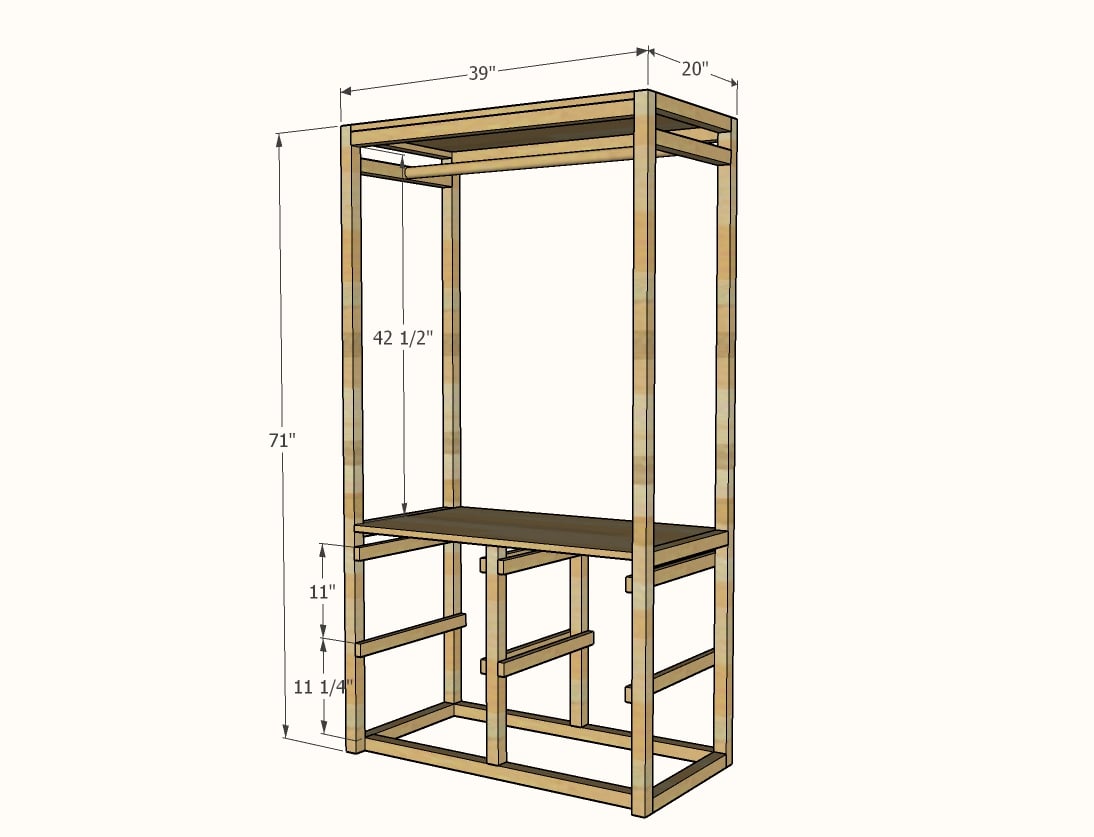

Does your laundry room need some quick organization? For about $75 total, you can make your own laundry sorter towers with hanging rods! Free plans from Ana-White.com

Pin For Later!

Dimensions

Preparation

Shopping List

- 7 - 2x2

- 2 - 1x2

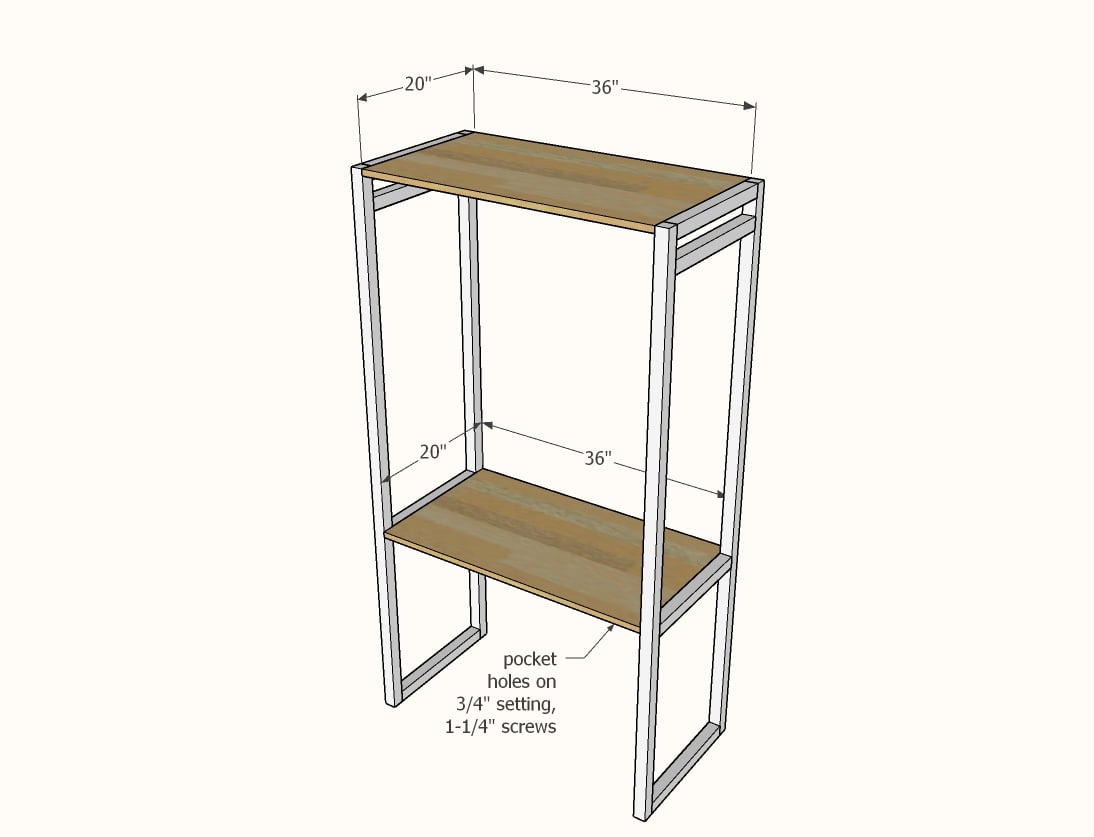

- 2 - project panels 20x36

- 1 - 36" dowel

- 2 - dowel holders

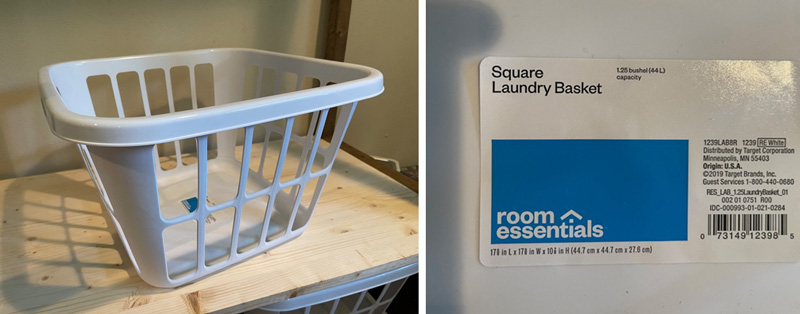

- 4 - Laundry Baskets

Cut List

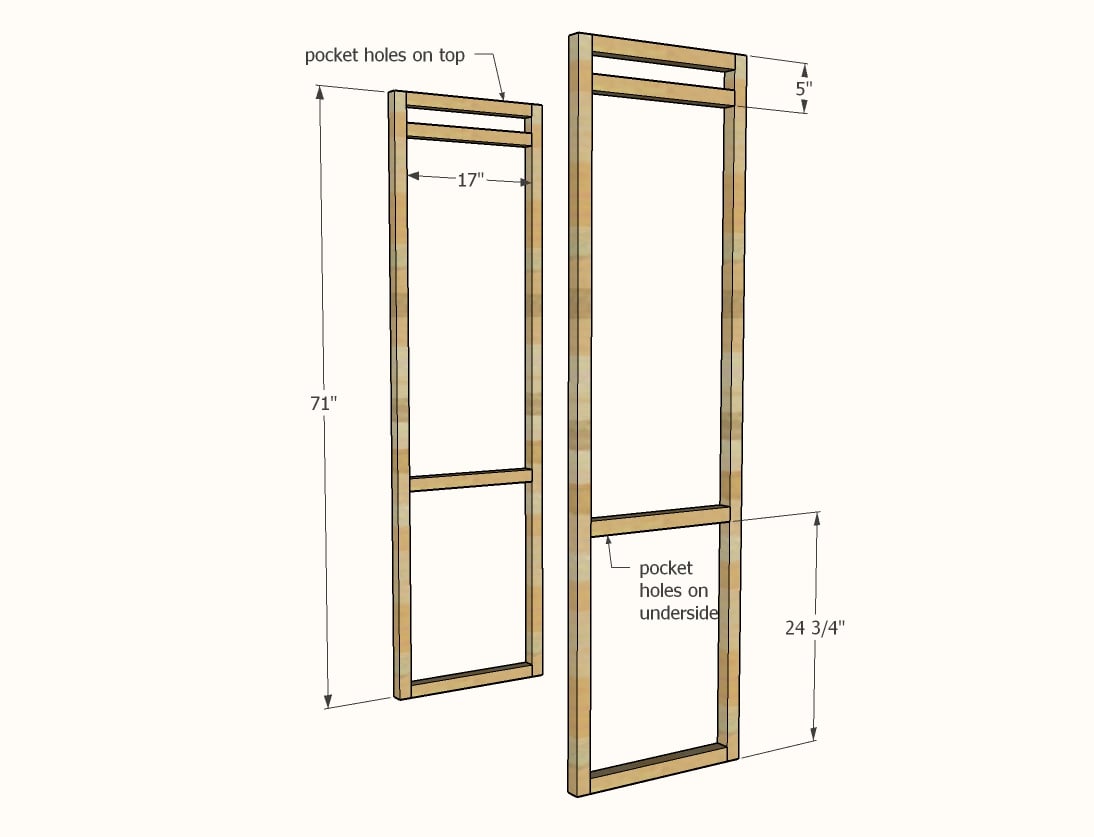

- 2x2 - 4 @71"Legs for ladder

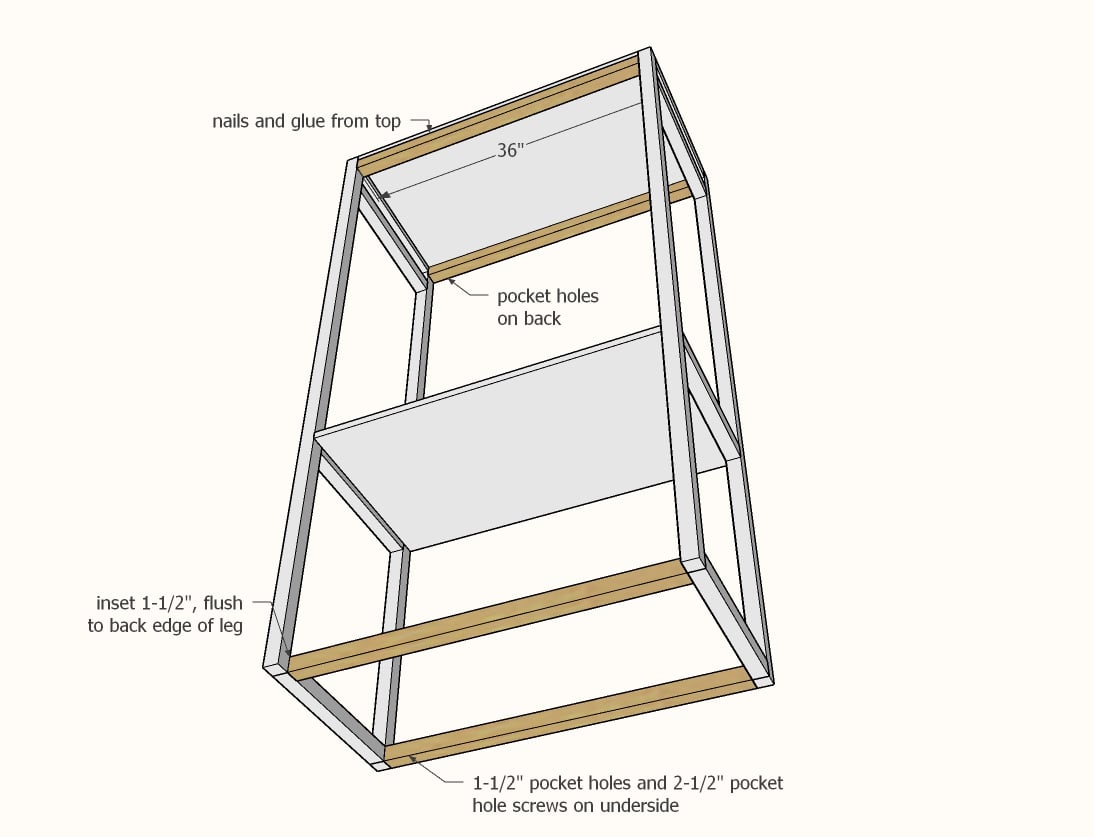

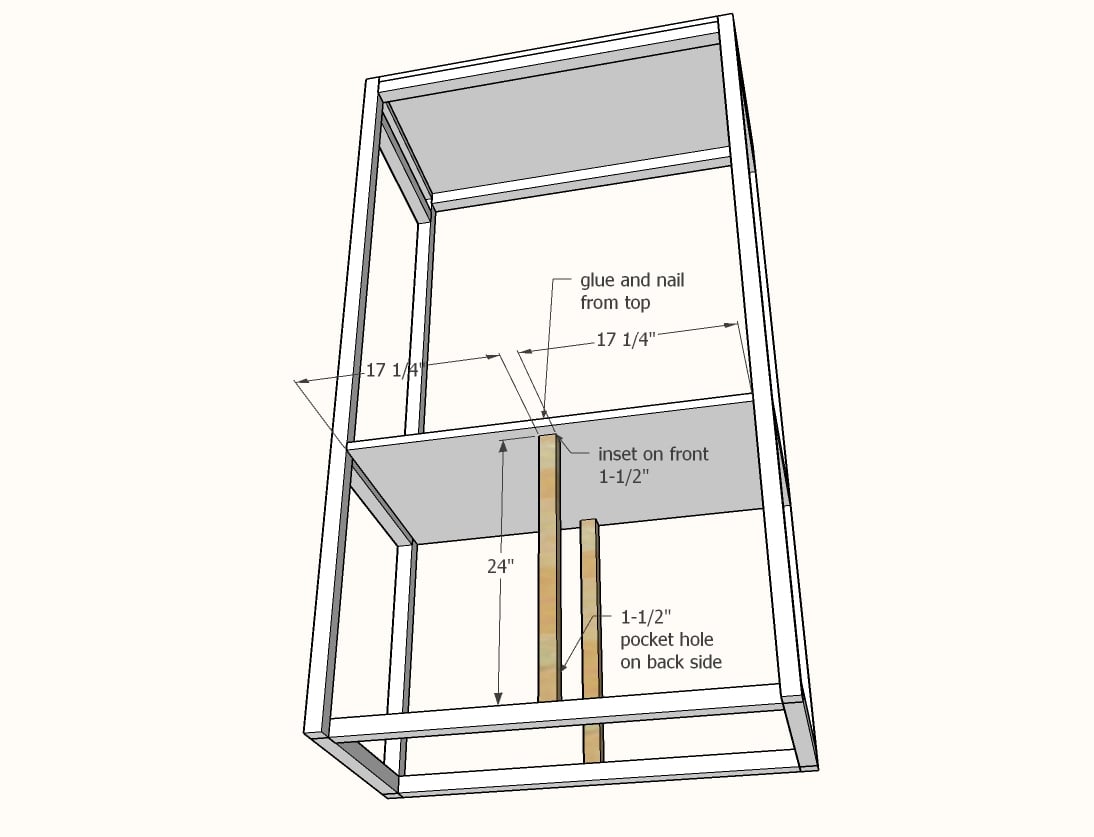

- 2x2 - 3@ 36" Bottom and back Supports

- 2x2 - 8@17" All side ladder supports

- 2x2 - 2@24" Front and back support of laundry basket section (I cut to fit, because there was a little variance where middle shelf was pocket holed and attached)

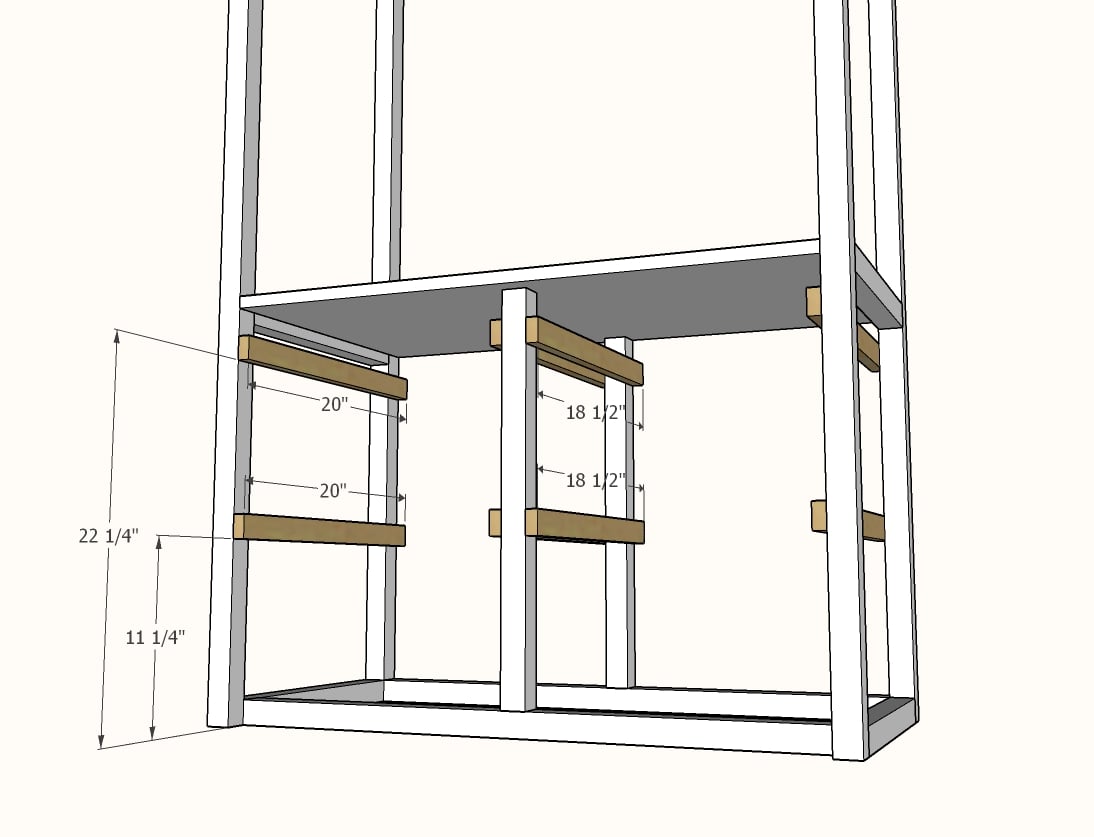

- 1x2 - 4 @20" (outside cleats)

- 1x2 - 4@18-1/2" (inside cleats)

- 3' dowel

- 4 laundry baskets (will need to adjust and preplan for your laundry baskets if different)

- 2 project panels 20"x 36"

General Instructions

This project can be built using either torq screws (star bit self drilling wood construction screws) or with pocket holes. In either case, you will need both 1-1/4" and 2-1/2" lengths.

Instructions

Step 1

Step 2

Step 3

Step 4

Project Type

Room