Do you need extra storage in your desk area? Adding bookshelf hutch towers to a desk system create tons more storage in an easy to access height. It also looks beautiful and give a desk a high end, built-in look.

This is a DIY project plan that will help you build your own bookshelf hutches for your desk, so you can save money and get the exact size and finish you need. The plans include video tutorial, configurator, recommended dimensions, diagrams, and more from Ana-White.com

MATCHING PLAN: Build the Modular Desk Bases with Free Plans Here

Pin For Later!

Preparation

3/4" hardwood plywood, ripped into strips 11-1/4" wide (maple or birch plywood recommended for painted finish)

3/4" wide edge banding in matching wood veneer

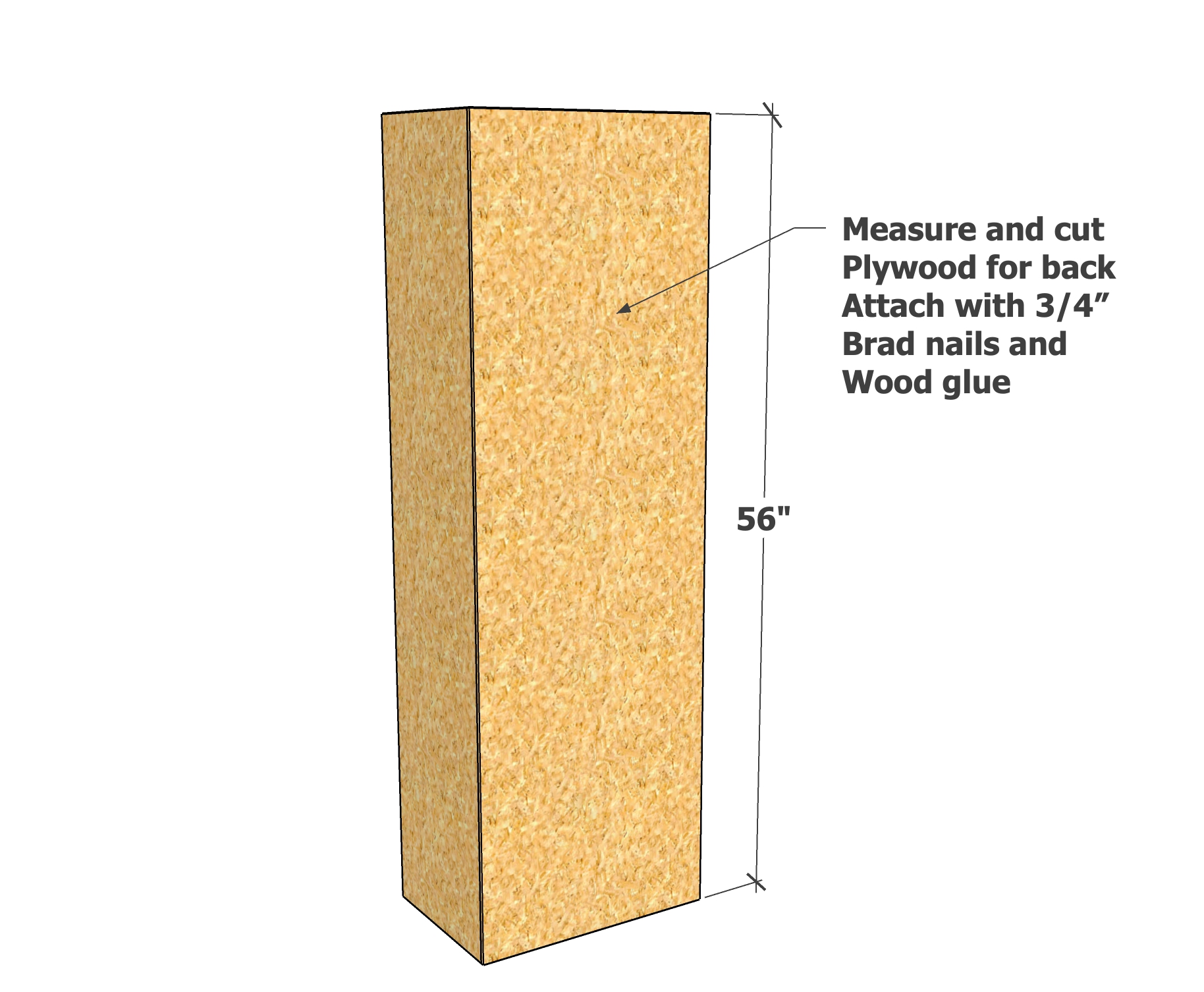

1/4" plywood for the back in matching wood veneer

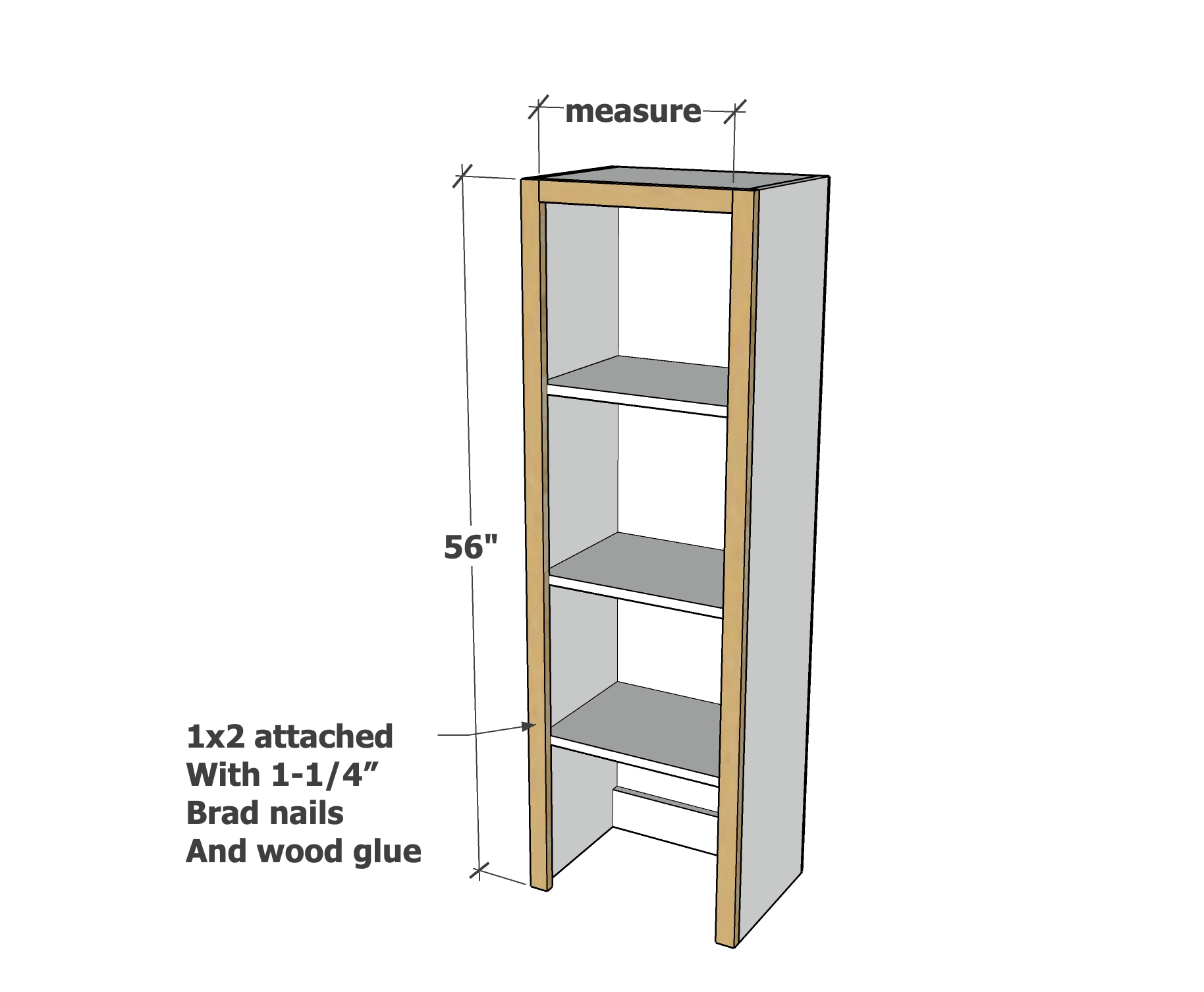

1x2 for face frame in matching wood veneer (pine or poplar most economical for painted finish)

1x4 for back bay support

Cut list for the plywood is generated in the Design App

1/4" plywood for the back is cut to fit

1x2s for the face frame should be cut to fit

1x4 bay support is cut to match the cut length of the shelves

Instructions

Step 1

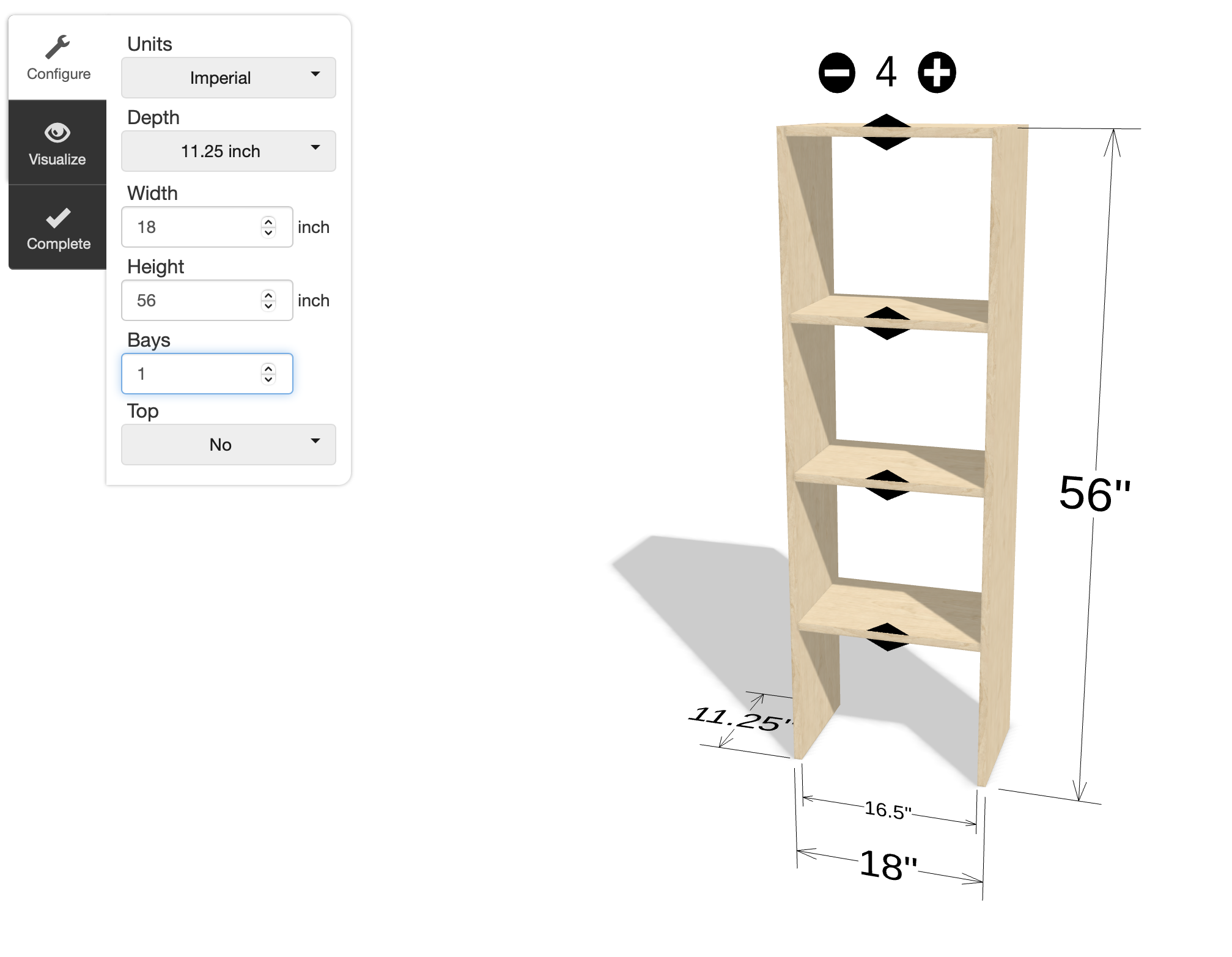

Custom Design Your Hutches

Use Ana's Design Tool to create the dimensions and cut list for your hutches and download the plans.

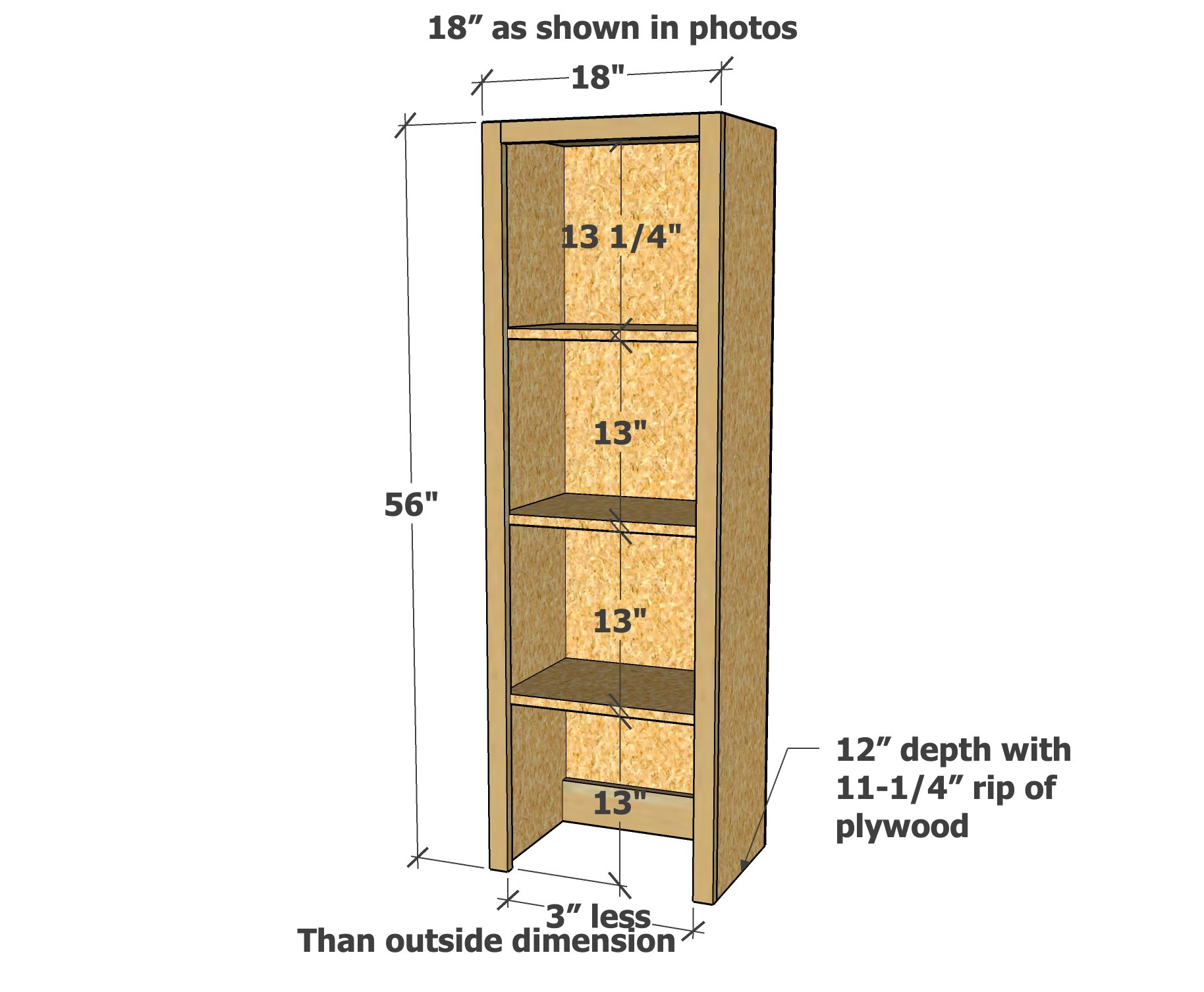

The parameters I entered are as follows:

- Depth: 11.25"

- Height: 56"

- Width: 18"

- Number of Shelves: 4

- Distance between shelves: 12.5" starting at the bottom, the distance left at the top shelf was more

Step 2

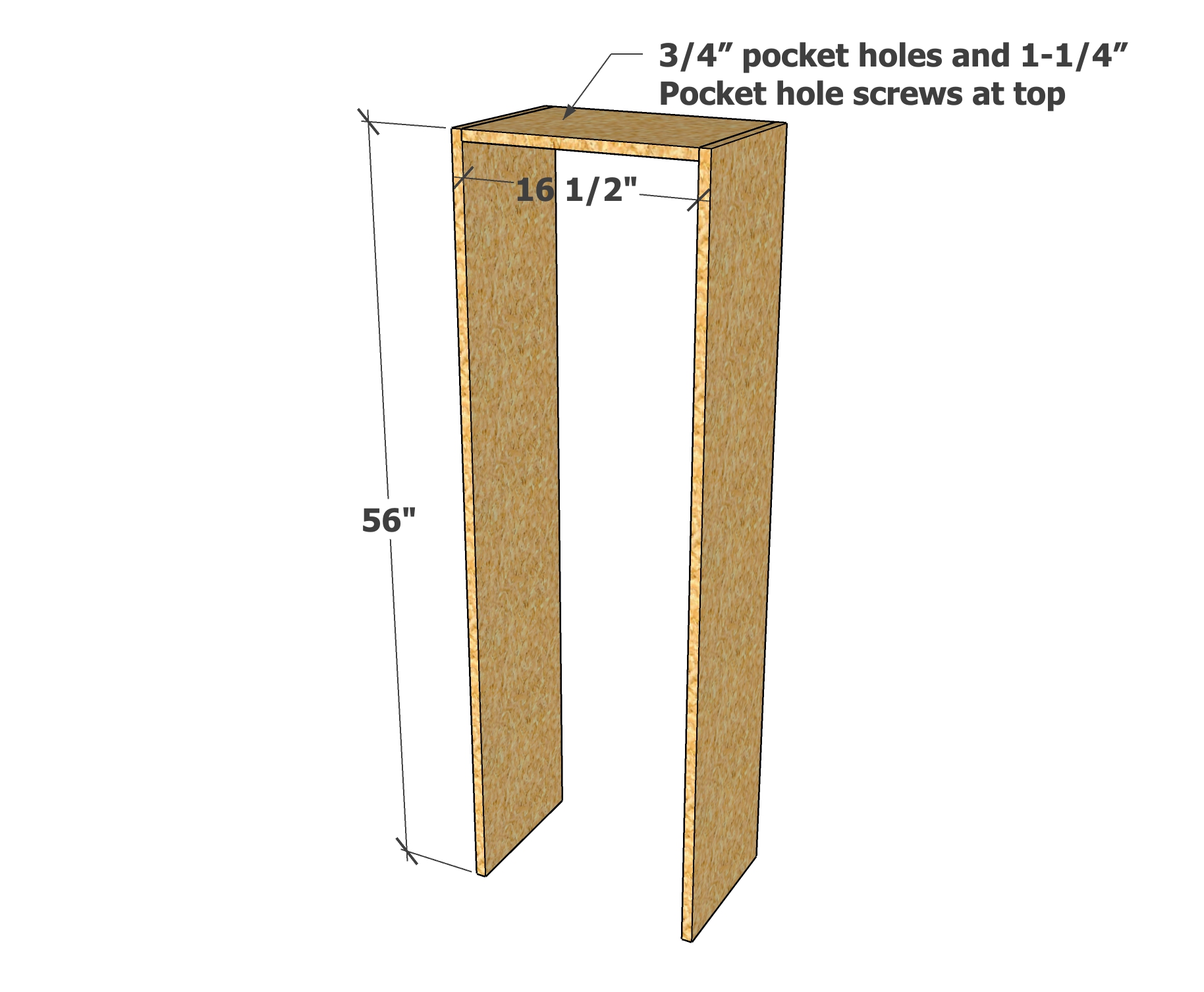

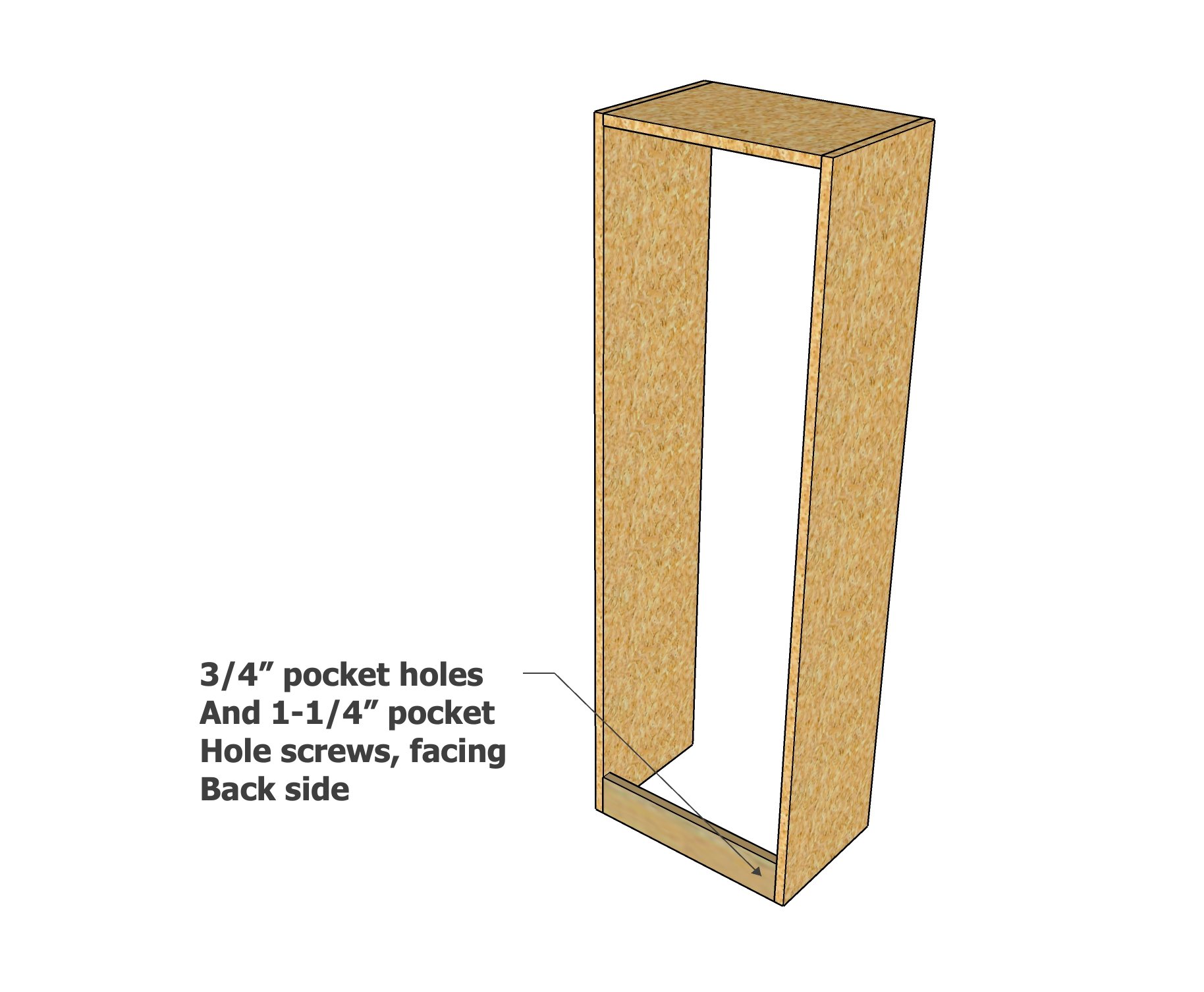

Cutting the Plywood Pieces

Once you have the plans downloaded from Ana's Design Tool, on the second page you will find the cut list.

Rip the 3/4" plywood into strips to match your width (my width is 11.25") by 8 feet long. It's best to use a tables or a track saw.

Then cross cut the plywood strips into the pieces you'll need.

TIP: I always plan out my cuts on scratch paper before I do any cutting to minimize scrap pieces.

Step 3

Step 4

Step 5

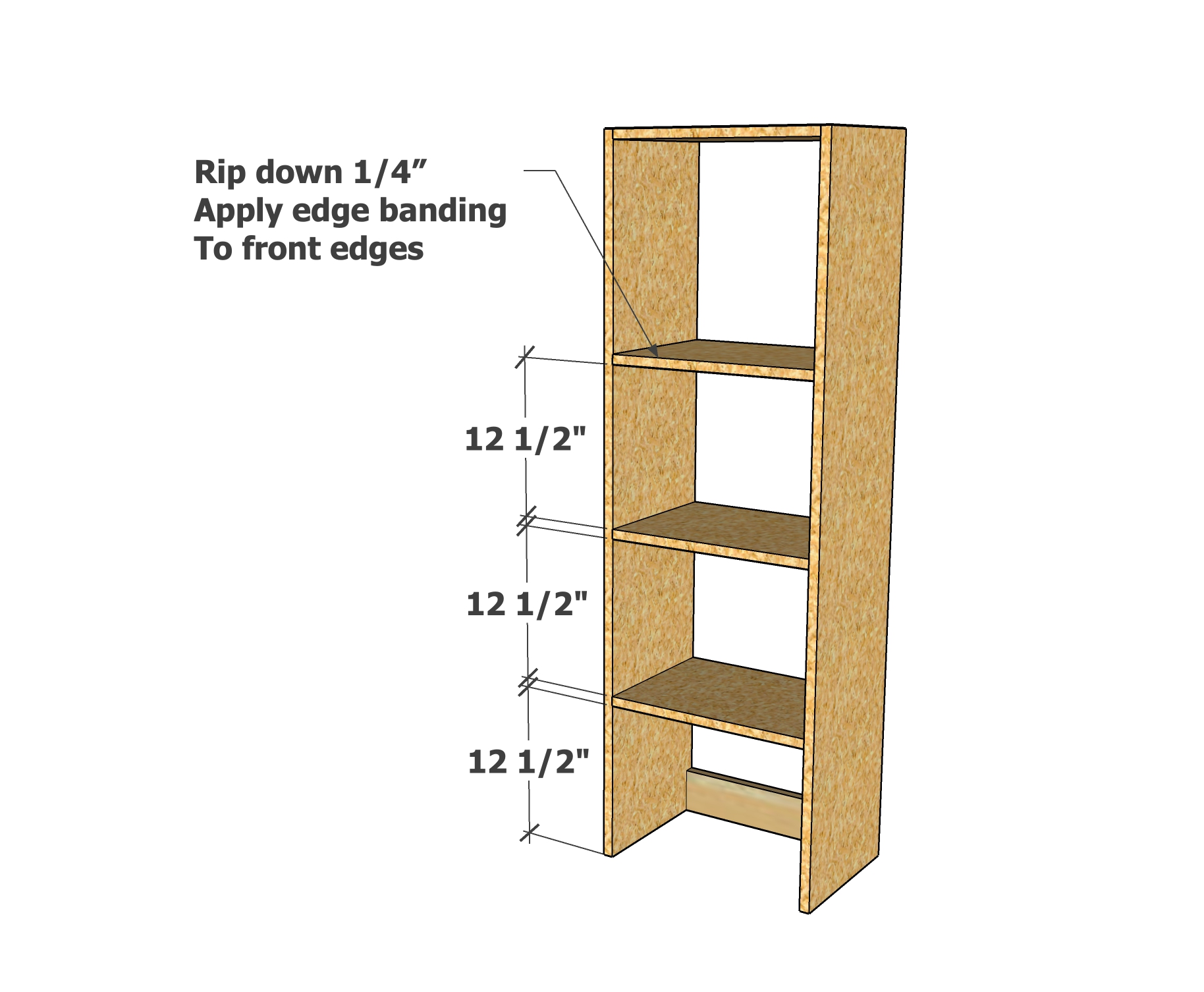

Adding the Shelves

For the shelves, I wanted them to have a finished front edge without a face frame.

So I ripped the shelf down to 11-1/8" width on my tables.

Then I applied edge banding to the front edge of the shelves. The process is shown in the video.

I attached the shelves with 1-1/4" brad nails and wood glue.

Step 6

Then I sanded with 120 grit sandpaper.

I removed all sanding residue with a vacuum with soft bristled brush and wiped clean with a damp, lint free cloth.