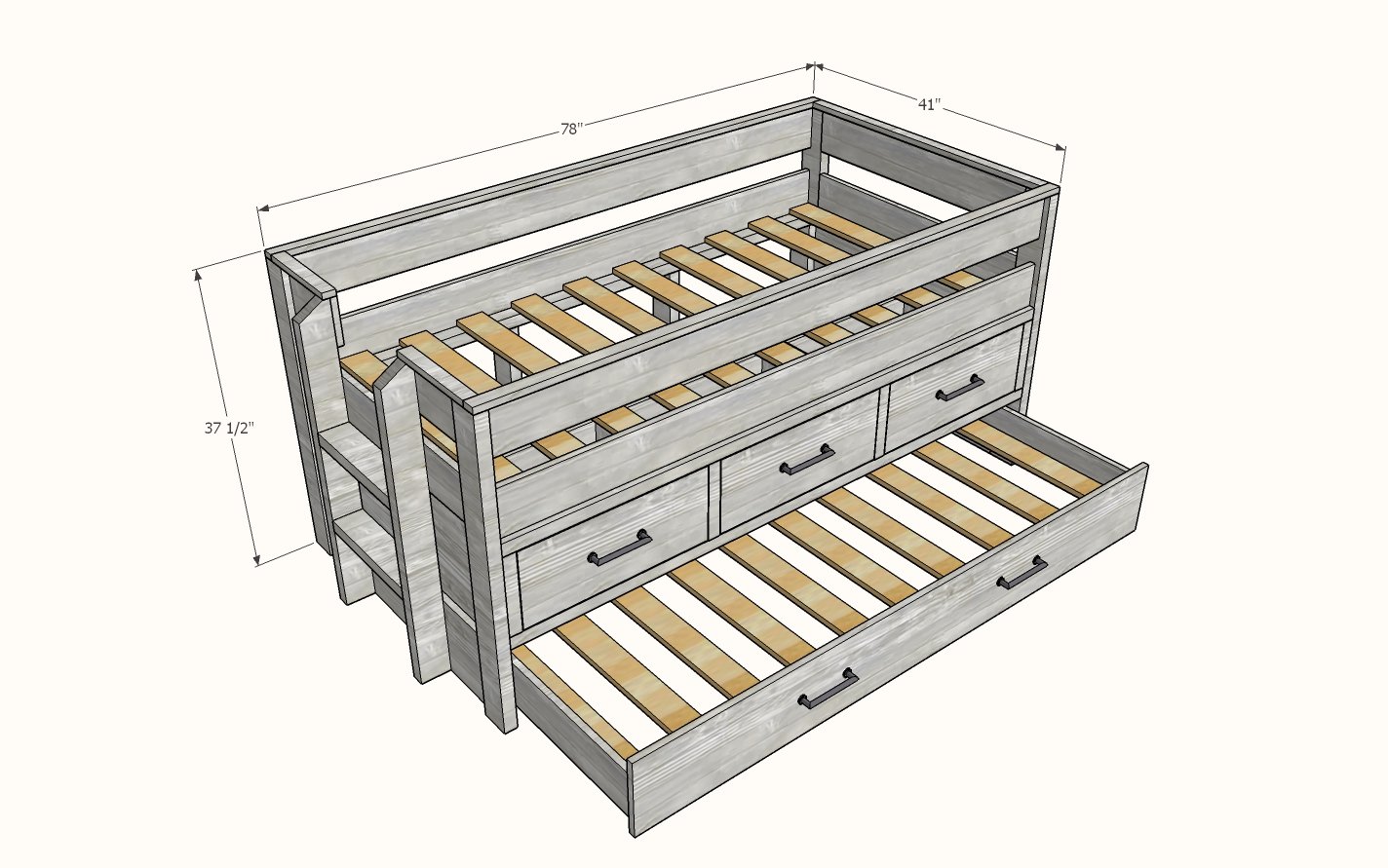

Build your own captains bed with trundle and storage drawers! Spend a couple hundred instead of a couple thousands! Choose your own finish and hardware.

Step by step plans include over 15 diagrams, detailed shopping list and cut list. Free plans by Ana-White.com

Pin For Later!

Preparation

6 - 2" caster wheels (50 pound load rating minimum)

3 - 18" drawer slides

9 - 2x4 @ 8 feet long

1- 2x2 @ 8 feet long

5 - 1x6 @ 10 feet long

4 - 1x2 @ 8 feet long

2 - 1x10 @ 10 feet long

10 - 1x4 or 1x3 @ 8 feet long (used for slats)

1 - 1/4" plywood sheet used for end panels and drawer bottoms

100 - 1-1/4" pocket hole screws

70 - 2-1/2" self tapping wood screws like these

8 - 2-1/2" pocket hole screws

200 - 1-1/4" brad nails

50 - 3/4" brad nails

wood glue

5 - handles or pulls

33" x 72" trundle mattress (sometimes called a "sleeper sofa bed mattress)

38" x 75" standard twin mattress

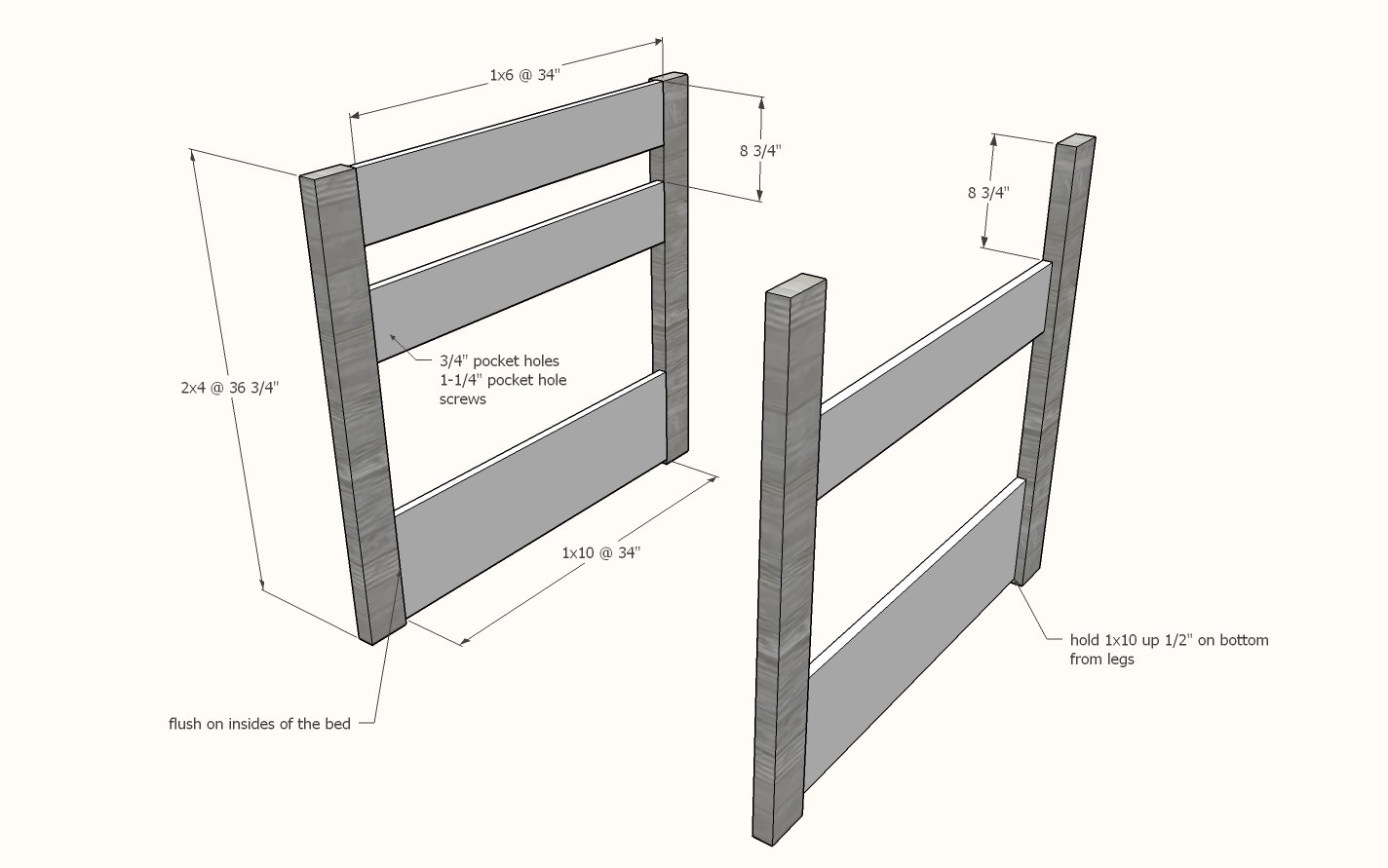

ENDS

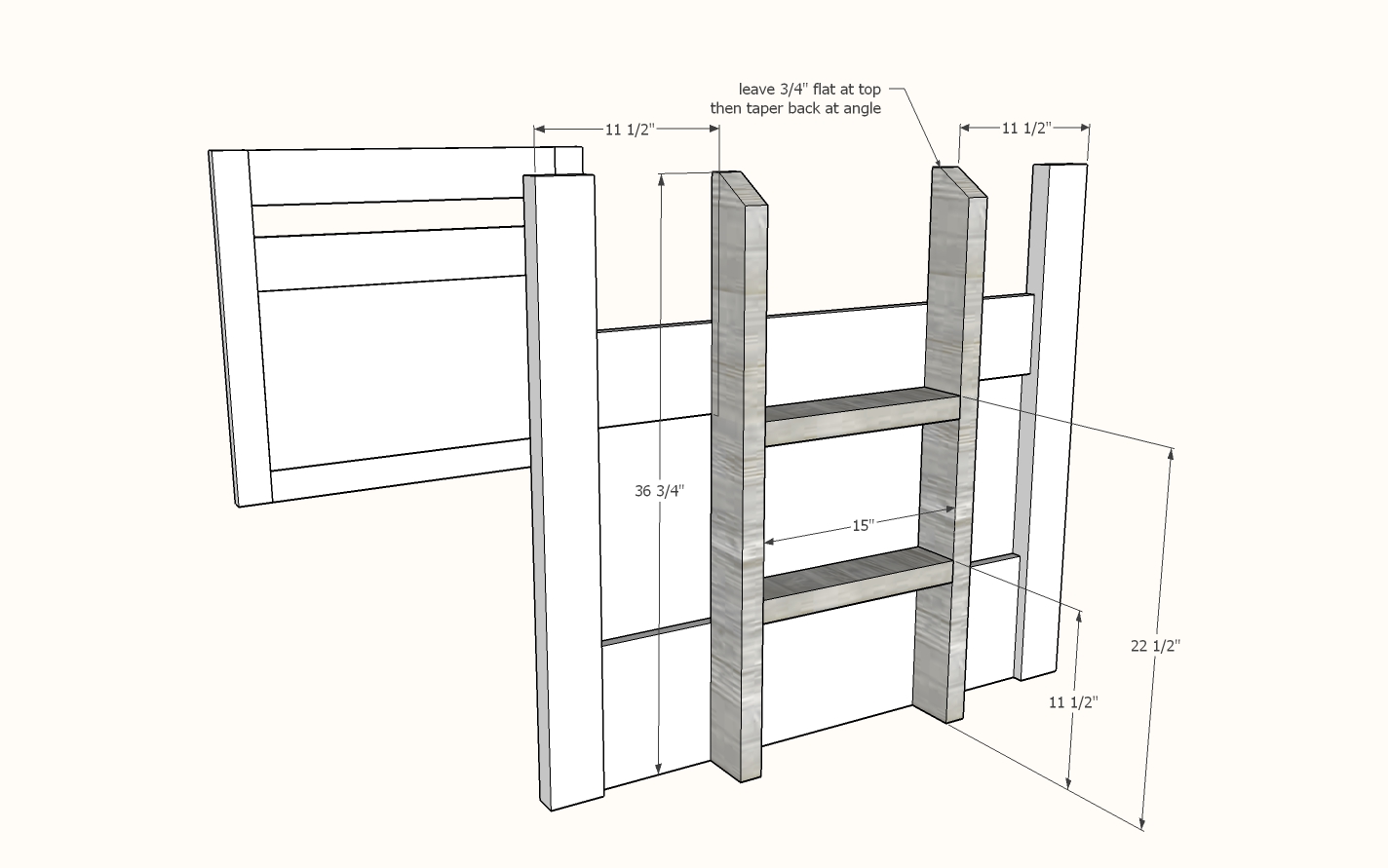

- 6 - 2x4 @ 36-3/4" - legs and ladder legs

- 2 - 1x10 @ 34" - bottom

- 3 - 1x6 @ 34" - top rails

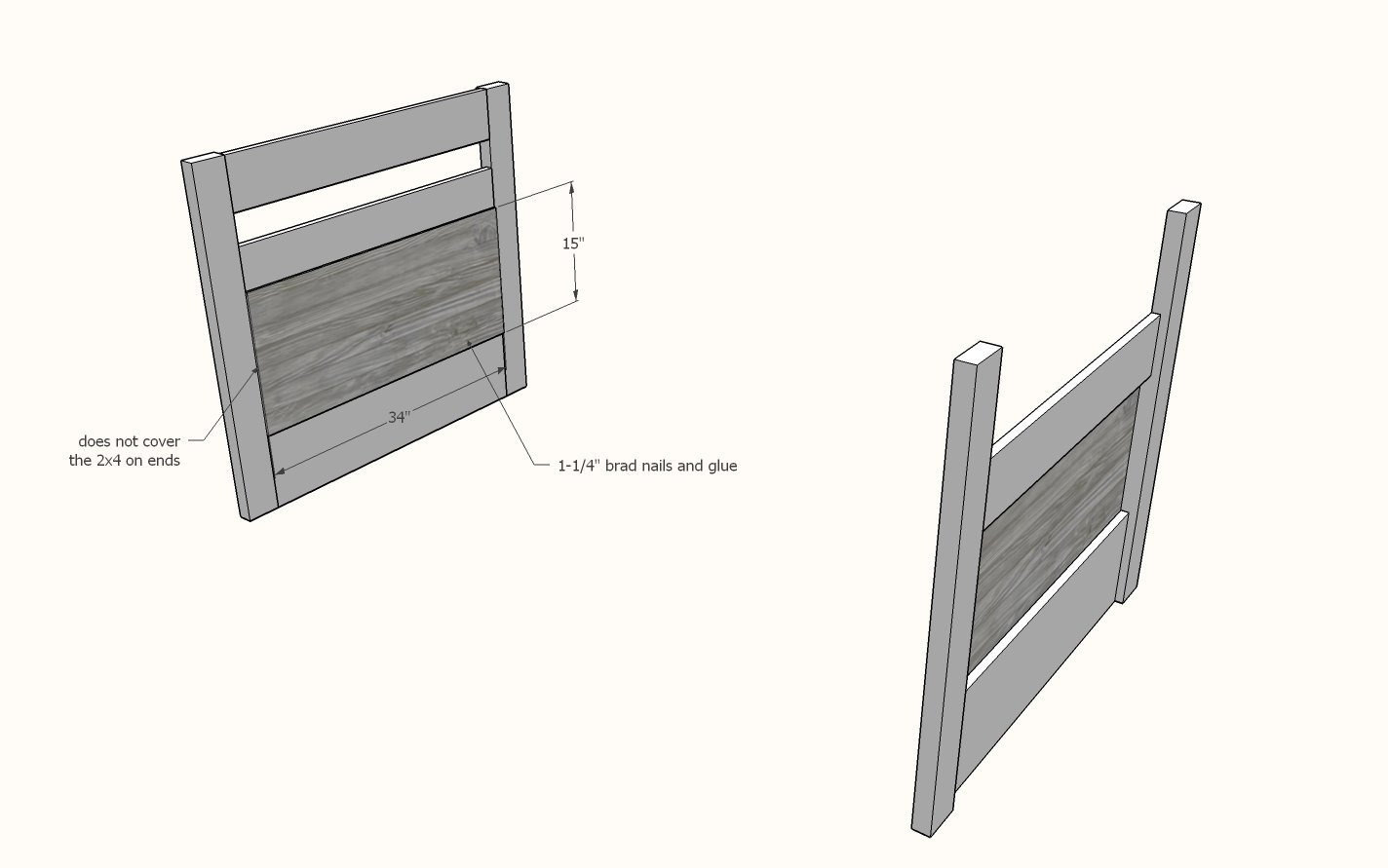

- 2 - 1/4" plywood @ 34" x 15" - end panels

- 2 - 2x4 @ 15" - ladder rungs

- 2 - 1x6 @ 9-1/2" - top rails on ladder side

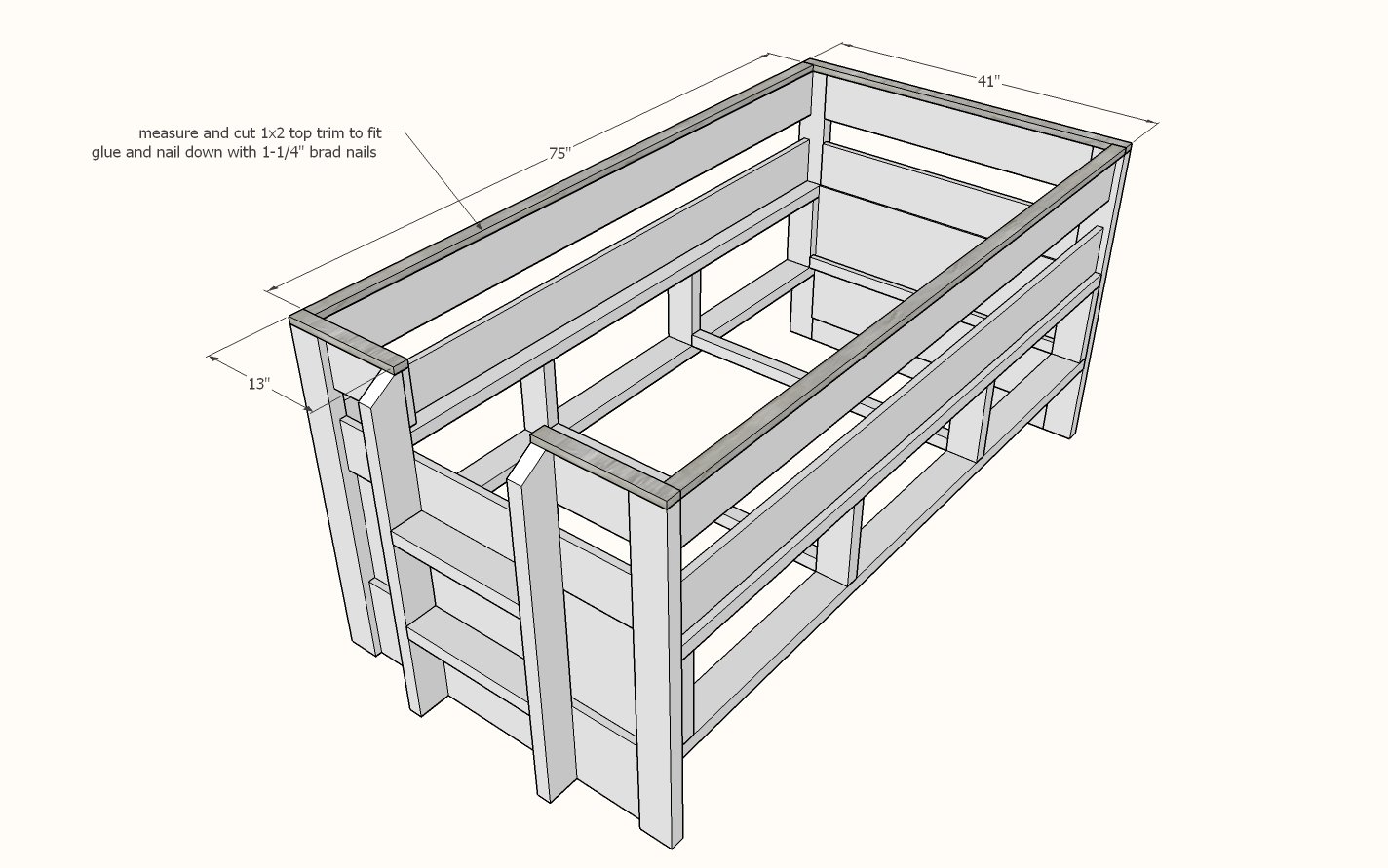

- 2 - 1x2 @ 13" - top trim ladder side

- 1 - 1x2 @ 41" - top trim end without ladder

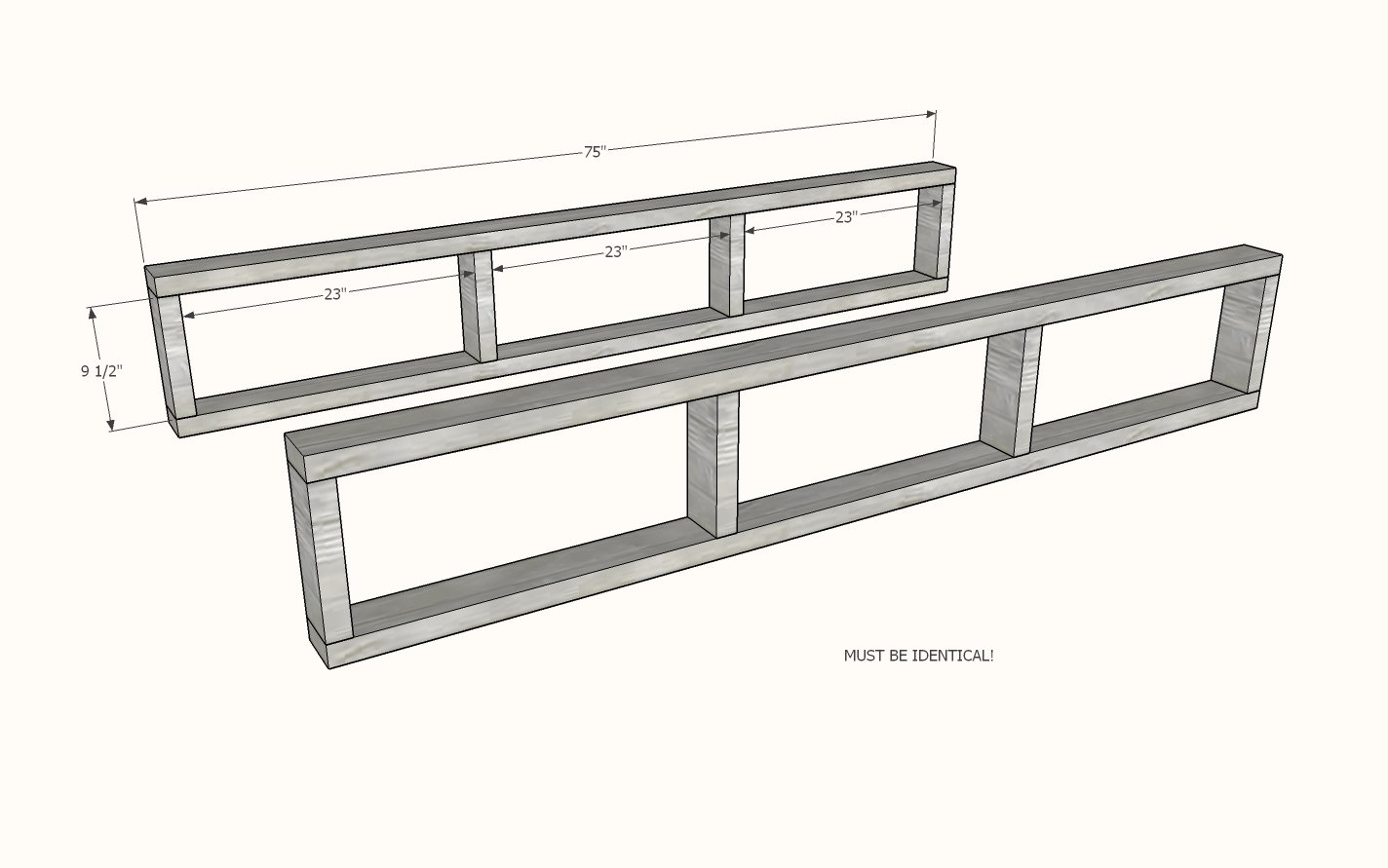

SIDES/CENTER

- 4 - 2x4 @ 75" - drawer support framing

- 8 - 2x4 @ 9-1/2" - drawer support framing

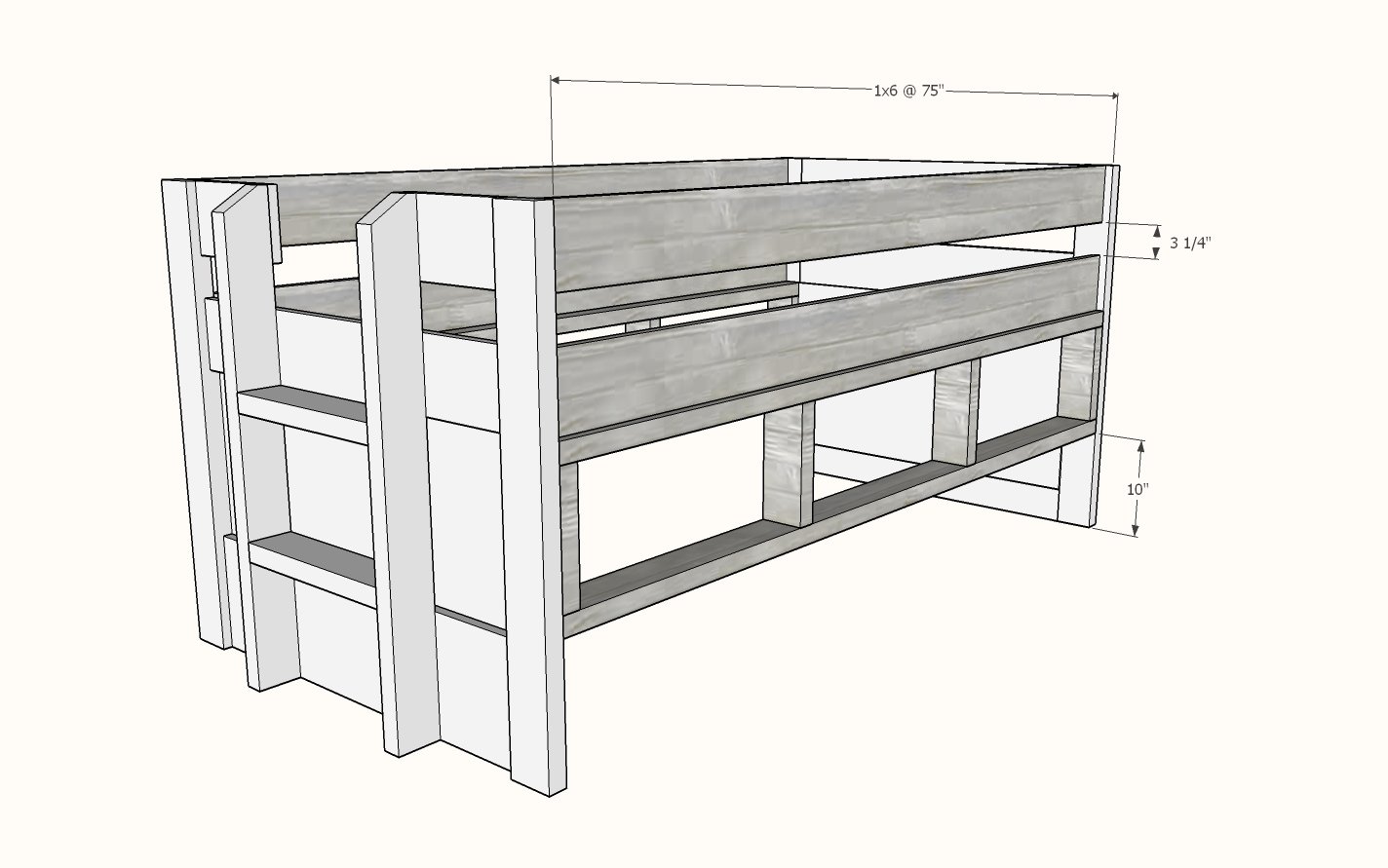

- 4 - 1x6 @ 75" - siderails

- 2 - 1x2 @ 75" - top trim, siderails

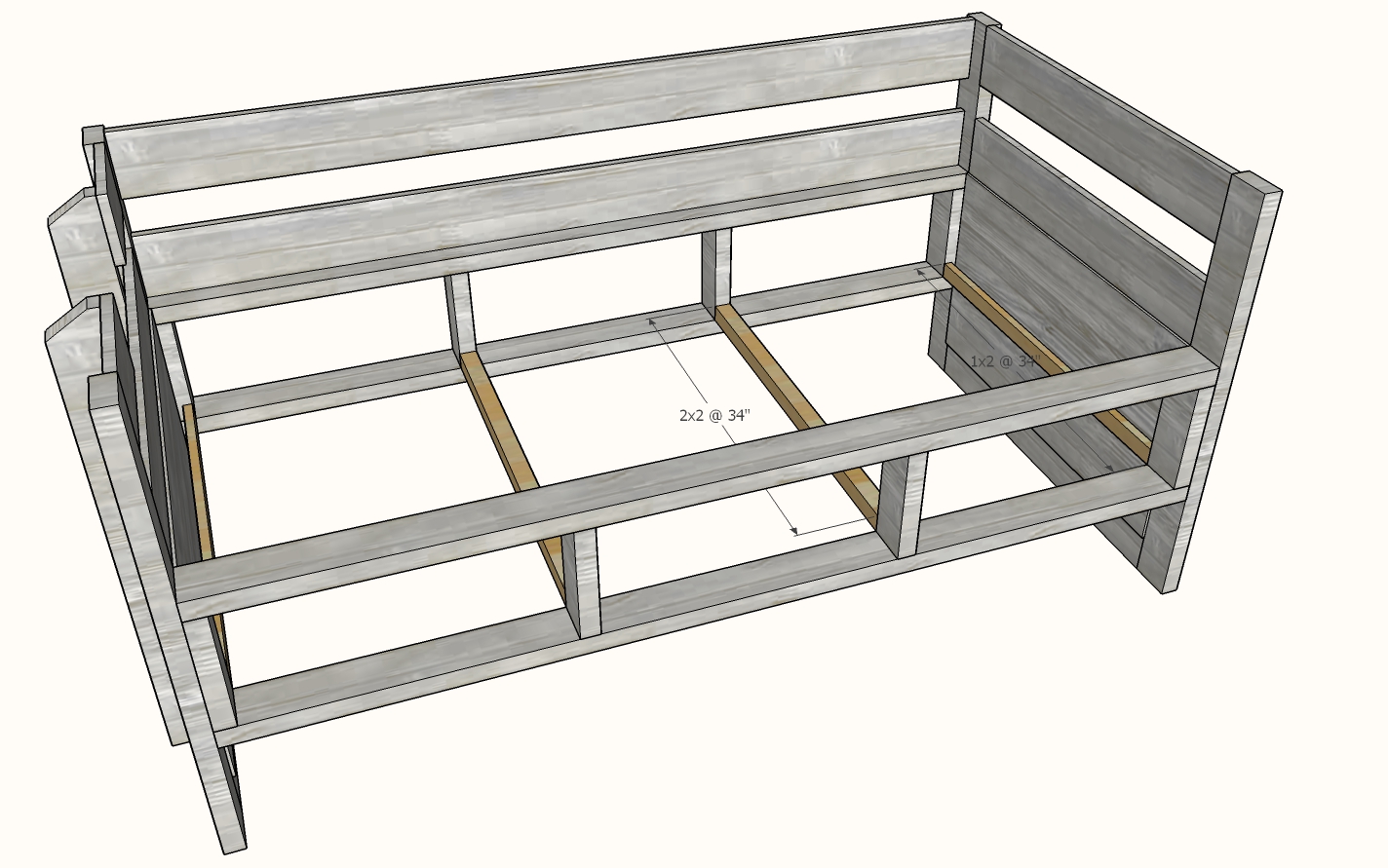

- 2 - 2x2 @ 34" - drawer support rails

- 2 - 1x2 @ 34" - drawer support rails, ends

- 10 - 1x4 @ 38" - bed slats

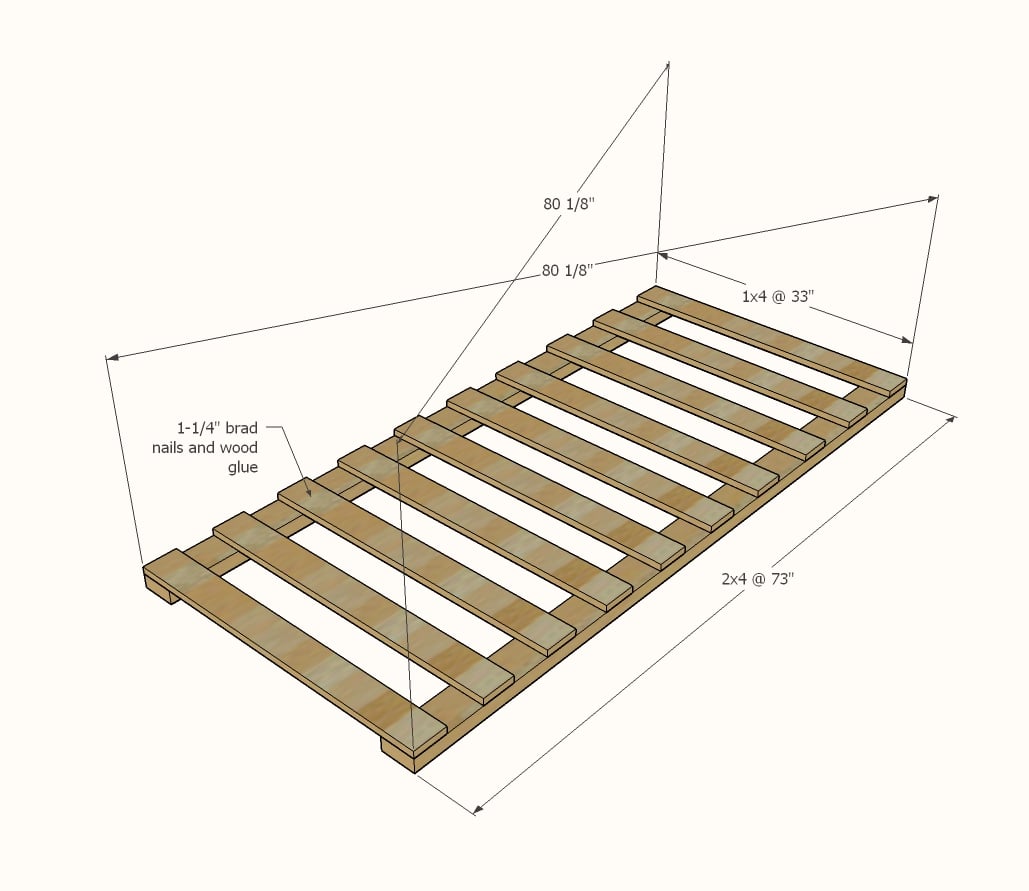

TRUNDLE

- 2 - 2x4 @ 73" - trundle supports

- 10 1x4 @ 33" - slats

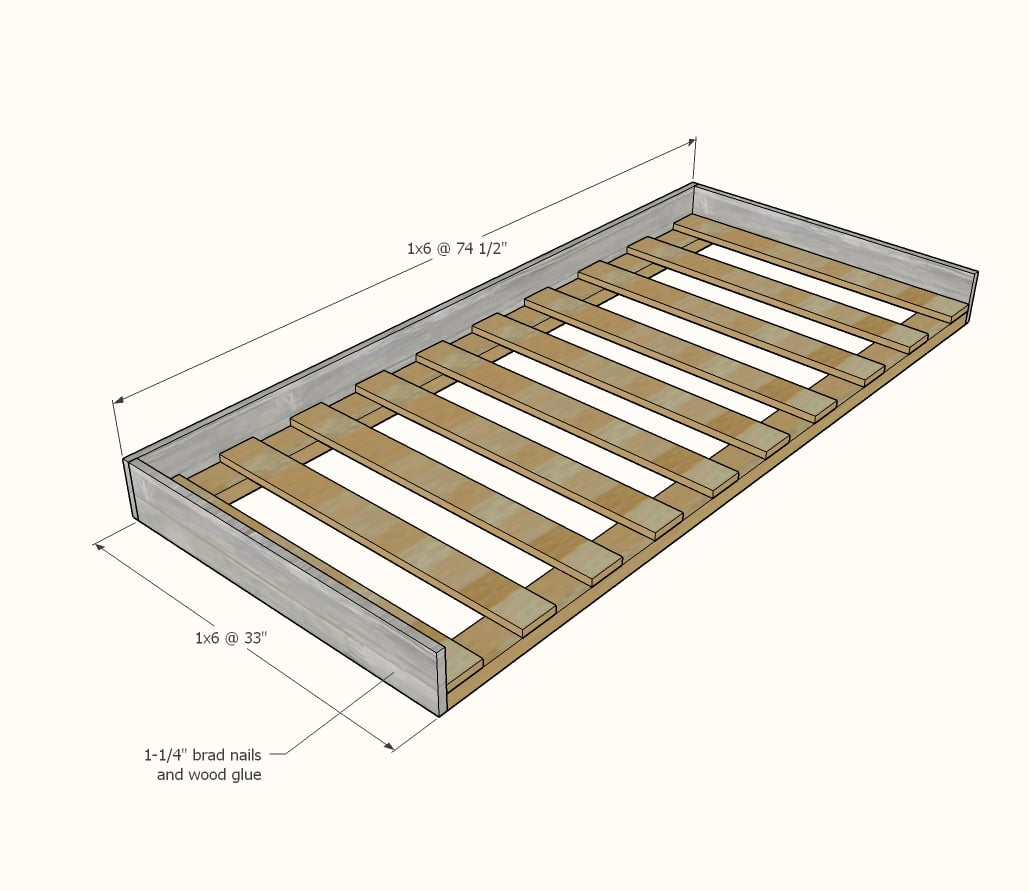

- 2 - 1x6 @ 33" - ends

- 1 - 1x6 @ 74-1/2" - back

- 1 - 1x10 @ 74-1/2" - front

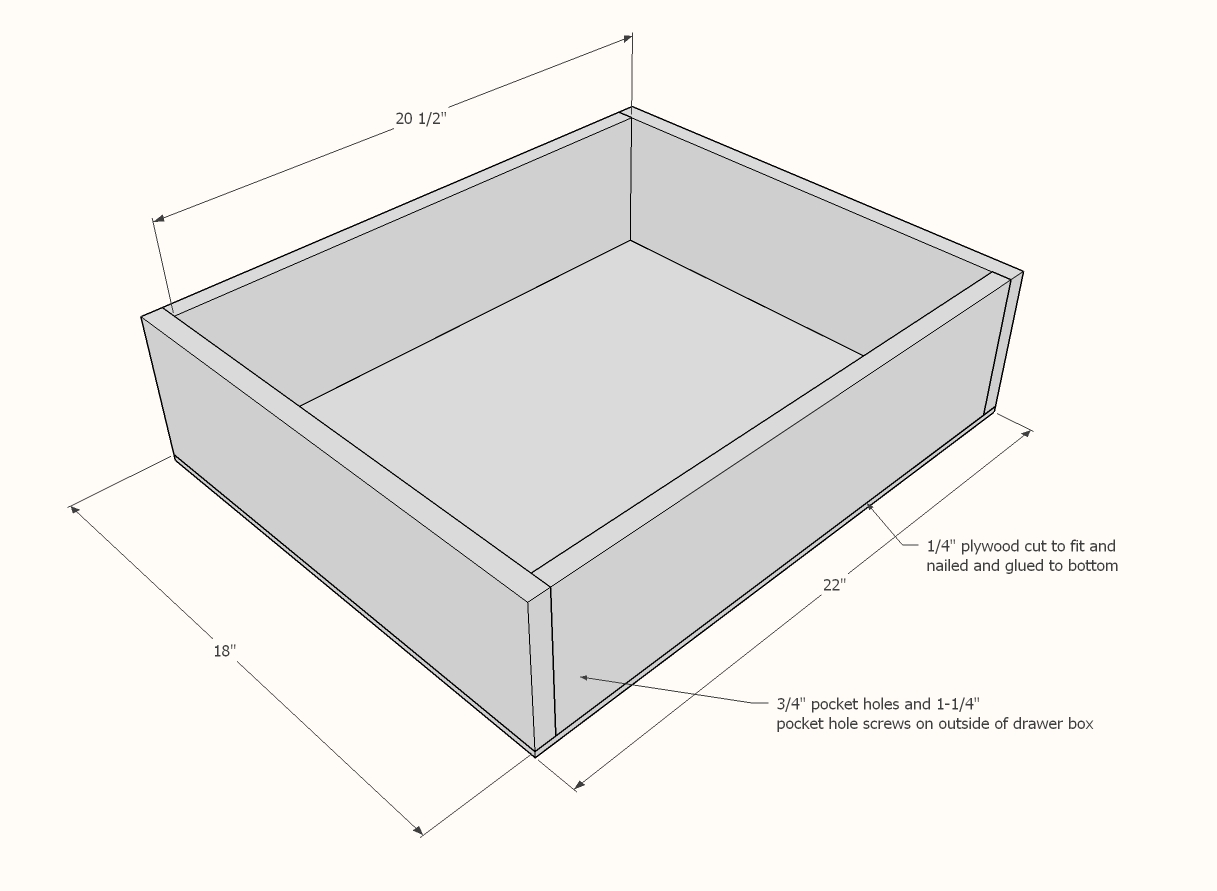

DRAWERS - ASSUMES OPENING OF 23" and 1/2" clearance drawer slides

- 6 - 1x6 @ 18" - drawer sides

- 6 - 1x6 @ 22" - drawer front/back

- 3 - 1/4" plywood @ 18" x 22" - drawer bottom

- 3 - 1x10 @ 22-3/4" - drawer face

Cut the longest cuts first to make sure you get those cuts before cutting smaller pieces

DO NOT cut boards in half for transport - cut according to cut list

Cut 1x and 2x boards with a compound miter saw (recommended) or a circular saw with straight edge.

Plywood needs to be cut with a circular saw or tablesaw.

The finished bed will be large in size and may not fit through a door opening. You may wish to build in pieces, finish pieces that are exposed in final product, then move into the room for final assembly

Instructions

Step 1

Step 3

Step 4

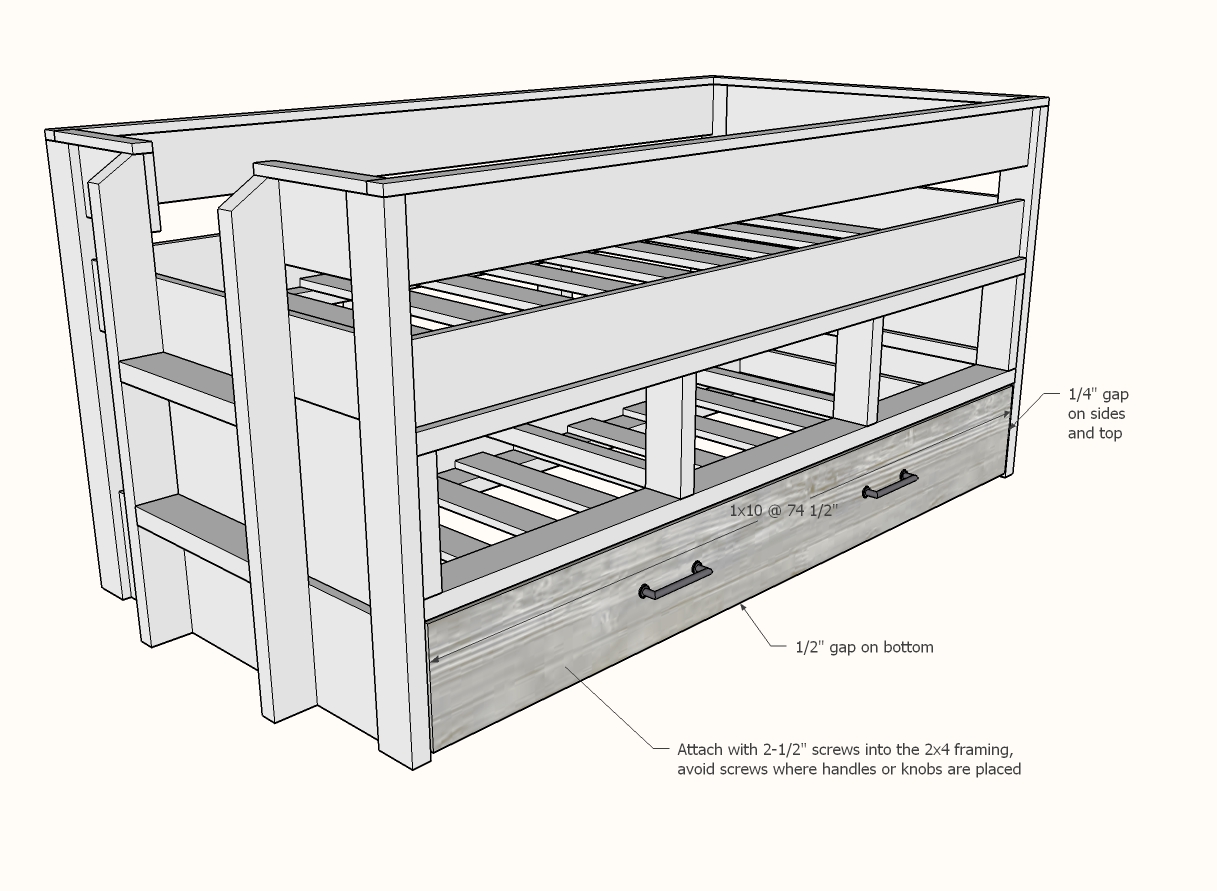

Step 5

Step 6

Paint or stain the 2x4 drawer frames and the 1x6 side rails.

Drill two 3/4" pocket holes into each end of the 1x6s.

For the bottom siderails, also drill a few 3/4" pocket holes facing downward to attach to the 2x4s on install.

Attach 1x6 to the ends with 1-1/4" pocket hole screws and glue.

Attach 2x4 drawer framing to end panels with 2-1/2" wood screws.

Attach bottom 1x6 siderail to the 2x4s with 1-1/4" pocket hole screws.

Step 7

Step 8

Step 9

Step 10

Step 11

Step 12

Step 14

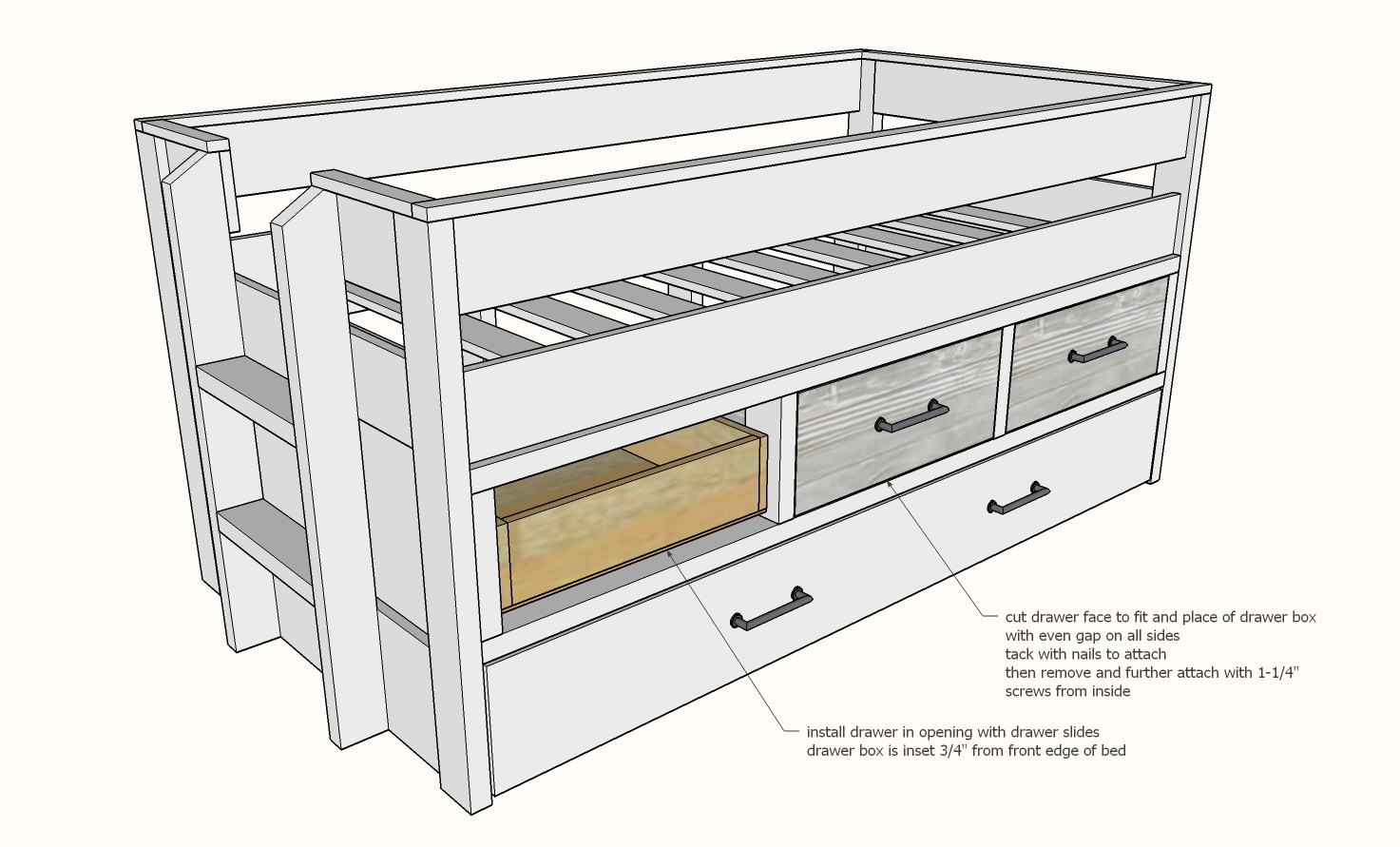

Read instructions with your drawer slides. This drawer tutorial assumes each drawer slide needs 1/2" clearance (1" overall). If you drawer slide differs you will need to adjust your drawer cuts.

Measure drawer openings and confirm the openings are 23" wide. If not, you will need to adjust the drawer width.

Build drawer boxes.

We recommend pocket holes on the outside (will be covered in later steps by drawer face)

Check drawers for square.

Glue and nail the plywood bottom to the drawer boxes.

Step 15

Install drawers inside the openings with drawer slides. INSET 3/4" from front edge of 2x4s to allow for the drawer face.

Cut drawer faces 1/4" smaller than opening.

Place drawer face over installed drawers.

Attach with a couple of 1-1/4" nails (avoid areas where knobs or pulls will be installed)

Remove the drawers and attach from inside with 1-1/4" screws (you can use pocket hole screws)

Comments

Blawson

Mon, 09/02/2019 - 18:54

Love this bed! Would love…

Love this bed! Would love to make for my son but he has a full size. How would I alter your plans to accommodate the full size bed?

klvno

Tue, 09/24/2019 - 19:59

Full Size Modification?

I also love this bed but need a full size bed...other than the size, it is perfect in every other aspect. I would love it if someone could tell me how to modify the plans for a full.

JDT227

Thu, 03/19/2020 - 20:25

Trundle mattress size

Hi Anna, why wouldn't a standard mattress fit as the trundle as well?

In reply to Trundle mattress size by JDT227

mvgreen3

Mon, 04/27/2020 - 18:01

I'm just finishing one of…

I'm just finishing one of these. The standard mattress I bought is a bit to long for the trundle, which slides under the main bed and is therefore shorter. The one she refers to is surprisingly comfortable but fits perfectly. I'd imagine you could make the entire bed a few inches longer and and use a standard mattress.

LouisF87

Mon, 09/21/2020 - 22:44

6 Drawers instead of 3

Just wondering if instead of the trundle bed if I could put 3 drawers with the same dimensions as the other 3.

Annegoldstein

Fri, 10/30/2020 - 12:13

Did you end up making this…

Did you end up making this with 6 instead of 3? Would love to see.

Webbuzzard

Tue, 08/17/2021 - 05:52

Drawer question

I love the design. Is there a way to prevent the drawers from opening when the trundle is out? I see a potential safety issue.

pemp

Sun, 03/27/2022 - 14:22

A couple of typos I spotted…

A couple of typos I spotted...

The shopping list does not include enough boards for the drawer boxes. To make them with 1x6s as in the plans, a today of 7 1x6 @ 10 feet are needed.

The drawer fronts/backs are 22" on the cutlist. They should be 20.5"