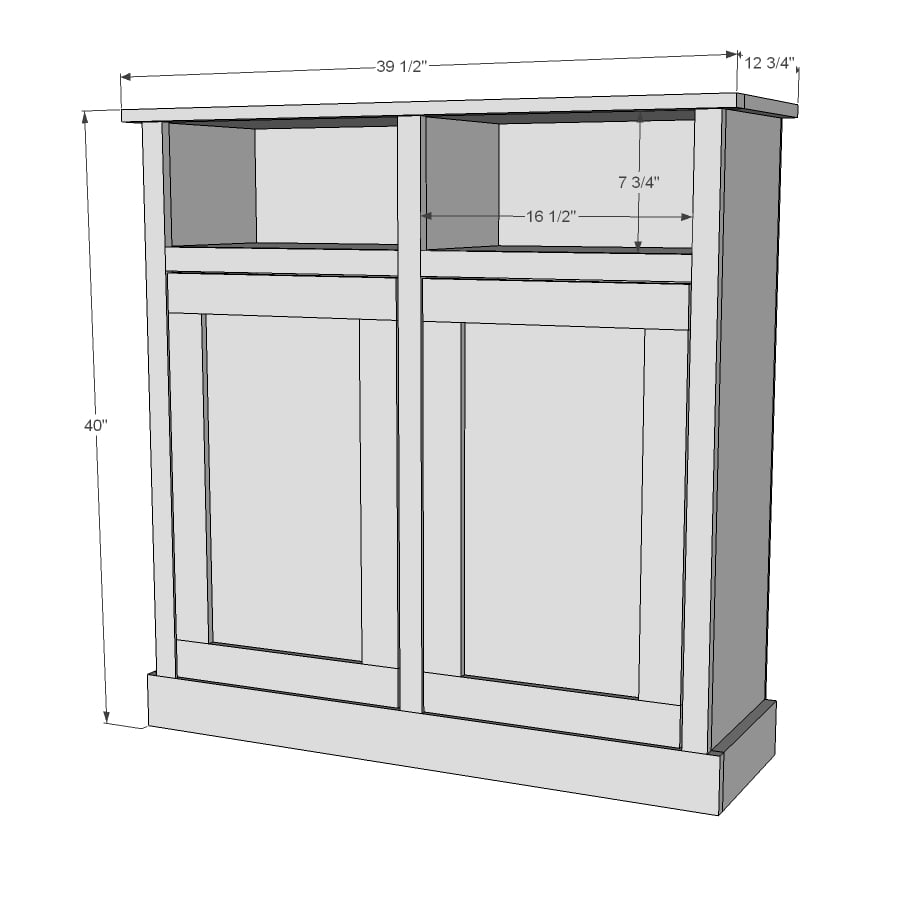

Free plans to build an open shelf console from Ana-White.com

Preparation

- 1 sheet 3/4" plywood cut into strips 11 1/4" wide (Whitney used PureBond Formaldehyde Free Plywood) or you can use 3 - 1x12 boards @ 8 feet long

- 1 - 1x4 @ 6 feet long

- 2 - 1x2 @ 8 feet long

- 2 - 1x3 @ 6 feet long

- 1/4 plywood (Whitney used PureBond) for back and door backs

- Recommend pocket hole construction with 1 1/4" pocket hole screws

- 1" and 1 1/4" brad nails for attaching face frame and 1/4" plywood

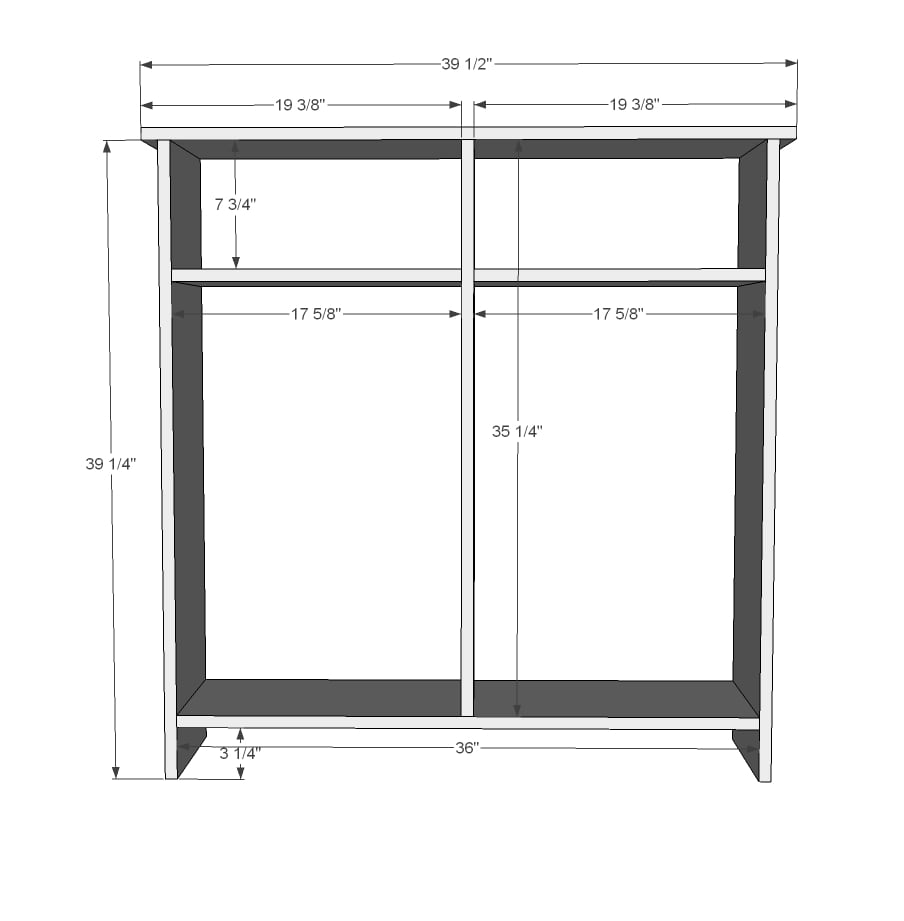

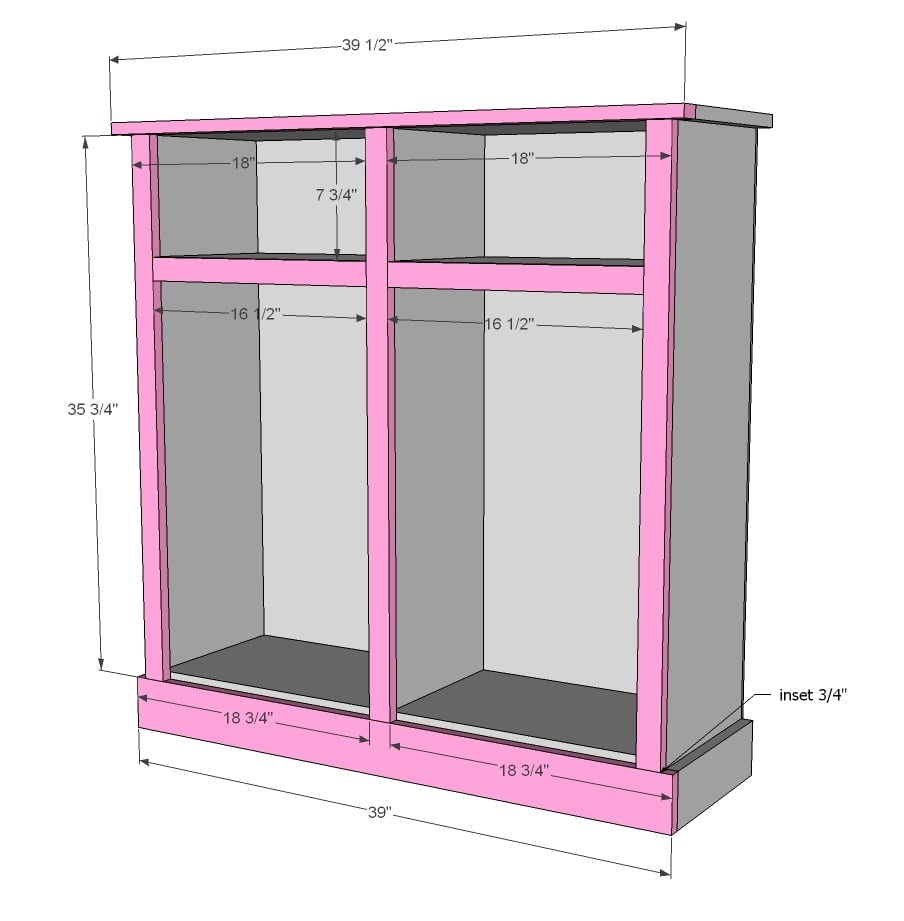

Sides - 2- 1x12 @ 39 1/4"

Top - 1- 1x12 @ 39 1/2"

Bottom Shelf - 1- 1x12 @ 36" (I positioned this shelf where the top of the shelf is 7 3/4" from the top of the cabinet)

Center Divider - 1- 1x12 @ 35 3/4"

Shelves under baskets - 2 - 1x12 @ 17 5/8"

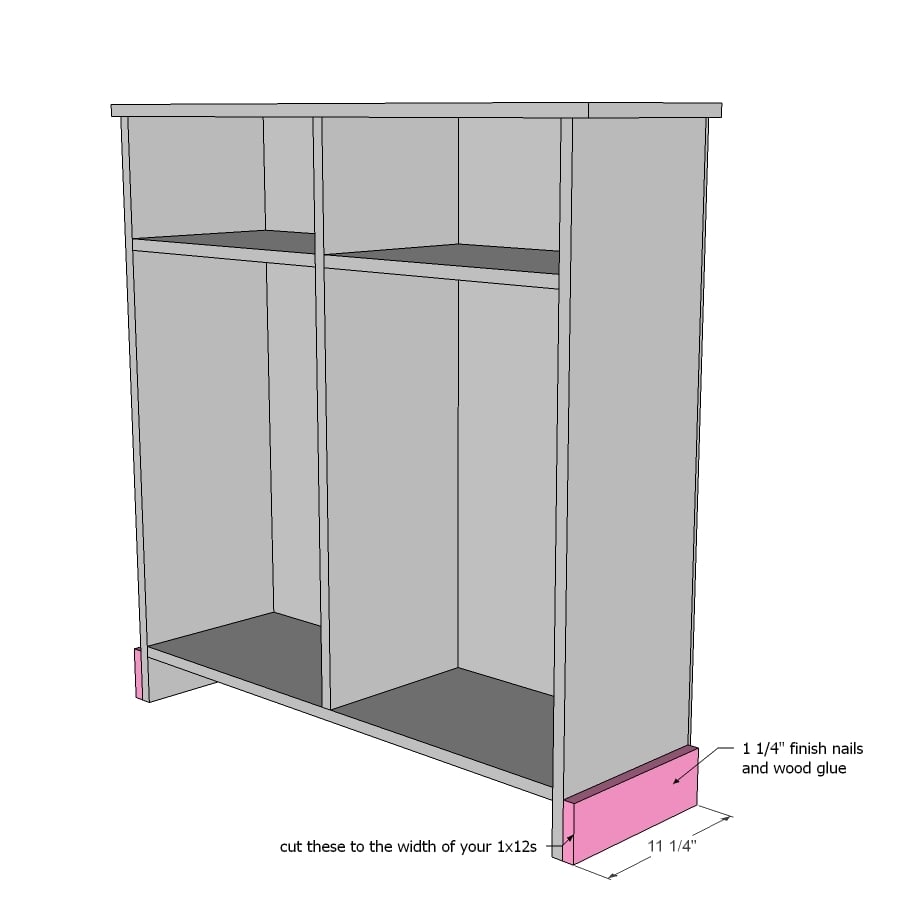

Footer Front - 1- 1x4 @ 39"

Footer sides - 2 - 1x4 @ 11 1/4"

Front Trim - 3 - 1x2 @ 35 3/4"

Top front - 1- 1x2 @ 39 1/2"

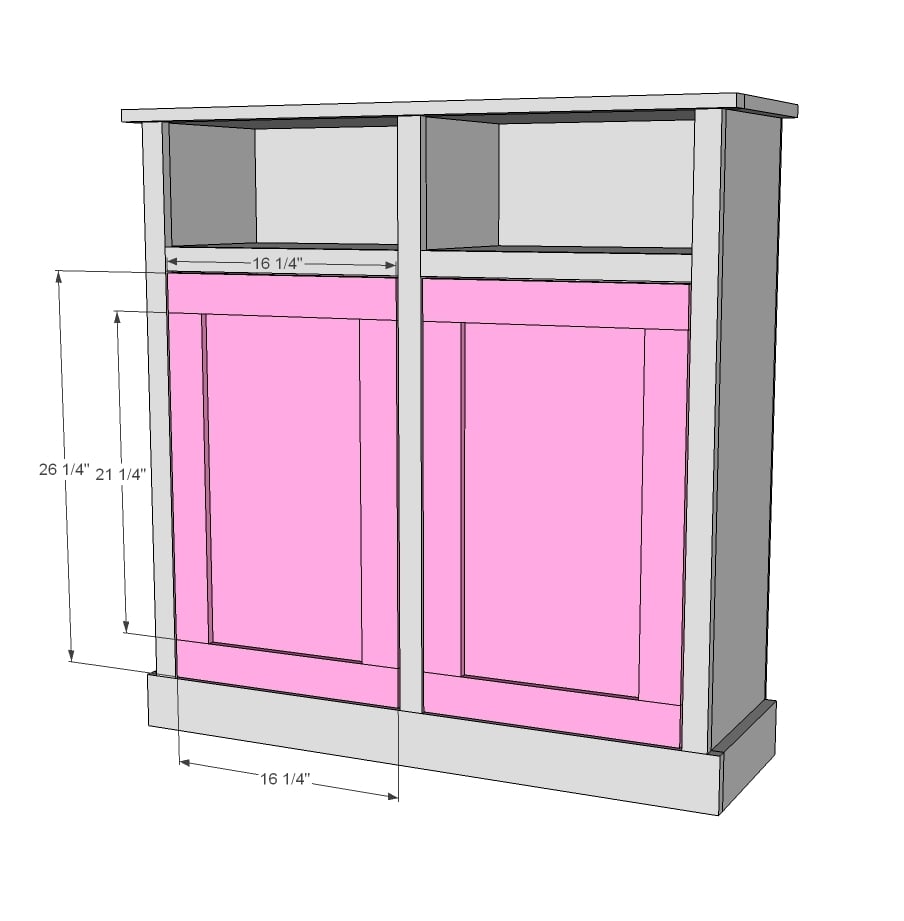

Doors - Whitney used 1x3 for the doors.

Door tops - 16 1/4"

Door Sides - 21 1/4" 1/4"

PureBond for the doors at 16"x26"

Optional shelves on inside from scraps. If you use the 1x12 it will need to be cut down about an inch to make room for the flush doors.

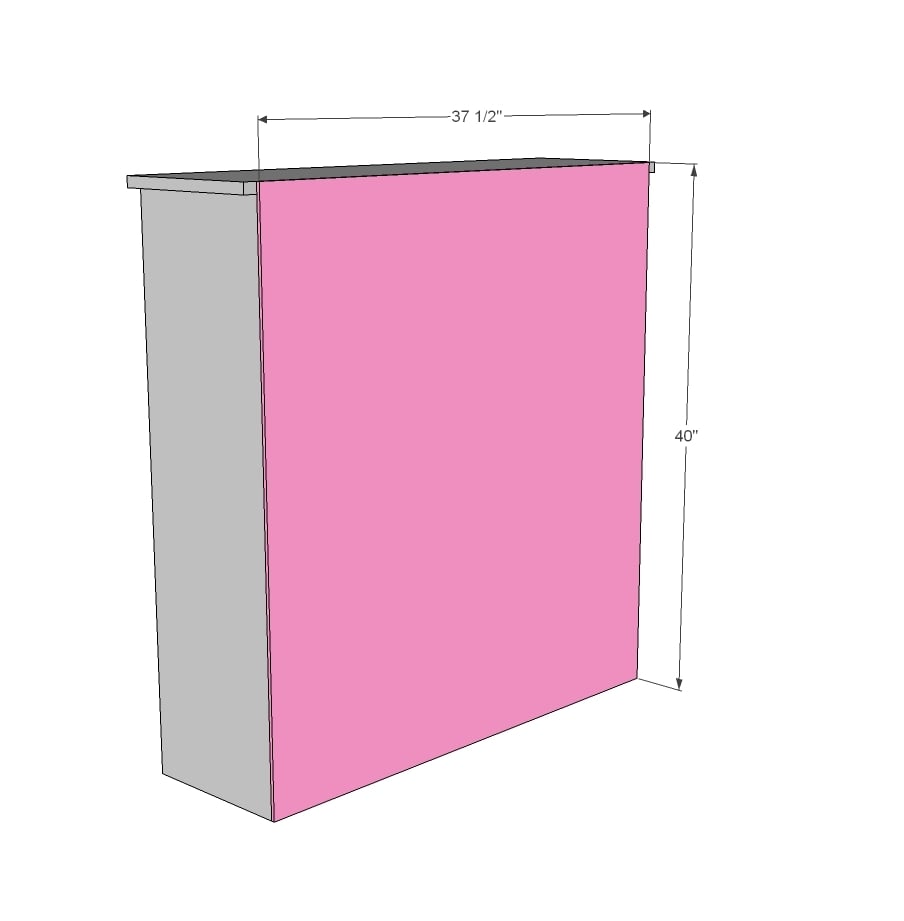

Back - 1/4" PureBond @ 37 1/2 x 39"

Please read through the entire plan and all comments before beginning this project. It is also advisable to review the Getting Started Section. Take all necessary precautions to build safely and smartly. Work on a clean level surface, free of imperfections or debris. Always use straight boards. Check for square after each step. Always predrill holes before attaching with screws. Use glue with finish nails for a stronger hold. Wipe excess glue off bare wood for stained projects, as dried glue will not take stain. Be safe, have fun, and ask for help if you need it. Good luck!

Instructions

Step 1

Step 4

It is always recommended to apply a test coat on a hidden area or scrap piece to ensure color evenness and adhesion. Use primer or wood conditioner as needed.

Comments

lscrandall

Tue, 08/06/2013 - 20:14

SHANTY OPEN SHELF CONSOLE GOES WINE CABINET

This weekend I took the plans from the SHANTY OPEN SHELF CONSOLE and modified it to become a wine cabinet. This wine cabinet is being donated to a local children's charity (United Services for Children) for their big auction night on August 17th here in St Charles Missouri. We hope the piece brings their school the much needed funds. Thank you Ana for providing a plan I could modify in a weekend to get this piece completed! You are awesome!!! PS - The momplex is looking great!

cassiet717

Tue, 10/22/2013 - 13:44

Missing Cuts for Step 4

Step 4 shows trim for the bottoms of the open shelves (2 - 16 1/2" pieces), but I don't see that on the cut list. Is it not supposed to be trimmed there or was it maybe left out?

SarahC

Wed, 11/18/2015 - 14:59

What kind of wood?

What kind of wood do you suggest using for the 1x2, 1x3, 1x4? Are furring strips ok or not for this kind of project? It's my first build and I plan on painting it.

Ana White Admin

Thu, 11/19/2015 - 12:23

Wood

I'd go with pine or doug fir and stir away from firring strips for this project.

cslavinsky

Fri, 01/08/2016 - 18:46

Can this withstand the weight of granite?

We have a slab of granite in our garage that would make the perfect top for this cabinet. Are there any adjustments that I would need to make in order to use the granite for the top? It's pretty heavy. Also, would I be able to use casters on the bottom, or should I leave it as is if I'm going to use the granite?

sharonhurff

Mon, 06/17/2019 - 07:21

How do you make the cabinet…

How do you make the cabinet doors flush? I put a shelf in the bottom portion and with the beadboard it won't sit flush.