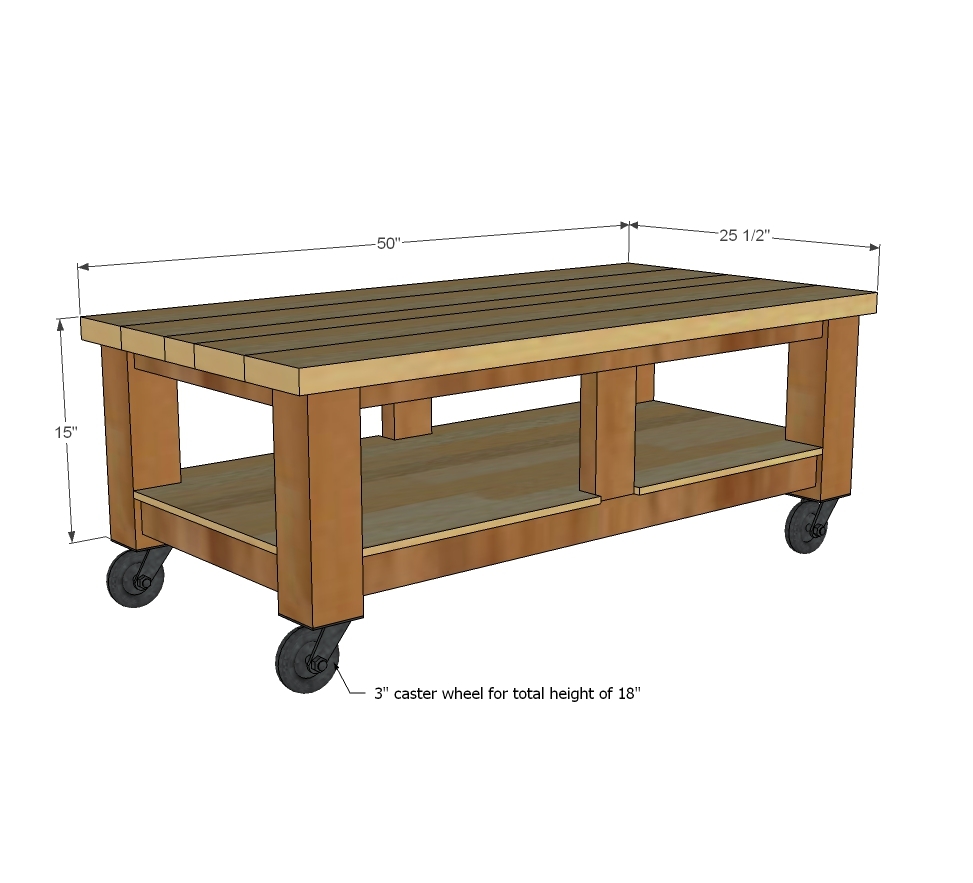

Build your own coffee table with free plans from Ana-White.com

This beautiful coffee table features a solid wood design - so you can paint or stain it any color! With room for baskets and optional casters, this coffee table is functional too!

Related: Build the Matching Console Table

Preparation

- 1 - 4x4 @ 6 feet long

- 1 - 1x3 @ 12 feet long

- 3 - 2x2 @ 8 feet long

- 1 - 2x4 @ 8 feet long

- 2 - 2x6 @ 9' stud length or 10 feet

- 1 - 1/2" thick plywood panel @ 24" x 48" (quarter sheet)

- 2 -1/2" pocket hole screws and 1-1/4" pocket hole screws (if you kept the 1x3s)

- 1" or longer brad nails (for nailing bottom shelf plywood down)

- 4 - caster wheels and screws to attach (if not included)

NOTE: Instead of 1x3s, Whitney used 2x3s which does not affect the plan (actually makes it stronger) but many of you cannot source 2x3s locally. If you do make this change, you will need to measure and cut a few boards that tie in to the 1x3s (step 2).

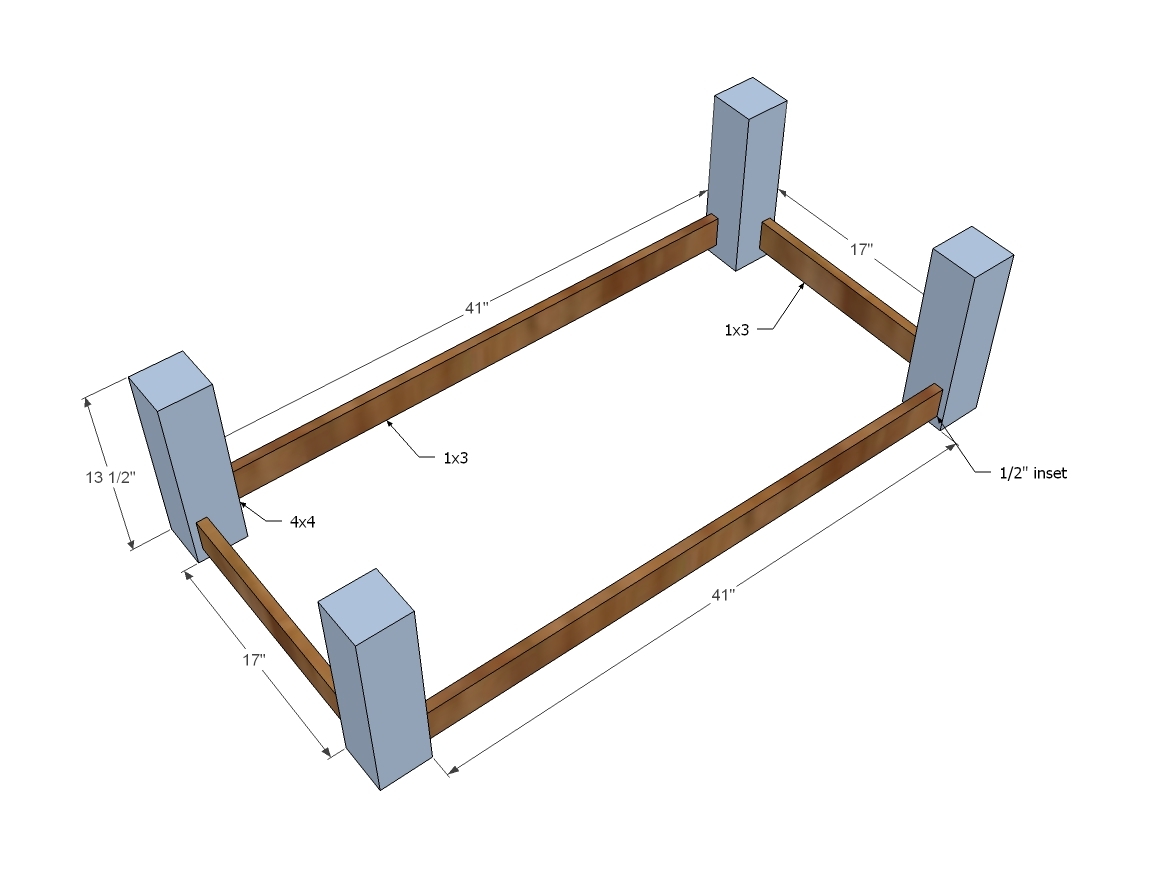

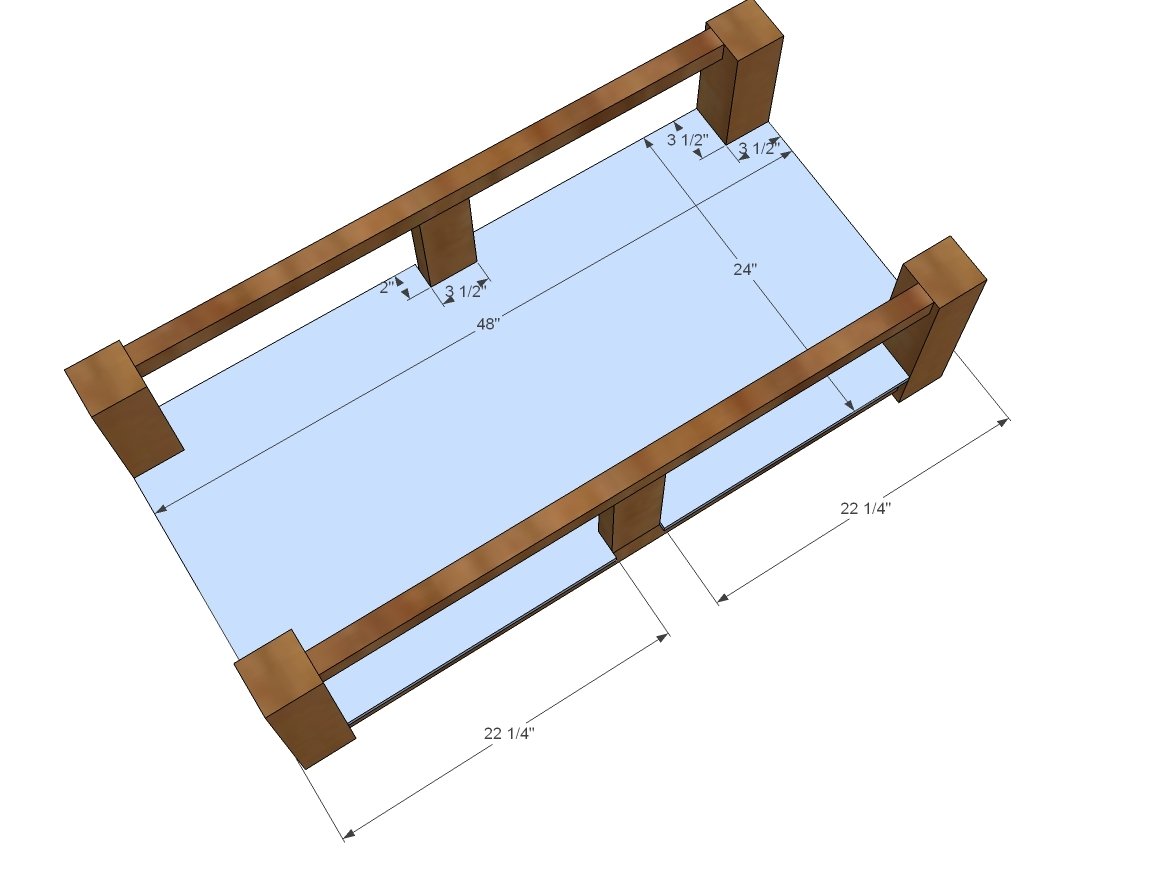

- 4 - 4x4 @ 13-1/2" (legs)

- 2 - 1x3 @ 17" (short aprons)

- 2 - 1x3 @ 41" (long aprons)

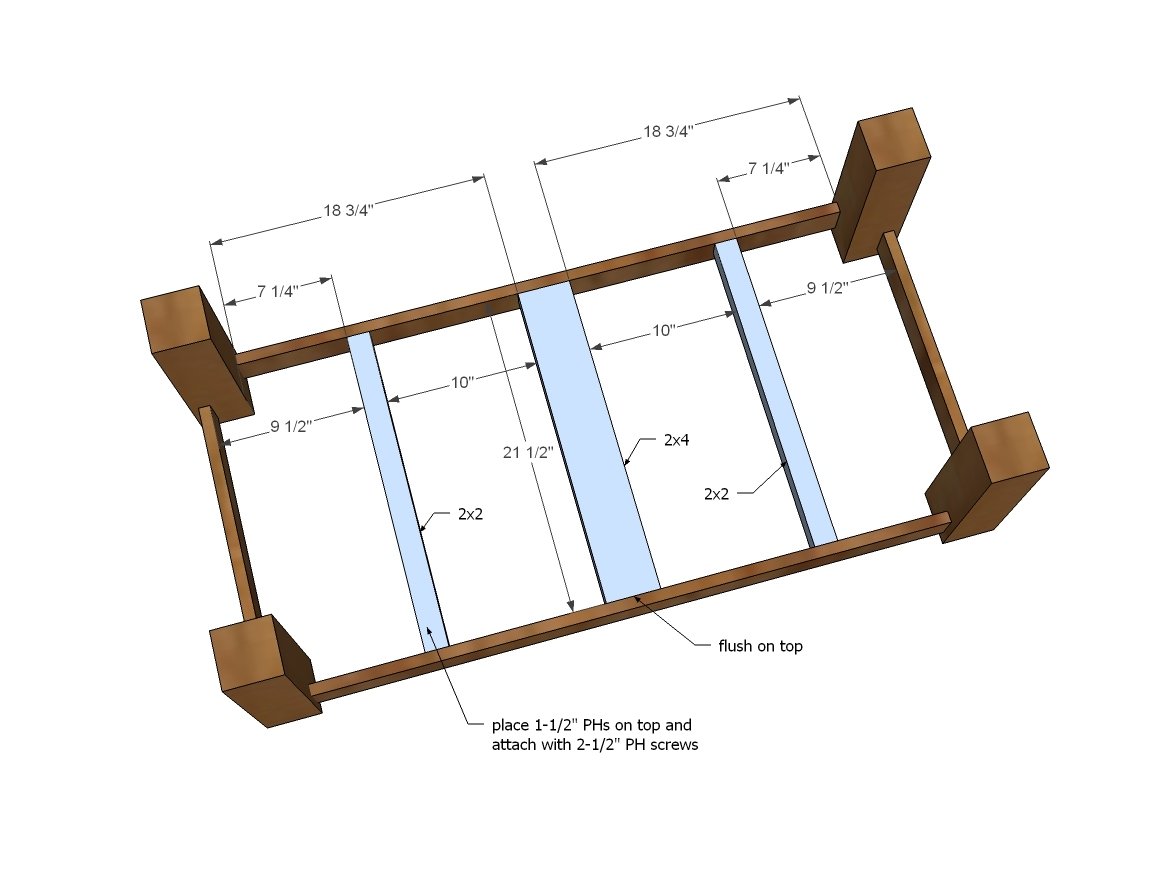

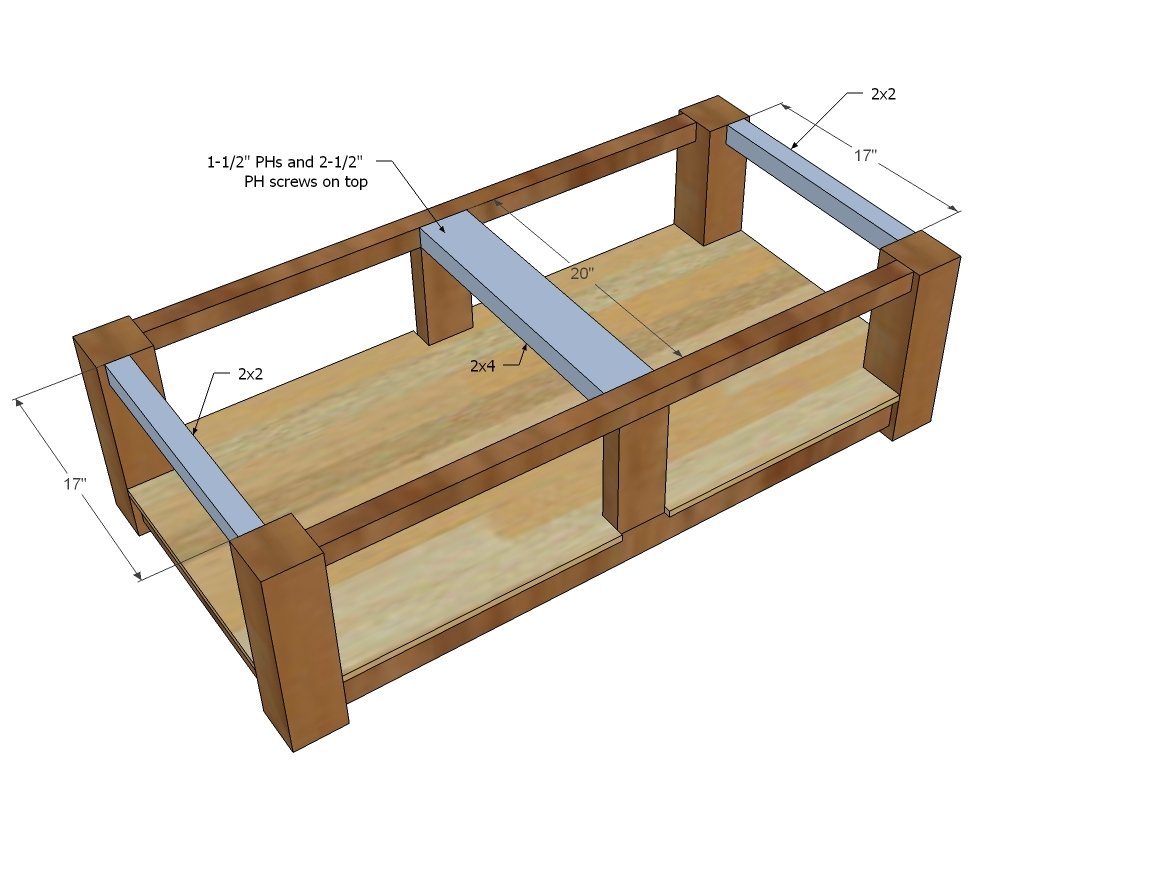

- 2 - 2x2 @ 21-1/2"

- 1 - 2x4 @ 21-1/2"

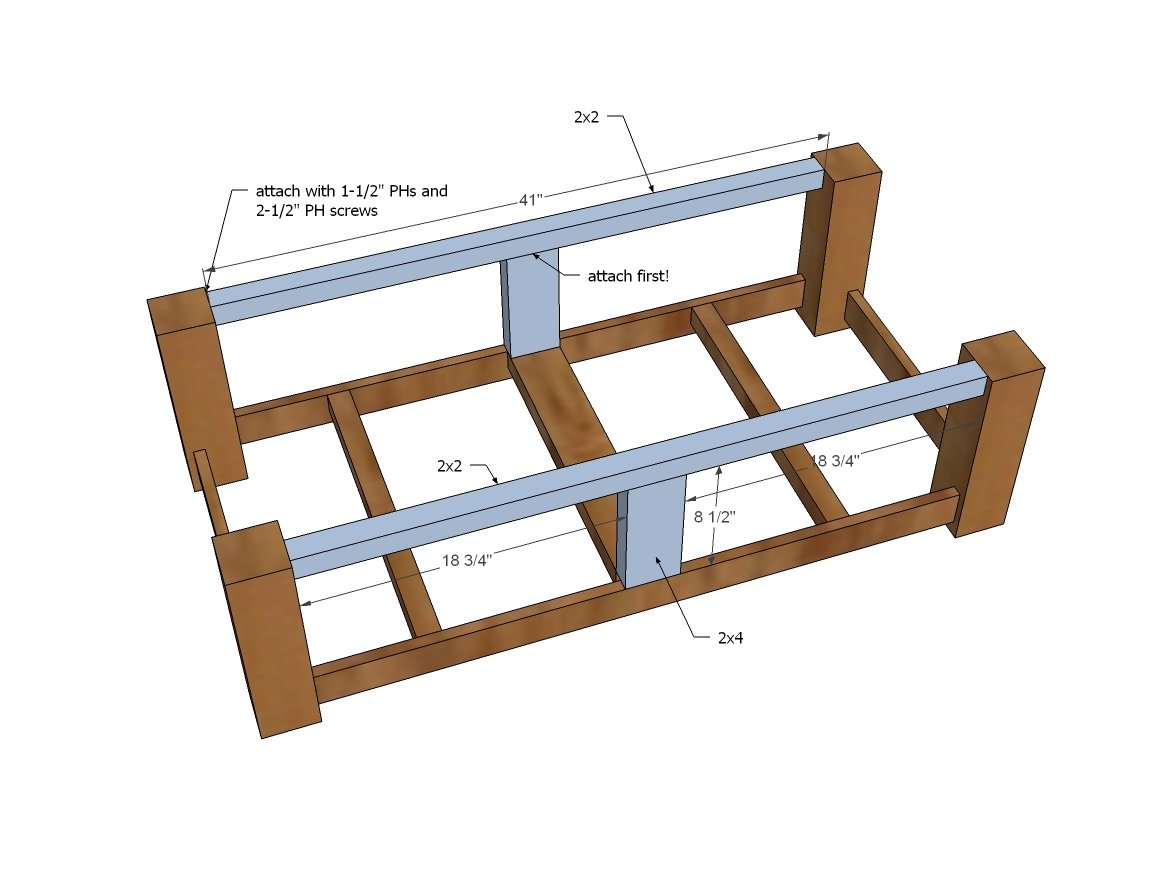

- 2 - 2x2 @ 41"

- 2 - 2x4 @ 8-1/2"

- 1 - 1/2" plywood @ 48" x 24"

- 2 - 2x2 @ 17"

- 1 - 2x4 @ 20" Tabletop

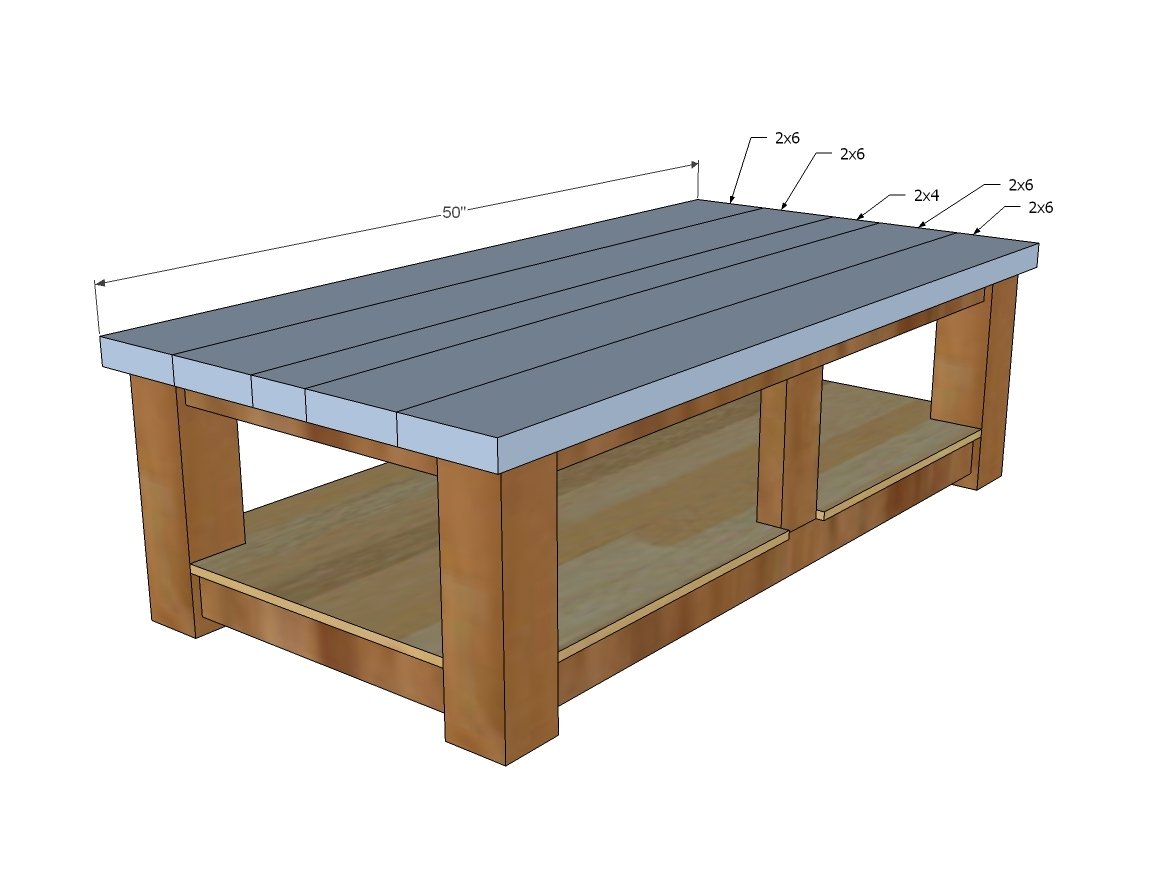

- 4 - 2x6 @ 50"

- 2 - 2x2 @ 50"

Please read through the entire plan and all comments before beginning this project. It is also advisable to review the Getting Started Section. Take all necessary precautions to build safely and smartly. Work on a clean level surface, free of imperfections or debris. Always use straight boards. Check for square after each step. Always predrill holes before attaching with screws. Use glue with finish nails for a stronger hold. Wipe excess glue off bare wood for stained projects, as dried glue will not take stain. Be safe, have fun, and ask for help if you need it. Good luck!

Instructions

Step 1

Step 2

Step 4

Step 6

Instead of the 2x4 down the center as pictured, Whitney liked using 2 - 2x2s spaced between the 2x6s to make it look more balanced - and I'd have to agree.

Build the tabletop first with 1-1/2" pocket holes and 2-1/2" pocket hole screws and wood glue. Then attach to base with through aprons and center undermount support with 2-1/2" screws (you can use pocket hole screws so you don't have to go out and buy special screws just for this step).

It is always recommended to apply a test coat on a hidden area or scrap piece to ensure color evenness and adhesion. Use primer or wood conditioner as needed.

Comments

AndyH

Thu, 02/20/2014 - 12:13

Where to get the 4 by 4s

Love these plans that use 4 by 4s for the legs but I cannot find anywhere that sells them untreated and Lowes and Home Depot both tell me they cannot order them.

Where can they be sourced from?

Thanks!

DIYER_MD

Thu, 02/20/2014 - 14:31

4 x 4's

The 4 x 4's can be purchased at Lowes. I have purchased untreated 4 x 4's there many times. Look for the Douglas-Fir type. Here is a link to their website with the 4 x 4's.

Lowes 4 x 4

carongirls

Fri, 02/21/2014 - 08:54

Same Here

No, not all Lowes sell 4x4's untreated. I have gone as far as 4 hours away to check different Lowes or Home Depot. Just not available in my area at all.