Simple to build end table or side table with a modern flair! Free DIY plans by ana-white.com

Pin for Later!

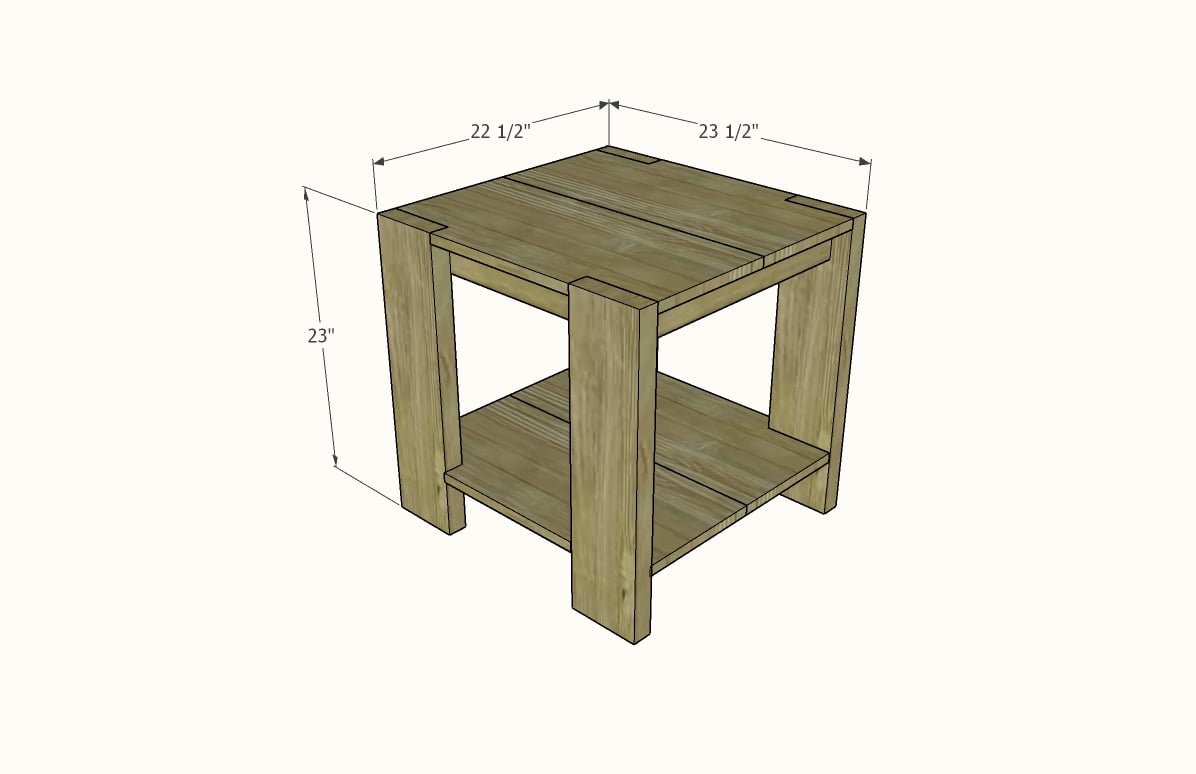

Dimensions

Dimensions shown in diagram, about 2 foot cube shape.

Preparation

Shopping List

- 1 - 1x12 @ 8 feet long

- 1 - 2x6 @ 8 feet long

- 1 - 1x3 @ 8 feet long

- 2 - 1x2 @ 8 feet long

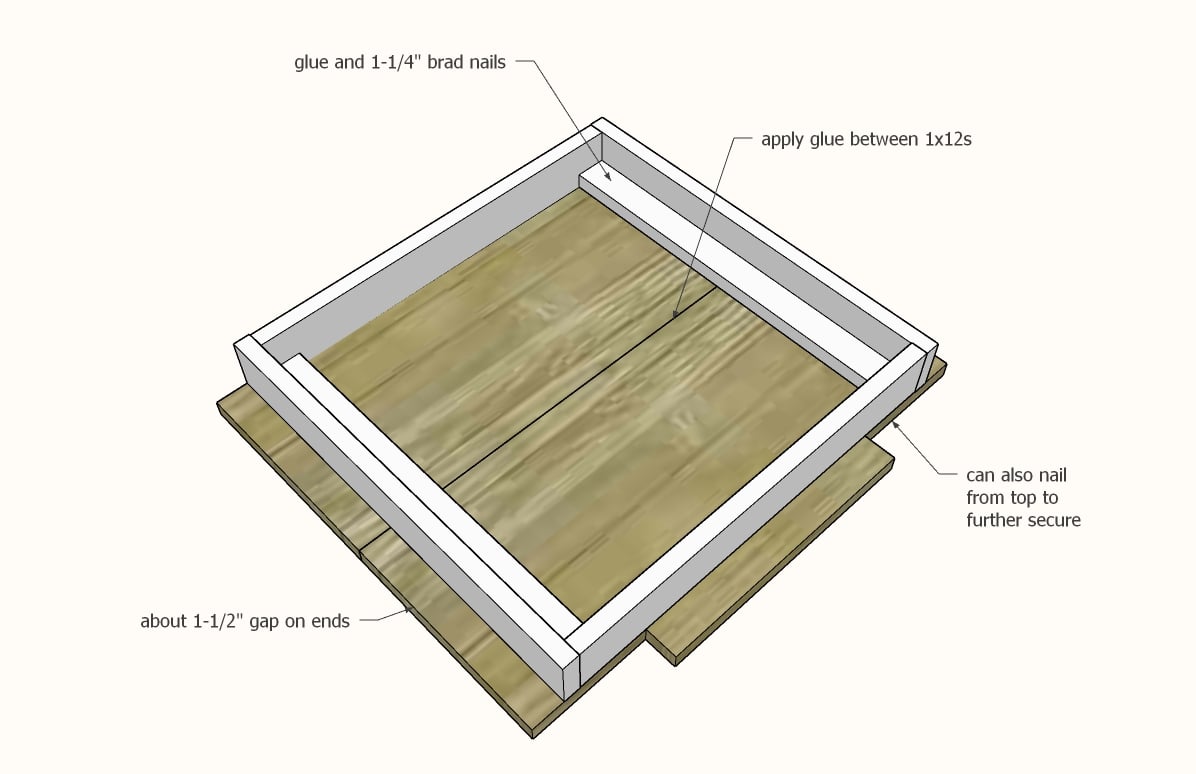

- 1-1/4" brad nails

- 16 - 2" long self tapping wood screws with star bit (SPAX or similar)

- wood glue

- 120 and 150 grit sand paper

- paint or stain

Cut List

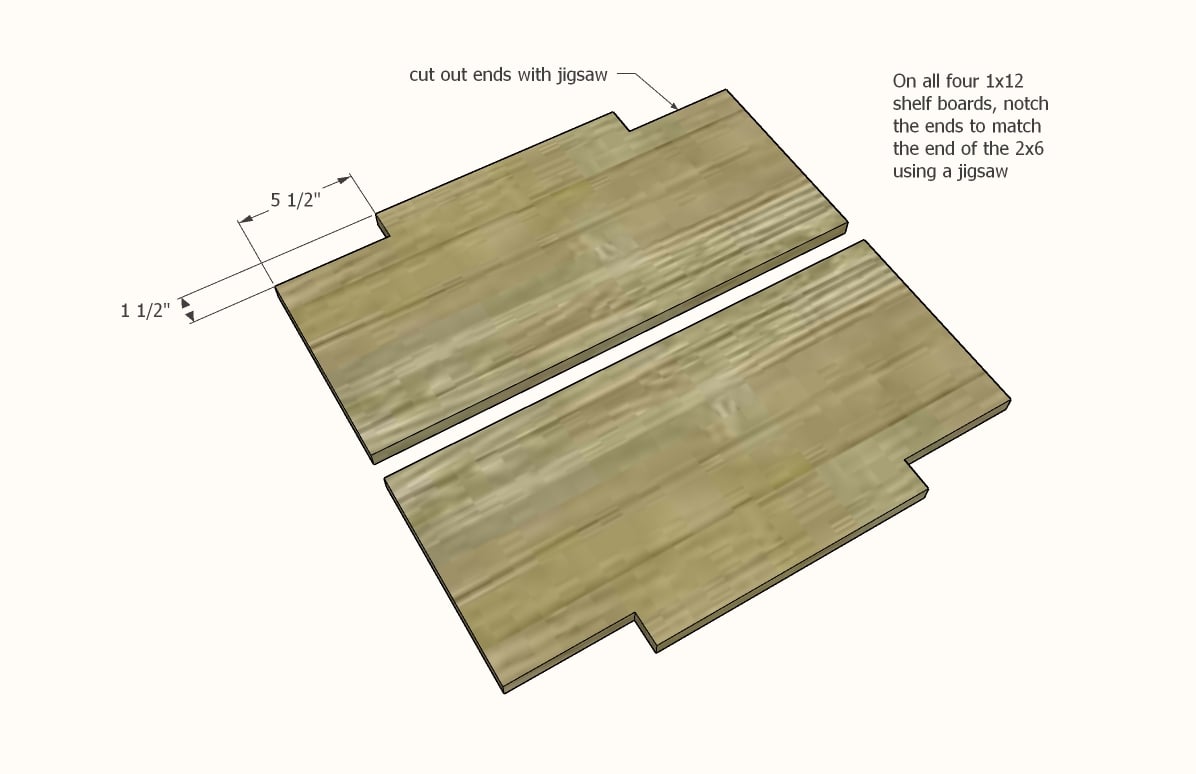

- 4 - 1x12 @ 23-1/2" - shelf boards

- 4 - 2x6 @ 23" - legs

Top Shelf Frame

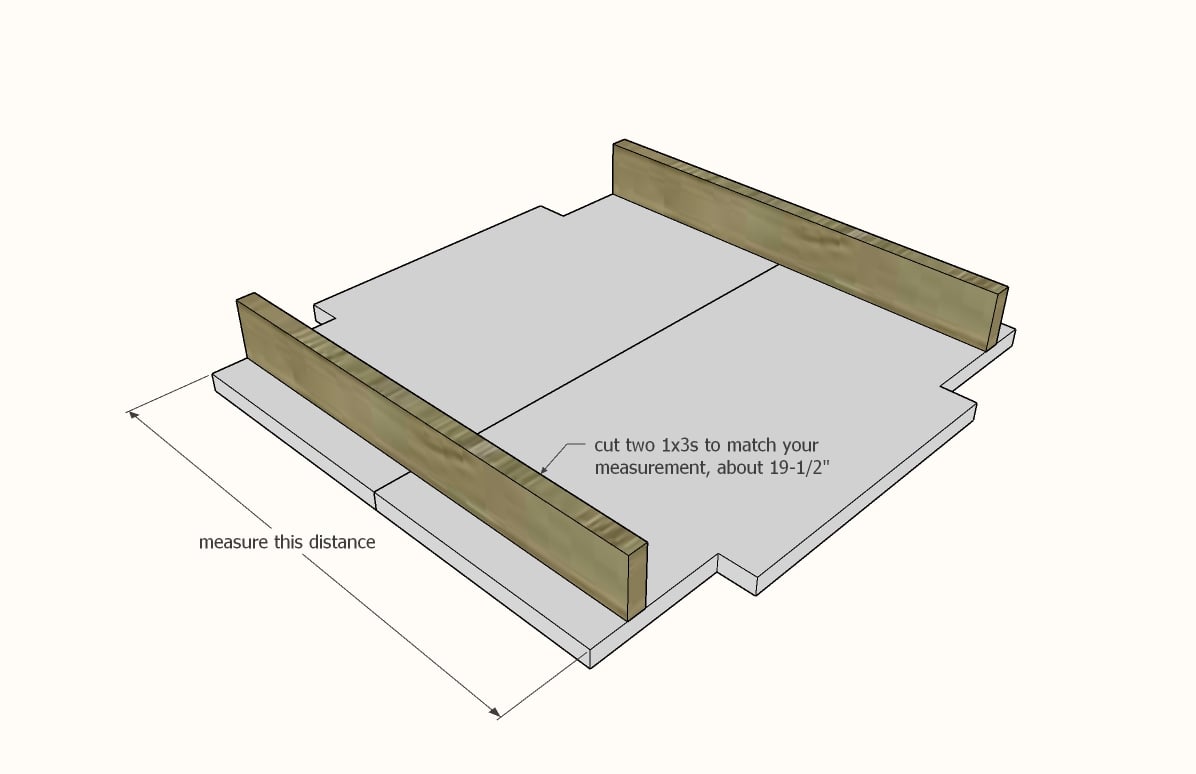

- 2 - 1x3 @ about 19-1/2" - measure and cut to fit

- 2 - 1x3 @ 19"

- 2 - 1x2 @ about 18" - measure and cut to fit

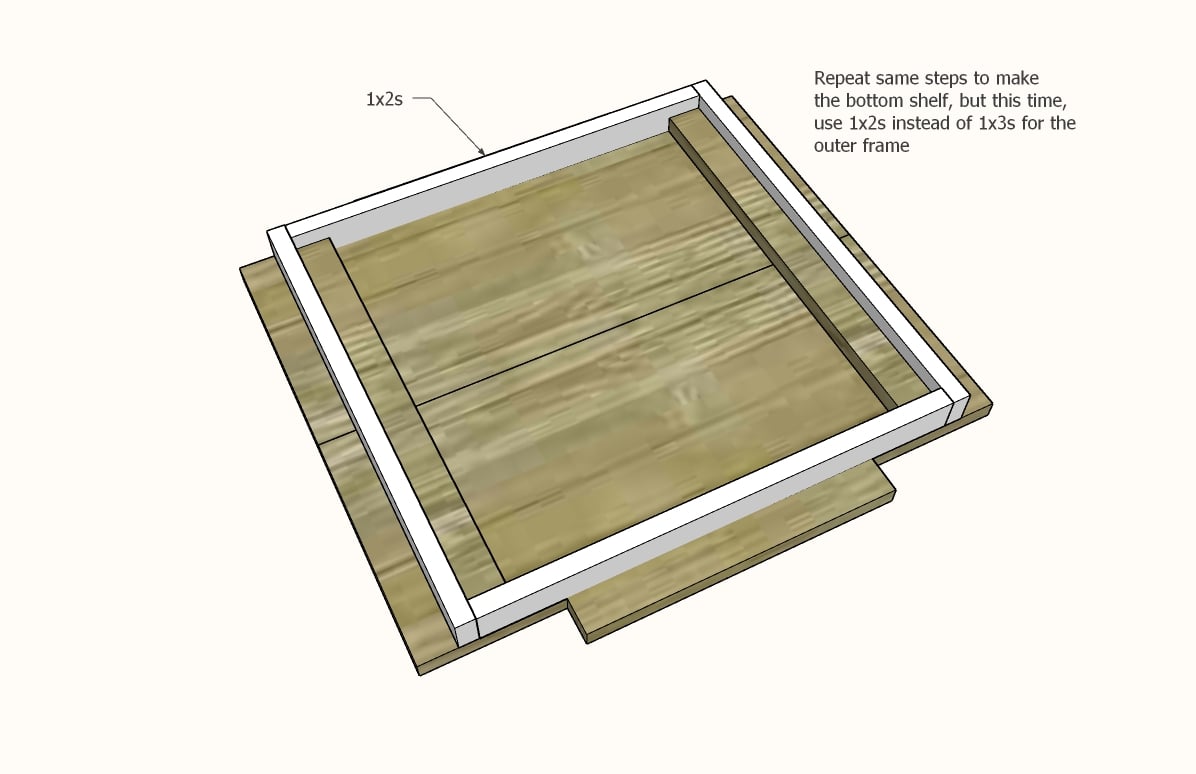

Bottom Shelf Frame

- 2 - 1x2 @ about 19-1/2" - measure and cut to fit

- 2 - 1x2 @ 19"

- 2 - 1x2 @ about 18" - measure and cut to fit

Instructions

Step 1

Step 2

Step 3

Step 4

Step 5

Step 7

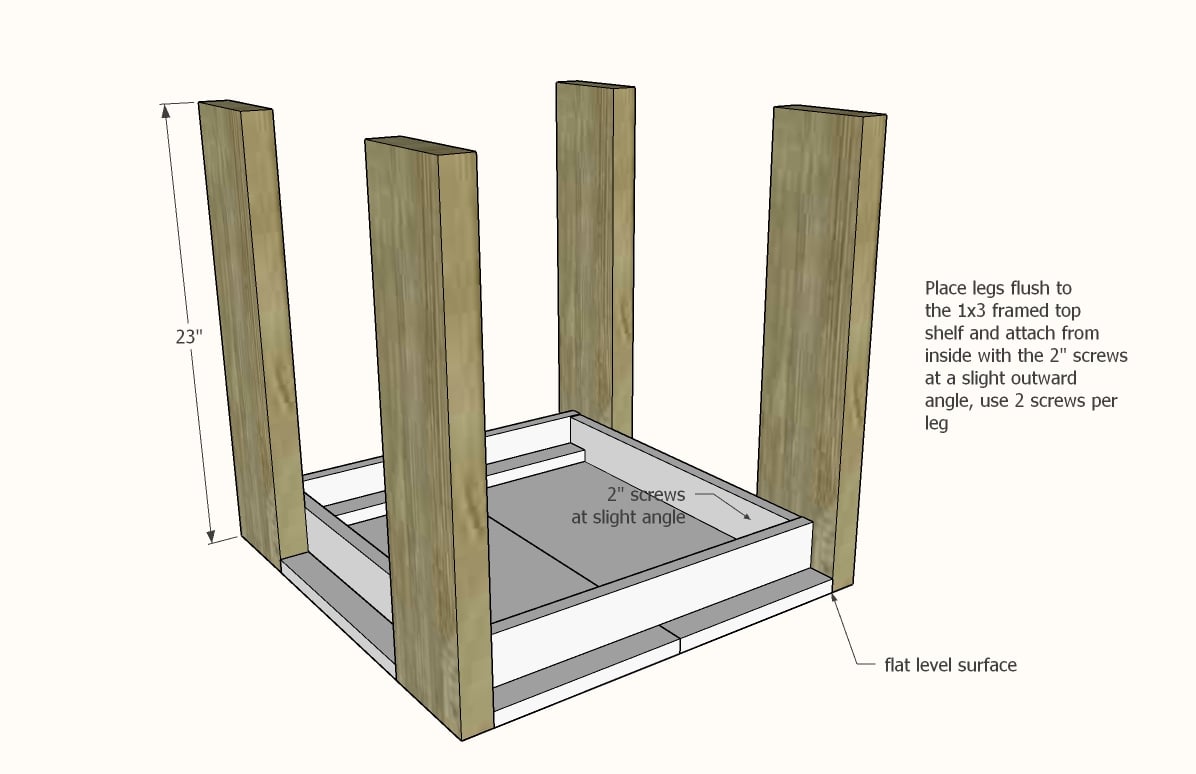

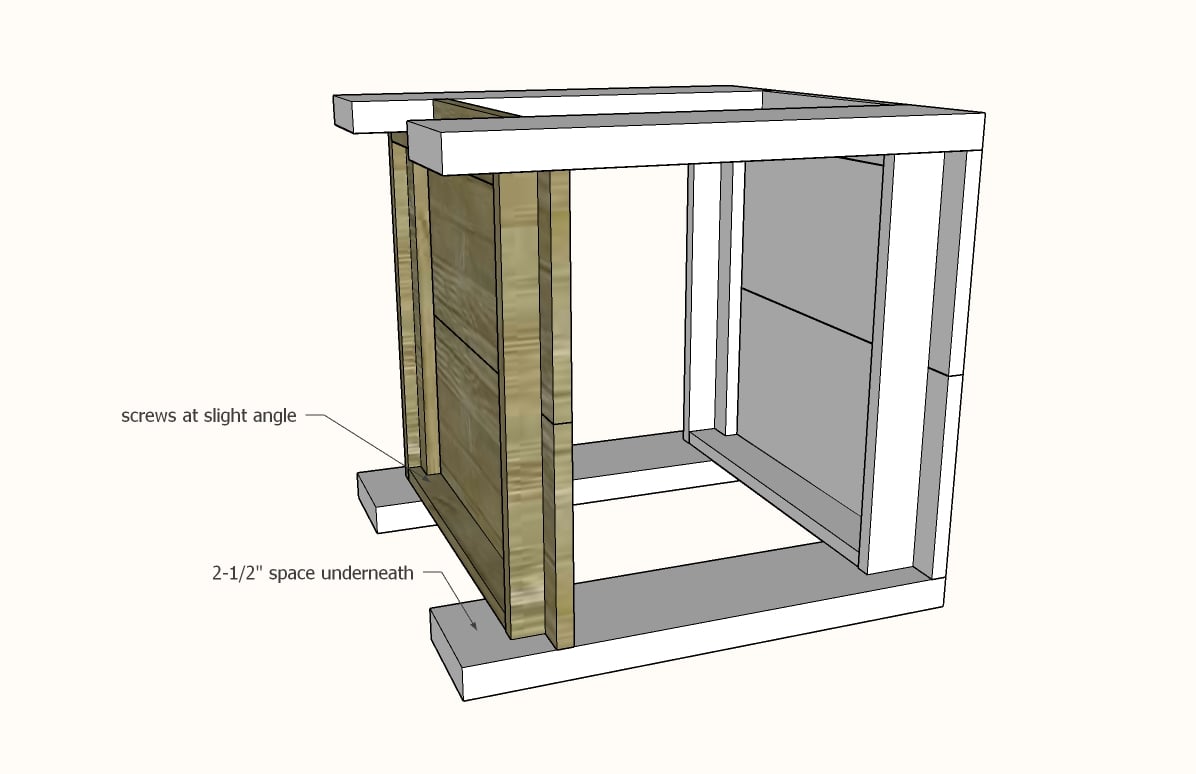

Place the top shelf (1x3 frame) face down on a flat level surface.

Attach from inside with 2" screws at a slight angle.

TIP: I only did one screw at first per leg, so that I could maneuver the legs somewhat while fitting the shelf in. After I was happy with the bottom shelf and the table sitting square, I then added the second screws.

Finishing Instructions

Preparation Instructions

Finishing is very important to the overall completed look.

Sand with 120 grit sandpaper, working in the direction of the grain.

If staining, follow with 150 grit sandpaper.

Remove sanding residue with a vaccuum and soft bristled brush attachment.

Wipe with a damp cloth and let dry.

Apply paint or stain according to manufacturer's directions.

Sand with 120 grit sandpaper, working in the direction of the grain.

If staining, follow with 150 grit sandpaper.

Remove sanding residue with a vaccuum and soft bristled brush attachment.

Wipe with a damp cloth and let dry.

Apply paint or stain according to manufacturer's directions.

Finish Used

I used Varathane Sunbleached with a clear poly top coat

Room