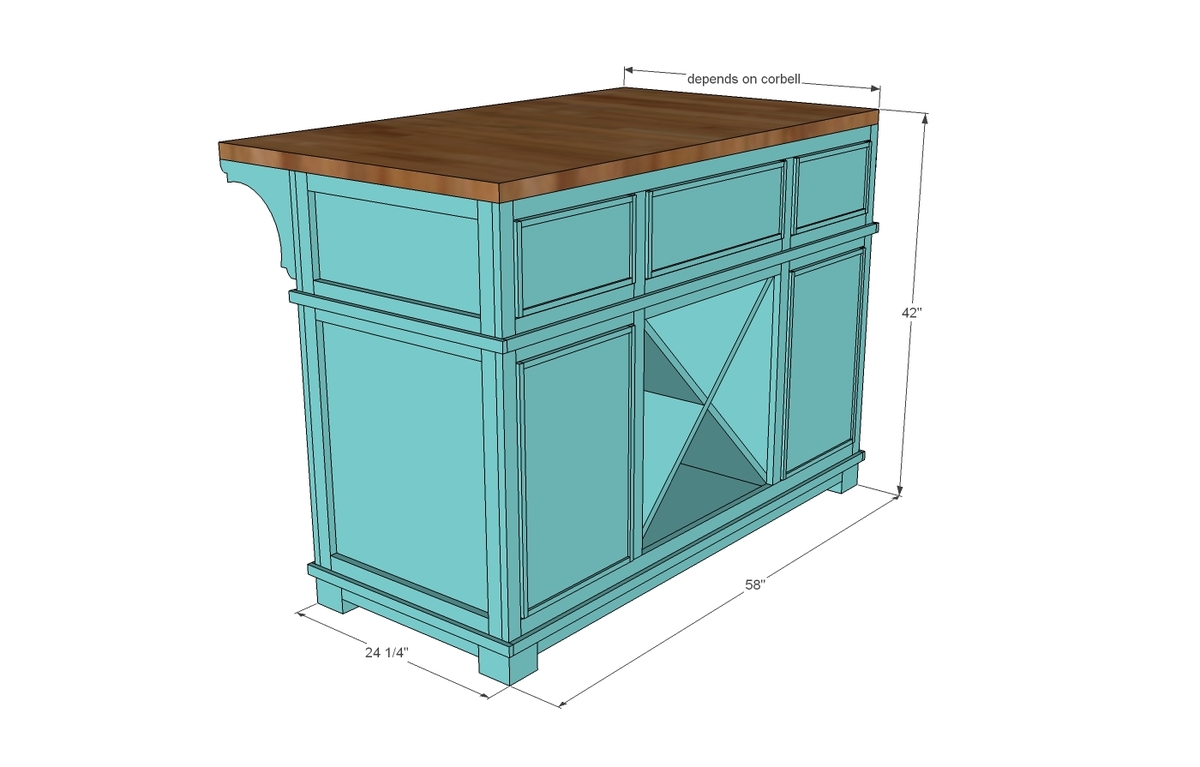

Free kitchen island plans from Ana-White.com

Preparation

2 sheets of 3/4" plywood ripped into strips 8 feet long x 22 1/2" wide

1 sheet 1/4" plwyood (back and drawer bottoms)

7 - 1x2 @ 8 feet long

2 - 1x4 @ 8 feet long

12 feet of 1x3s or 2x3s (for base)

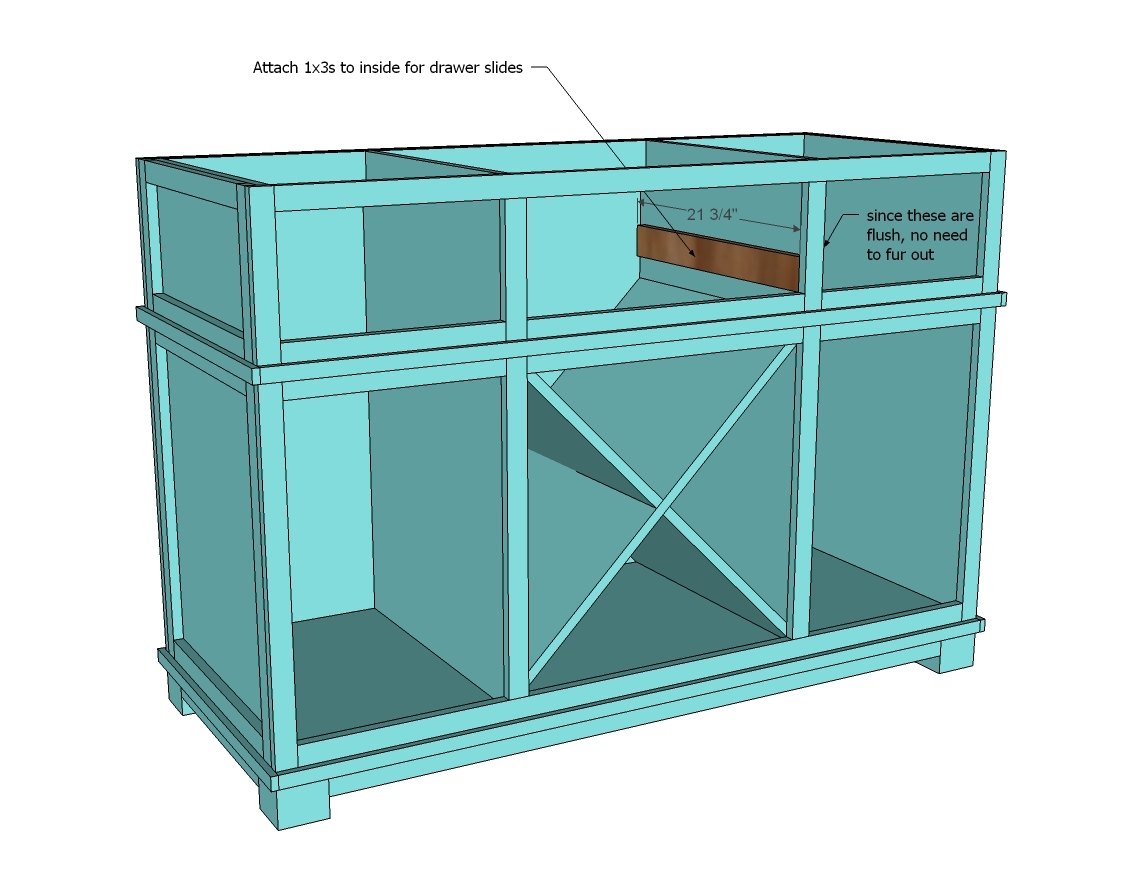

10 feet of 1x3s (supports and drawer furring)

18" of 4x4s

20 feet of 1x6s

3 sets of 21" Euro Style bottom corner mount drawer slides (the white cheapo ones)

2 sets of inset hinges

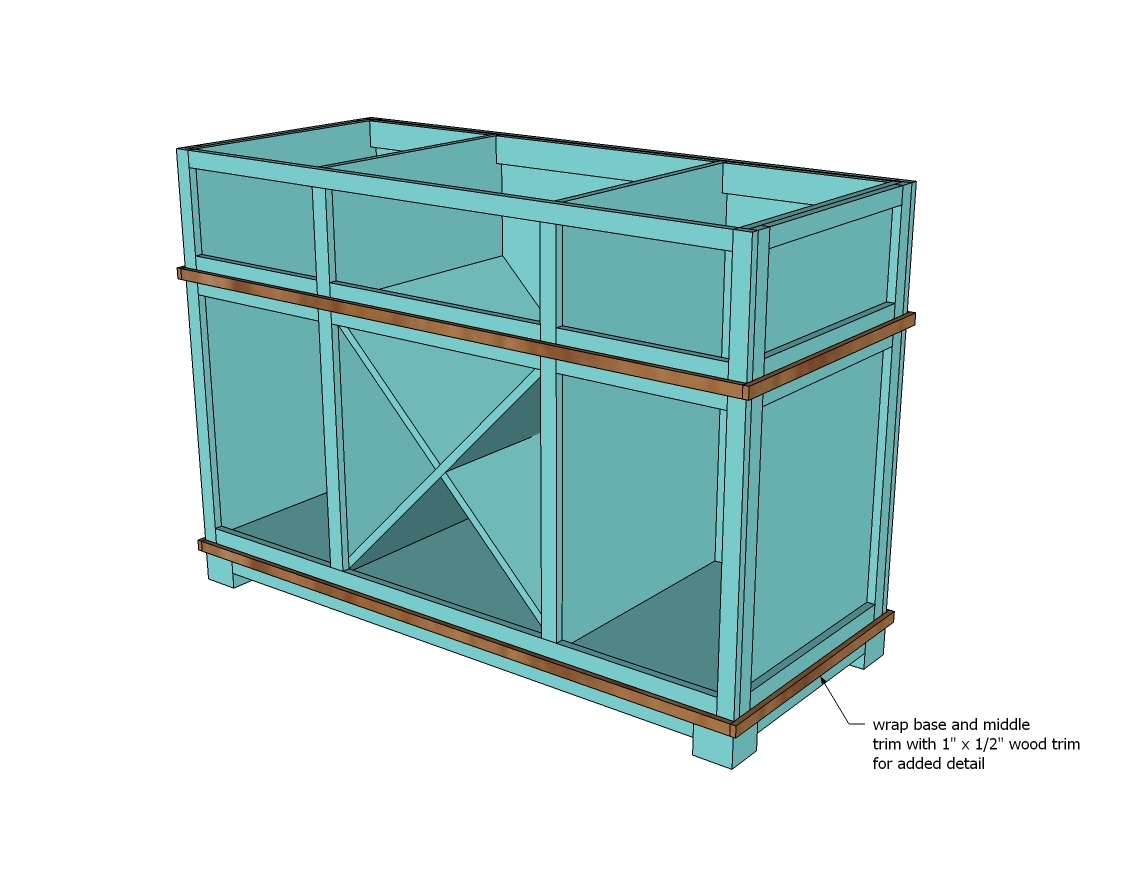

7 - 8 foot sticks of wood moulding 1" x 1/2"

1 1/4" pocket hole screws

1" and 1 1/4" finish nails

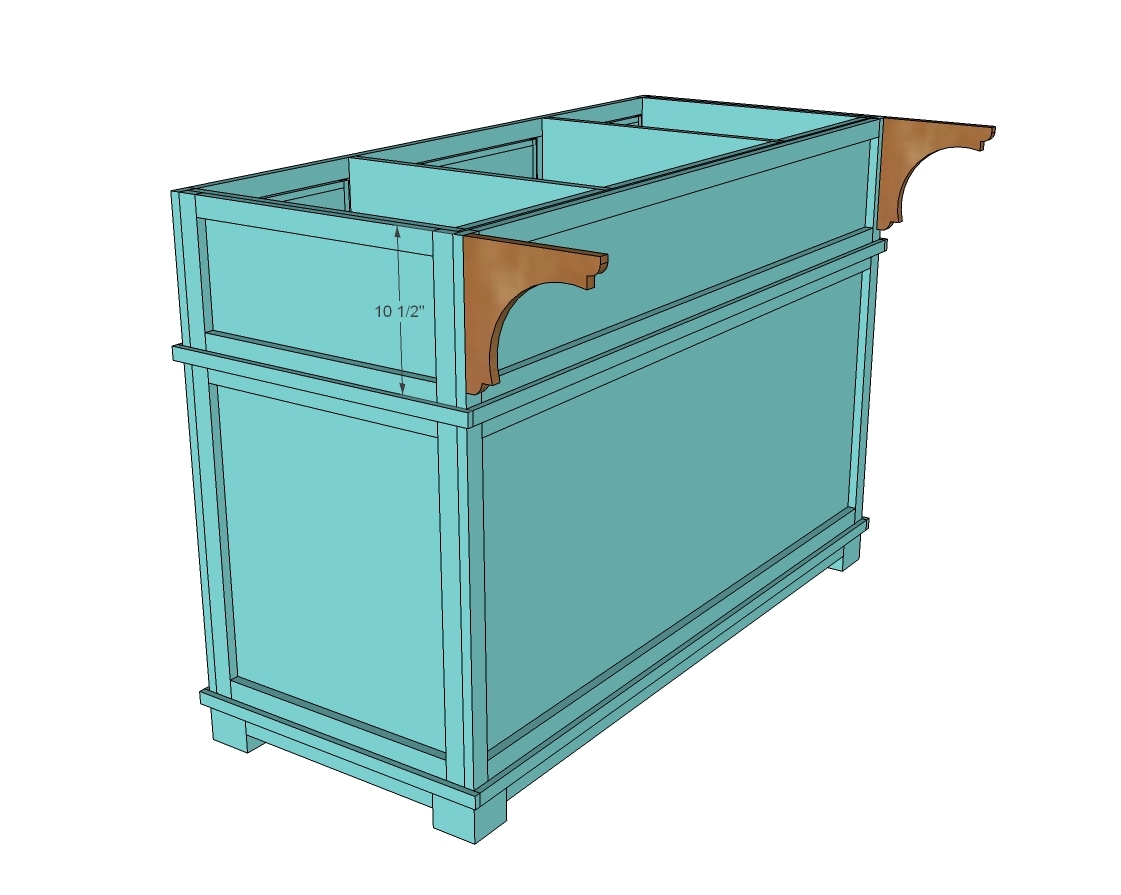

2 corbells - less than 10 1/2" tall

countertop made to fit

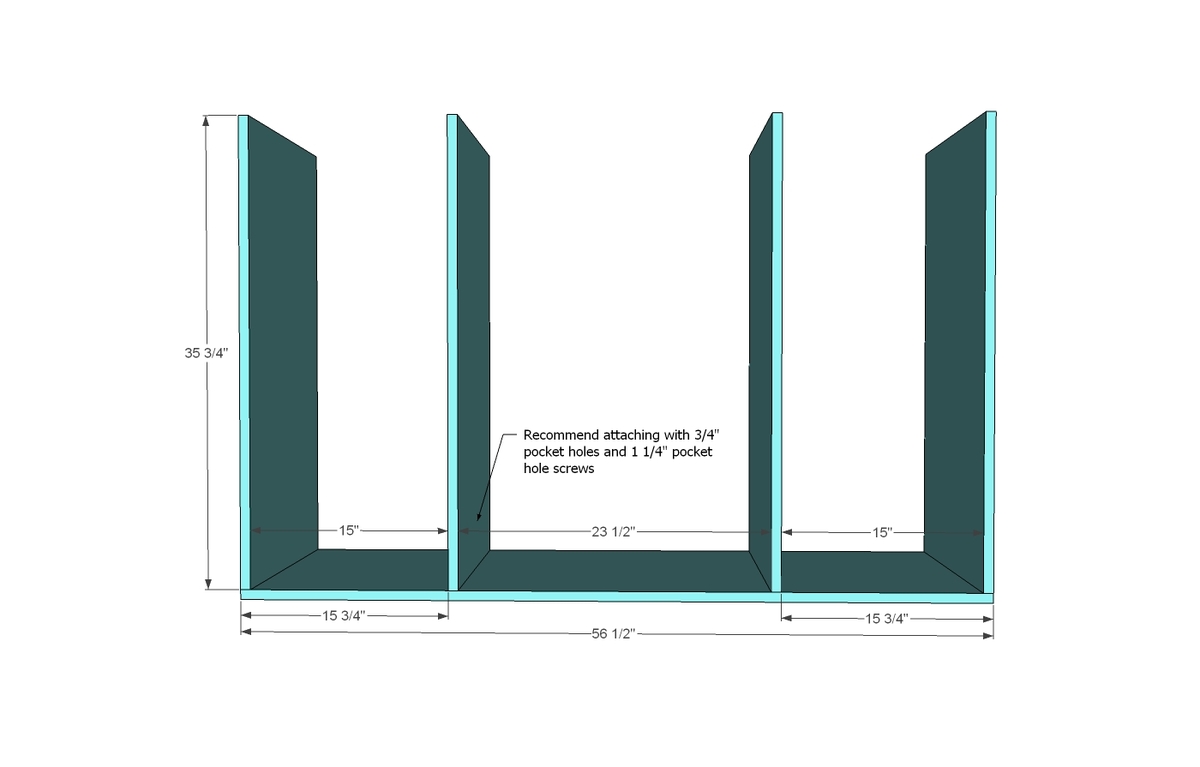

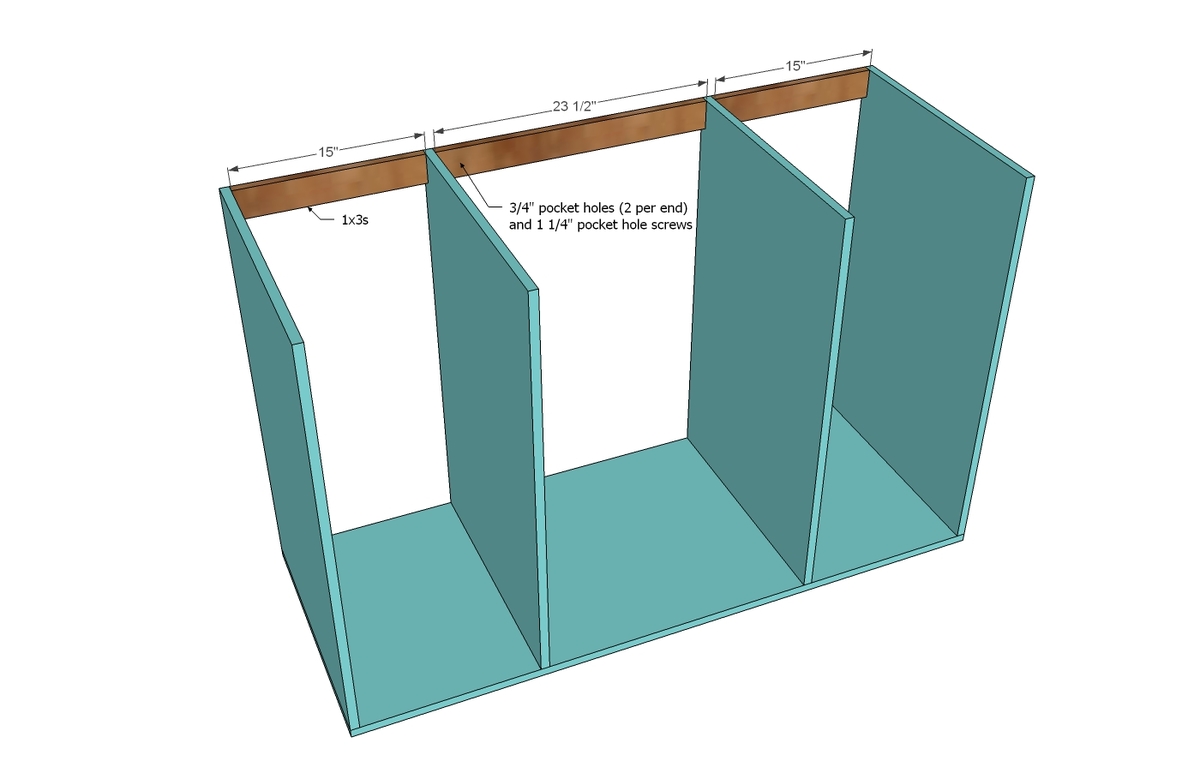

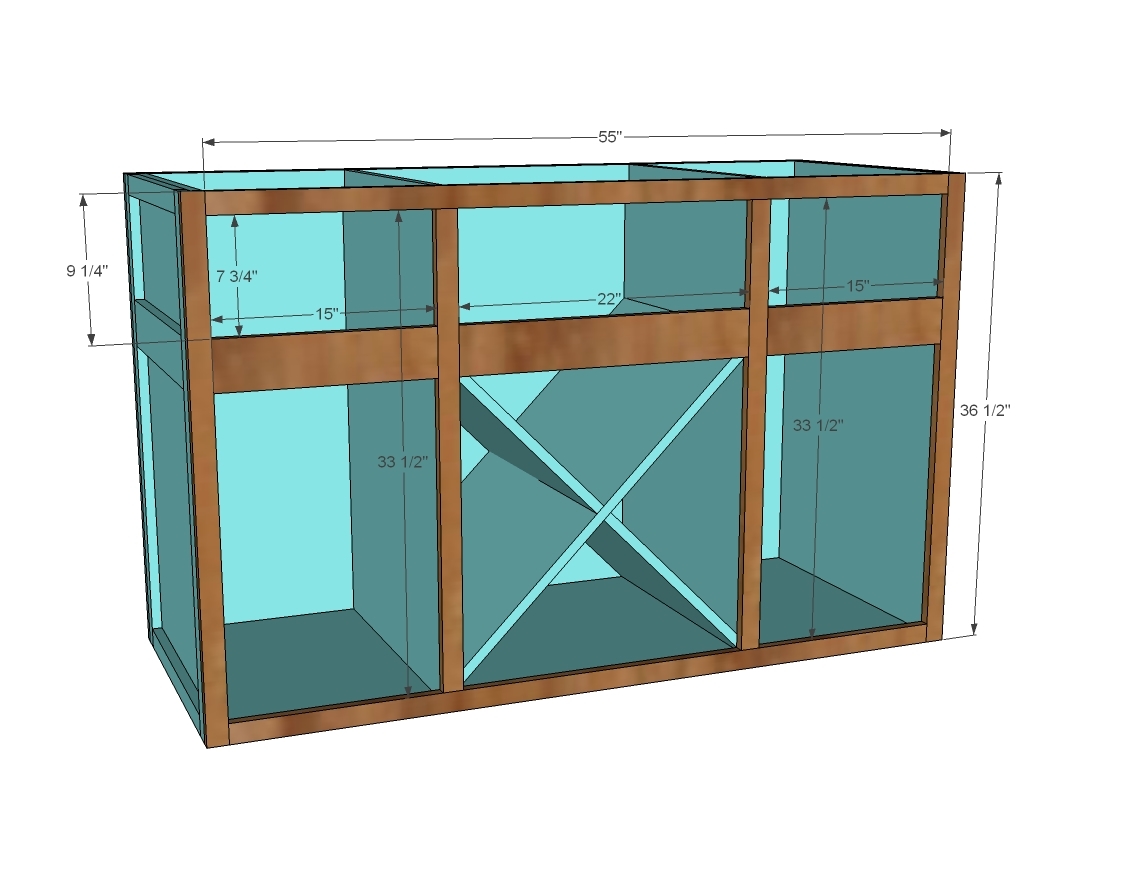

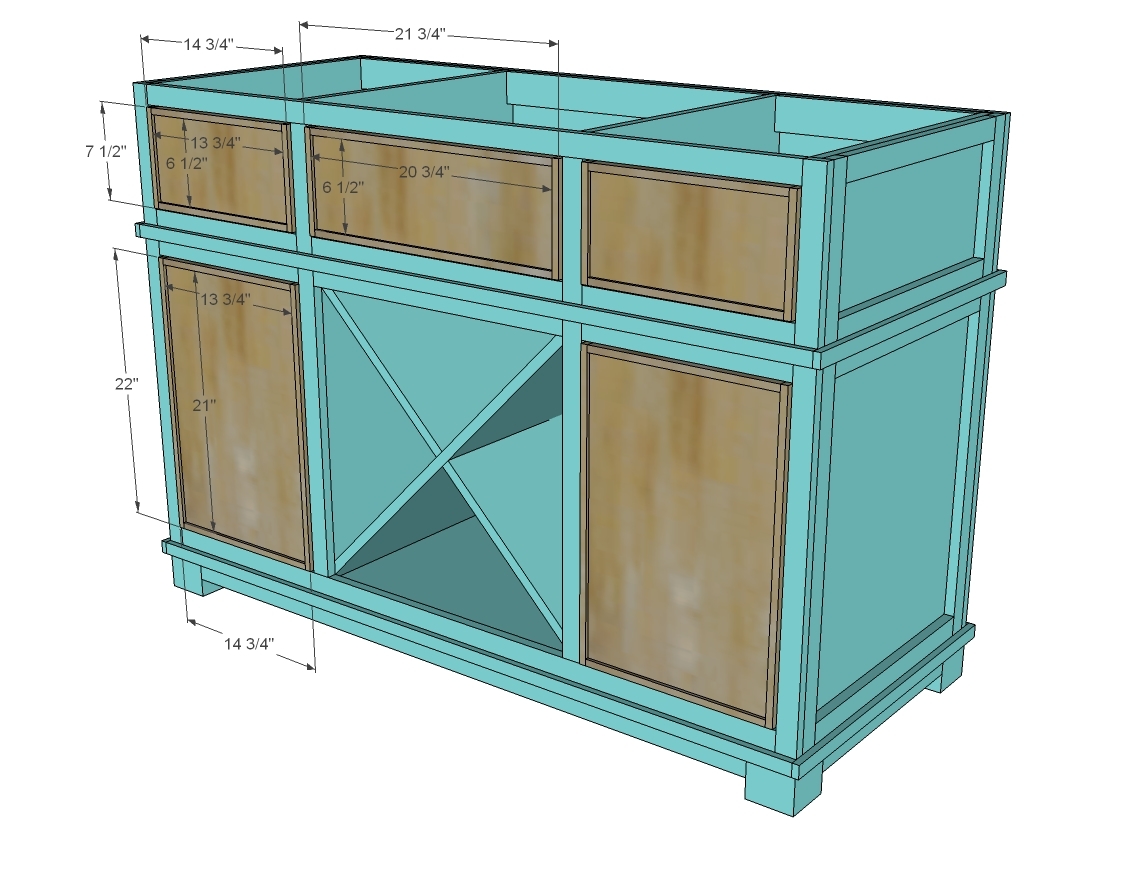

Main Carcass

1 - 3/4" plywood @ 22 1/2" x 56 1/2" (bottom)

4 - 3/4" plywood @ 22 1/2" x 35 3/4" (sides and dividers)

2 - 1x3 @ 15" (back supports)

1 - 1x3 @ 23 1/2" (center back support)

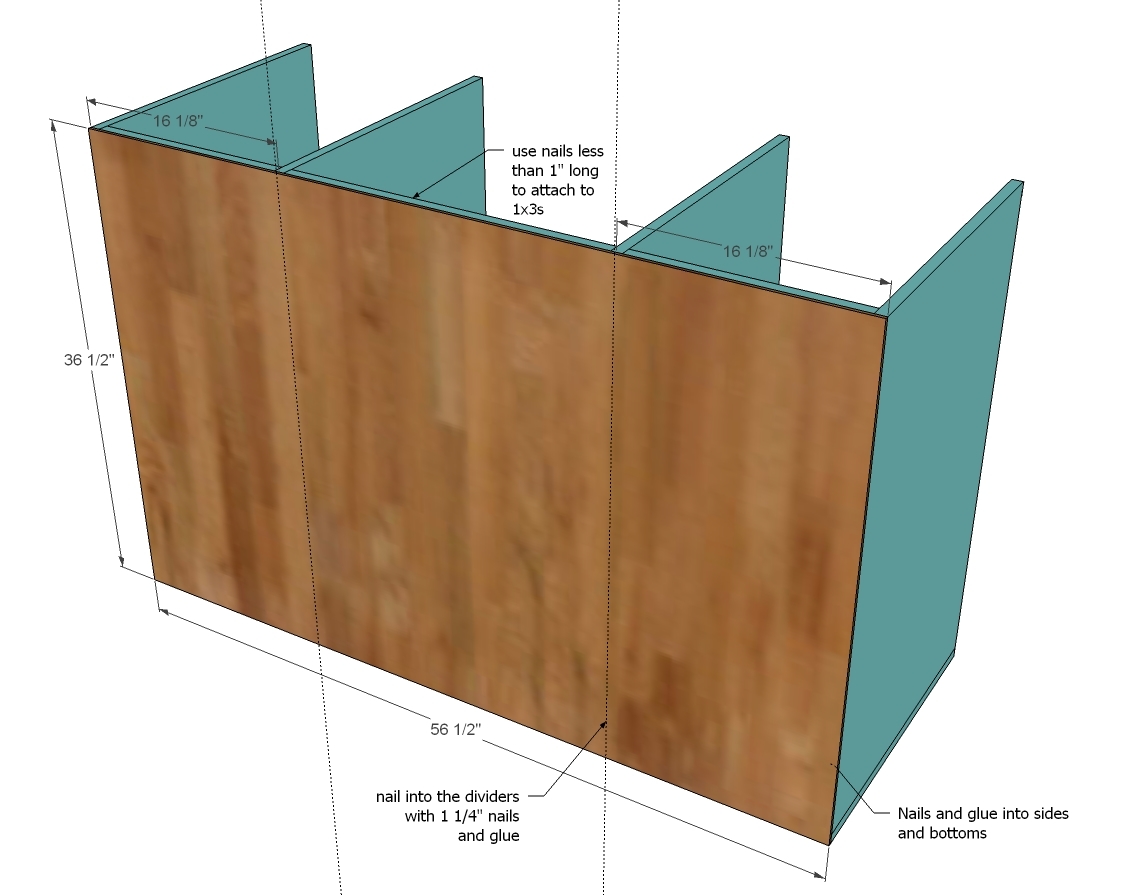

1 - 1/4" plywood @ 36 1/2" x 56 1/2" (back)

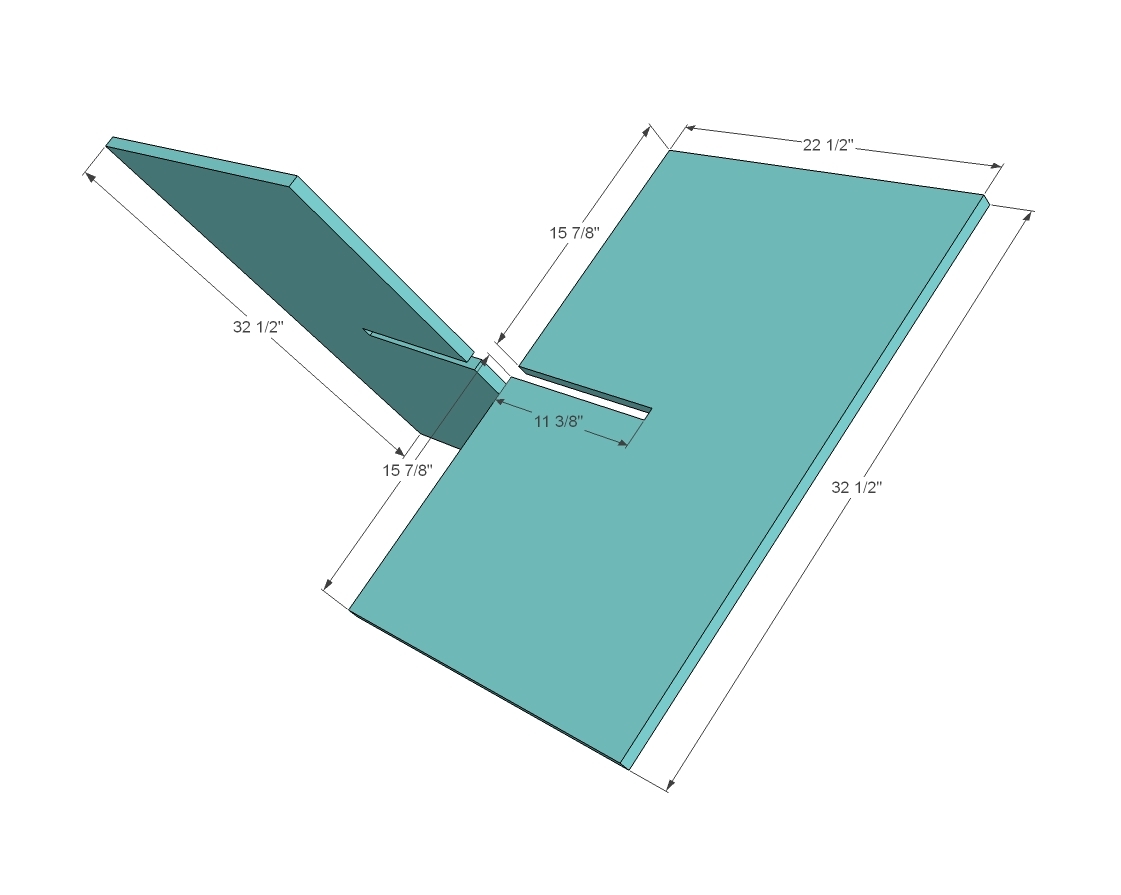

2 - 3/4" plywood @ x 32 1/2" (center X pieces)

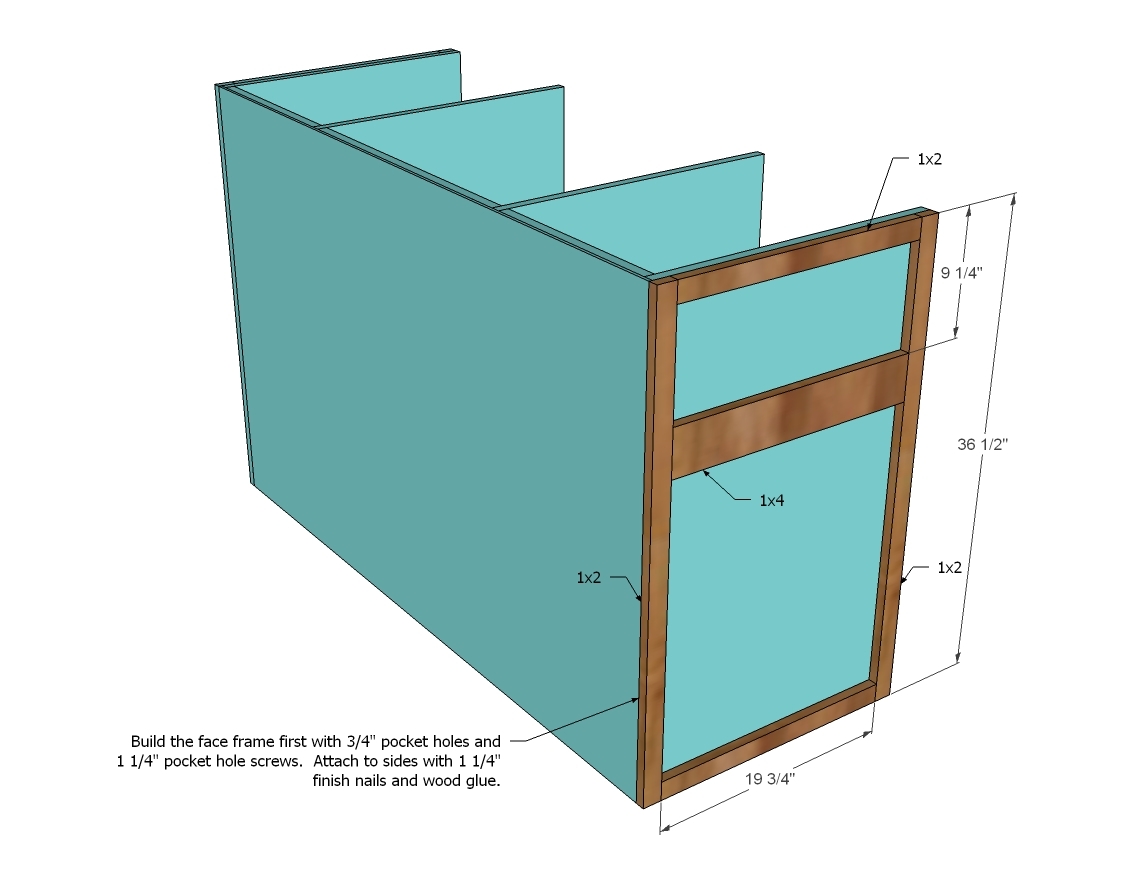

Side Face Frames (recommend cutting to fit)

4 - 1x2 @ 36 1/2"

4 - 1x2 @ 19 3/4"

2 - 1x4 @ 19 3/4"

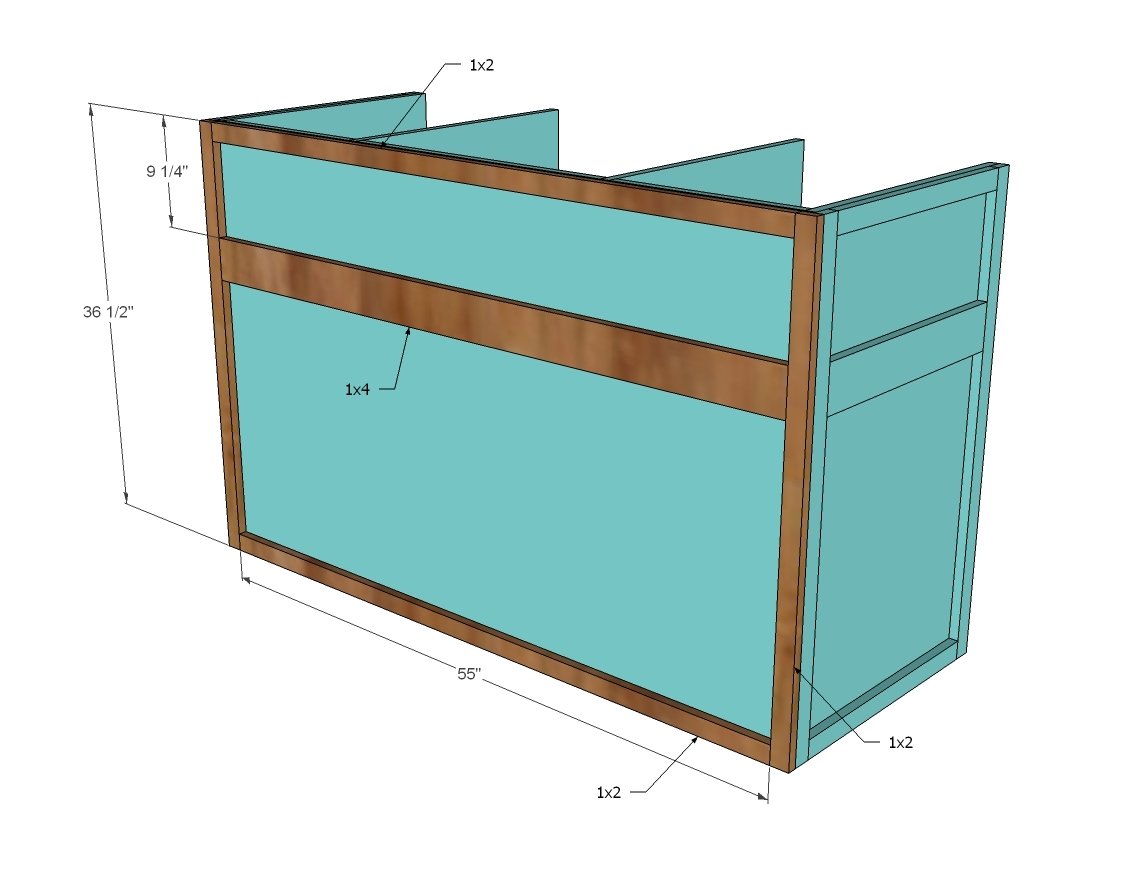

Back Face Frame (recommend cutting to fit)

2 - 1x2 @ 36 1/2"

2 - 1x2 @ 55"

1 - 1x4 @ 55"

Front Face Frame (recommed cutting to fit)

2 - 1x2 @ 36 1/2"

2 - 1x2 @ 55"

2 - 1x2 @ 33 1/2"

2 - 1x4 @ 15"

1 - 1x4 @ 22"

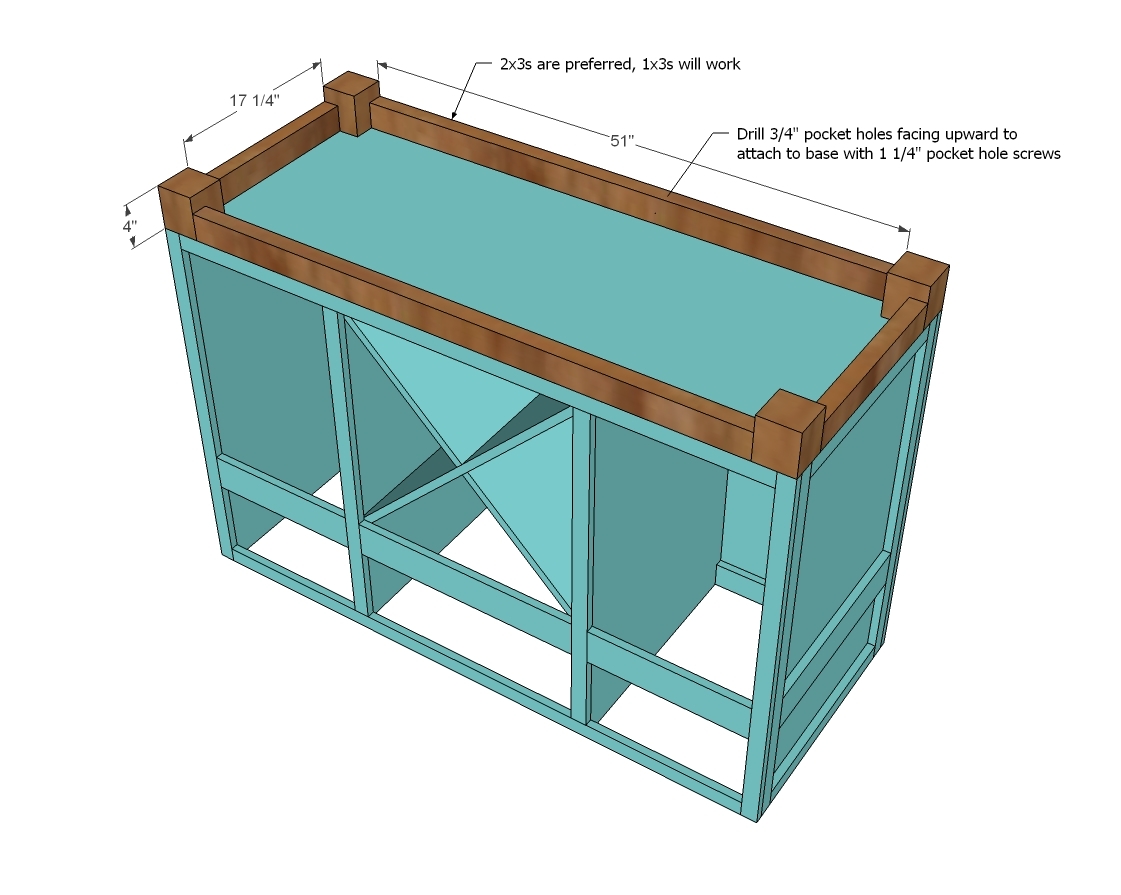

Bottom Base

4 - 4x4 @ 4"

2 - 2x3s or 1x3s @ 17 1/4"

2 - 2x3s or 1x3s @ 51"

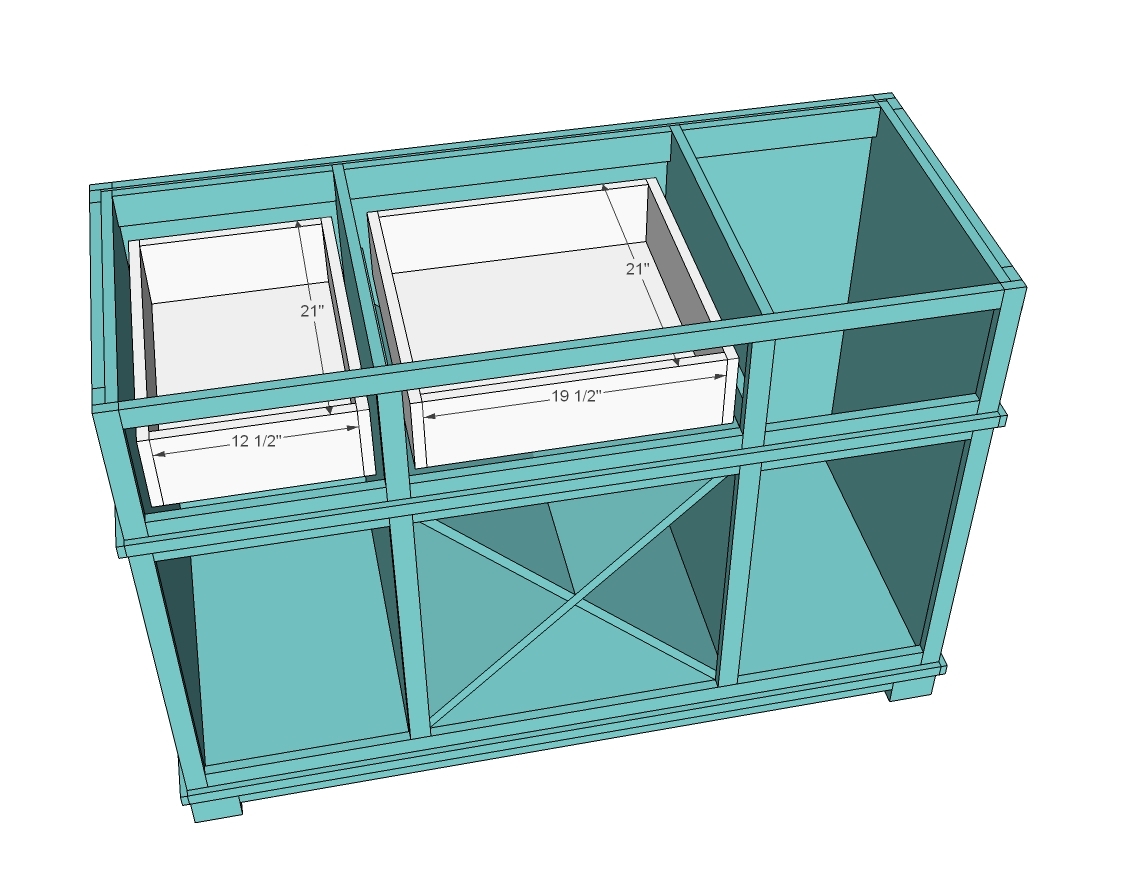

Drawers (cut drawers to fit drawer slides and opening - cut list is for openings of 15" and 22" with 1/2 clearance drawer slides)

2 - 1x3 @ 21 3/4" (center drawer furring)

6 - 1x6 @ 21" (drawer sides)

4 - 1x6 @ 12 1/2" (smaller drawer fronts/backs)

2 - 1x6 @ 19 1/2" (larger drawer fronts/backs)

Cut Drawer faces to fit - shown with edge trimming 1/2" thick around all sides

Please read through the entire plan and all comments before beginning this project. It is also advisable to review the Getting Started Section. Take all necessary precautions to build safely and smartly. Work on a clean level surface, free of imperfections or debris. Always use straight boards. Check for square after each step. Always predrill holes before attaching with screws. Use glue with finish nails for a stronger hold. Wipe excess glue off bare wood for stained projects, as dried glue will not take stain. Be safe, have fun, and ask for help if you need it. Good luck!

Instructions

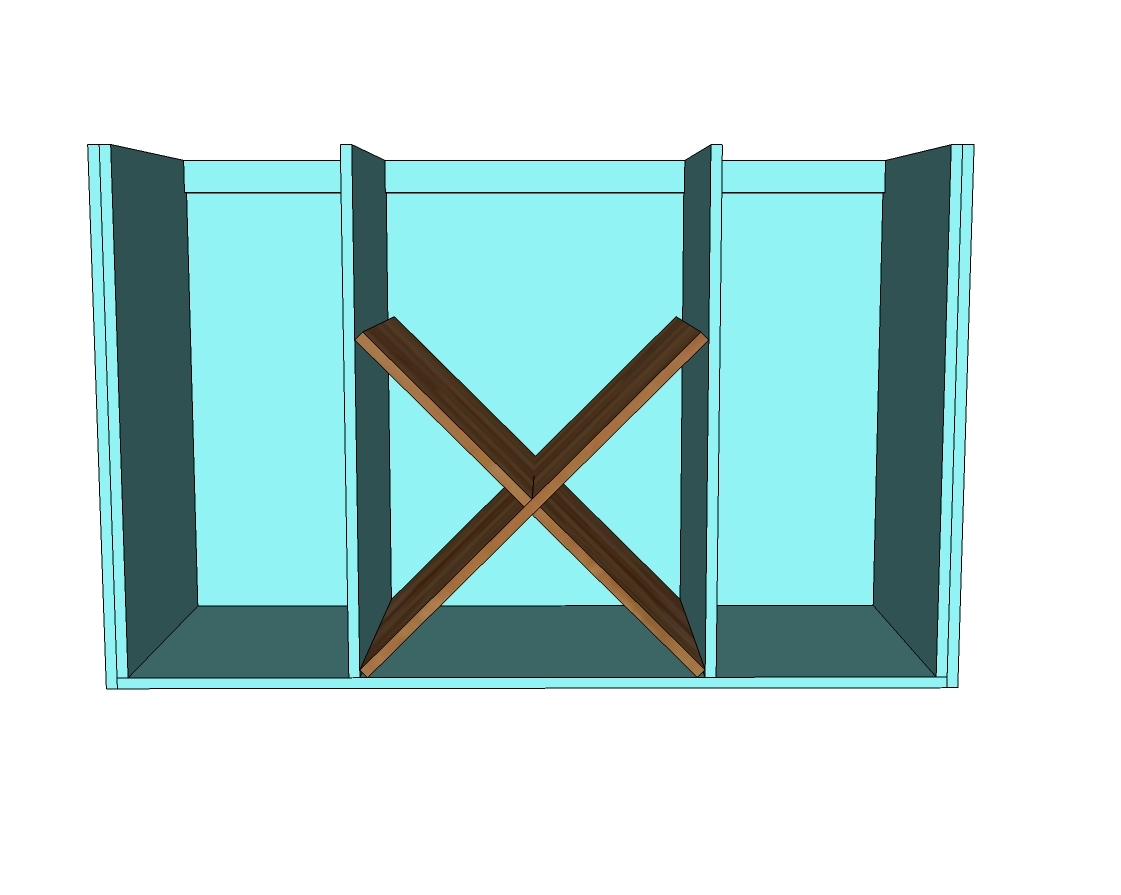

Step 2

Step 4

Measure and cut your side face frames to fit. Build first with 3/4" pocket holes and 1 1/4" pocket hole screws. Then nail on to sides.

NOTE: If you are opting to not place the edge banding around door/drawer faces (see step 13) - and would like to use just 1x8 boards for the drawer faces, leave a 7 1/2" gap between the top 1x2 and 1x4 (for 7 1/4" wide 1x8s) by moving the 1x4 board upward on the face frame slightly. Do the same for the back and front face frames.

Step 6

Step 8

Step 11

Step 12

Drawers should be built to fit openings and drawer slides. Hide 3/4" pocket holes and 1 1/4" pocket hole screws to the outsides - the drawer face will cover them up. The bottoms of these drawers are simply 1/4" plywood cut to fit - this works if you use bottom or bottom corner mount drawer slides.

Install drawers inside cabient with drawer slides.

Step 13

Step 14

It is always recommended to apply a test coat on a hidden area or scrap piece to ensure color evenness and adhesion. Use primer or wood conditioner as needed.