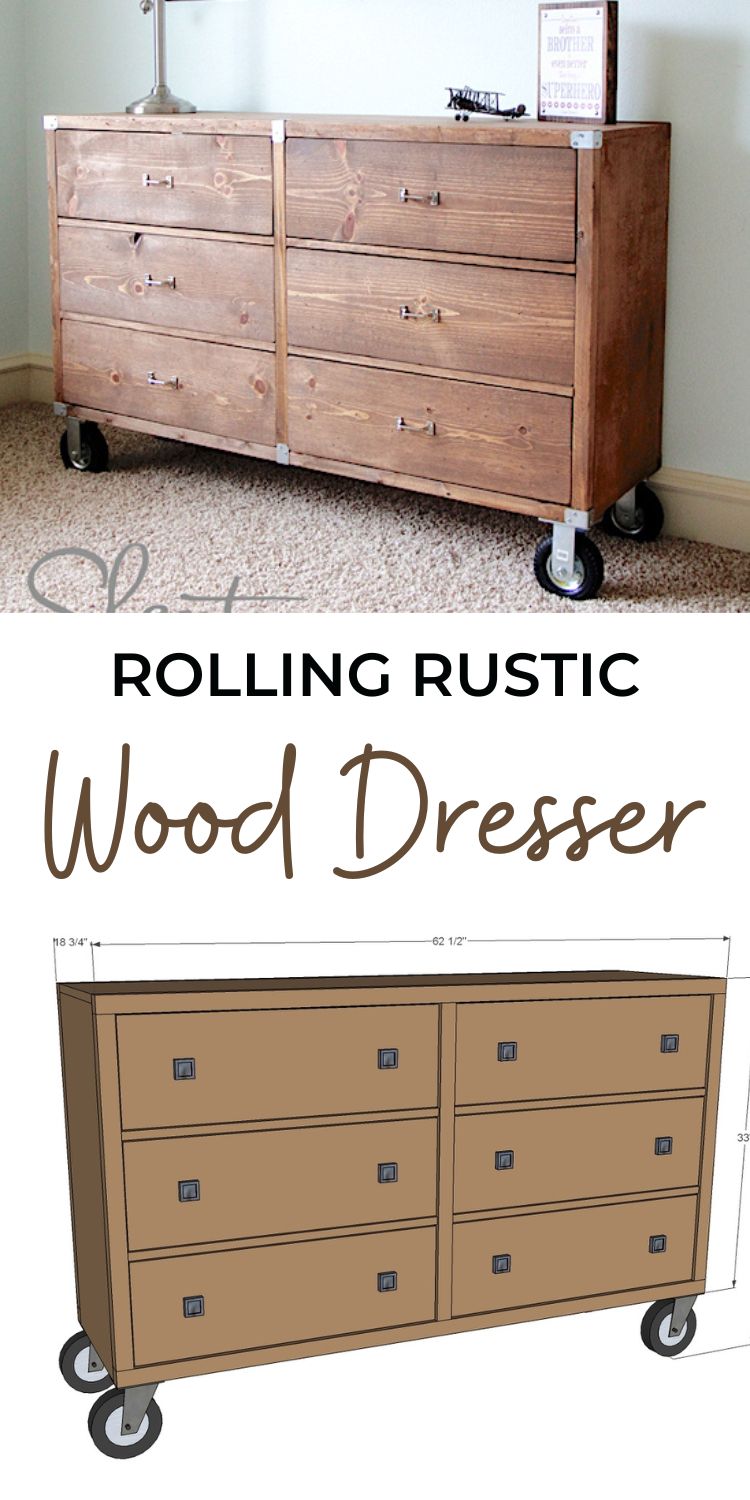

Free plans to build a solid wood, rolling dresser from ana-white.com

This dresser is beautiful and blends with just about any style and decor. The plans include step by step diagrams, shopping list, cut list and more.

Pin For Later!

Preparation

- 1 - sheet 3/4” plywood ripped into strips 15 3/4” wide referred to as 1x16 boards throughout this plan

- 3 - 1x2 @ 8 feet long

- 6 - 2x2 @ 8 feet long (MUST BE VERY STRAIGHT)

- 6 - 1x8 @ 8 feet long

- 2 - 1x10 @ 8 feet long

- 1 - 1/4” plywood for drawer bottoms/back

- 6 - 16” euro style white drawer slides (bottom corner mount)

- 1 1/4” and 2 1/2” Pocket Hole screws

- 1 1/4” brad nails

- Knobs or handles

- 6” caster wheels and screws to attach

NOTE: This plan assumes your 1x10 boards are 9 1/4" wide to fit a 9 1/2" wide drawer opening. Measure the width of your 1x10s and adjust if necessary, allowing for an 1/8" gap around all sides of drawer faces.

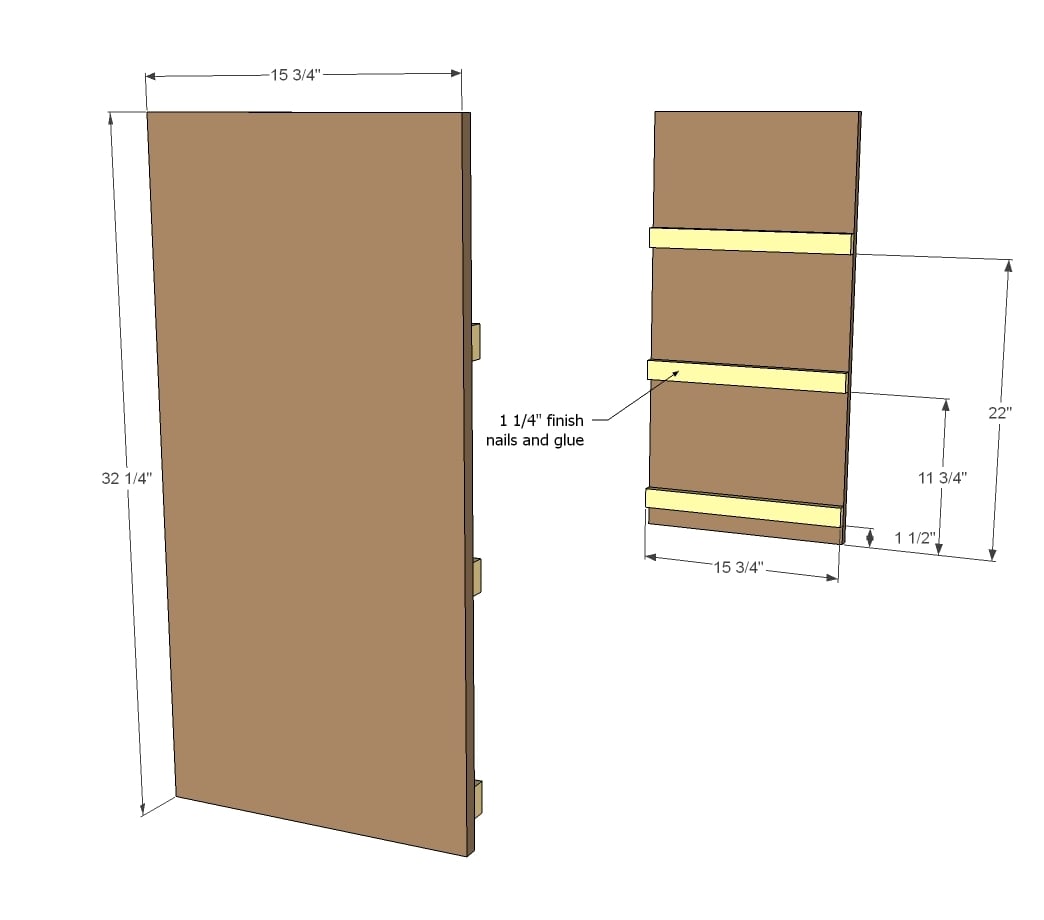

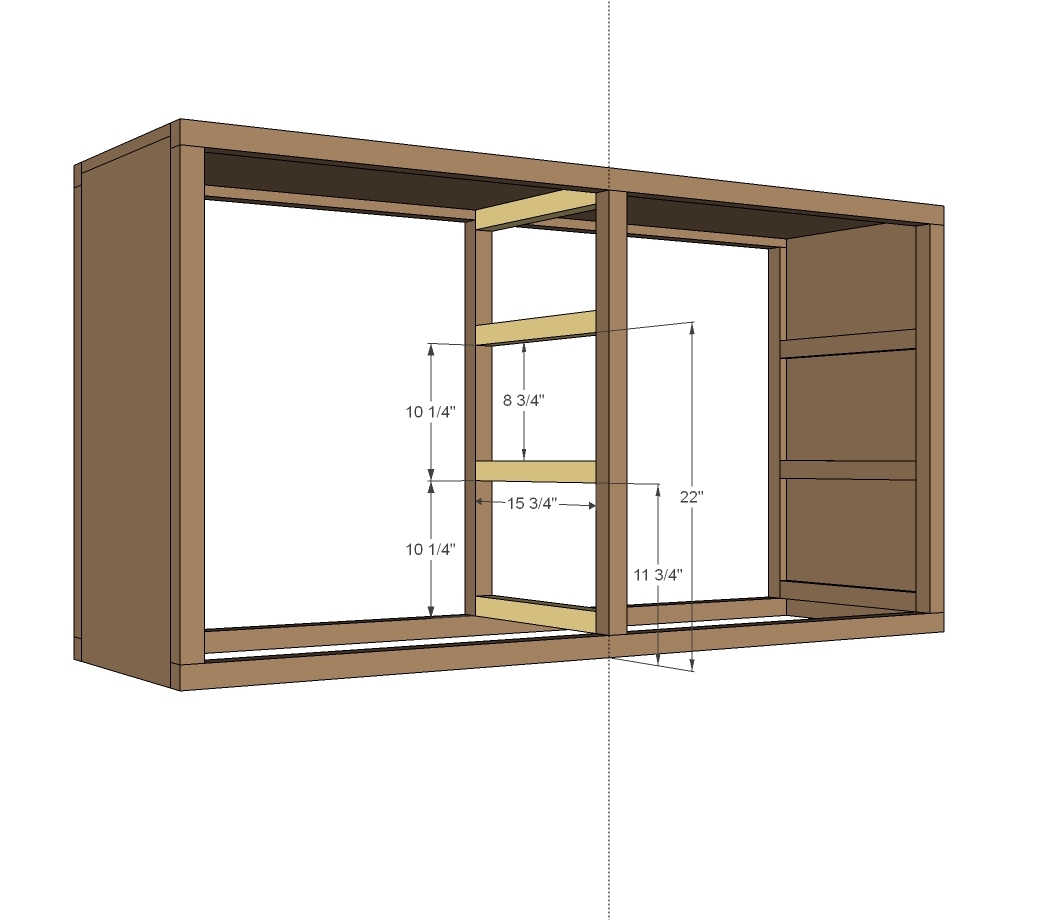

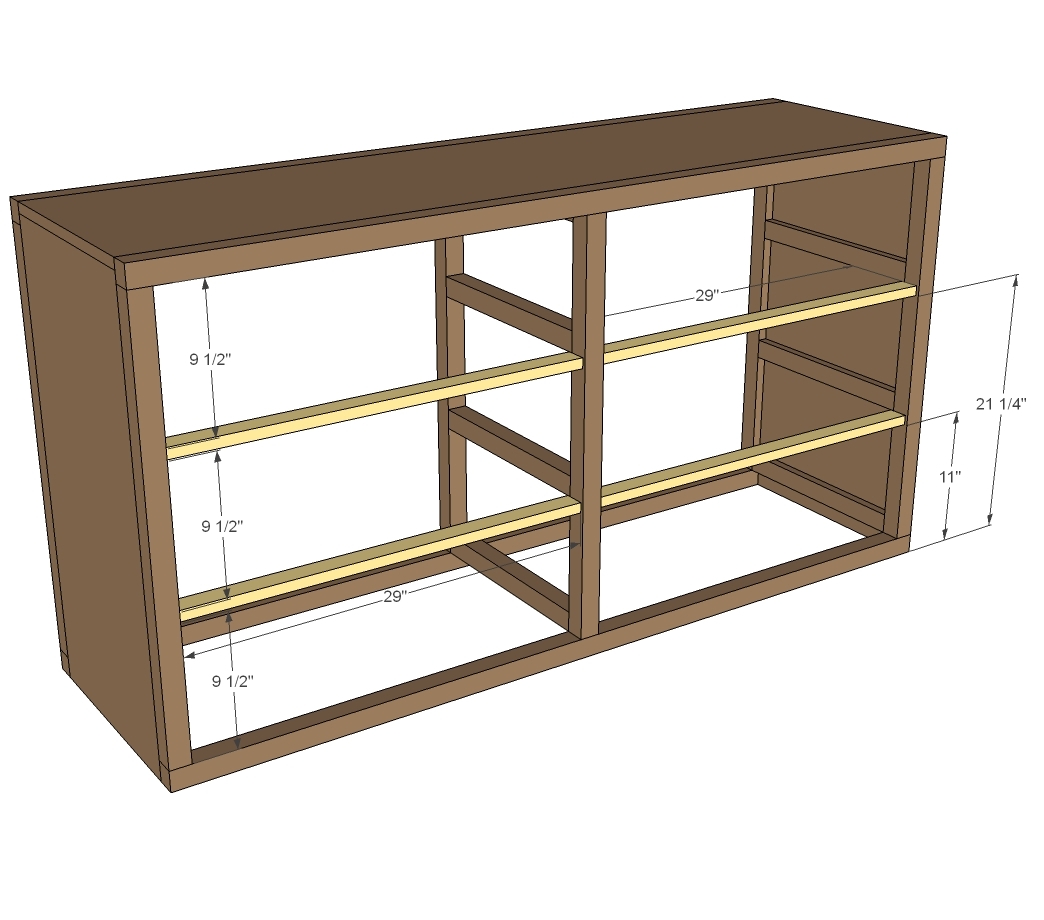

- 2 - 1x16 @ 32 1/4”

- 6 - 1x2 @ 15 3/4”

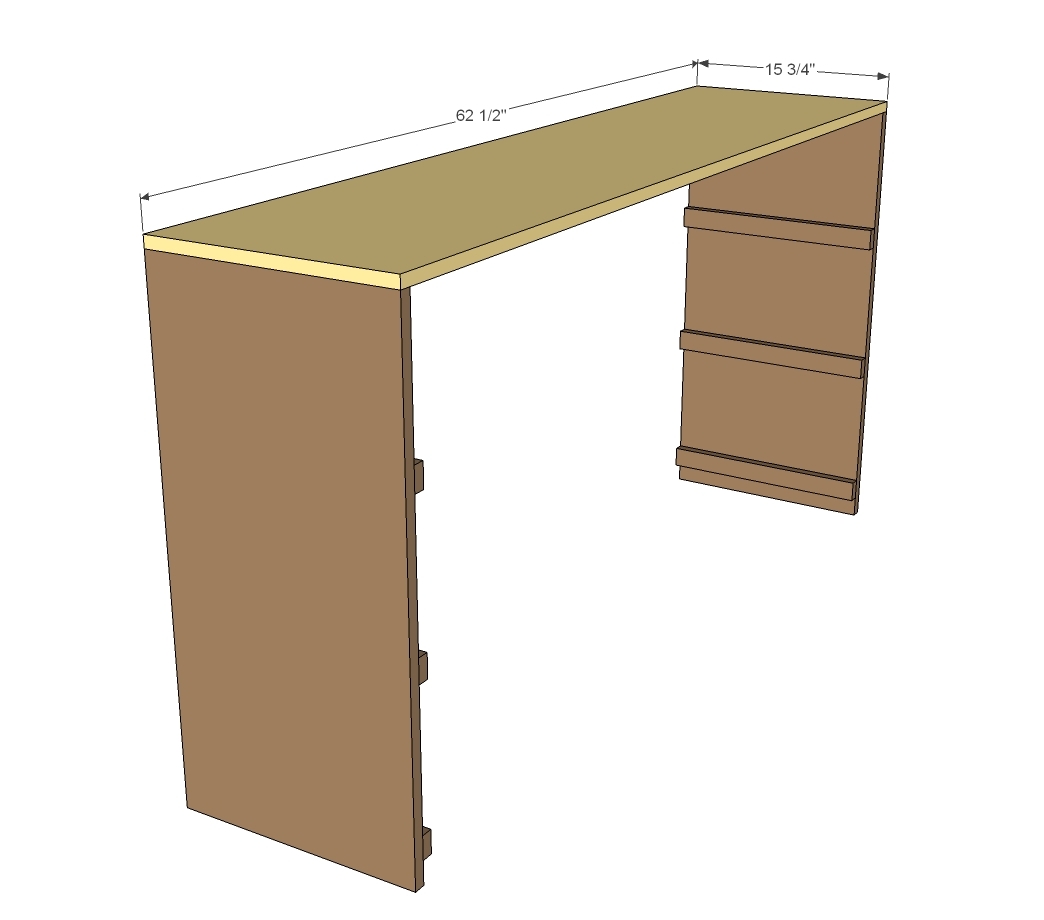

- 1 - 1x16 @ 62 1/2”

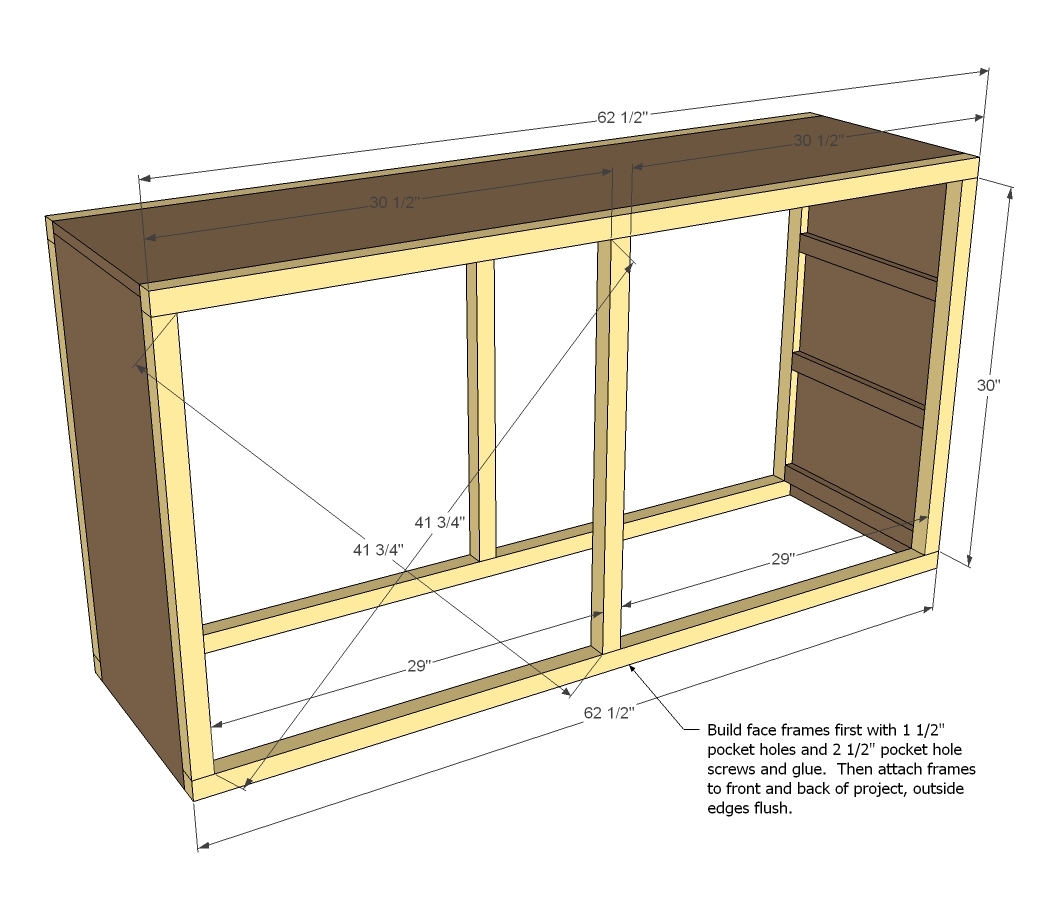

- 4 - 2x2 @ 62 1/2”

- 6 - 2x2 @ 30”

- 4 - 2x2 15 3/4”

- 4 - 1x2 @ 29”

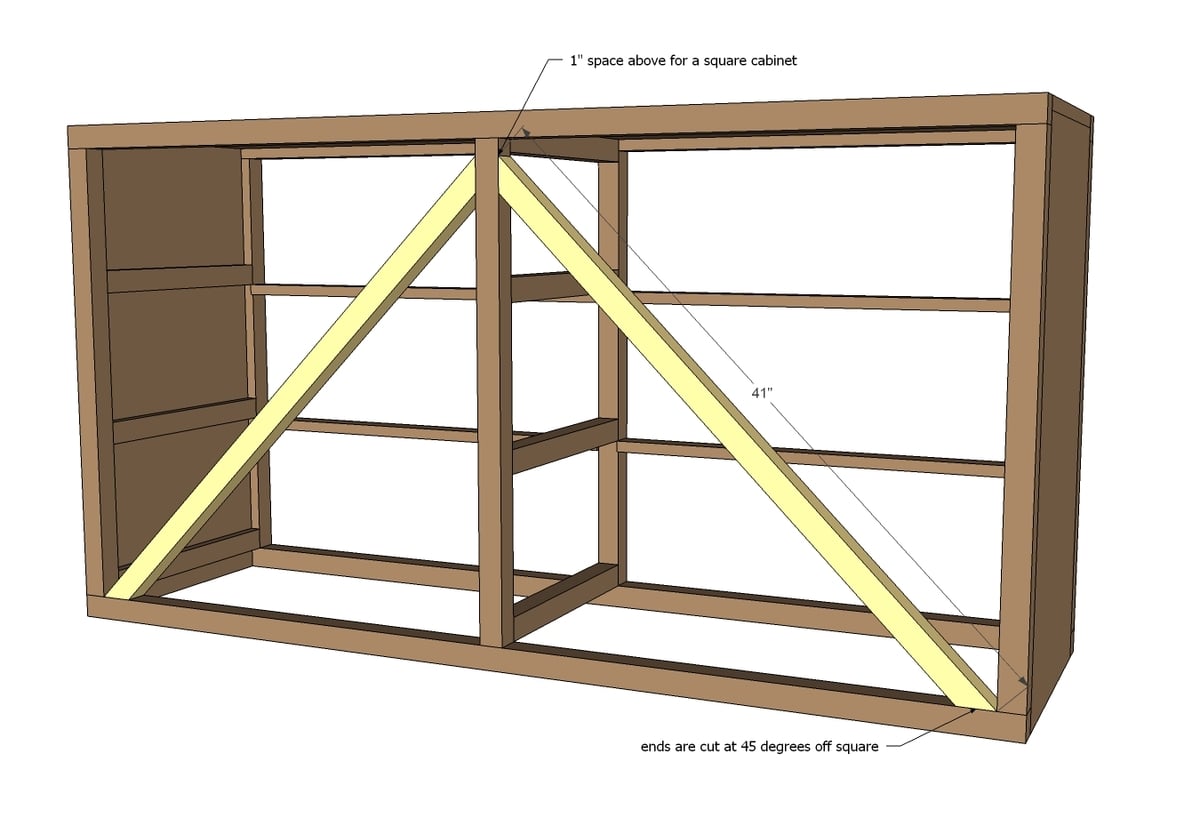

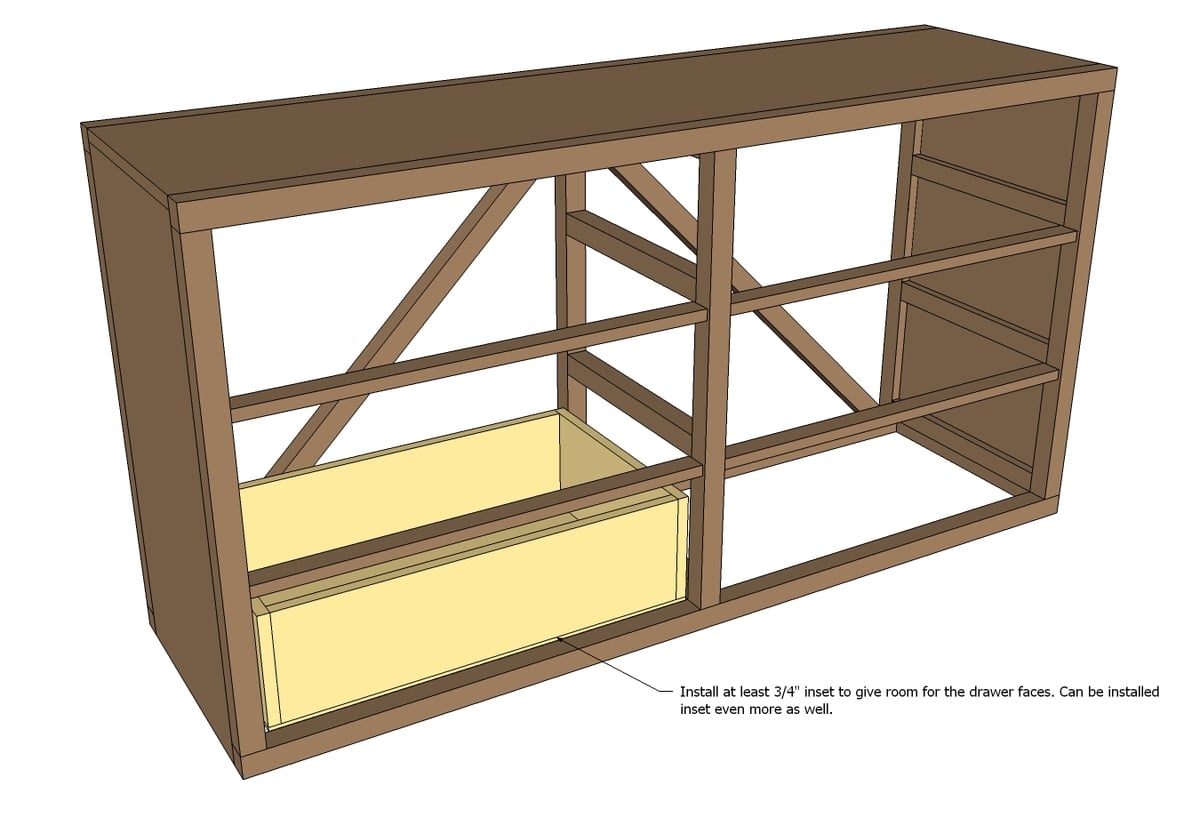

- 2 - 2x2 @ 41” (both ends cut at 45 degrees off square, ends NOT parallel, longest point measurement)

DRAWERS

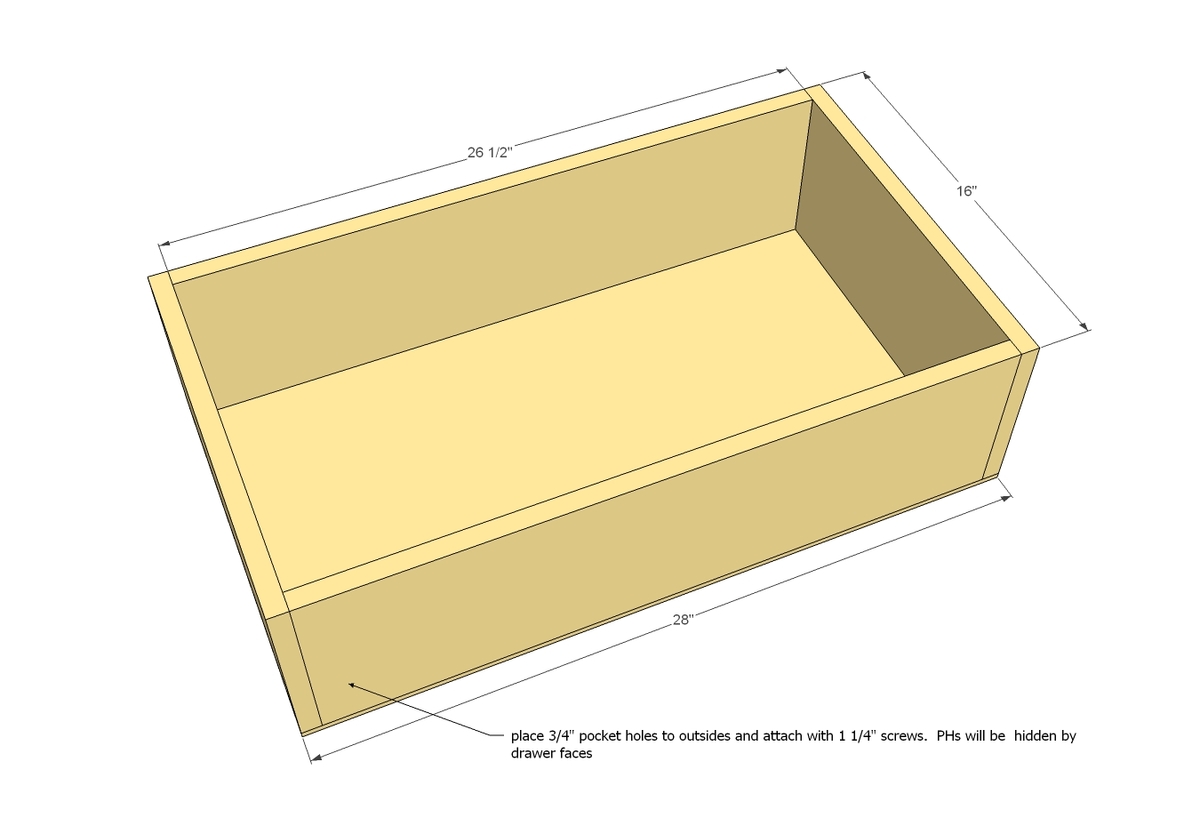

- 12 - 1x8 @ 26 1/2”

- 12 - 1x8 @ 16”

- 6 - 1/4” plywood 28” x 16” (tip: have 1/4” plywood ripped into 16” widths at hardware store)

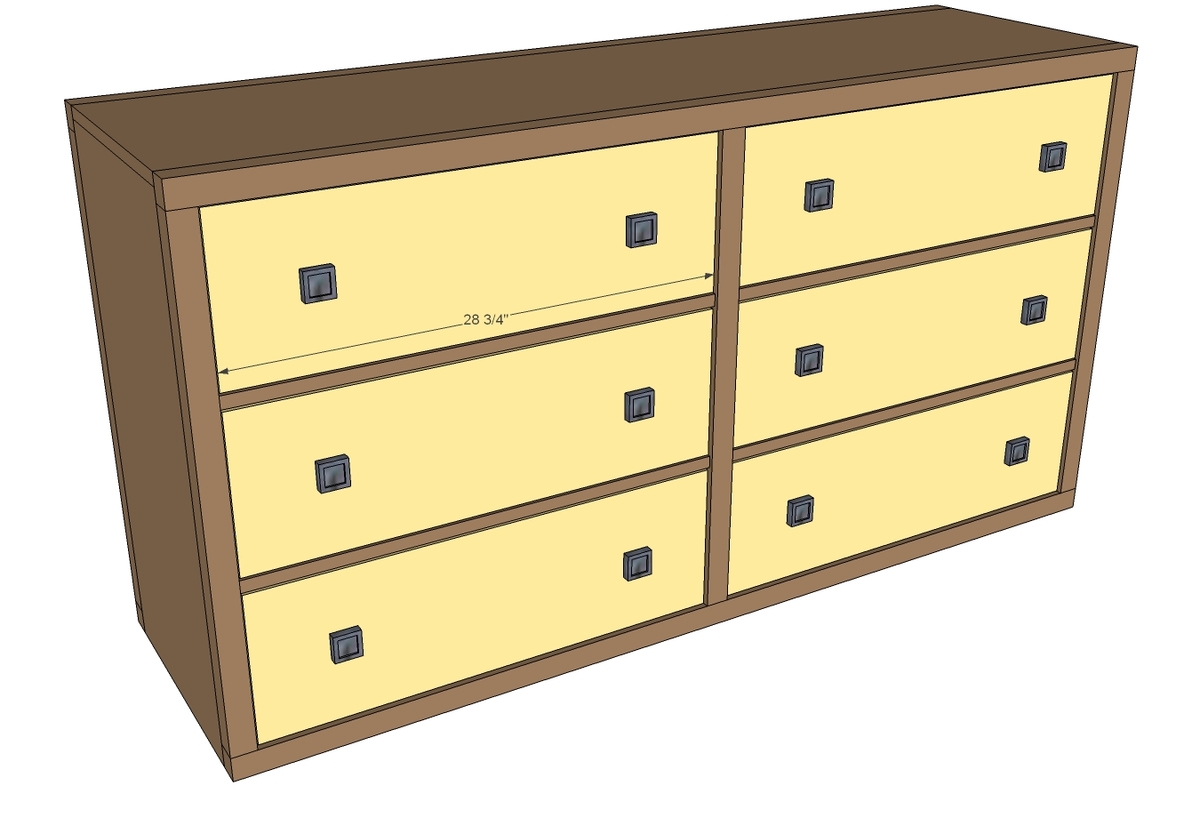

- 6 - 1x10 @ 28 3/4”

Back of dreser is optional

Please read through the entire plan and all comments before beginning this project. It is also advisable to review the Getting Started Section. Take all necessary precautions to build safely and smartly. Work on a clean level surface, free of imperfections or debris. Always use straight boards. Check for square after each step. Always predrill holes before attaching with screws. Use glue with finish nails for a stronger hold. Wipe excess glue off bare wood for stained projects, as dried glue will not take stain. Be safe, have fun, and ask for help if you need it. Good luck!

Instructions

Step 1

Step 2

Step 3

Step 4

Step 5

Step 6

These guys are to help take the weight off the center of the dresser and distribute it, and also to keep things square. You may feel you don't need them - I'm an overbuilding kinda gal :) Another option if you find your dresser needs additional center support (hey, you never know, you may be storing gold in there!) you can add and additional 5th wheel to the center.

Step 7

Drawer time! It's super important that your drawers are square and measure 1" less than the overall interior width of the drawer opening. NOTE that some drawer slides may vary in clearance requirements, so always read through the drawer slide instructions before building drawer boxes.

Drawer video - please watch this video for drawer installation:

Step 9

Now the fun part! Attach faces, with even 1/8" gap around all sides. I do this by setting in place with 1/8" shims on bottom and sides and attaching with glue and a couple of 1 1/4" finish nails. Then I open the door and attach from inside with a few 1 1/4" screws to secure. NOTE: Depending on your hardware, you may wish to attach hardware first to drawer face.

It is always recommended to apply a test coat on a hidden area or scrap piece to ensure color evenness and adhesion. Use primer or wood conditioner as needed.

Comments

Katie B (not verified)

Wed, 01/09/2013 - 14:52

Is there a price breakdown

Is there a price breakdown anywhere??

Jimbo09

Tue, 09/29/2015 - 08:36

Price Breakdown at my local lowes.

I went to lowes today to pick up enough product for building 2 of these dressers, one for me and one for my son, some extras, like the Kreg rip cut guide, and some stuff for a 2X6 bathroom door and a few other things for other projects. My total for everything was 483.68. now, I will breakdown cost for one dresser.

Shopping List:

1 - sheet 3/4” plywood ripped into strips 15 3/4” wide referred to as 1x16 boards throughout this plan

23.58

3 - 1x2 @ 8 feet long

1.12 each, total-3.36

6 - 2x2 @ 8 feet long (MUST BE VERY STRAIGHT!!!!)

1.67 each. total 10.02

6 - 1x8 @ 8 feet long

8.62 each, total 51.72

2- 1x10 @ 8 feet long

12.37 each, total 24.74

1 - 1/4” plywood for drawer bottoms/back

21.92

6 - 16” euro style white drawer slides (bottom corner mount)

5.27 each, total 31.62

1 1/4” and 2 1/2” PH screws

1 1/4” finish nails

Knobs or handles on hand.

I ommitted the wheels, knobs vary, mine were 1.68 each, total 10.08.

total cost of just materials, without knobs and wheels:

166.96 + tax so, 176.96 here in PA.

I thought this breakdown may help people get an idea in advance for this project. I budgeted $500 just for the dressers because I was unsure, no I am getting some other projects in the works as well.

Greg (not verified)

Thu, 01/10/2013 - 05:59

2x2

Where do you find 2x2 wood? I was building another dresser and could only find 2x2 in oak in a 36" piece at the orange box store.

I ended up having to rip down 2x6s but that was in pine. I would love to find somewhere that sells 2x2 in hardwoods for good furniture like this.

Dan S (not verified)

Thu, 01/17/2013 - 23:46

Home depot and Lowes sells

Home depot and Lowes sells them in their lumber dept. They are usually by the 1x2 and 1x3 if you can find those. Hope that helps

Tanja

Sun, 09/15/2013 - 06:42

Great design!

Luv this design! Wondering... with a little tweeking.. these would make great cabinets in my new 'old world, modern' kitchen! I'm traditional old world my hubby is more modern... LOL. Dresser looks great!

keltik

Fri, 07/11/2014 - 08:45

Legs instead of wheels?

I really like this, but would prefer legs instead of wheels. Looking at the design, I could make the 2x2's longer than 30", but the plywood is attached to them. I could maybe cut 4 2x2s at 3" long and then attach underneath?

Any suggestions? I'm new to this. :)

jgbreeden

Sat, 07/12/2014 - 10:20

Extend the 2x2s

Definitely extend the 2x2s. If you cut short stubs, they would have no lateral support. It should not change how the plywood attaches, you'll just need to cut the lower rails 3" shorter.

Klevine34

Tue, 10/18/2016 - 21:40

Change it up

Is it possible to make this a 6 drawer vertical dresser with some measurement tweaking? I love it, just have a narrow space.

Klevine34

Sun, 10/23/2016 - 20:32

I love this dresser but I'm

I love this dresser but I'm needing to build a vertical 6 drawer dresser for the space I have. If I would alter this plan a bit, would I still need the supports in the back?

huckleb33y

Wed, 07/14/2021 - 19:36

Where can i find the metal…

Where can i find the metal pieces that are on the corners and in the middle of the dresser for decoration and what would i look up to find them?