, longer piece - we used cheaper plywood here)

1 - 3/4" plywood @ 15" x 5" (base support, longer piece - we used cheaper plywood here)

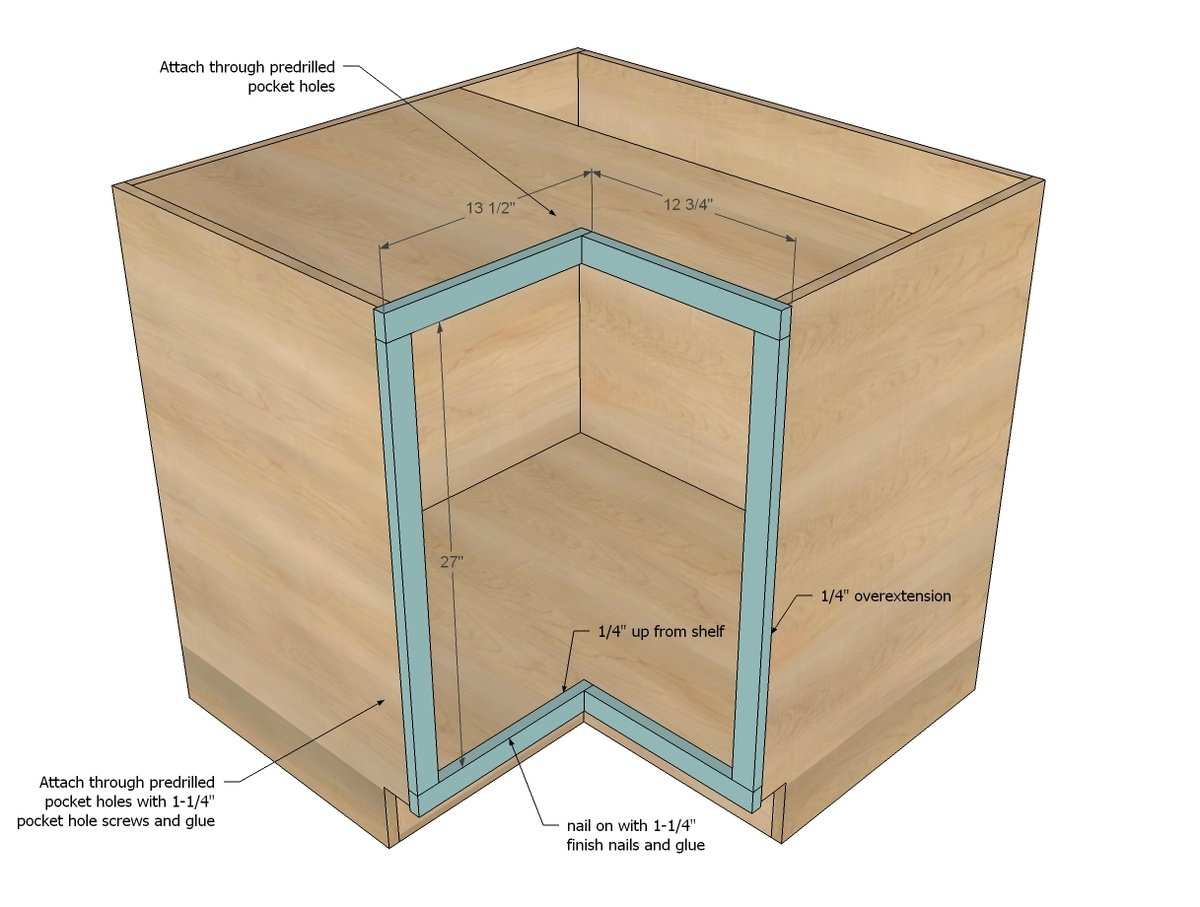

FACE FRAME

2 - 1x2 @ 27" (should match face frame stiles from other base cabinets)

2 - 1x2 @ 13 1/2"

2 - 1x2 @ 12 3/4"

Please read through the entire plan and all comments before beginning this project. It is also advisable to review the Getting Started Section. Take all necessary precautions to build safely and smartly. Work on a clean level surface, free of imperfections or debris. Always use straight boards. Check for square after each step. Always predrill holes before attaching with screws. Use glue with finish nails for a stronger hold. Wipe excess glue off bare wood for stained projects, as dried glue will not take stain. Be safe, have fun, and ask for help if you need it. Good luck!

Instructions

Step 1

IMPORTANT!!!! There are many different kitchen cabinet plans on this site. This base cabinet is designed to work with the base cabinets built for the White Momplex Kitchen (Sewing Mom) with a side panel overall measurment of 34-1/2" tall by 22-1/4" wide, with a 4-1/2" x 2-1/2" toekick.

So this is the overkill part ....... I put 3/4" plywood on the two back sides. We did use a cheaper plywood for the backs because it's not every going to be seen.

Make sure you drill 3/4" pocket holes along the back side edges so you can attach the sides in later steps.

Step 2

Step 3

Step 4

Instead of buying another sheet of plywood for the top, we used a scrap from the back to make up the top, cutting out the pie cut front from it. The plywood must be at least 34" x 20" to start with.

NOTE: Also drill 3/4" pocket holes facing forward on the front pie cut edges on top for attaching the face frame in later steps.

Step 6

Step 7

It is always recommended to apply a test coat on a hidden area or scrap piece to ensure color evenness and adhesion. Use primer or wood conditioner as needed.

Comments

mbdarrington

Mon, 11/25/2013 - 22:00

This is perfect!

What a beautiful cabinet and just what I was looking for. I am getting ready to build this cabinet in the next month. The kitchen we are building is very small and this particular cabinet will have a sink in it. Do you have any advice on building the top so it is "sink ready"? Our sink will be something like this:

http://www.wayfair.com/Houzer-Legend-31.88-x-17-Topmount-Corner-Bowl-Ki…

Steve Hutcherson

Fri, 05/01/2015 - 15:34

INSPIRATION

Thanks so much for the inspiration. Never thought we could build our own cabinets!!

casamaia

Tue, 09/15/2015 - 08:11

paint

Hi, what type of paint did you used?

Patti312

Sat, 03/26/2016 - 08:29

36" Corner Base pie cut base cabinet

Hi Love these plans and presently building this cabinet. I have only one question:: What size lazy suzan insert is used. I am seeing that there are more than one size and I can't seem to find the size in the plans. Thanks.

gogadgo

Thu, 05/31/2018 - 09:58

Door measurement

Hi Anna,

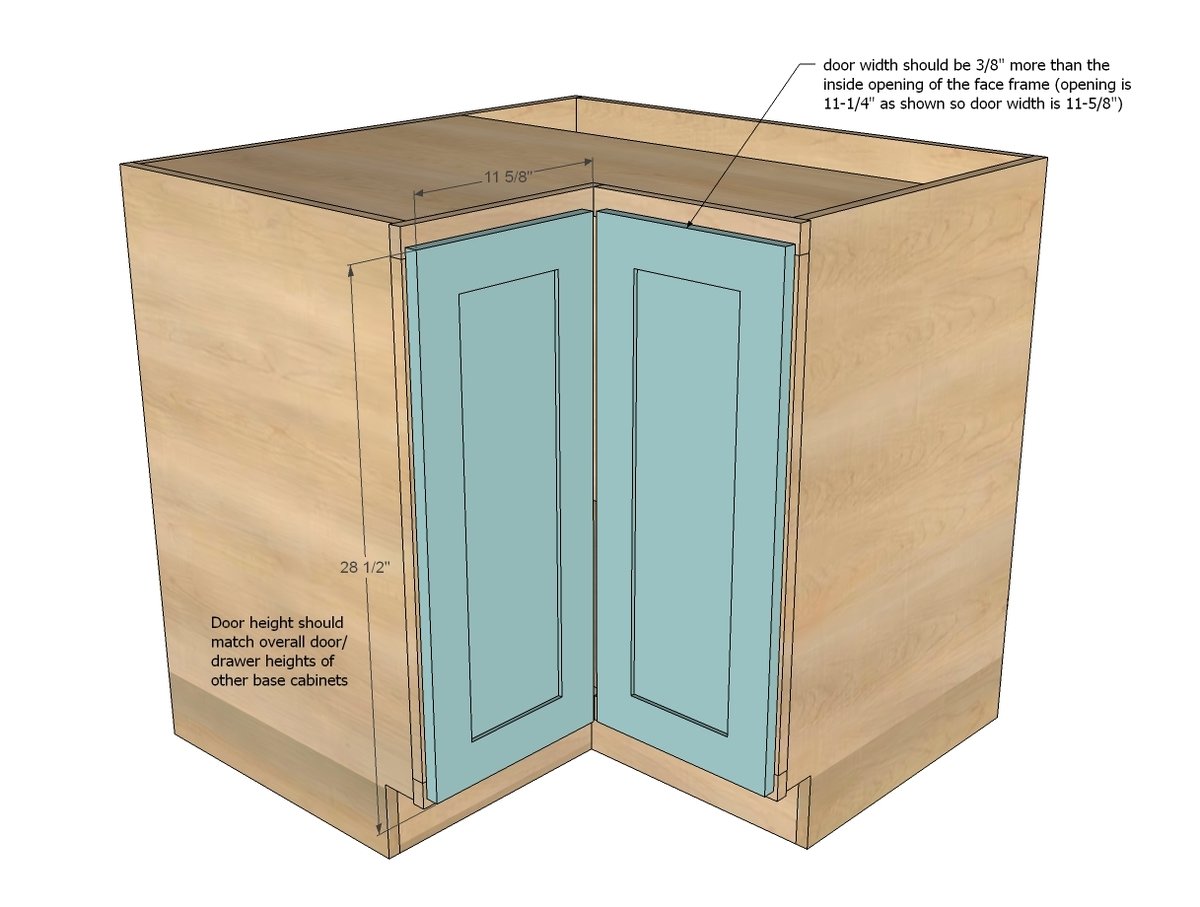

I built this cabinet and am at a loss of how to measure door panels for ordering, what do you recommend?

Brooklyn Beer

Sun, 02/13/2022 - 06:10

size modification

I do not have 36" but 33 " of space coming out of my corner. Has anyone modified this by 3 inches?