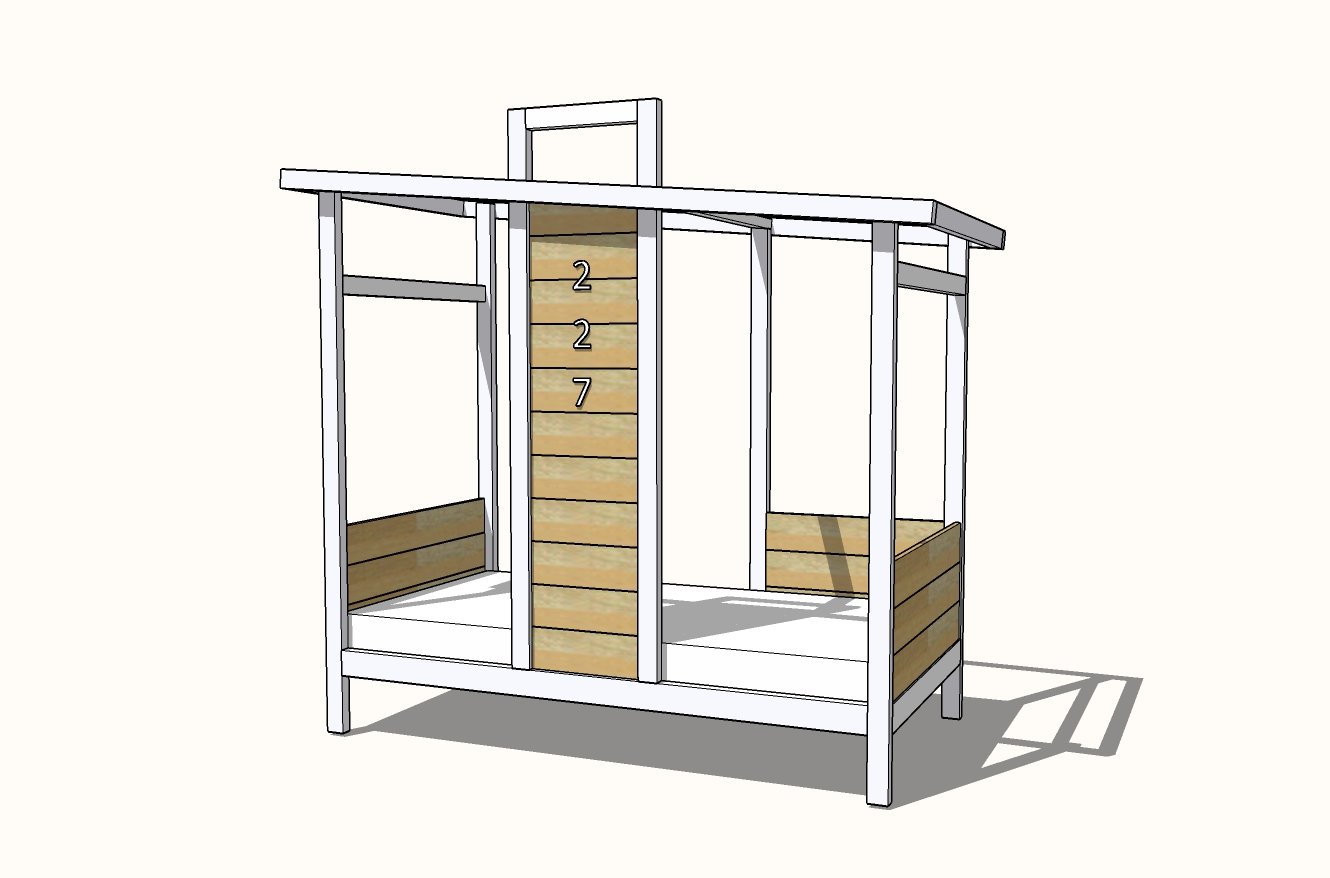

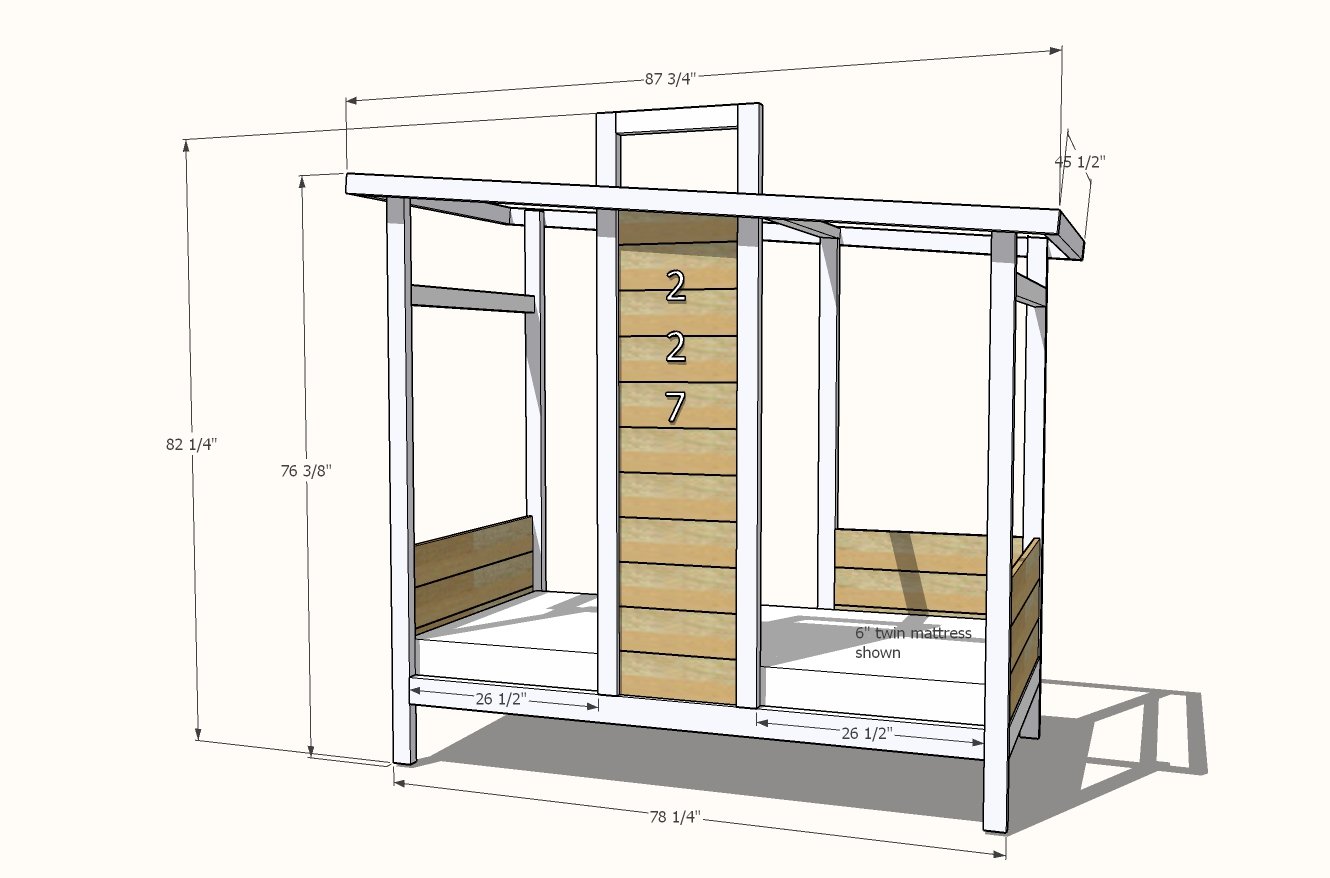

Free plans to build a twin sized house bed frame that is shaped like a modern tiny house! You'll need basic wood building tools and some off the shelf lumber to create this dream kids bed. Plans are for twin sized house bed frame.

Preparation

- 9 - 2x3 @ 8 feet long or stud length, find good straight boards

- 3 - 2x4 @ 8 feet long or stud length

- 2 - 2x2 @ 8 feet long (can be furring strips)

- 6 - 1x4 furring strips @ 8 feet long (for bed slats)

- 6 - 1x6 @ 8 feet long (will be used for the wood panels)

- 2 - 1x3 @ 8 feet long

- 2 - 1x2 @ 8 feet long

- 60 - 2-3/4" self tapping construction screws (can be between 2-1/2" and 3" long, prefer #8 or #9 size)

- 50 - 1-1/4" coarse Kreg Pocket Hole Screws

- 25 - 2-1/2" Kreg Pocket Hole Screws

- 3/8" wood dowel for filling pocket holes, about 3 feet

- 1-1/4" brad nails

- wood glue

- Paint with primer or wood stain

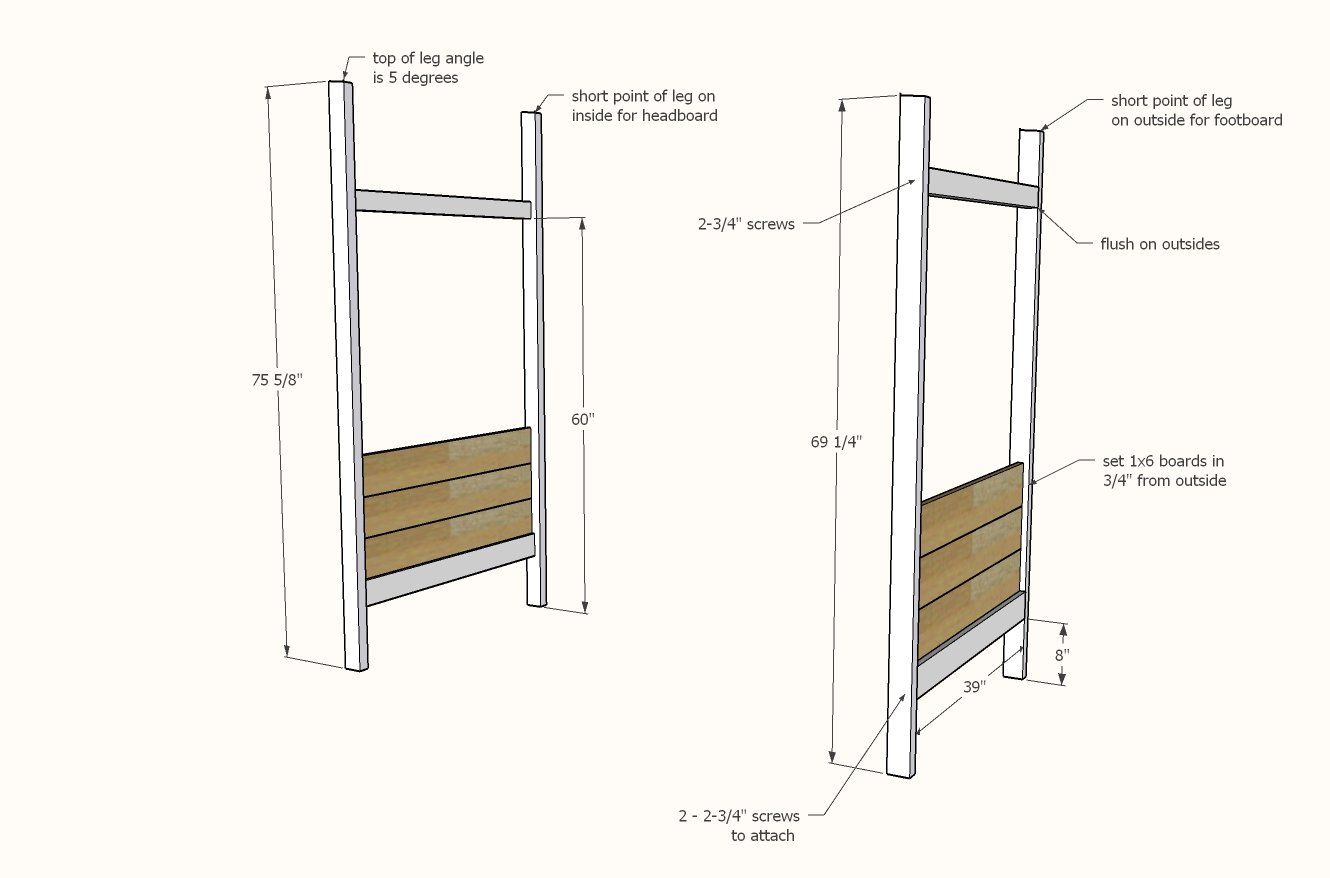

Headboard and Footboard

- 2 - 2x3 @ 75-5/8 - longest point measurement, one end cut at 5 degrees off square

- 2 - 2x3 @ 69-1/4" - longest point measurement, one end cut at 5 degrees off square

- 2 - 2x4 @ 39" - bottom support

- 2 - 2x3 @ 39" - top support

- 6 - 1x6 @ 39" - wood panels

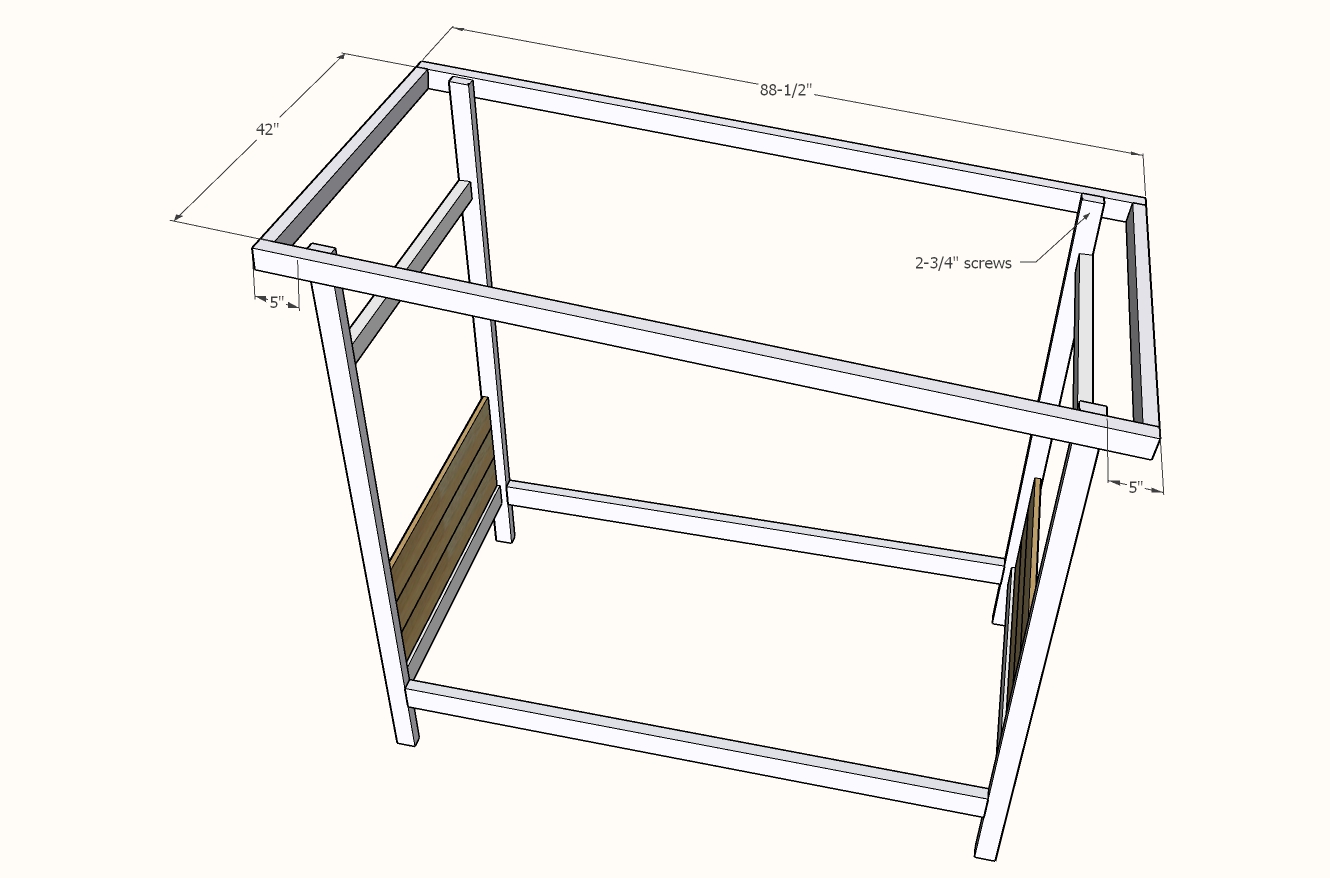

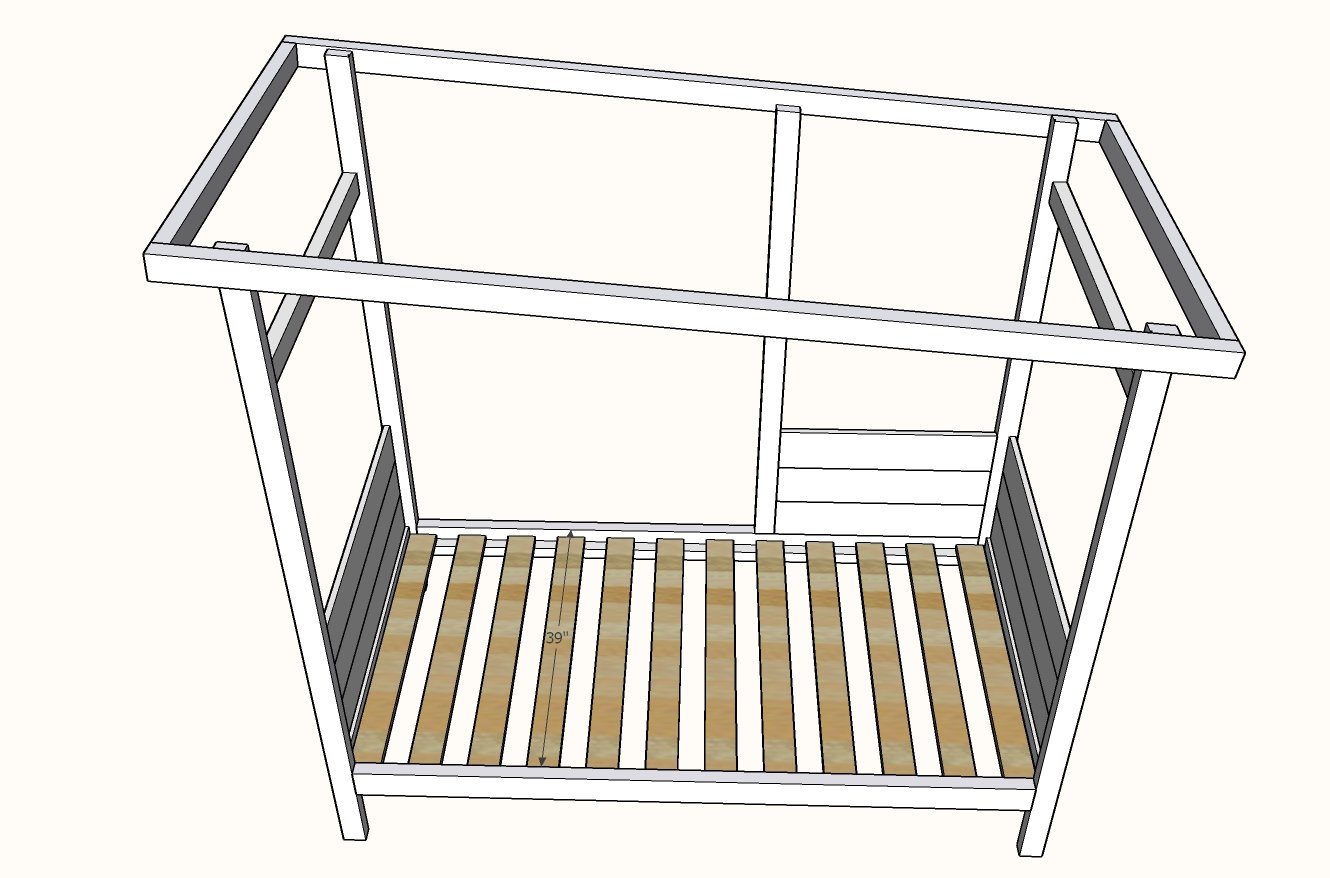

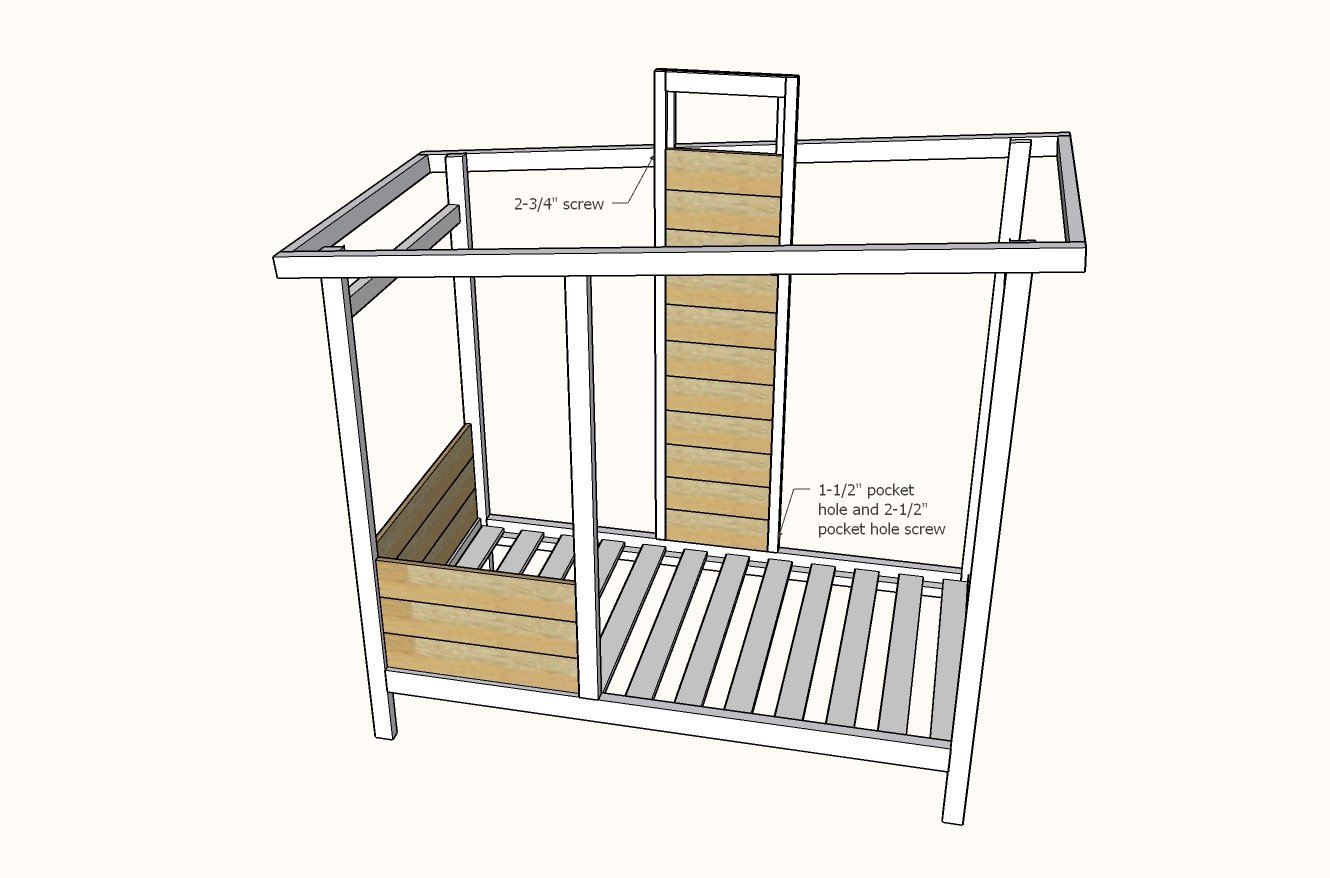

Bed Frame System

- 2 - 2x4 @ 73-1/4" - siderails

- 2 - 2x2 @ 75-1/4" - inside cleats

- 12 - 1x4 @ 39" - bed slats

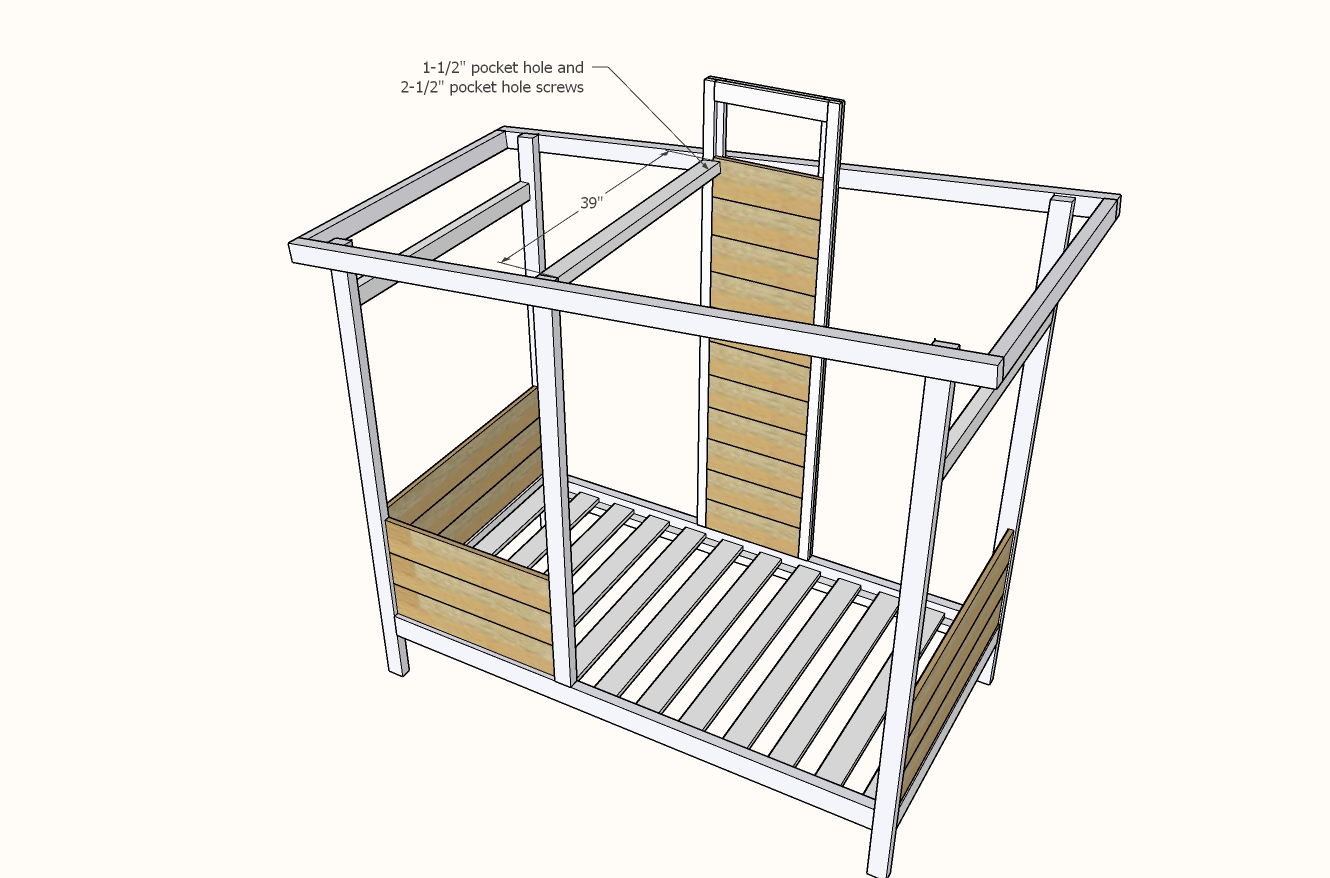

Roof

- 2 - 2x3 @ 88-1/2" - sides

- 2 - 2x3 @ 42" - ends

- 1 - 2x3 @ 39" - center of roof (installed in last step)

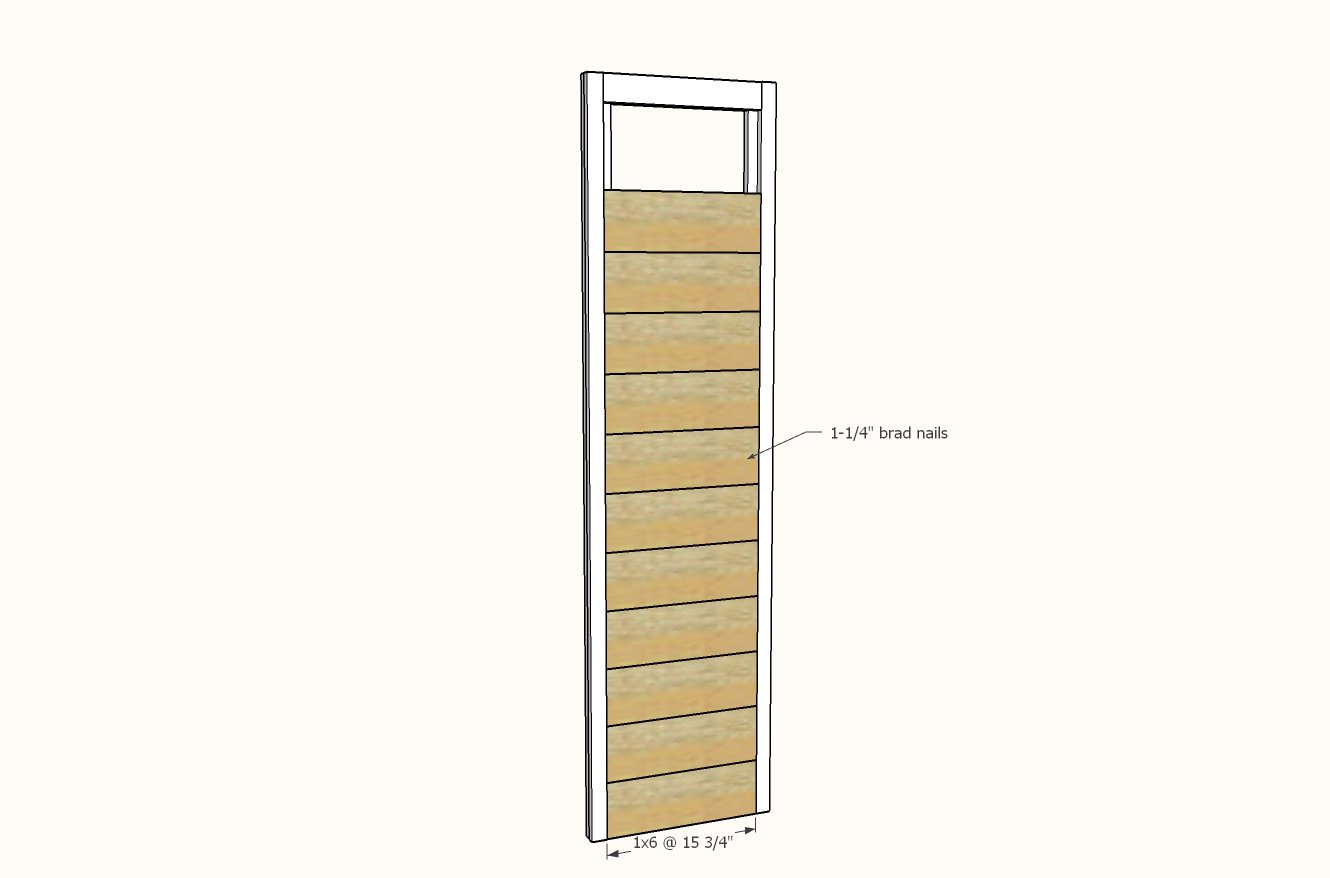

Back Wall

- 1 - 2x3 @ 60" - long point measurement, one end cut at 5 degrees off square

- 3 - 1x6 @ 27-1/4" - back wall panel

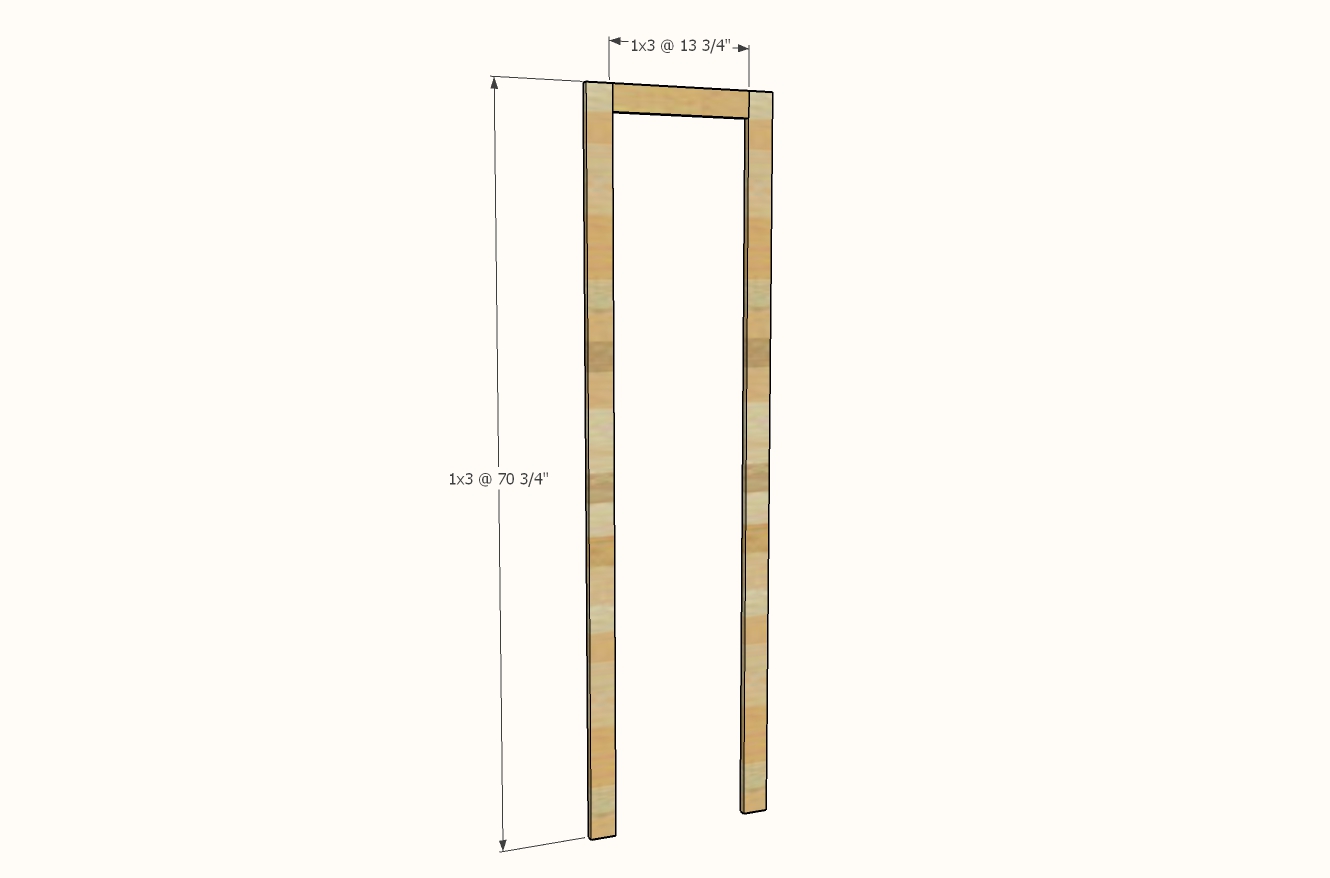

Front Wall

- 2 - 1x3 @ 70-3/4" - front frame

- 1 - 1x3 @ 13-3/4" - front frame

- 2 - 1x2 @ 70-3/4" - back frame

- 1 - 1x3 @ 15-3/4" - back frame

- 11 - 1x6 @ 15-3/4" - front wall panel boards

Instructions

Step 1

Build the frame for the headboard and footboard first using 2-3/4" self tapping construction screws.

Glue and add the 1x6 panel boards with 3/4" pocket holes and 1-1/4" pocket hole screws. I recommend two pocket holes per each end of the 1x6 boards, and one in the center, joining the 1x6 boards together edge to edge.

Insert the 3/8" dowel into the pocket holes and use a flush trim hand saw to cut off the excess to fill the pocket holes.

Paint or stain the headboard and footboard.

Since this bed is too large to fit through a standard doorway, I recommend painting or staining the remaining pieces in portions, and then bringing all the pieces into the room for final assembly.

Step 2

Step 3

Step 4

Drill 1-1/2" pocket holes on straight cut end of back wall 2x3.

Attach to the siderail.

Attach at top with construction screws.

Attach 1x6 wood panel boards in between and fill pocket holes with the wood dowel and cut off excess.

NOTE: For easy disassembly, DO NOT glue the pocket hole plugs so they could be removed