Free woodworking plans to build a large contemporary style bookcase for a modern home office. Featuring step by step diagrams, cut list and shopping list, these beginning do it yourself furniture plans are designed for anyone to build with simple tools and off the shelf materials.

Special thanks to Columbia Forest Products and their beautiful Formaldahyde Free PureBond Plywood for supplying the wood for this project.

Preparation

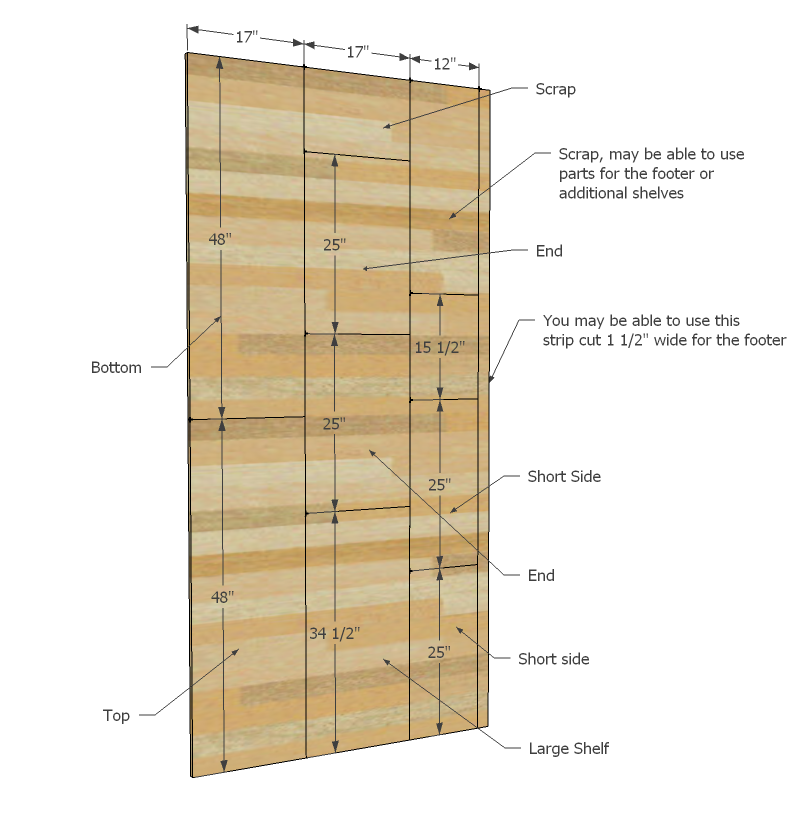

1 - Sheet 3/4" PureBond Hardwood Plywood (available at The Home Depot)

2 - 1x17 @ 48" (Top/Bottom)

1 - 1x17 @ 34 1/2" (Shelf)

2 - 1x17 @ 25" (Ends)

2 - 1x12 @ 25" (Small Bookshelf Sides)

1 - 1x12 @ 12" (Small Bookshelf Shelf)

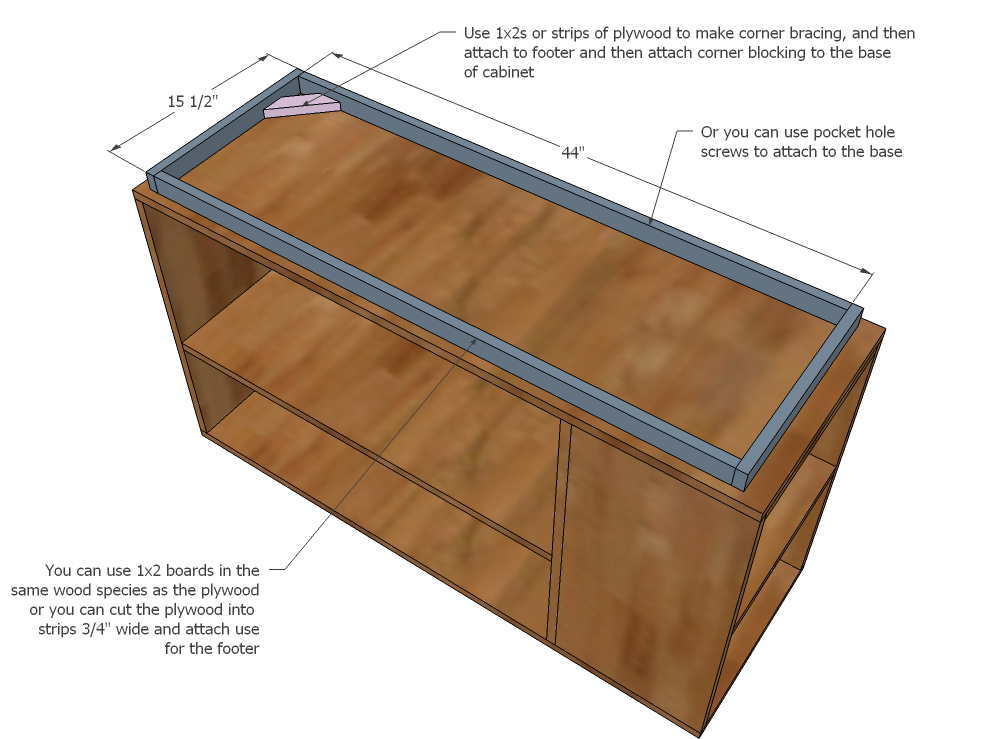

2 - 1x2 @ 45"

2 - 1x2 @ 15 1/2"

Please read through the entire plan and all comments before beginning this project. It is also advisable to review the Getting Started Section. Take all necessary precautions to build safely and smartly. Work on a clean level surface, free of imperfections or debris. Always use straight boards. Check for square after each step. Always predrill holes before attaching with screws. Use glue with finish nails for a stronger hold. Wipe excess glue off bare wood for stained projects, as dried glue will not take stain. Be safe, have fun, and ask for help if you need it. Good luck!

Instructions

Step 1

As mentioned with the Open Bookshelf Base it is important to cut your plywood square and with the grain of the plywood, also taking into account how a circular saw works, and the easiest method to cut. Have your Home Depot cut the plywood into 3 strips, 17" wide, and one strip 12" wide. Save the scrap strip - you may be able to use it for the footer if it's square and 1 1/2" wide. Once your strips are cut, you can use them like boards - I will refer to the strips as 1x17 and 1x12, although the strips are not true 1xs.

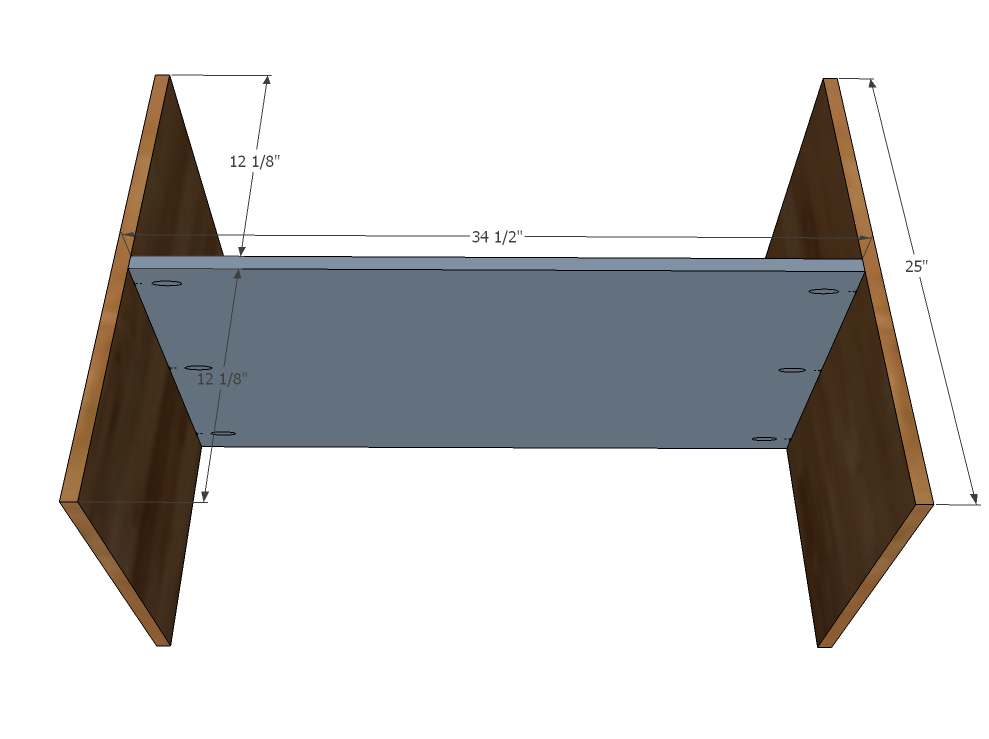

Step 2

I've included in the diagrams pocket holes for Kreg Jig users. For those of you without, you can countersink 2" screws from the outside for joints with glue. Attach shelf to ends as shown above.

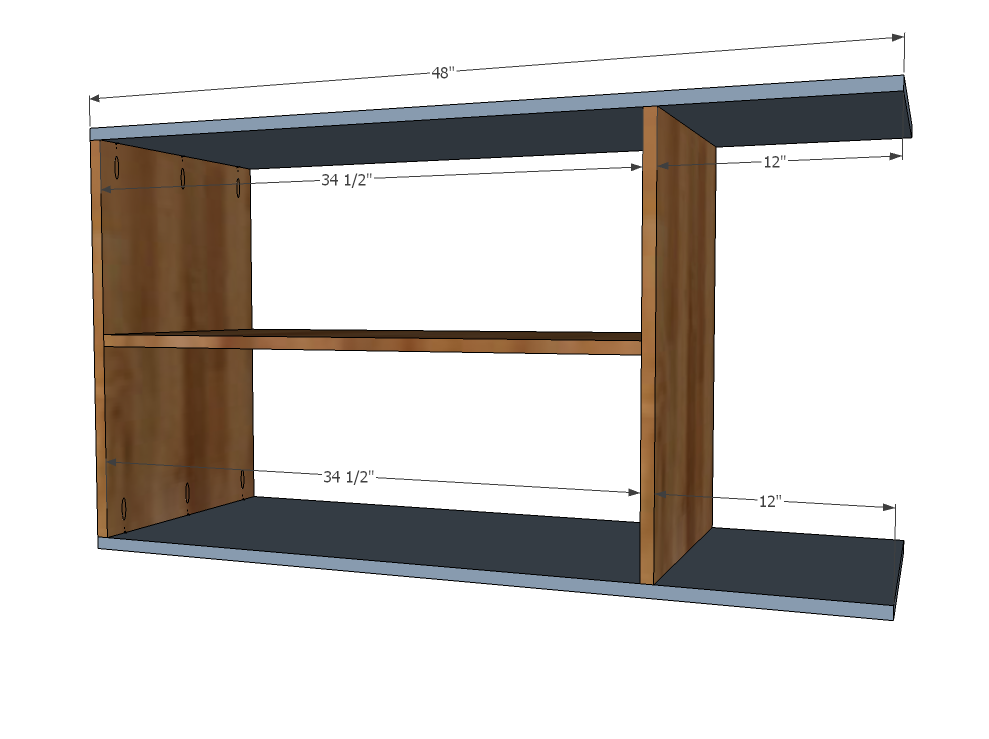

Step 6

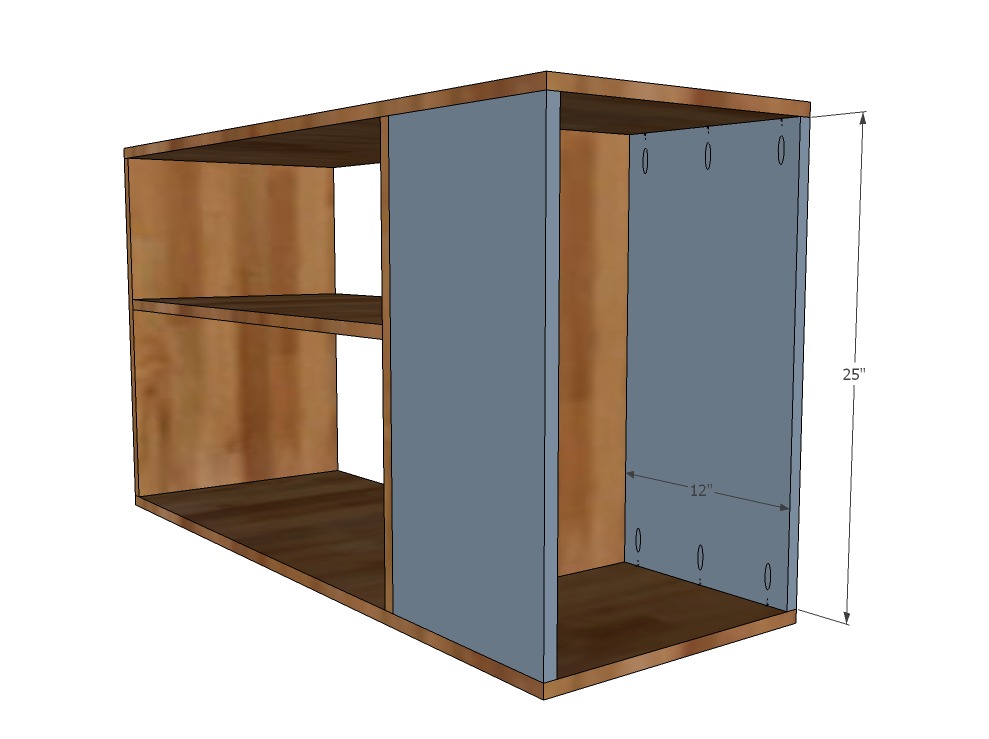

Step 7

Apply edge banding to all exposed plywood edges as recommended by the manufacturer. The edge banding we used was iron on, and it's very simple to do. We trimmed the excess off with a utility knife and then sanded outside corners for a smooth joint. Results? You can't tell what's the original plywood and what we ironed on!

It is always recommended to apply a test coat on a hidden area or scrap piece to ensure color evenness and adhesion. Use primer or wood conditioner as needed.

Comments

Erica Havey (not verified)

Thu, 06/30/2011 - 14:16

How much did this cost you

How much did this cost you Ana? Or maybe how much did the whole desk cost if you don't know each individual piece?

Ana White

Thu, 06/30/2011 - 14:25

Cost of Eco Office

Hi Erica, for the entire office with desktop (so one bookshelf base, one double bookshelf "fence", and one drawer/file base (plans not yet published and desktop) requires about 3 sheets of plywood. I used PureBond, which runs in the neighborhood of $50 a sheet. Add in varnish, drawer slides, 1x2s (if you used them and not plywood) and hardware, we estimate the entire office to be in the $200 range. That's a steal, considering it's made of hardwood 3/4" plywood, and the plywood is uses soy based glue and is formaldehyde free.

Hunter (not verified)

Mon, 07/04/2011 - 17:38

I am so excited to build this

I am so excited to build this for my office! Do you know when you will be posting the drawer/file base plans?

Beth Mosier (not verified)

Thu, 06/30/2011 - 16:54

Desk

I love this. I am trying to make a table/desk for my sewing machine. This is great for this end. What plans would be best for making the other end for a single desk?

Beth

Pam the Goatherd

Fri, 07/01/2011 - 11:04

I have been trying to adapt

I have been trying to adapt one of your other plans to build this very thing as my media console! I'm glad now that I waited to build it until I finished a couple other projects first. I'm going to make it 24" deep instead of the 17" so it will hold our clunky old-fashioned tv which we use for watching DVDs and ancient VHS videos. The bookcase end will hold my husband's "to go" stuff that he takes out of his pockets when he gets home after work as well as his briefcase. I'm also planning on adding at least one more shelf to each section so we can store all our CDS/DVDs/VHS right under the tv and will also use a shelf as a charging station where we will have ALL of our battery, phone, etc. chargers in one place. I can't wait to get it built and get things organized. Heading to Big Blue next week to buy the wood.

DonDeHogar (not verified)

Fri, 07/01/2011 - 13:19

Thanks!

Loved the quote: Work smarter not harder.

There's a gift award for you at my blog: http://dondehogar.blogspot.com/2011/07/mimos-para-el-alma.html It's my humble way of saying thank you for your example, your hard work and for helping us all make our own furniture.

tootspyrus

Fri, 07/01/2011 - 17:29

Marvellous

That is beautiful ! I was trying to draw some plan to make my own working desk at home, but honesty, you rock ! That's what is going to be in my computer room ! Thank you so much

angiemicn

Mon, 07/04/2011 - 02:26

Awesome!

This is AWESOME Ana, thank you so much!