Do you need a nice, sturdy, great looking bed frame, but don't want to pay a fortune? Here's how you can DIY your own for about the cost of the box spring (and you don't need a box spring!). This is the perfect bed for kids, guest rooms, an airbnb, or apartment life. Free plans by Ana-White.com

Preparation

TWIN BED FRAME SHOPPING LIST - Mattress 39" x 75"

- 4 - 2x4 @ 8' long or 92-5/8" stud length

- 1 - 2x6 @ 10' long

- 1 - 2x6 @ 8' long or 92-5/8" stud length

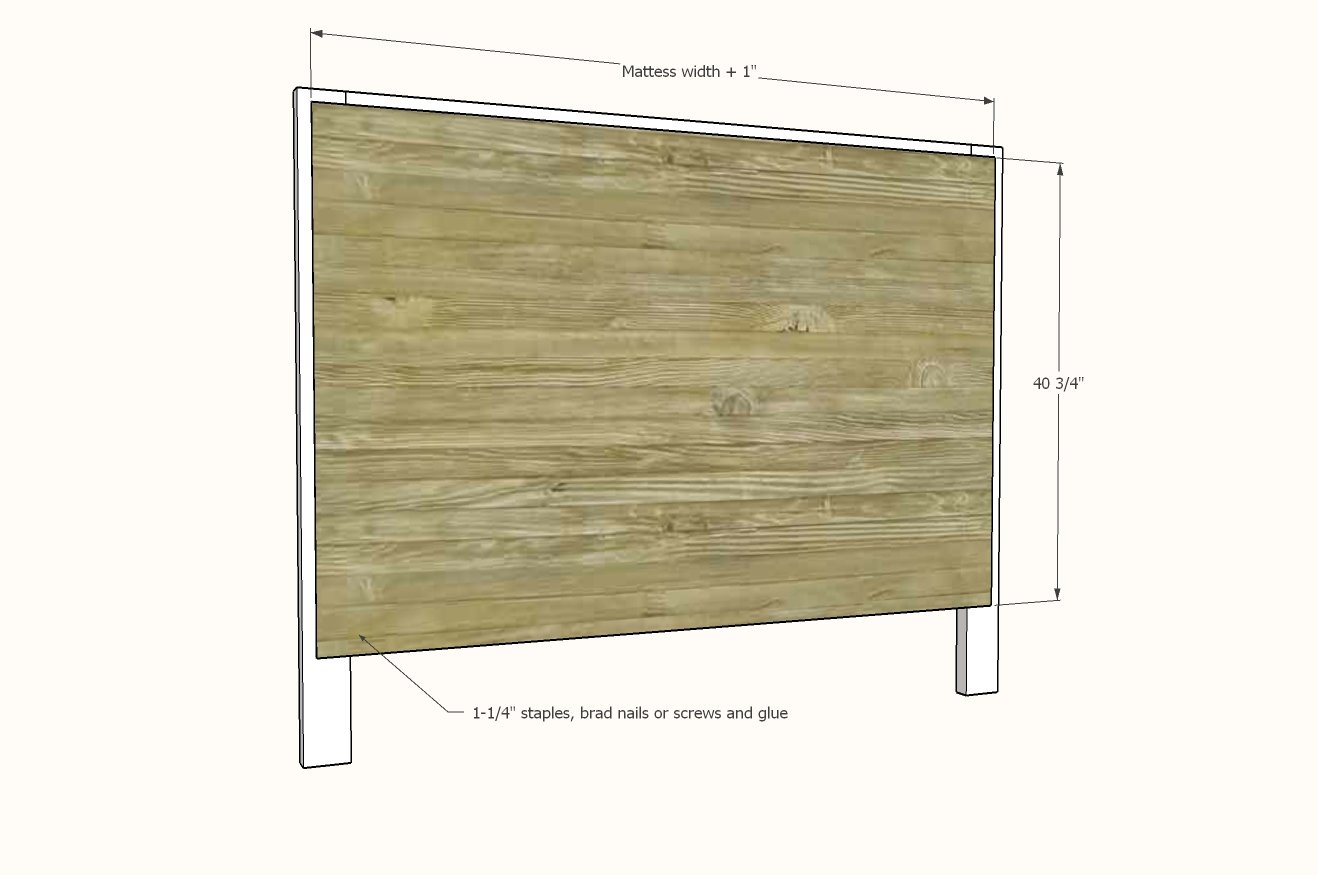

- 1 - 1/4" to 1/2" thick plywood or similar @ 40" x 40-3/4" (a half sheet is enough)

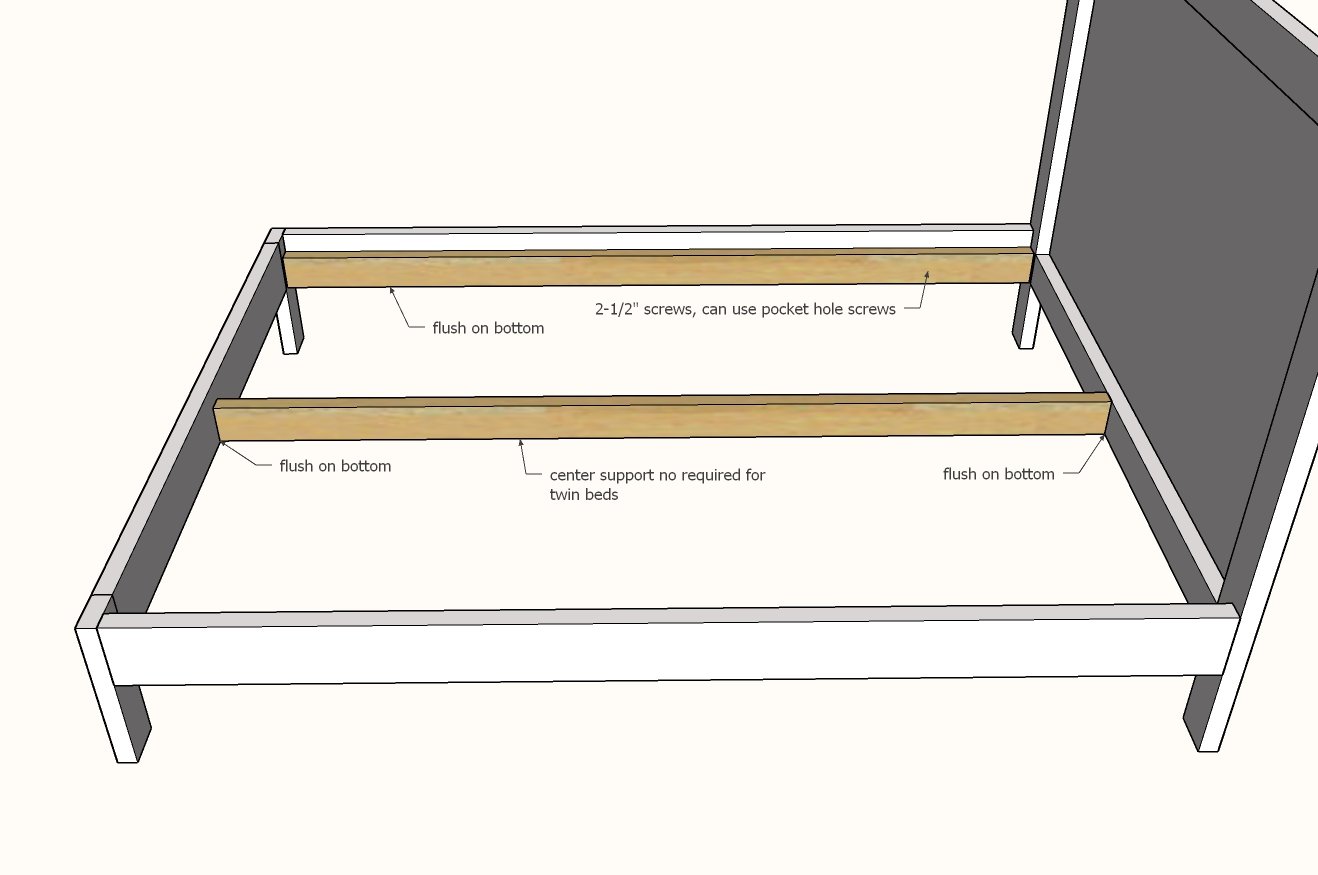

- 6 - 1x4 or 7 - 1x3 @ 8 feet long

- About 40 - 2-1/2" long Kreg Pocket Hole Screws

- About 50 - 1-1/4" long screws, brad nails, or staples for attaching back plywood and slats

- Wood Glue

FULL OR DOUBLE BED FRAME CUT LIST - Mattress 54" x 75"

- 3 - 2x4 @ 8' long or 92-5/8" stud length (cut 75" pieces from these boards and footboard legs)

- 2 - 2x4 @ 10' long or 104-5/8" stud length (cut the 50" pieces from these boards)

- 3 - 2x6 @ 8' long or 92-5/8" stud length

- 1 - 1/4" to 1/2" thick plywood or similar @ 55" x 40-3/4"

- 6 - 1x4 or 7 - 1x3 @ 10 feet long

- About 45 - 2-1/2" long Kreg Pocket Hole Screws

- About 60 - 1-1/4" long screws, brad nails, or staples for attaching back plywood and slats

- Wood Glue

QUEEN BED FRAME CUT LIST - Mattress 60" x 75"

- 3 - 2x4 @ 8' long or 92-5/8" stud length (cut 75" pieces from these boards and footboard legs)

- 2 - 2x4 @ 10' long (cut the 50" and 56" pieces from these boards)

- 3 - 2x6 @ 8' long or 92-5/8" stud length

- 1 - 1/4" to 1/2" thick plywood or similar @ 61" x 40-3/4"

- 6 - 1x4 or 7 - 1x3 @ 10 feet long

- About 45 - 2-1/2" long Kreg Pocket Hole Screws

- About 60 - 1-1/4" long screws, brad nails, or staples for attaching back plywood and slats

- Wood Glue

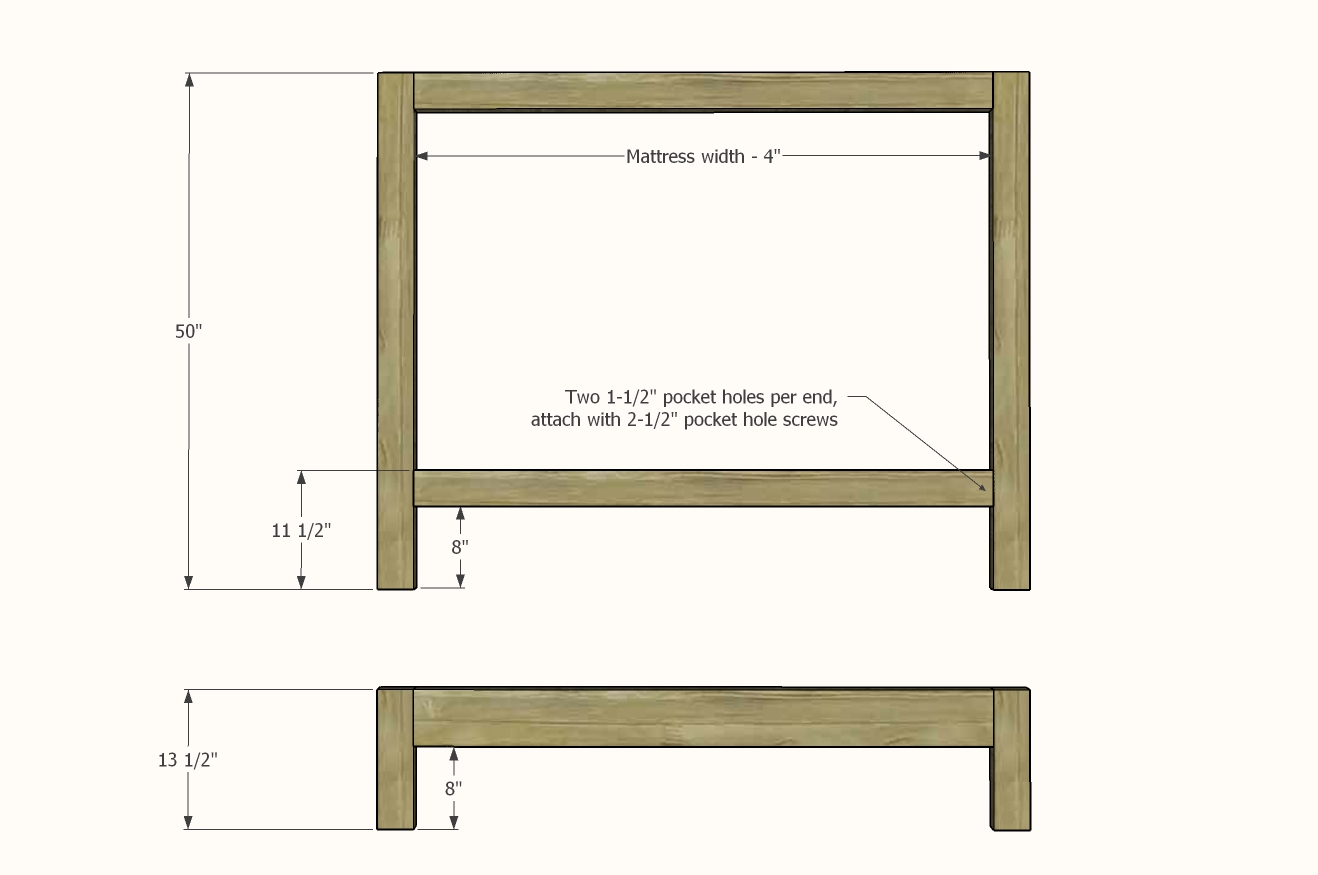

TWIN BED FRAME CUT LIST - Mattress 39" x 75"

- 2 - 2x4 @ 50" - headboard legs

- 2 - 2x4 @ 35" - headboard top and bottom

- 2 - 2x4 @ 13-1/2" - footboard legs

- 1 - 2x6 @ 35" - footboard main board

- 1 - 1/4" to 1/2" thick plywood or similar @ 40" x 40-3/4"

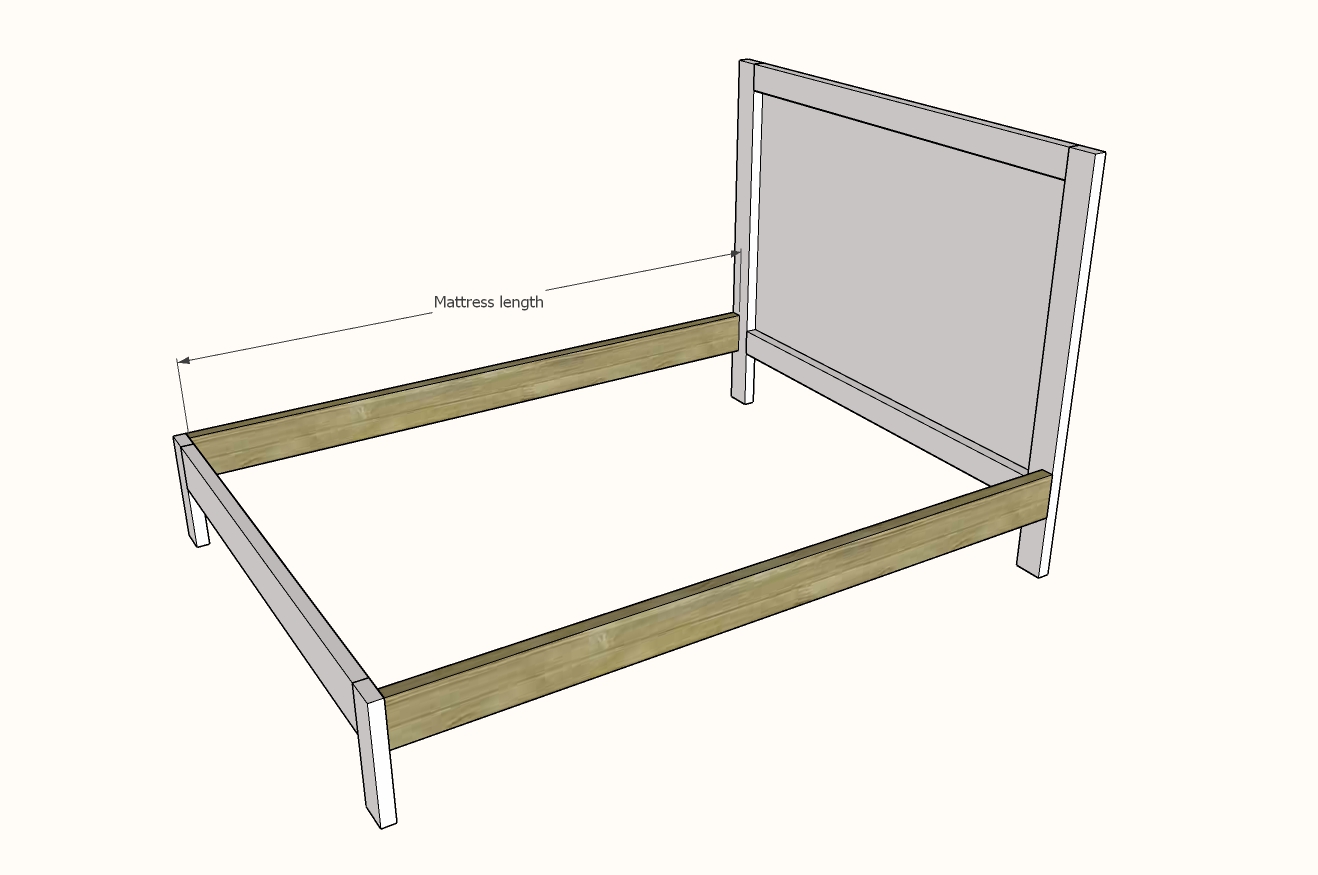

- 2 - 2x6 @ 75" - siderails

- 2 - 2x4 @ 75" - inside cleats

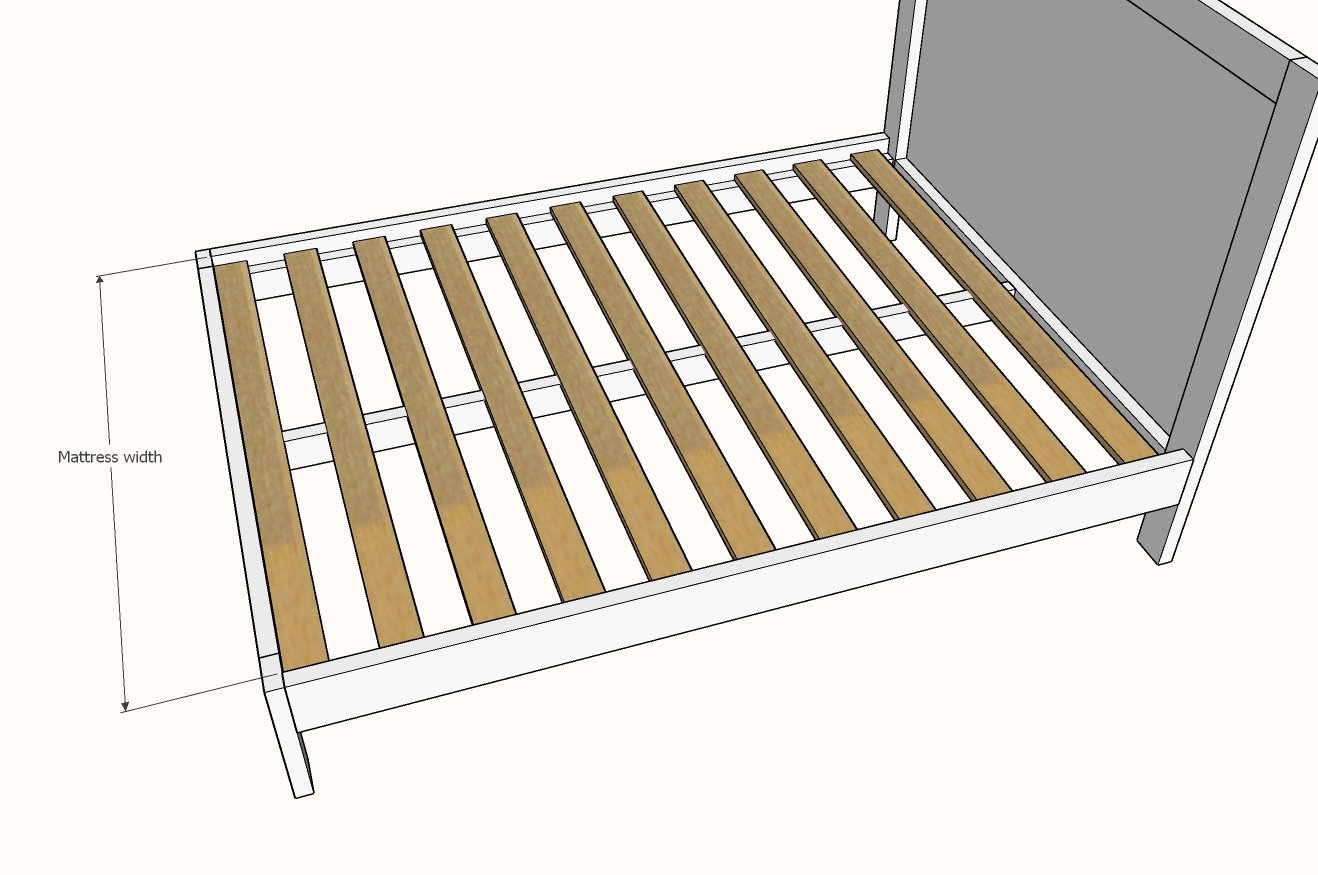

- 12 - 1x4 or 14 - 1x3 @ 39" - bed slats

FULL OR DOUBLE BED FRAME CUT LIST - Mattress 54" x 75"

- 2 - 2x4 @ 50" - headboard legs

- 2 - 2x4 @ 50" - headboard top and bottom

- 2 - 2x4 @ 13-1/2" - footboard legs

- 1 - 2x6 @ 50" - footboard main board

- 1 - 1/4" to 1/2" thick plywood or similar @ 55" x 40-3/4"

- 2 - 2x6 @ 75" - siderails

- 2 - 2x4 @ 75" - inside cleats

- 12 - 1x4 or 14 - 1x3 @ 54" - bed slats

QUEEN BED FRAME CUT LIST - Mattress 60" x 75"

- 2 - 2x4 @ 50" - headboard legs

- 2 - 2x4 @ 56" - headboard top and bottom

- 2 - 2x4 @ 13-1/2" - footboard legs

- 1 - 2x6 @ 56" - footboard main board

- 1 - 1/4" to 1/2" thick plywood or similar @ 61" x 40-3/4"

- 2 - 2x6 @ 80" - siderails

- 2 - 2x4 @ 80" - inside cleats

- 12 - 1x4 or 14 - 1x3 @ 60" - bed slats

The plywood cut doesn't have to be perfect - so have the hardware store make the cuts for you - it will be easier to transport and handle too.

Comments

Chantcaps

Tue, 10/13/2020 - 08:48

Wow!

This is amazing! Do you happen to have plans for a king?

DitchGuru

Sat, 10/17/2020 - 09:31

Standard King

A standard king bed (not a cali king) is the same length, but it is 16" wider than a queen bed so all your width measurements would have to be increased by 16". So the plans would be the same as a queen, except the headboard top and bottom and the footboard main board cut lengths would be 72" instead of 56".

Also you would increase the bed slats from 60" to 76" and your plywood would be cut to 77" x 40-3/4", instead of 61" x 40-3/4".

Don't forget when purchasing your wood, this would change your shopping list.

DitchGuru

Sat, 10/17/2020 - 10:01

Twin XL and Cali King

Also anyone making a Twin XL as I am, everything would be the same as a twin except the siderails and the inside cleats would be 80" instead of 75".

A cali king is 72" x 84", so both width (12") and length (4") would have to be increased accordingly to the queen plans. So the plans would be the same as a queen, except the headboard top and bottom and the footboard main board cut lengths would be 68" instead of 56".

Also you would increase the bed slats from 60" to 72" and your plywood would be cut to 73" x 40-3/4", instead of 61" x 40-3/4". The siderails and the inside cleats would be 84" instead of 75".

Hope this helps everyone.

aunty jay

Wed, 10/14/2020 - 12:39

Down load plans

How do I get the plans