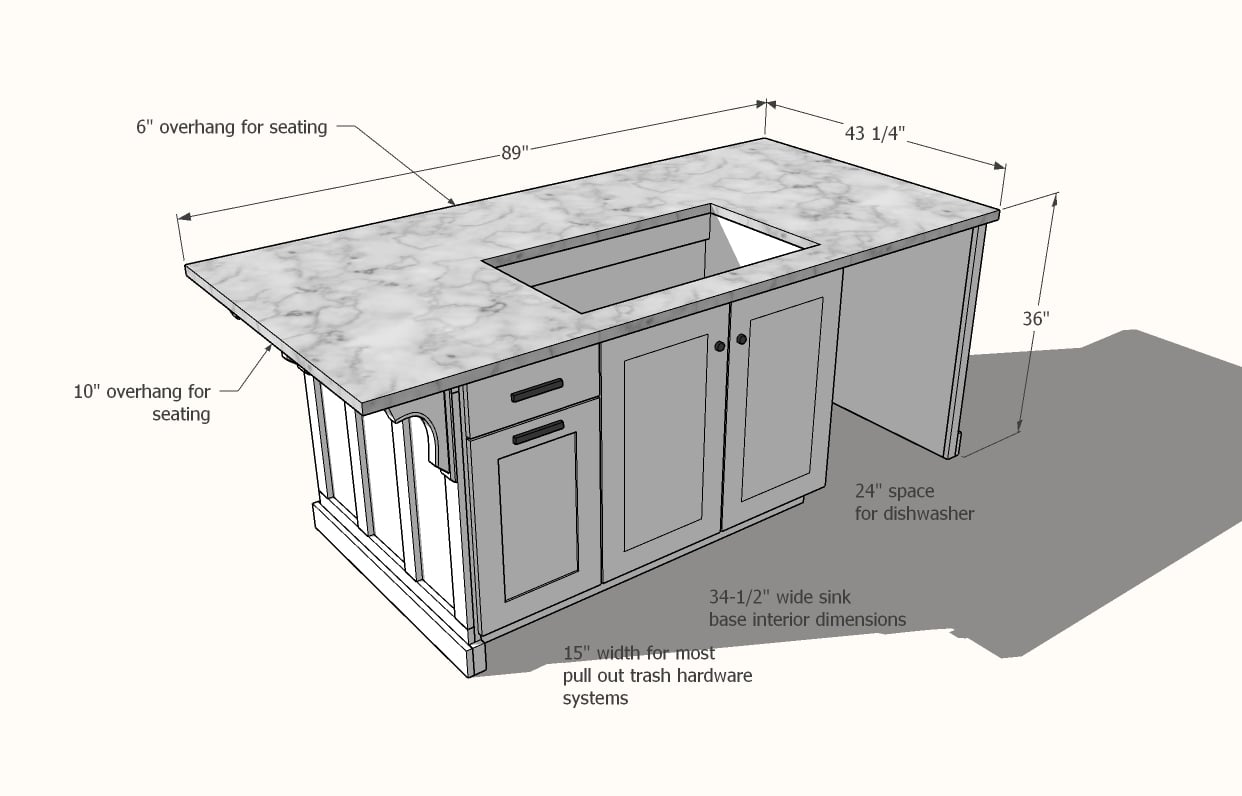

Free plans for building your own kitchen island with sink, dishwasher and open shelving. Space for five stools, seating on two sides. Includes video tutorial. By Ana-White.com

Pin for Later!

Preparation

- 2 Sheets of 3/4" thick hardwood plywood (or use Shelf Help to have plywood precut and edgebanded and shipped to you)

- Edge banding for front exposed edges of plywood

- 1 - 4x8 sheet of 1/2" hardwood plywood

- 5 - 1x2x8' trim boards

- 2 - 1x6x8' trim boards

- 1 - 1x3x10' trim board

- 3 - 1x4x8' trim boards for drawers and baseboard

- 6 - 1x3x8' furring strips or similar for bay supports

- 1 set of 20" full extension drawer slides

- 1 - double trash pull out with max width of 15"

- 2 sets of Concealed Hinges, Frameless Half Overlay

- 2 - 9" x 12" corbels

- 1-1/4" pocket hole screws (About 120, coarse thread recommended)

- 1-1/4" brad nails and wood glue

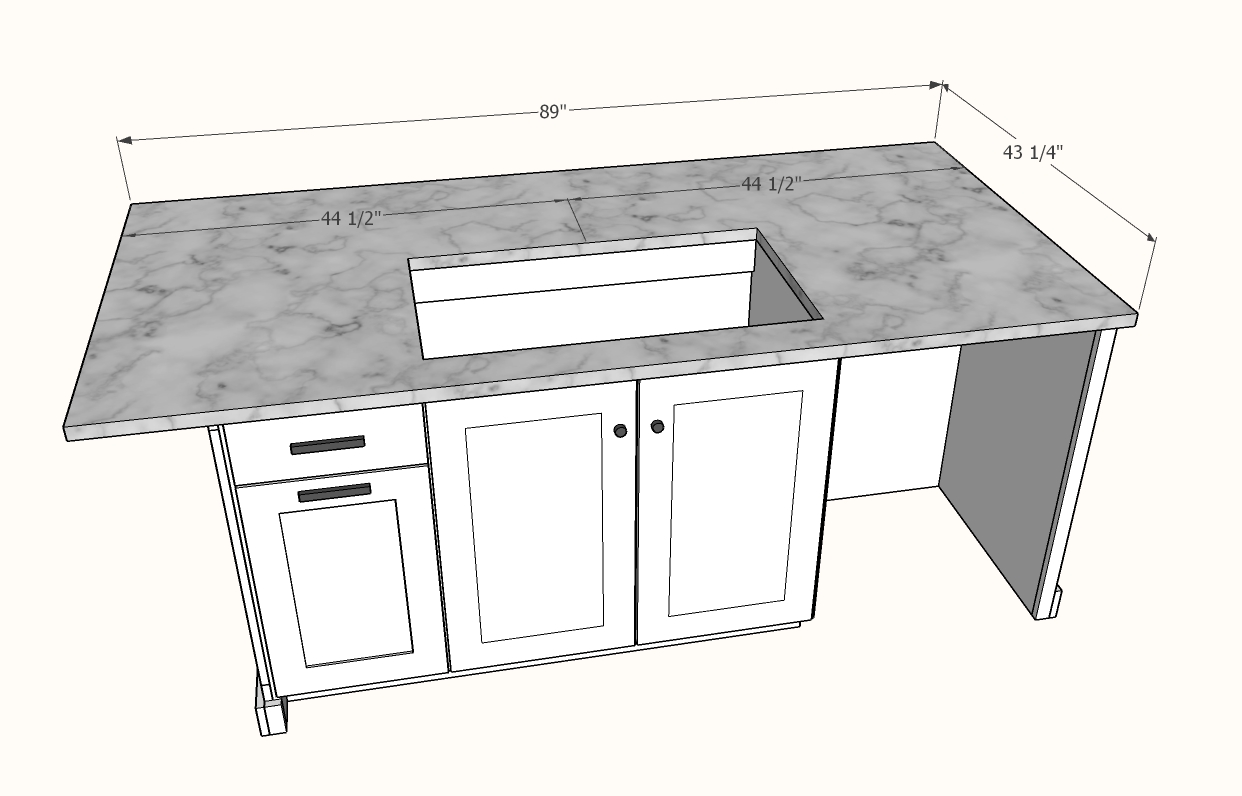

- Countertop sourced seperately

- Door sizes shown in cut list and diagrams

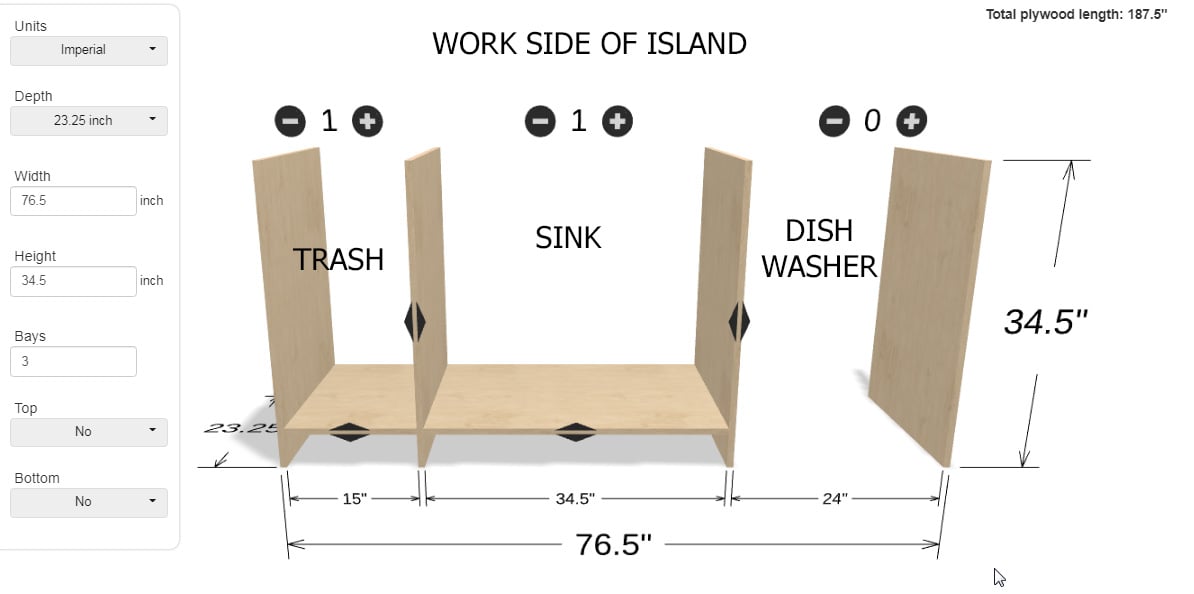

Plywood Carcass Pieces - front edges should be edge banded

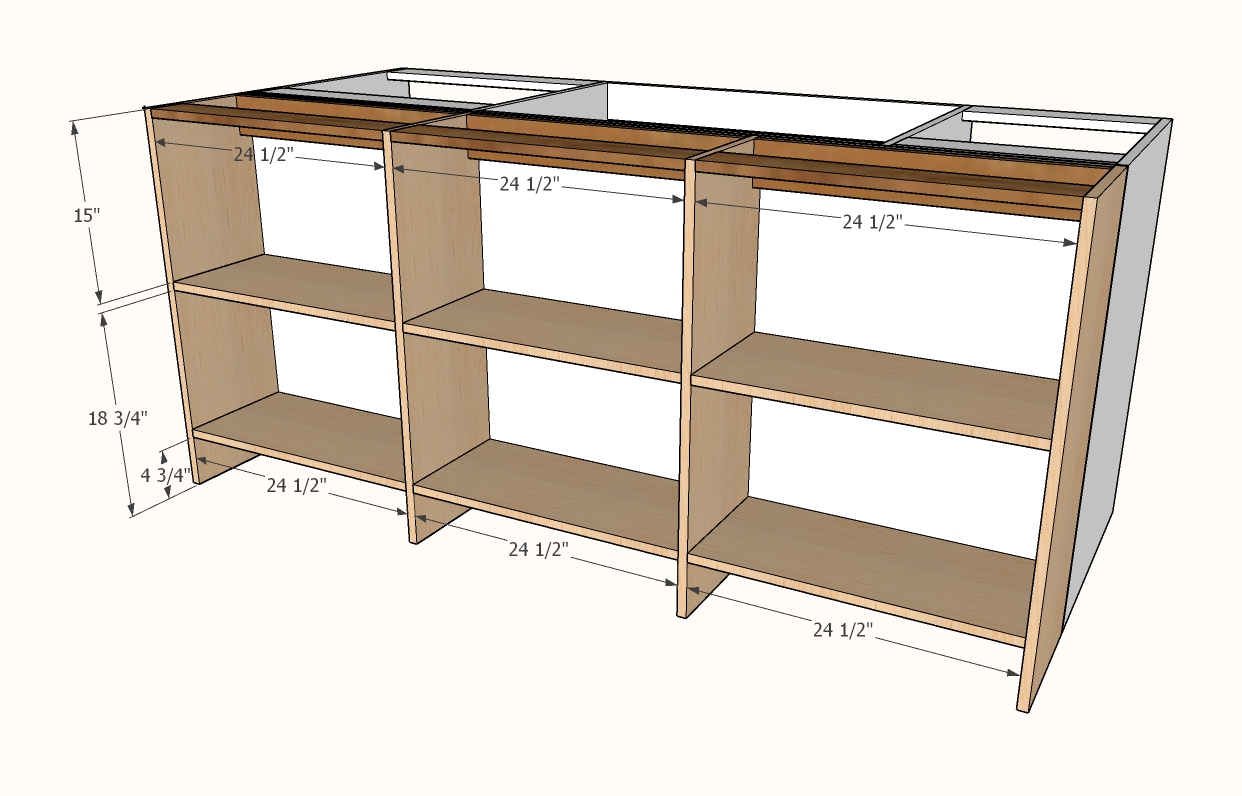

- 5 - 3/4" plywood @ 23-1/4" x 34-1/2"

- 1 - 3/4" plywood @ 23-1/4" x 15"

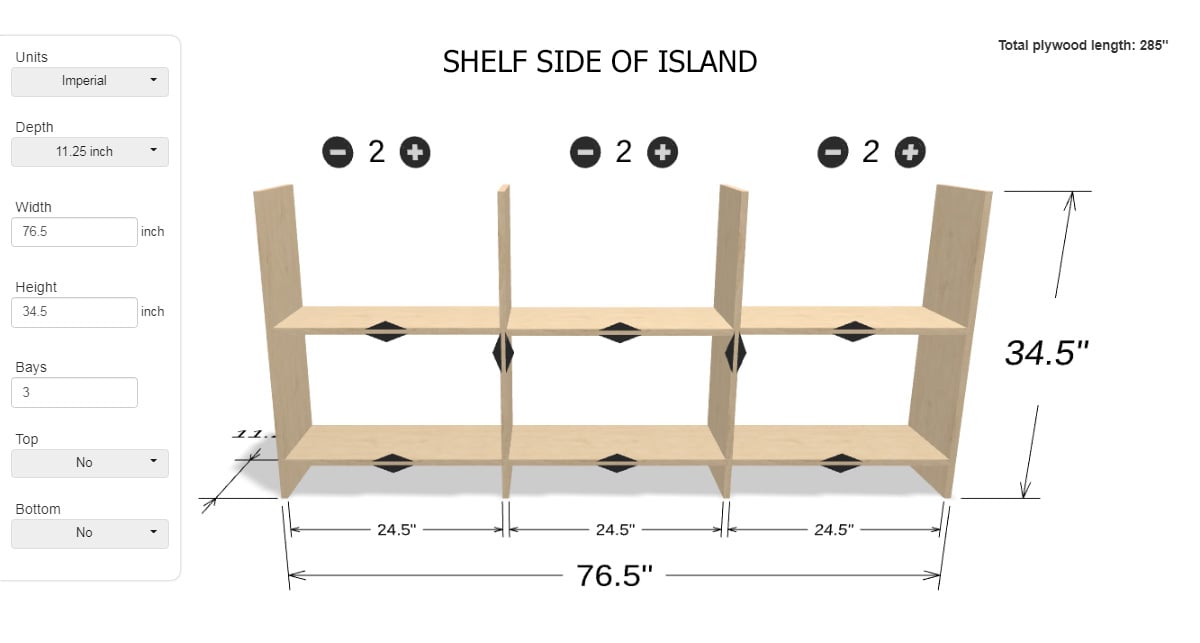

- 4 - 3/4" plywood @ 11-1/4" x 34-1/2"

- 6 - 3/4" plywood @ 11-1/4" x 24-1/2"

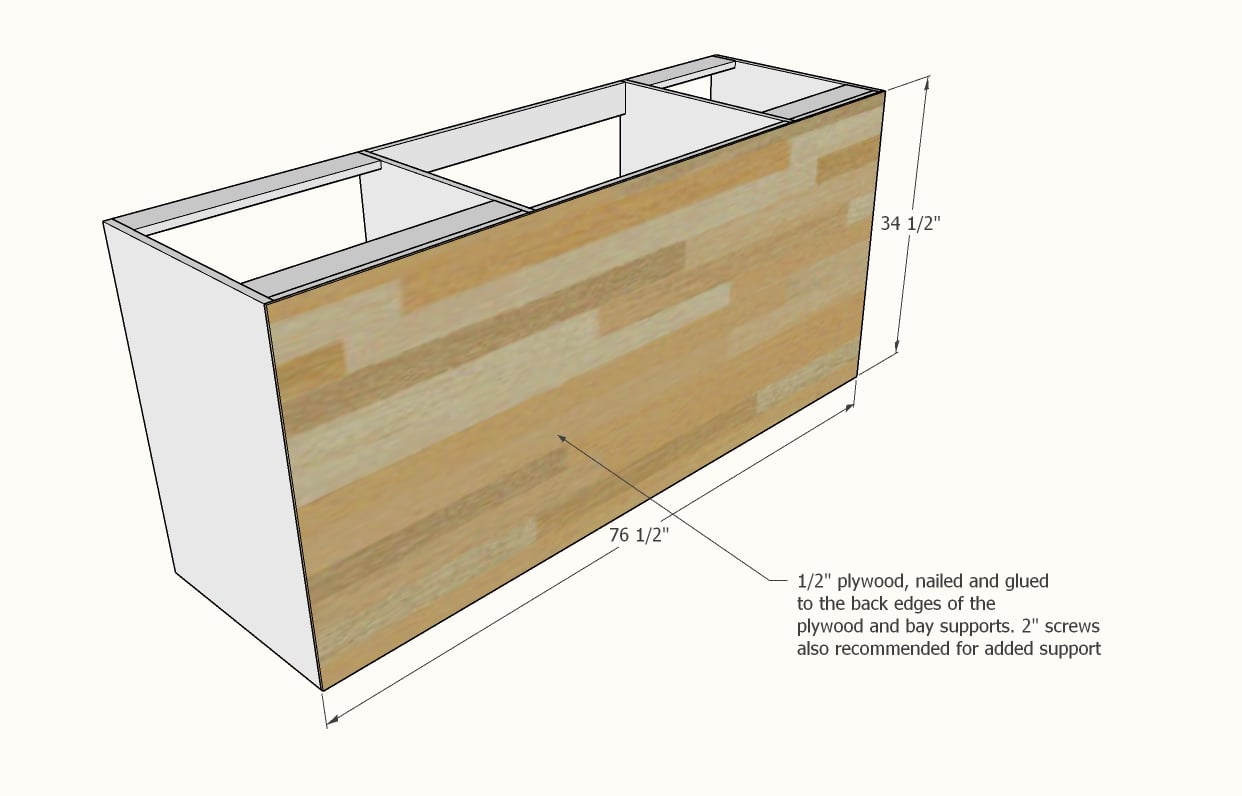

- 1 - 1/2" plywood @ 76-1/2" x 34-1/2" - back

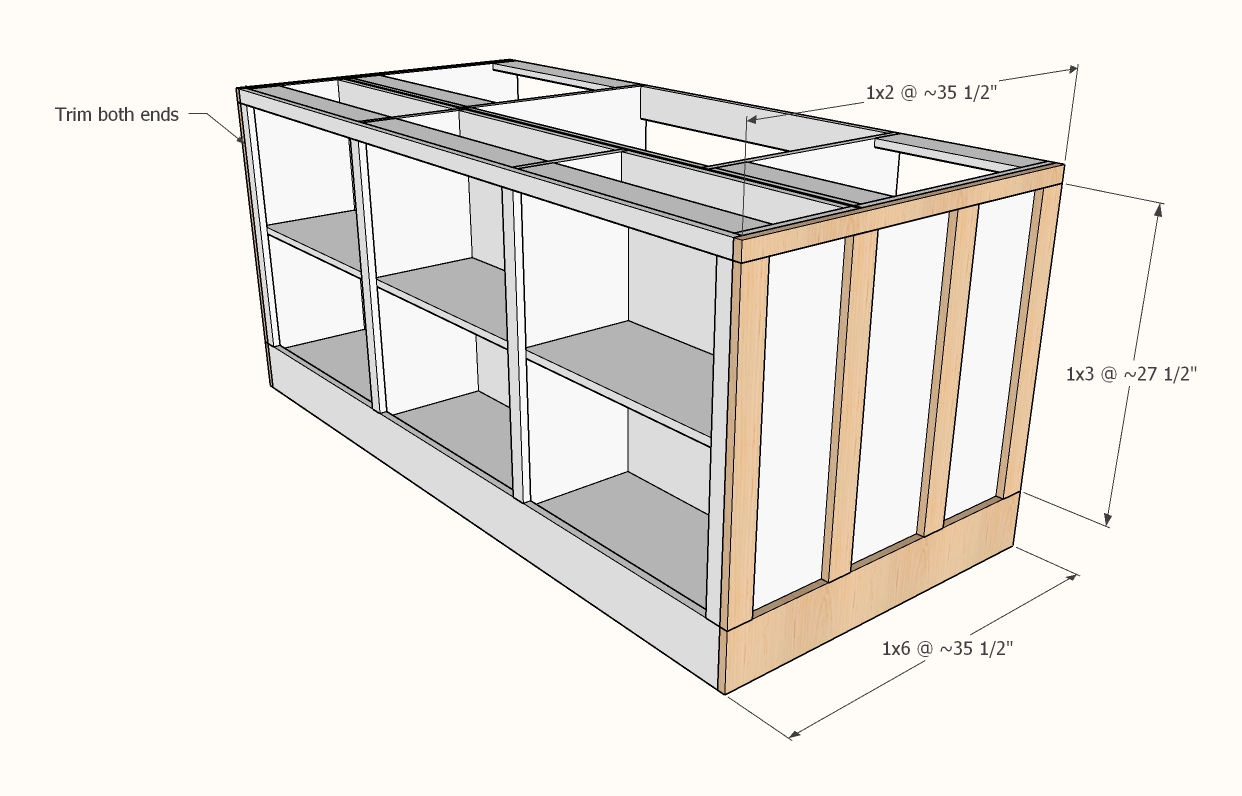

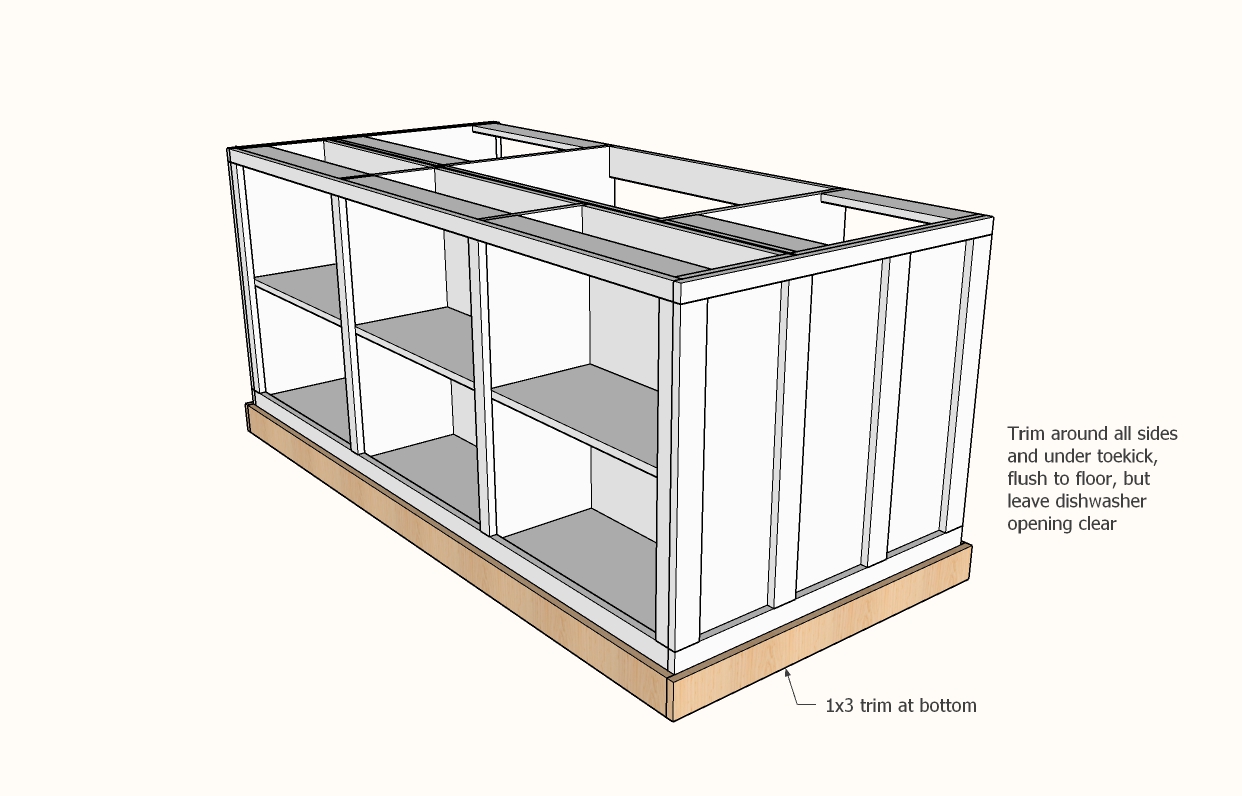

Trim (should be measured and cut to fit)

- 1 - 1x2 @ 76-1/2"

- 1 - 1x6 @ 76-1/2"

- 4 - 1x2 @ 27-1/2"

- 2 - 1x2 @ 35-3/4"

- 2 - 1x6 @ 35-3/4"

- 4 - 1x3 @ 27-1/2"

- 4 - 1x2 @ 27-1/2" - mid stiles on ends, can be 1x3s

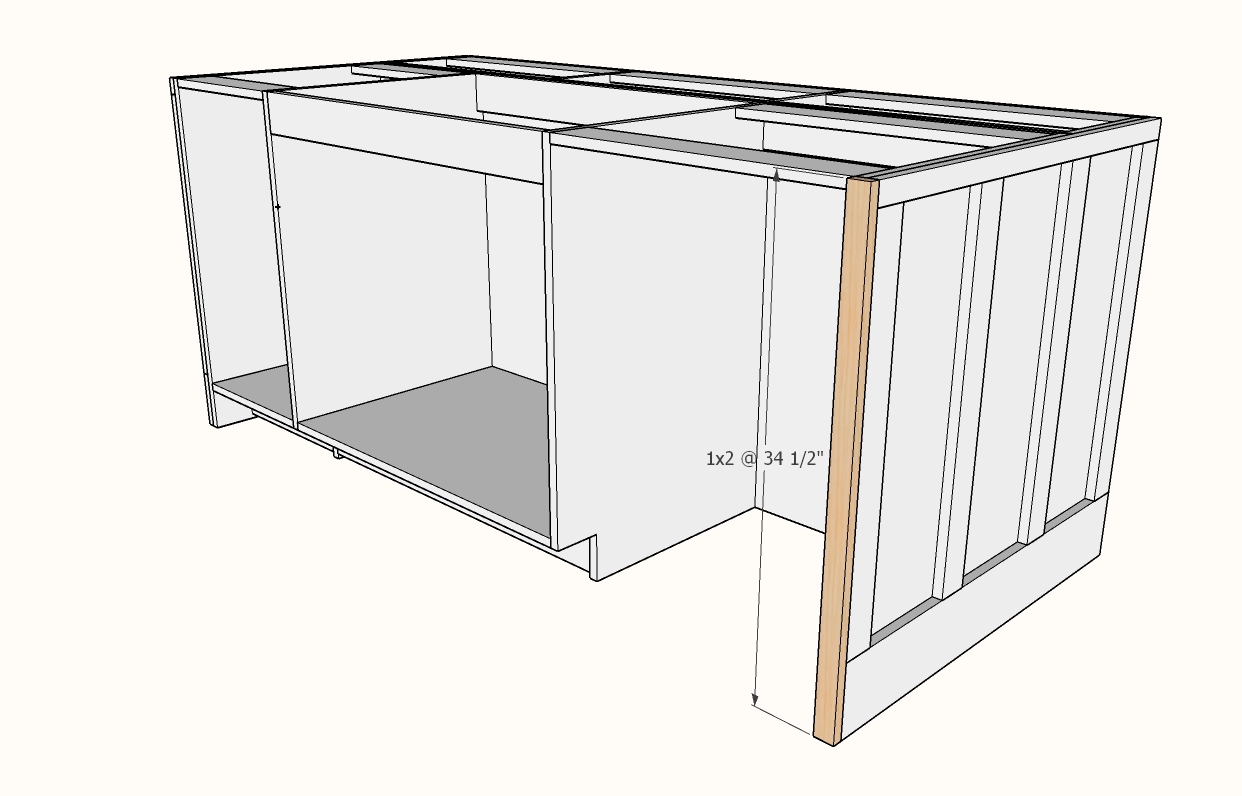

- 1 - 1x2 @ 34-1/2" - dishwasher end panel trim

- 1x4 baseboard should be measured and cut to fit

Drawer (should be cut to fit)

- 2 - 1x4 @ 20" - drawer sides

- 2 - 1x4 @ ABOUT 12-1/2" - Measure and cut to fit after installing the drawer sides inside the cabinet

- 1 - 1/2" plywood @ ABOUT 14" x 20" - measure and cut to fit

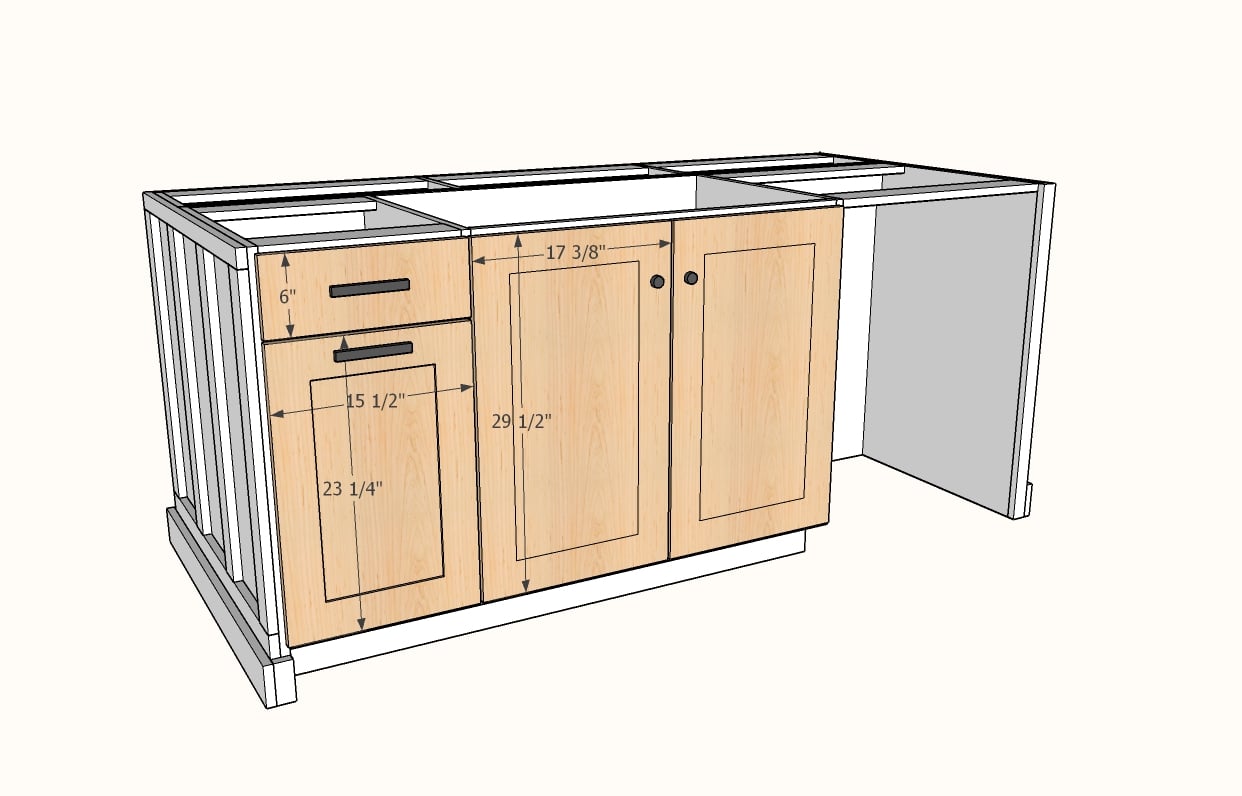

Doors and Drawer Faces

- 6" x 15-1/2" - Drawer Face on Trash Pull Out

- 23-1/4" x 15-1/2" - Door on Trash Pull Out

- 2 @ 17-3/8" x 29-1/2" - Doors on Sink Base

Instructions

Step 1

A big part of this project is cutting the plywood pieces for the cabinets and open shelves. I have listed the cuts needed in the cut list, but you can also use our Shelf Help cutting service to have the pieces cut and shipped direct to you. Here is the two configurations you will need if you use Shelf Help.

Step 2

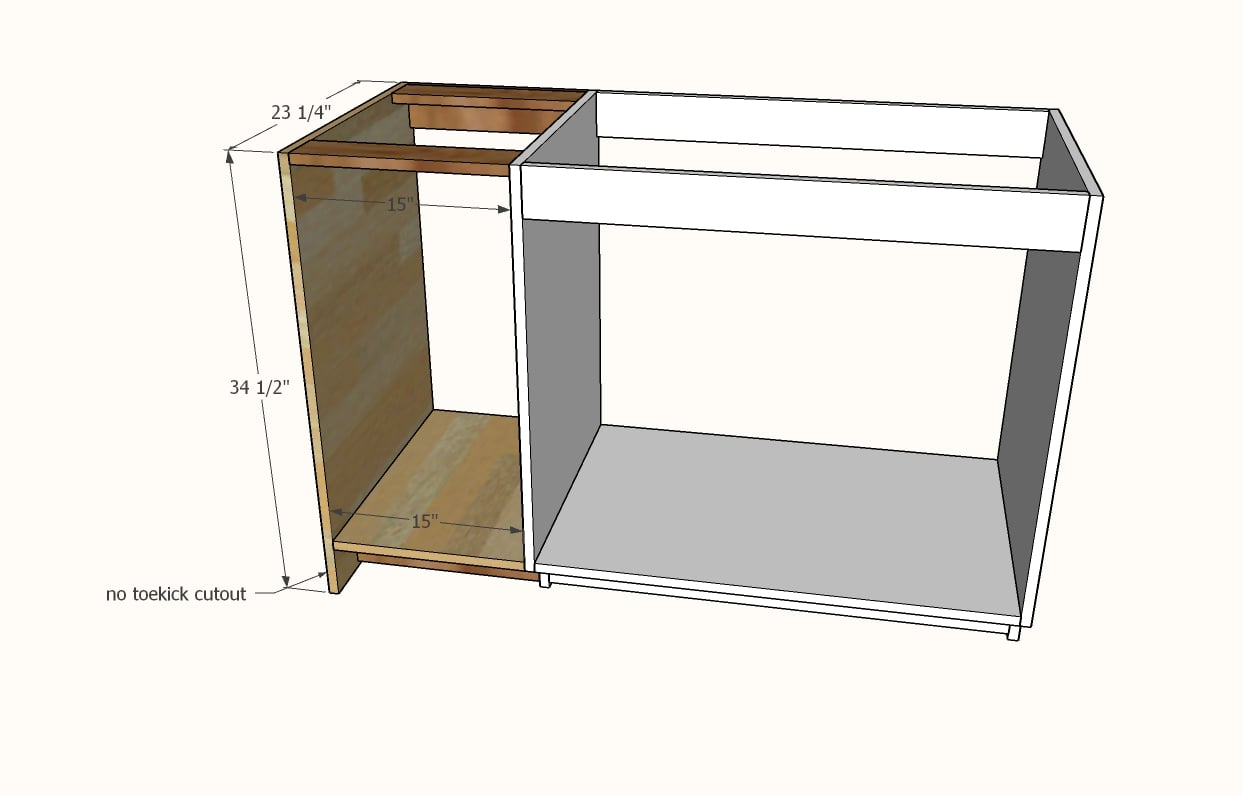

Start by building the sink base.

Cut out toekicks in the front edges of the plywood, 4" x 4", using a jigsaw.

Use 3/4" pocket holes and 1-1/4" pocket hole screws to attach the shelf to the sides, bottom is flush to toekick cut out (there will be a 4" space under the shelf).

Cut three bay supports from 1x3 or 1x4 boards and attach with pocket holes to further strengthen the cabinet. Notice how the top bay supports are run vertically? Sinks are so big these days, this will give you maximum clearance for a sink.

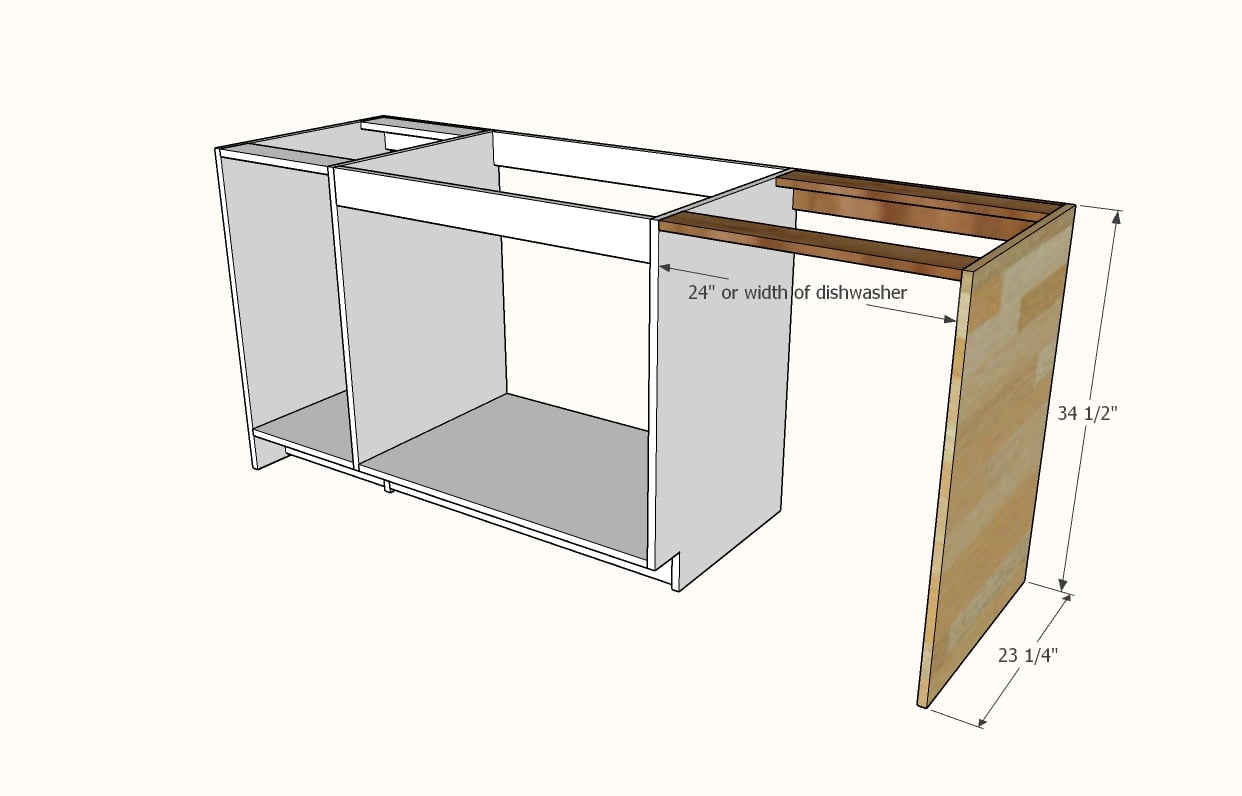

Step 4

Repeat these steps for the dishwasher panel. Please double check the clearance needed for your dishwasher - 24" is a standard, but some dishwashers need more.

Add the bay supports - you may not be able to add the top front bay support depending on your dishwasher clearance needed.

I also recommend a bay support at the bottom back for further support.

TIP: You can also drill pocket holes facing downward in the dishwasher panel for attaching the panel to the floor on installation.

Step 5

Step 6

Step 7

Step 8

Step 11

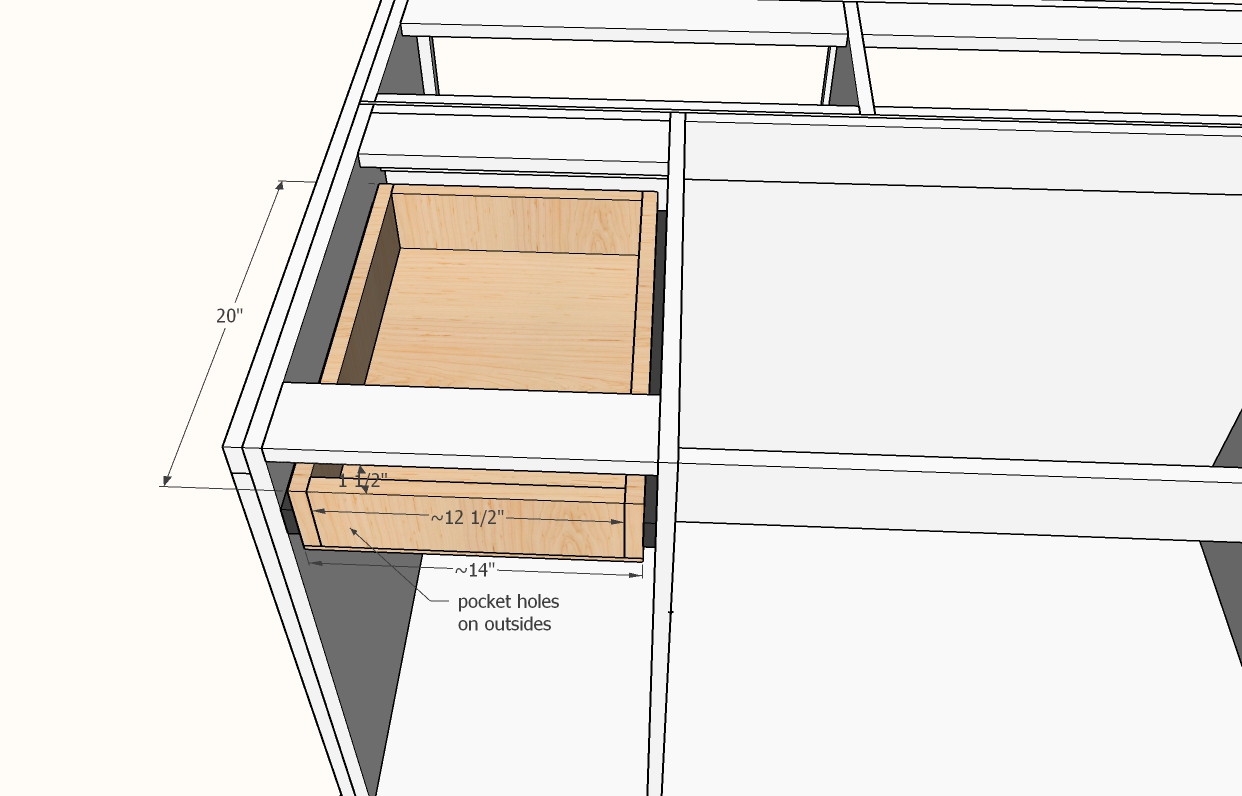

Build the drawer with 1x4 boards.

First cut two 1x4 @ 20" long.

Install the drawer sides to the drawer slide and install inside the cavity.

Measure between the two installed drawer sides and cut two 1x4s to match - should be about 12-1/2" long.

Attach to the two drawer sides with pocket hole screws on the outside.

Measure and cut 1/2" thick plywood for the drawer bottom. Attach with glue and nails.

NOTE: Make sure you install the drawer at a height that will be covered by the drawer face.

Here is my video tutorial of installing drawer boxes

Step 12

Attach the drawer face to the drawer box.

Install doors with Frameless Hinges, HALF OVERLAY like these.

Here is a video I did on installing these hinges