Create a beautiful entry for about $80 with our rustic hall tree. Built using 2x lumber, it's sturdy, functional, and gorgeous! Our free step by step plans include shopping and cut lists, and full diagrams. Plans by Ana-White.com

Build the entire collection and upgrade your home -

Collections

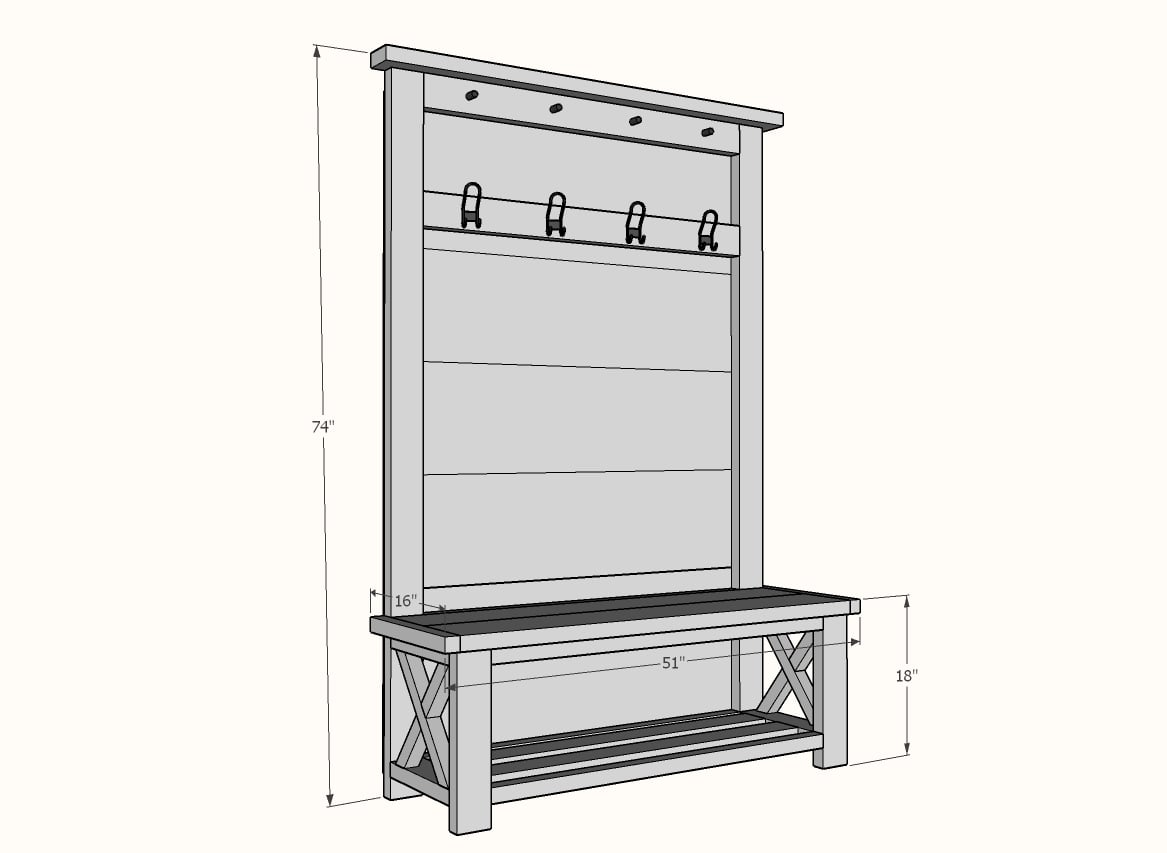

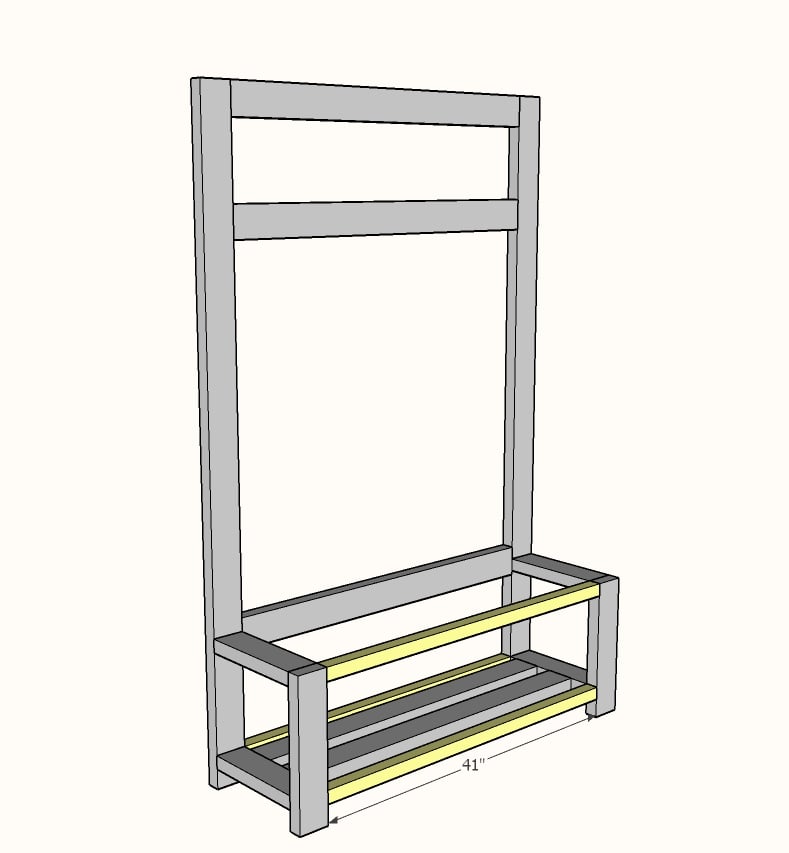

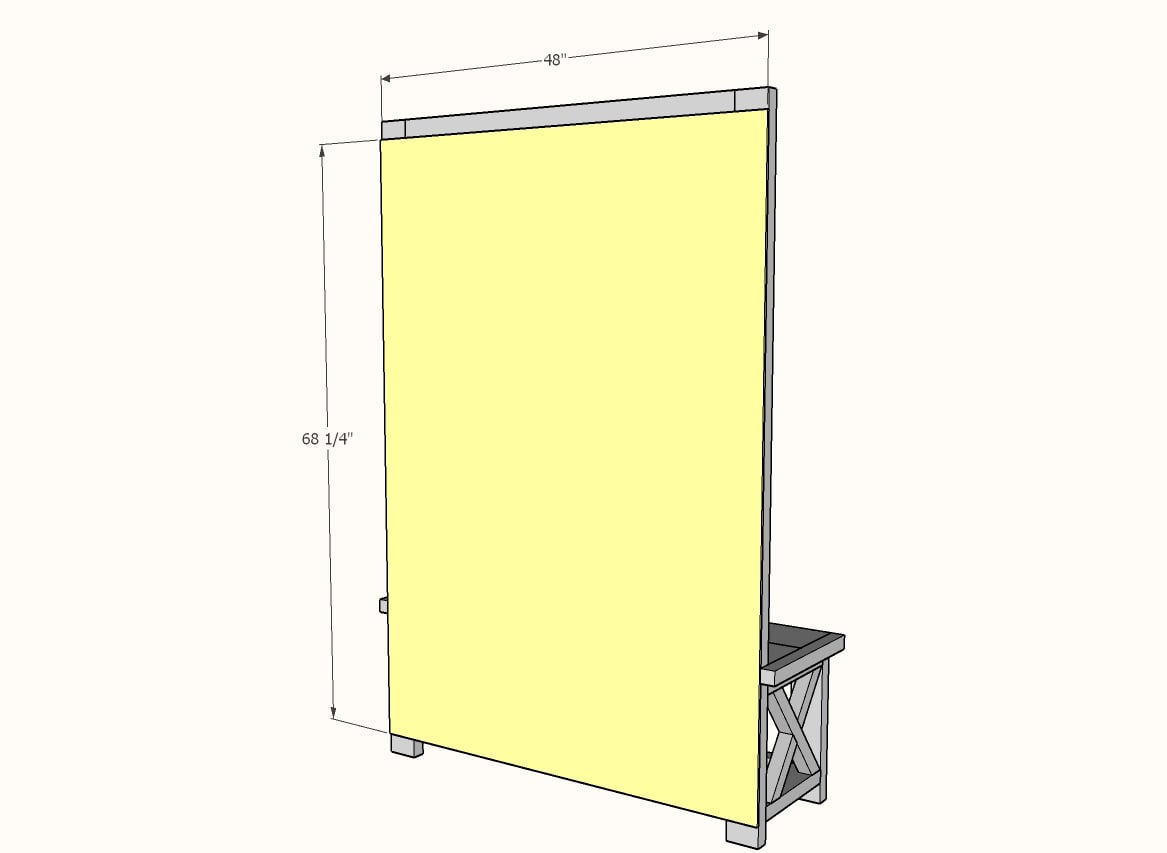

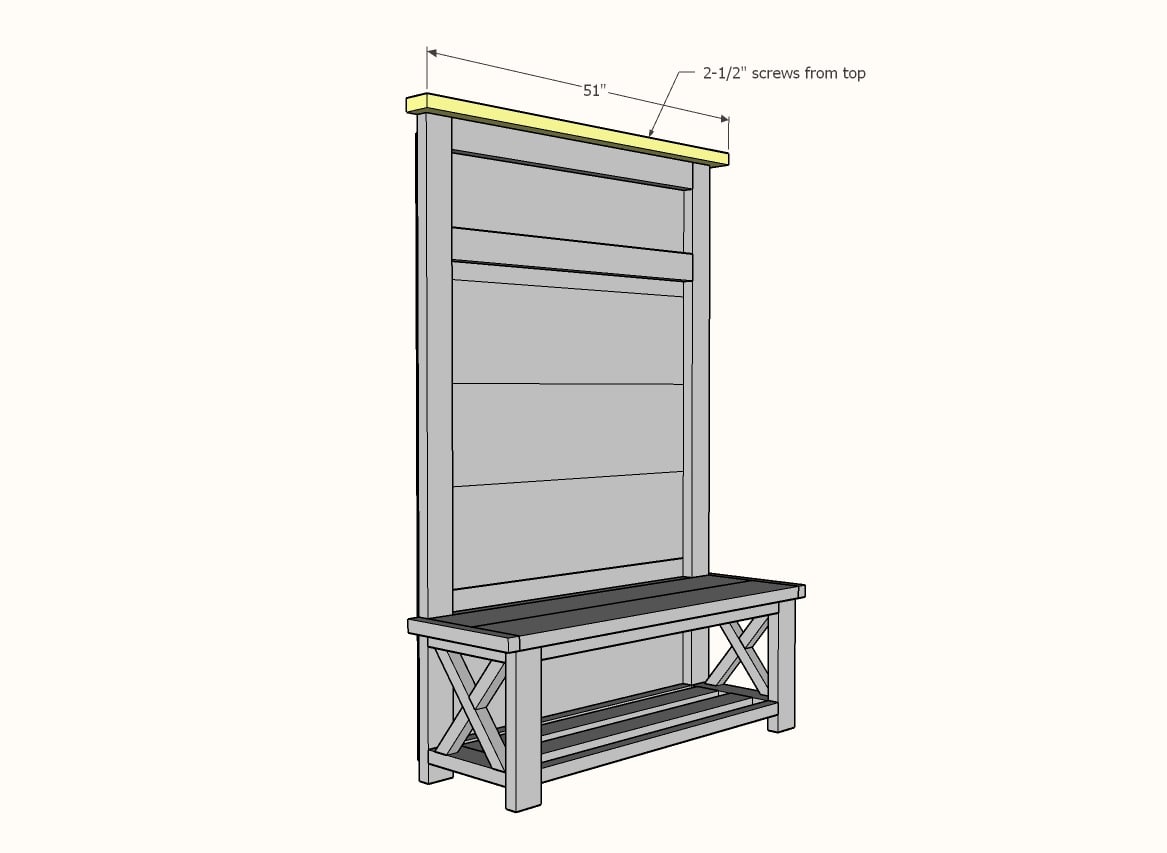

Dimensions

Dimensions shown in diagram

Preparation

Shopping List

- 6 - 2x4 x 8 feet long

- 3 - 2x2 x 8 feet long

- 1 - 2x8 x 8 feet long

- 50 - 2-1/2" pocket hole screws

- 25 - 2-1/2" self tapping wood screws for attaching the top (can use the pocket hole screws too)

- 3/4" brad nails for attaching the back and wood glue

- 4 hooks

Cut List

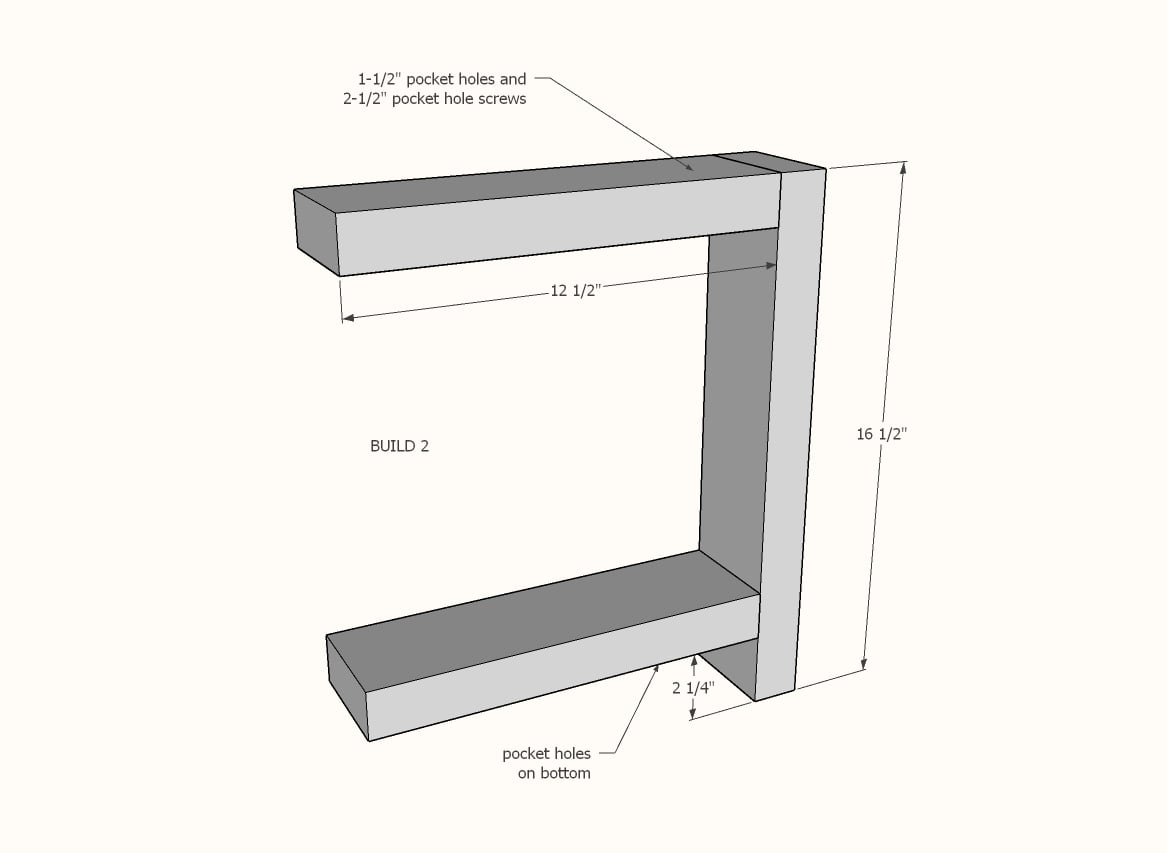

- 2 - 2x4 @ 16-1/2" - front legs

- 4 - 2x4 @ 12-1/2" - ends

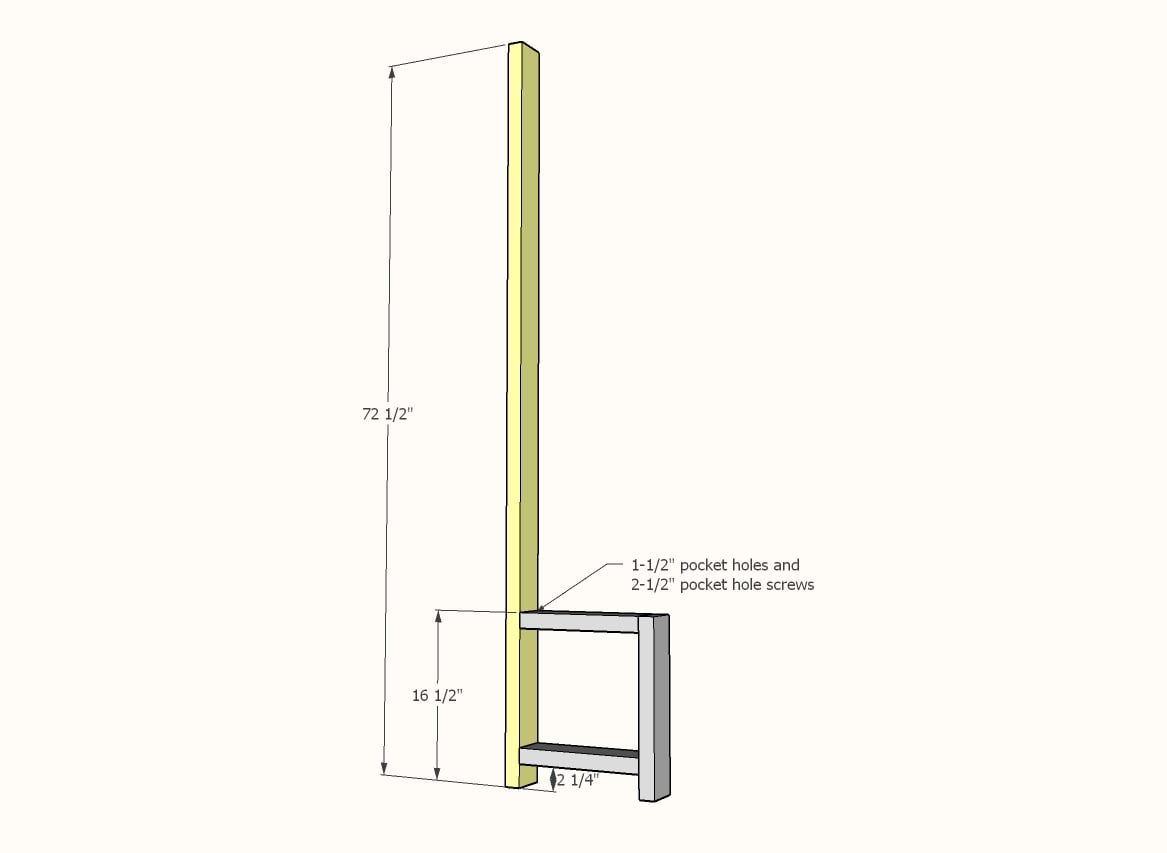

- 2 - 2x4 @ 72-1/2" - back legs

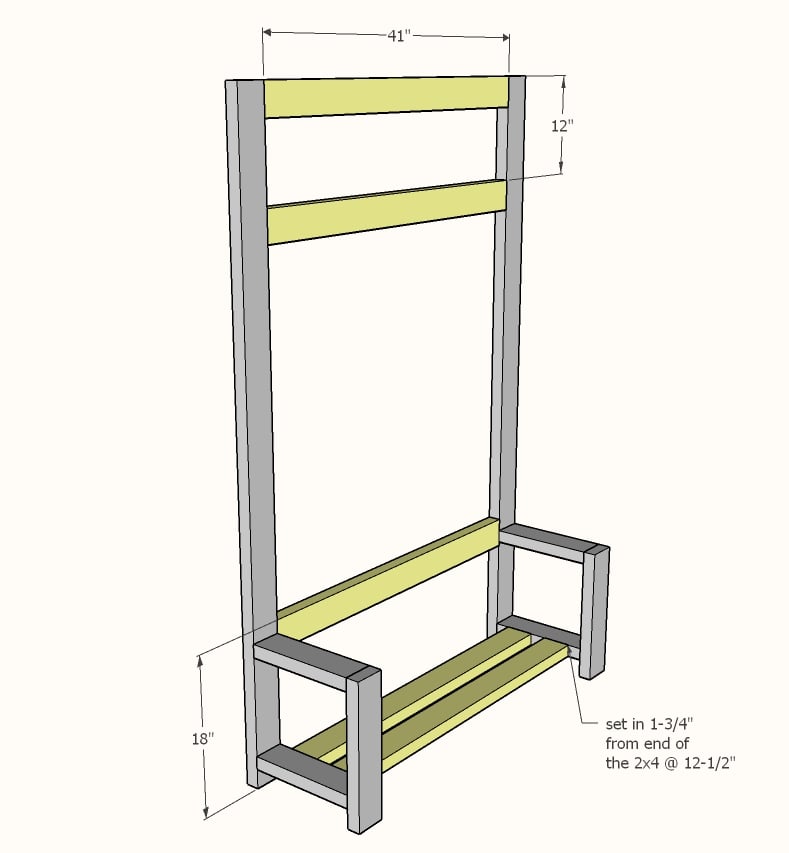

- 5 - 2x4 @ 41" - horizontal tie ins

- 3 - 2x2 @ 41" - horizontal tie ins

- 2x2s for the Xs scribed and cut in plan

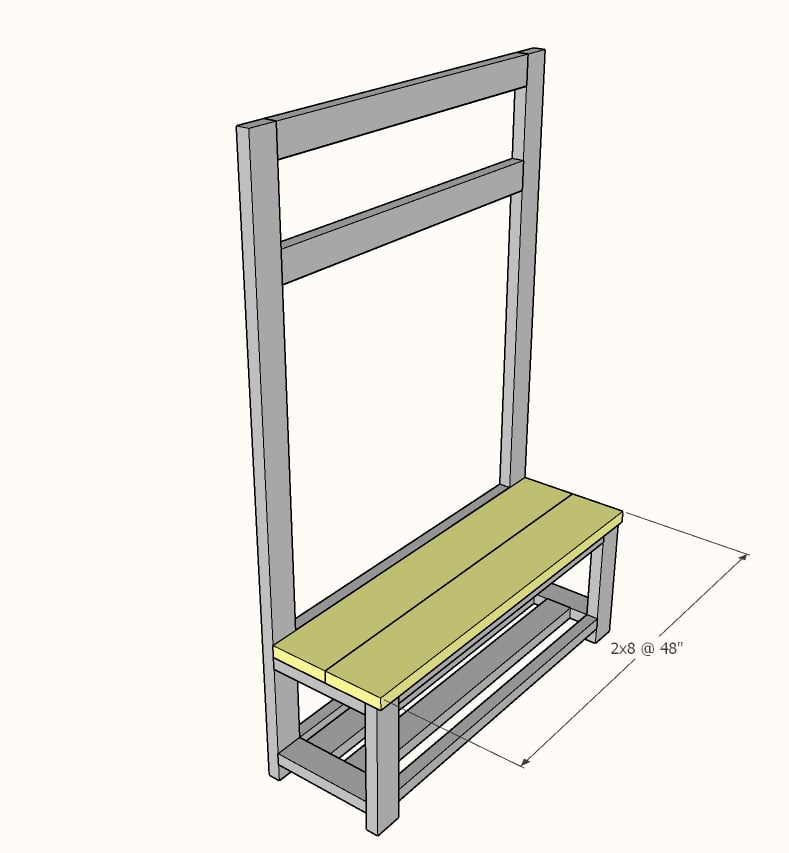

- 2 - 2x8 @ 48" - seat

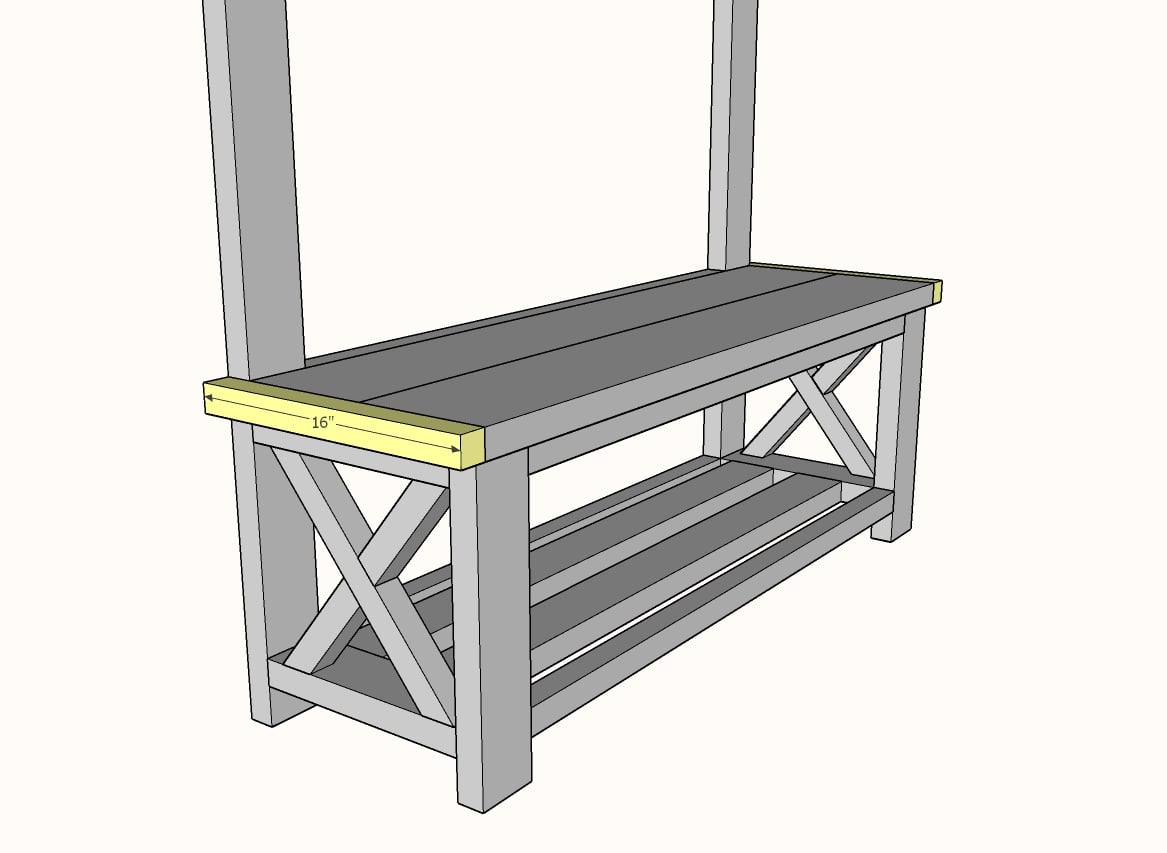

- 2 - 2x2 @ 16" - seat ends

- 1 - 2x4 @ 51" - top

- 1/4" plywood 48" x 68-1/2" - back

Instructions

Step 1

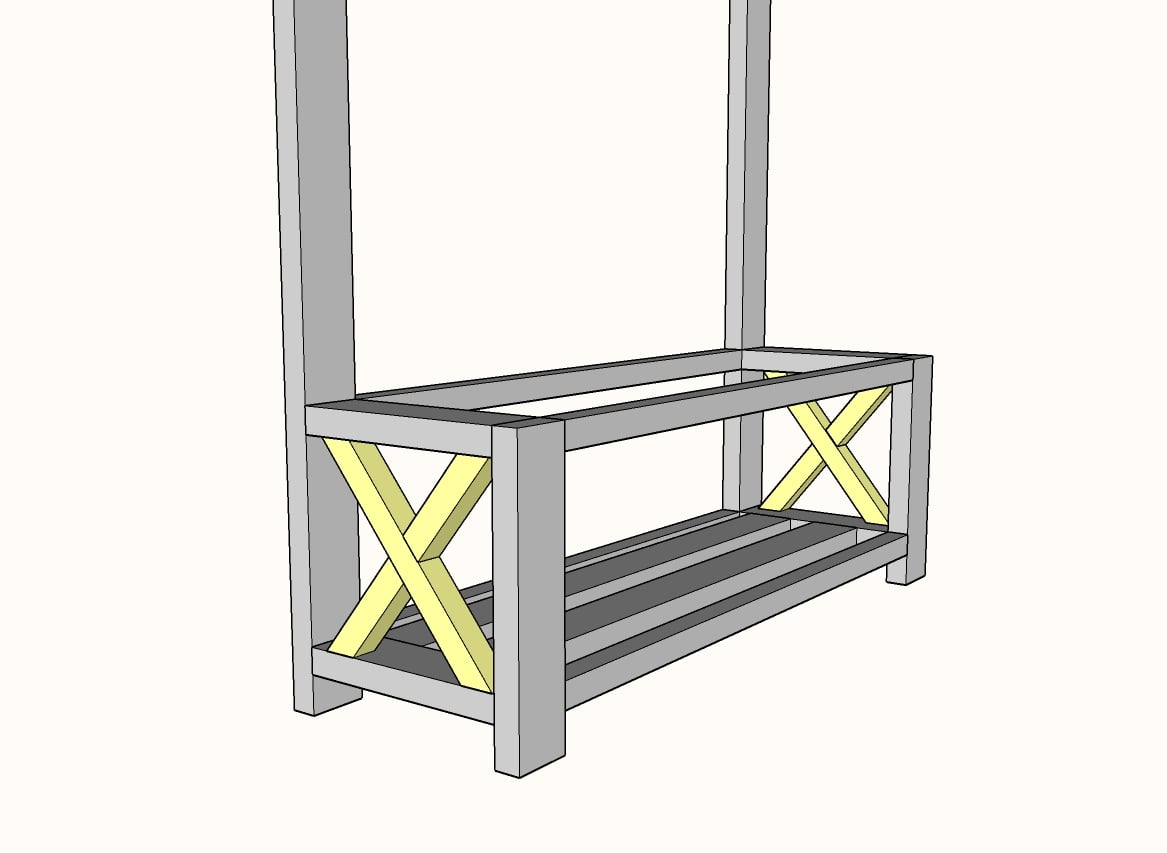

Step 3

Step 4

Step 5

Scribe and cut the Xs as demonstrated in the video.

Attach the smaller X pieces to the larger piece with single 1-1/2" pocket holes with 2-1/2" pocket hole screws.

Then use 2-1/2" screws to attach the X from the outside of the legs. You can also use 2-1/2" pocket hole screws if you don't have other screws.

Step 6

Step 7

Finishing Instructions

Finish Used

For the finish we used Behr Marquee in off the shelf white in a semi-gloss finish. We sprayed and then finished with rollers and brushes.

Project Type

Room

Comments

SuperGeorge

Mon, 12/30/2019 - 12:02

Completed this about a week…

Completed this about a week ago. As usual, I went with the "--" instead of the "X", but it still turns out great. Would have loved to upload, but no such opportunity. I need to look for my next project (preferably a bookshelf)

cdadams1223

Sat, 02/22/2020 - 16:38

Finished building this today…

Finished building this today. It was a fun build and I'll probably build a few more for friends/family. Wish I could figure out how to post my build.

jman11

Fri, 05/15/2020 - 14:39

Great Design!

Thanks for the plan. I built it with a few edits to make it slightly less rustic!

mpbmw94

Mon, 03/08/2021 - 11:46

Halltree

Thank you for the plan Ana. I changed it up a bit but I enjoyed building this halltree.