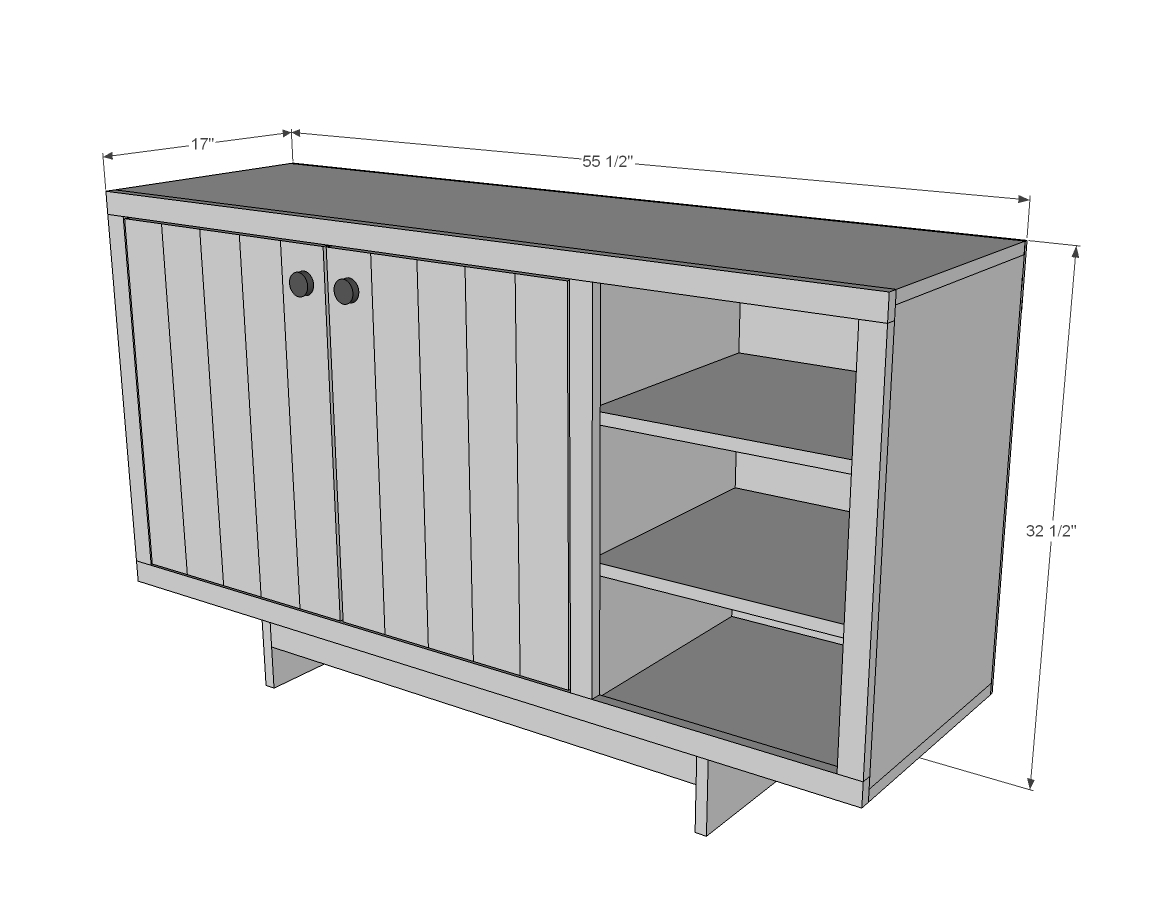

This easy to build console table or buffet cabinet adds style and storage to your space! Free step by step plans from Ana-White.com

Preparation

1 sheet 3/4" plywood ripped into strips 15 3/4" wide

3 - 1x2 @ 8 feet long

1 sheet 1/4" plywood or backerboard

1 - 1x6 @ 6 feet long

1 - 1x3 @ 3 feet long

2 - 1x4 @ 10 feet long

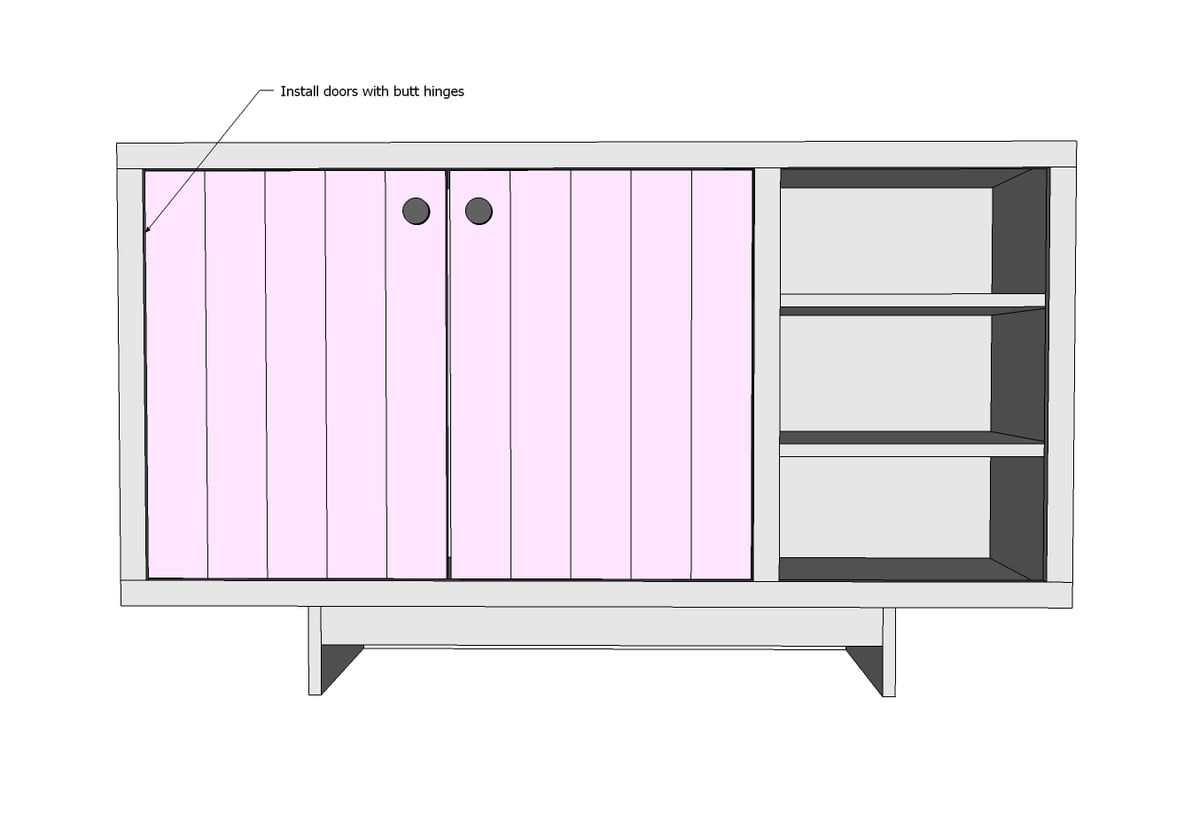

2 sets of butt hinges

magentic clasp or hasp (recommended)

2 knobs edge banding or 1x1 pine trim for finishing small shelf exposed plywood edges (I used pieces of 1x2 ripped in half)

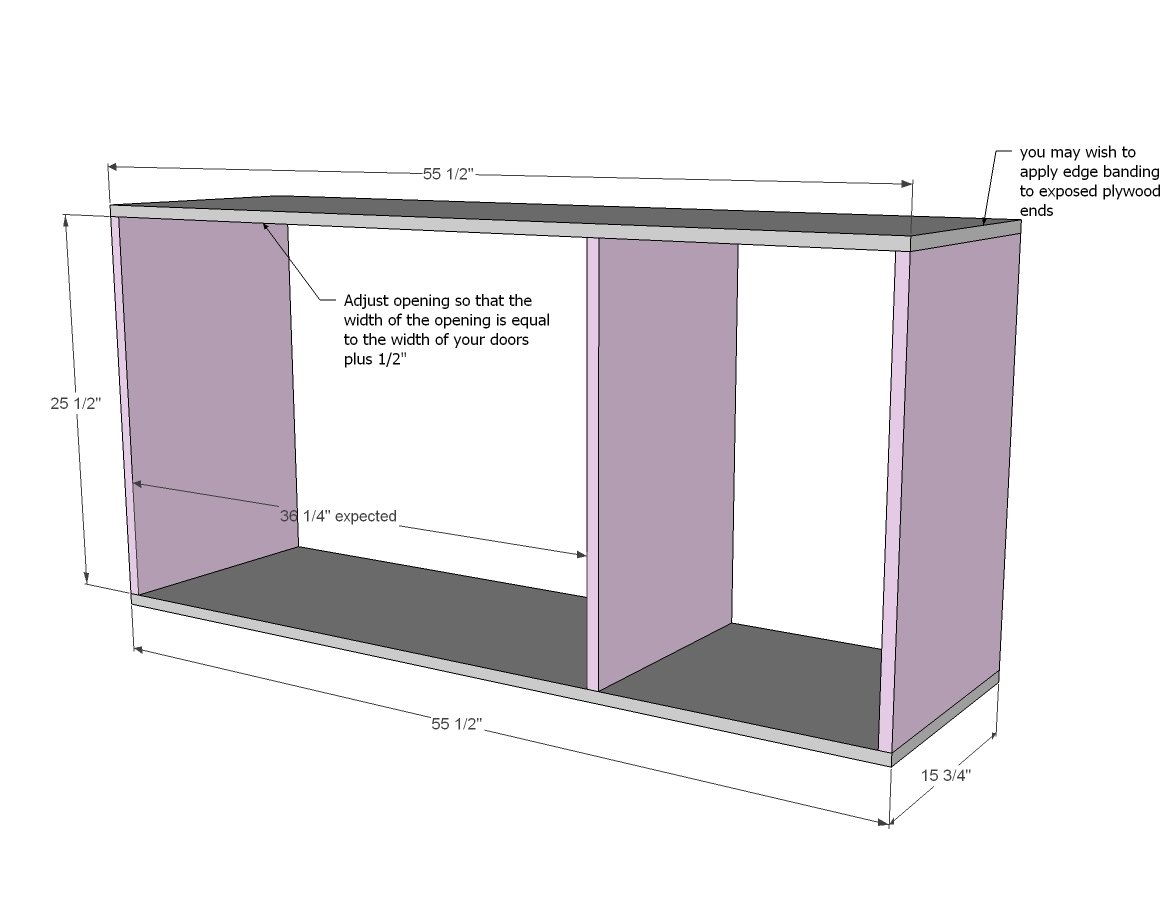

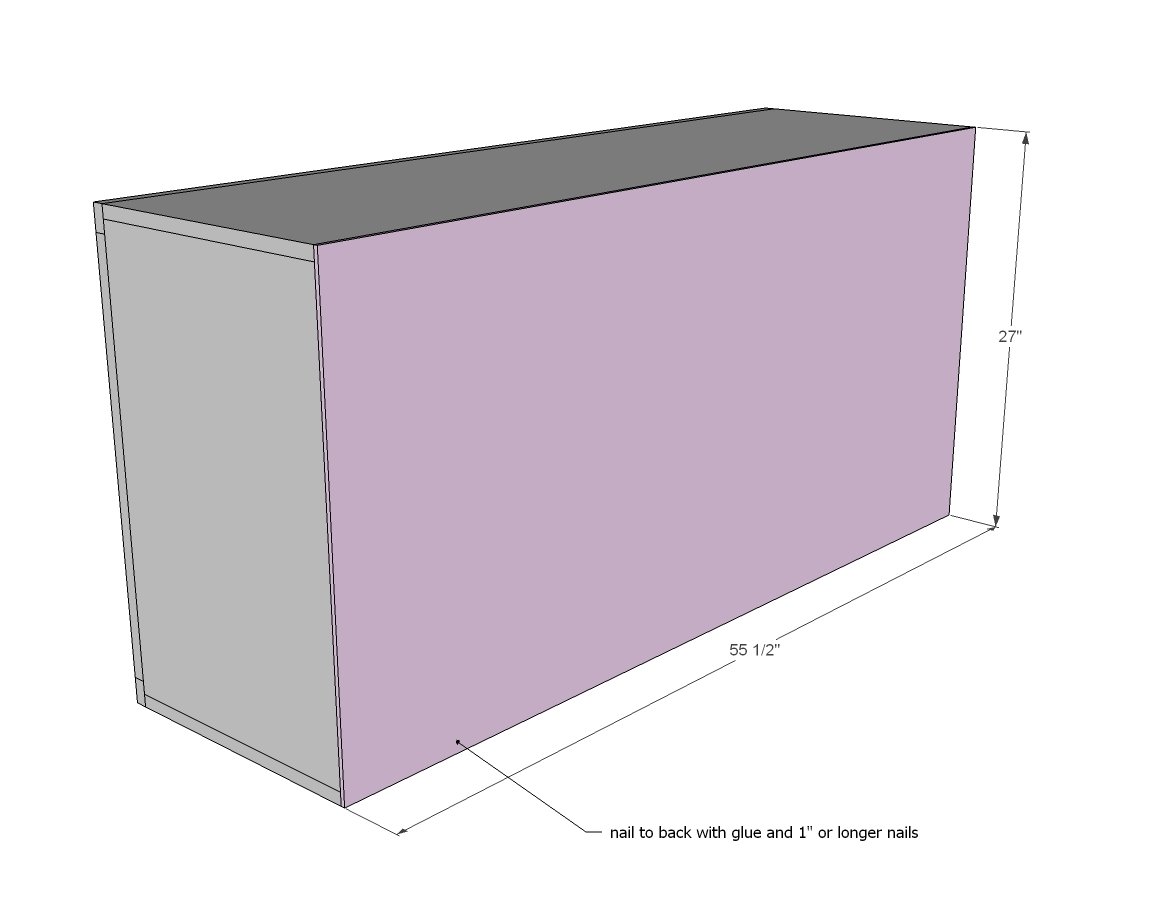

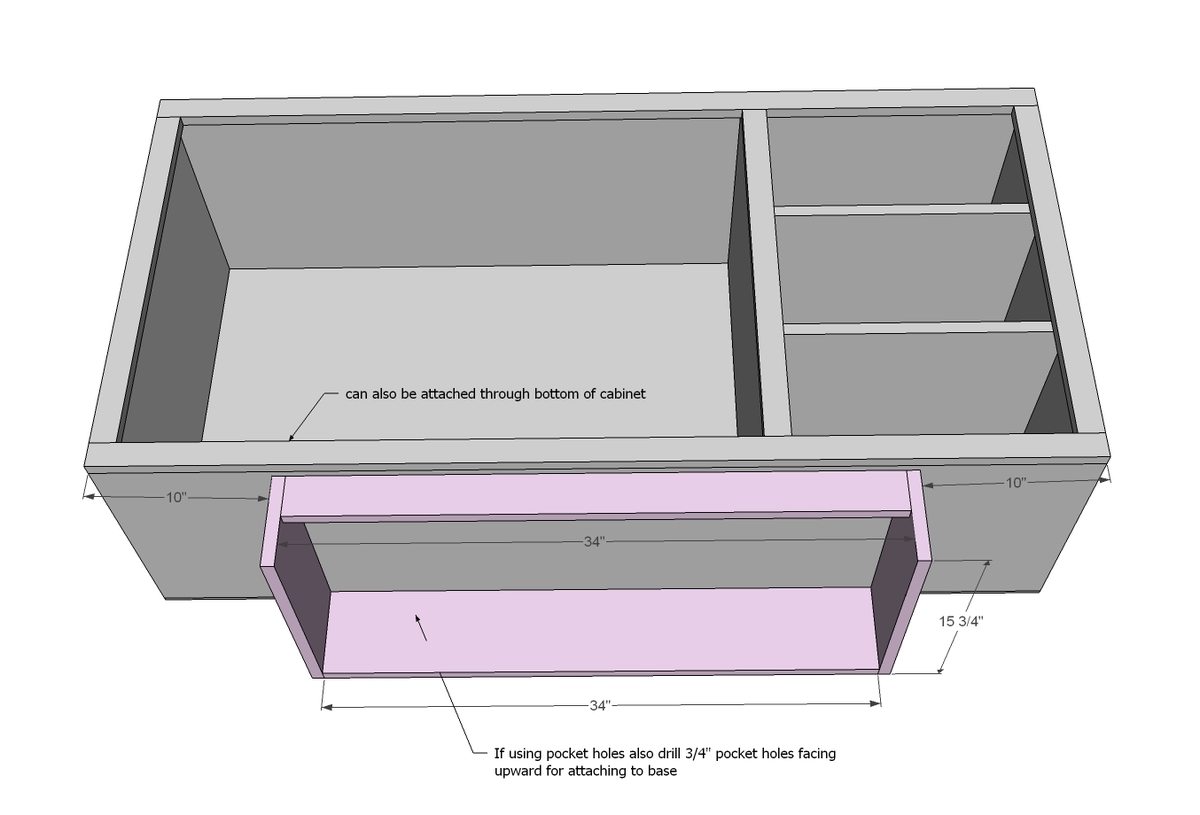

BOX 2 - 3/4" plywood @ 15 3/4" x 55 1/2" (top and bottom)

1 - 3/4" plywood @ 15 3/4" x 36 1/4" (main shelf - cut to fit)

3 - 3/4" plywood @ 15 3/4" x 25 1/2" (sides/dividers)

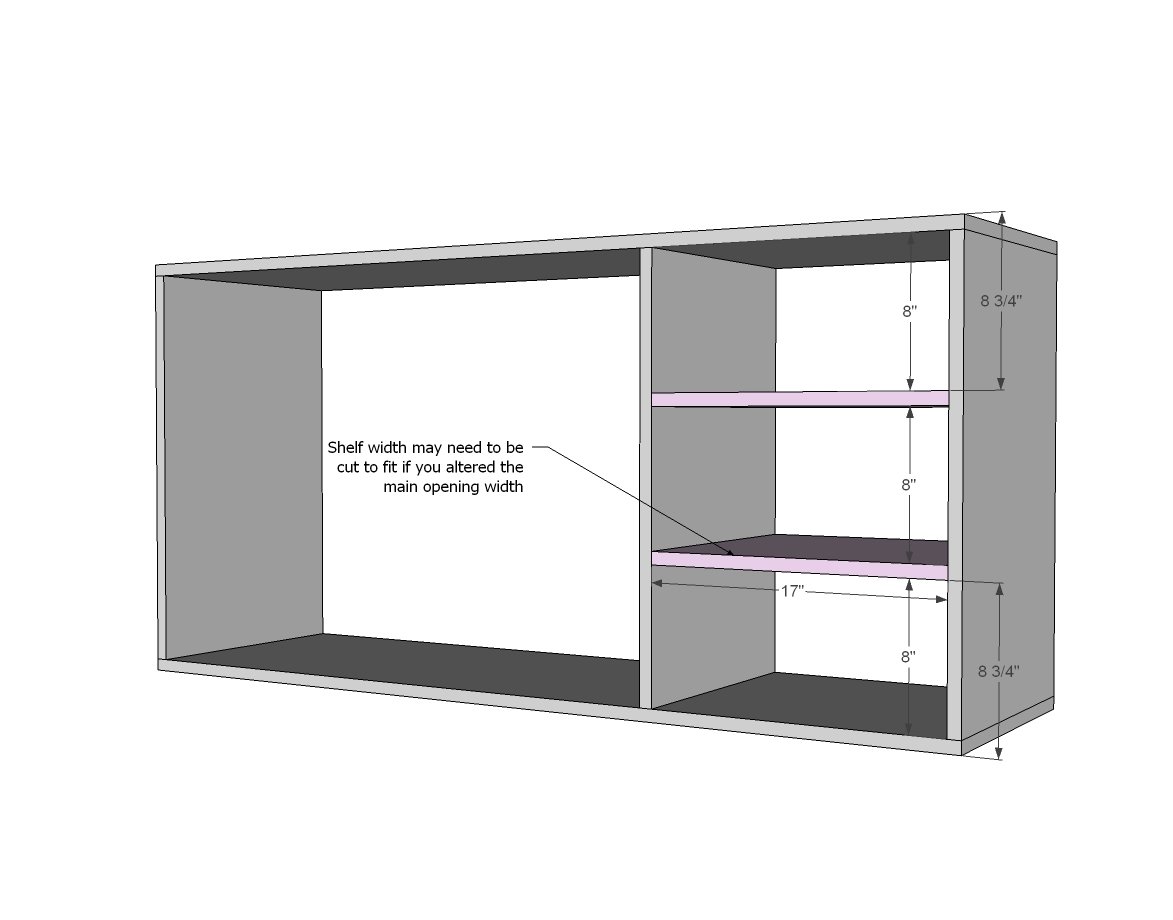

2 - 3/4" plywood @ 15 3/4" x 17" (small shelves - cut to fit)

1 - 1/4" plywood @ 55 1/2" x 27" FACE FRAME

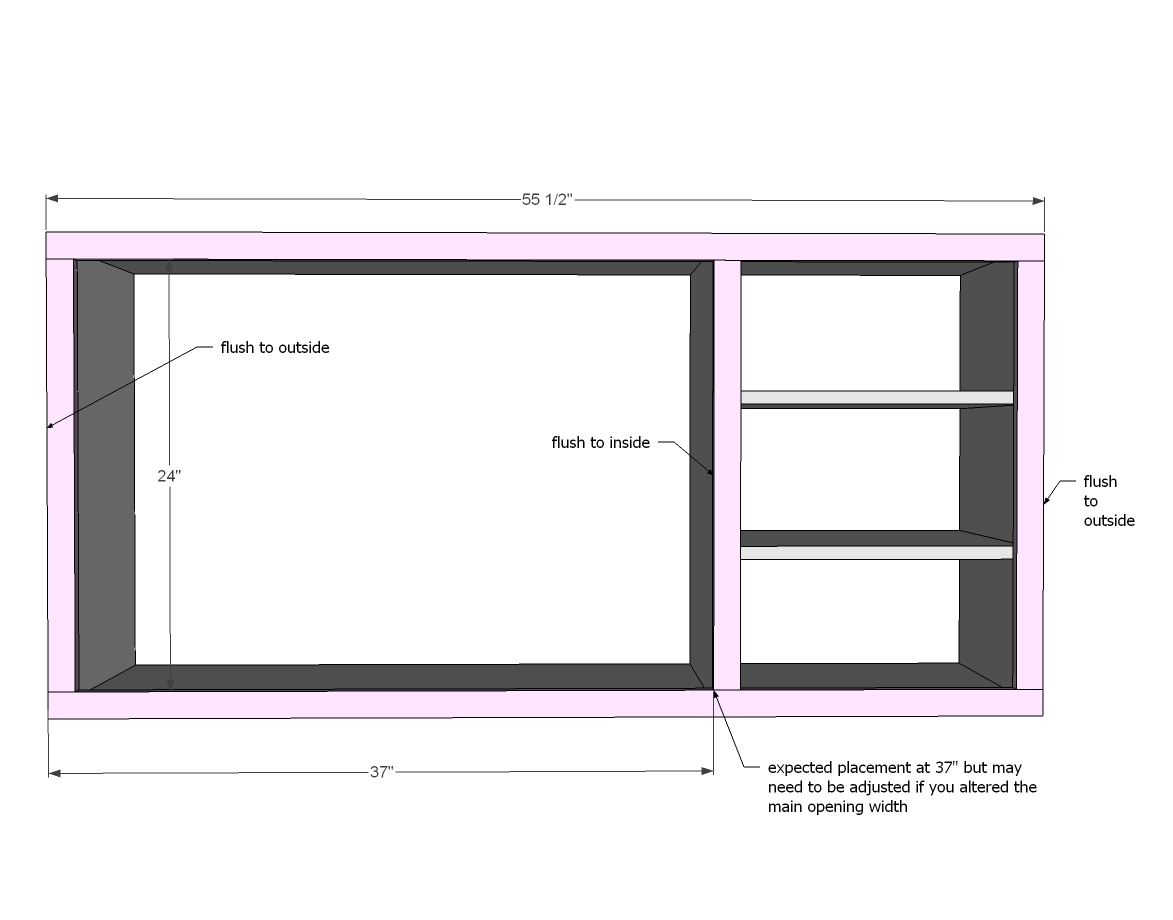

2 - 1x2 @ 55 1/2"

3 - 1x2 @ 24" BASE

2 - 1x6 @ 15 3/4"

1 - 1x6 @ 34"

1 - 1x3 @ 34" DOORS

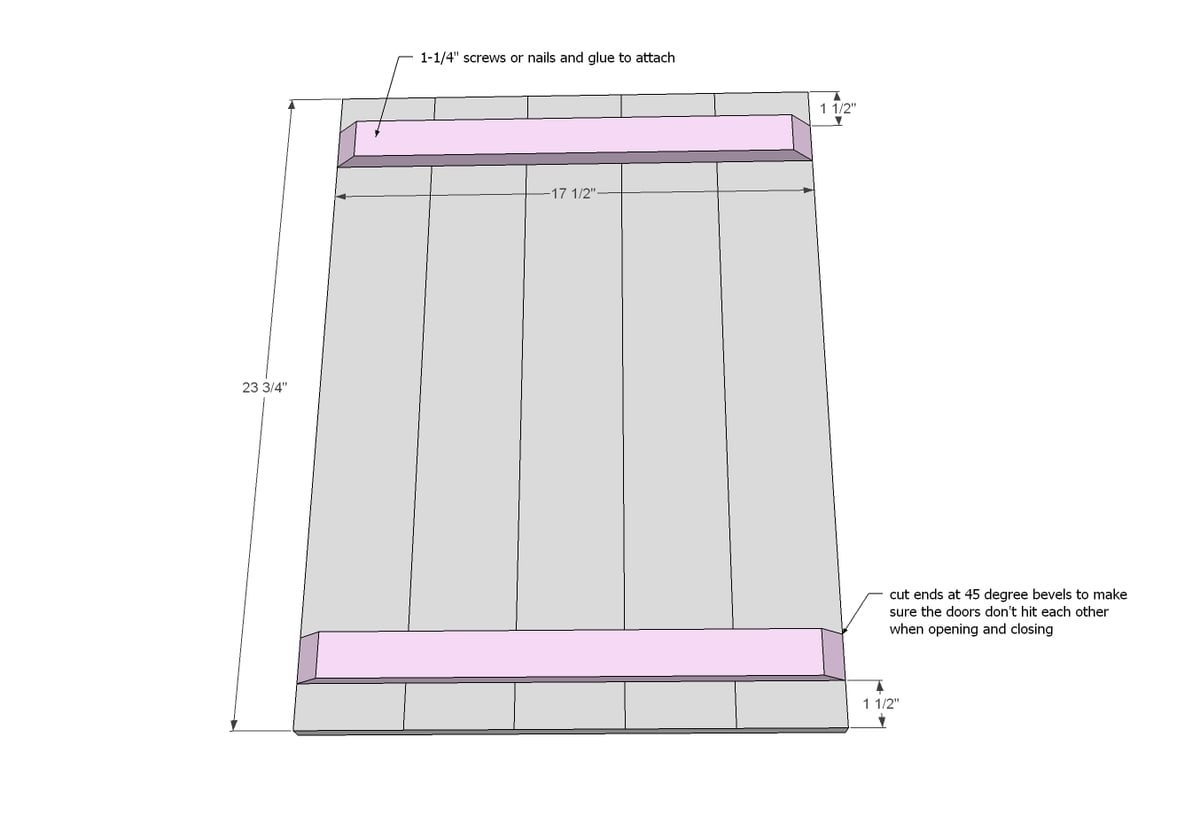

4 - 1x2 @ 17 1/2" (both ends beveled at 45 degrees off square, long point to long point)

5 - 1x4 @ 23 3/4"

TIP: Make sure you plan so all the plywood cuts fit on the same sheet of plywood. There's just enough - not alot of extra!

Please read through the entire plan and all comments before beginning this project. It is also advisable to review the Getting Started Section. Take all necessary precautions to build safely and smartly. Work on a clean level surface, free of imperfections or debris. Always use straight boards. Check for square after each step. Always predrill holes before attaching with screws. Use glue with finish nails for a stronger hold. Wipe excess glue off bare wood for stained projects, as dried glue will not take stain. Be safe, have fun, and ask for help if you need it. Good luck!

Instructions

Step 1

NOTE on getting doors to fit perfectly: So here's the deal - wood isn't always true to widths. Measure your 1x4 boards that you will use for the doors. If they measure 3 1/2' wide, then you can just proceed. If they don't, I recommend modifiying the main opening width to the width of your finished doors + 1/2" for clearance around doors + 1-1/2" for the face framing. You could also build your doors first (see step 6) and then measure the finished door, add 1/2", add another 1 1/2" for the face framing, and this will be the main opening width. Another option is if your 1x4 boards are a little on the narrow side, you could leave gaps between the 1x4s as you build the doors. If the 1x4 boards are too wide (not likely) you could build the door and then trim it down to fit. A final option is to just go ahead and build the box, but hold off on the middle 1x2 in the face frame (next step) until after you build the doors. Then attach the middle 1x2 in the face frame to give you just enough room for your doors. Just giving you options so your doors look beautiful when done with an even gap around them!

So once you get that figured out, it's time to build the box. We use 3/4" pocket holes (3 per end of each of the sides and divider) and 1-1/4" pocket hole screws. Another option is 2" wood screws or nails and glue (nails aren't as strong but since this project is face framed with a full back and isn't for sitting or climbing on, would most likely be enough).

The main shelf can be added at this step too.

Step 2

Step 3

Step 6

Step 7

Step 8

To achieve this stain, the entire cabinet was stained a medium stain. Then for the doors, selective boards were sanded down to remove some of the stain, lightening the boards. Other boards were given another layer of darker stain. And for the lighter areas, I taped off areas and sanded all the stain off to give the appearance of a past board to board joint.

It is always recommended to apply a test coat on a hidden area or scrap piece to ensure color evenness and adhesion. Use primer or wood conditioner as needed.

Comments

jaimecostiglio

Wed, 10/23/2013 - 06:57

Looking good Mommy (and the console too!)

A perfect fit for that new Alaskan baby, love the rustic build and finish. So exciting for you to see your family expanding!

Juanita_r

Fri, 10/25/2013 - 02:55

Cutest bump ever and awesome

Cutest bump ever and awesome console. You continue to amaze us Ana!

dzmom

Wed, 01/22/2014 - 06:39

finish

This is my next project, but I want the exact finish. Can you give me some direction?

eksthompson

Tue, 02/17/2015 - 20:06

Need to modify...help!

First, Ana, you are awesome! Thank you so much for creating this site!

So, this will be my first ever project. I was so excited and proud when I went to Home Depot to get the lumber. I spent lots of time picking out boards that were both straight AND pretty. So, getting ready to see what we still needed to cut tonight, and find that Home Depot cut almost all my boards at least a 1/4 in. off! What I'm wondering is, can I just modify the whole thing by taking 1/2 in. off all the boards? Do I have to do it for both dimensions if so? We only took the half inch off on the one side (so instead of the 1/4 in. plywood being the original 55 1/2 in. X 27in., it is 55 x 27.). I hope this makes sense.

Thank you!

Bander

Fri, 02/20/2015 - 11:51

If it is just the backing

If it is just the backing that is short, you can get away with 1/2 in because you can attach it without fully overlapping the boards at the end and it will still look fine from the front. (No one will know but you). If the rest of your boards are short, you will have to shorten the piece by the same amount in whatever dimension(s) you are short, or get new boards cut.

MN1987

Fri, 02/17/2017 - 06:36

Door area width question

Thanks for these great plans. I am in the middle of making this and have been struggling with the 1-1/2 inch addition to the door-area width that's called for to accommodate the face frame. If the face frame only overhangs on one side (since it's flush inside on the right side), why wouldn't the add-on be just 3/4-inch to accommodate the face frame for both doors? Thanks for your help!

Konzen@94

Wed, 07/29/2020 - 09:56

I'm also stuck on this. The…

I'm also stuck on this. The drawing differs from the written instructions.