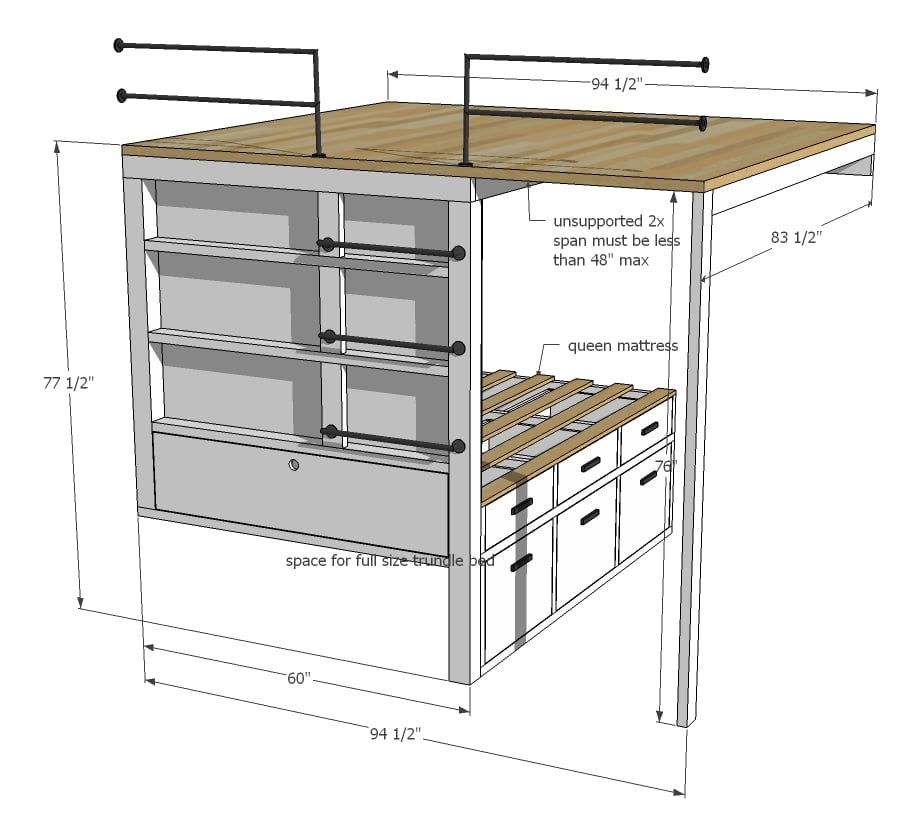

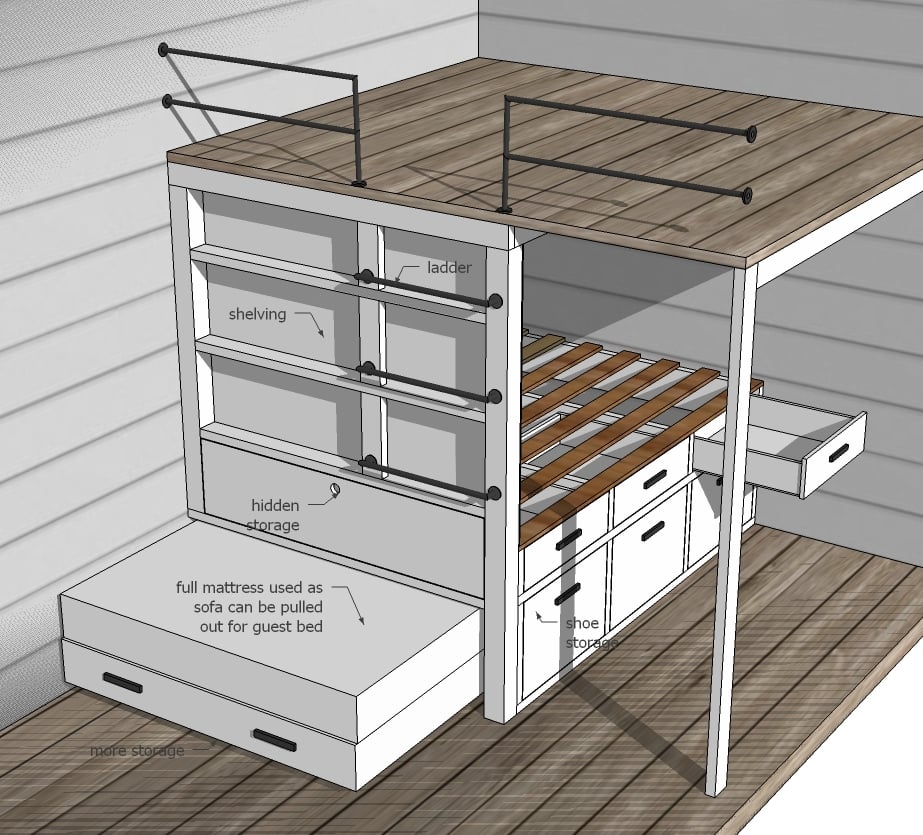

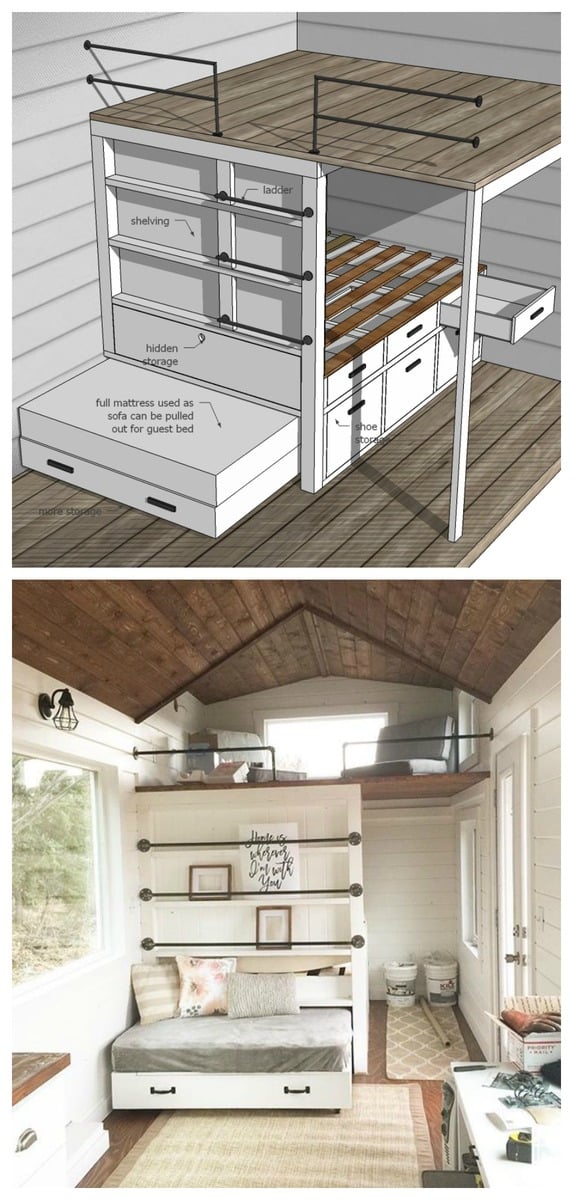

Plans for a tiny house loft with lower bedroom, storage drawers, and hidden sofa that converts to a guest bed. Detailed plans by Ana-White.com

Preparation

- 2 - 4X4 @ 6 FEET LONG

- 14 - 2X4 @ 8 FEET LONG

- 1 - 2X8 @ 8 FEET LONG

- 2 - 2X8 @ 10 FEET LONG

- 3 - 1X6 @ 8 FEET LONG

- 2X6 TONGUE AND GROOVE FOR UPSTAIRS LOFT OF OTHER FLOORING

- 1 SHEET OF 1/4" PLYWOOD FOR DRAWER BOTTOMS/SHOE STORAGE BACKS

- 1 SHEET OF BEADBOARD, PANELING OR 1X6 T&G FOR BACK OF WALL

- 1 SHEET OF 3/4" PLYWOOD FOR DRAWER/DOOR FACES

- 2-1/2" POCKET HOLE SCREWS

- 2-3/4" SELF TAPPING WOOD SCREWS (SPAX OR SIMILAR)

- 5" LAG SCREWS FOR ATTACHING 4X4 TO WALL (JUST NEED A FEW)

- 1-1/4" NAILS FOR ATTACHING SLATS TO FRAMING AND WALL MATERIAL BACKING

- 3 - 24" BOTTOM SIDE MOUNT DRAWER SLIDES (WHITE)

- 4 SETS OF HINGES IF HINGES ARE NOT SELF CLOSING MAY NEED CLASPS OR HASPS

- 6 KNOBS OR HANDLES

- BLACK PIPE FOR LADDER AND RAILING

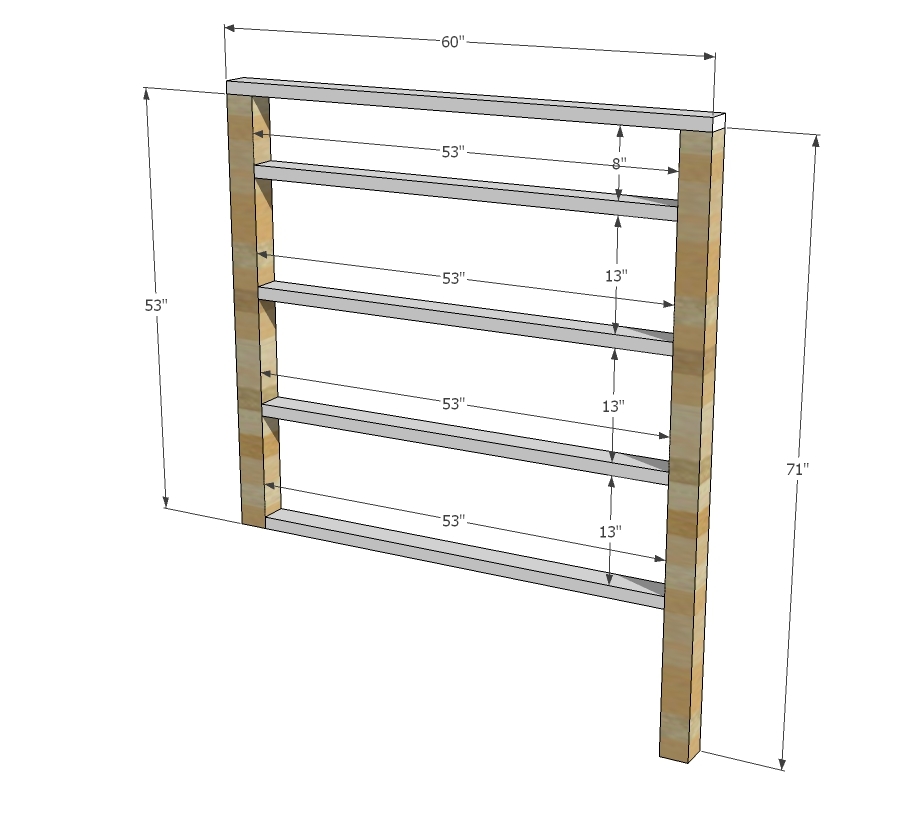

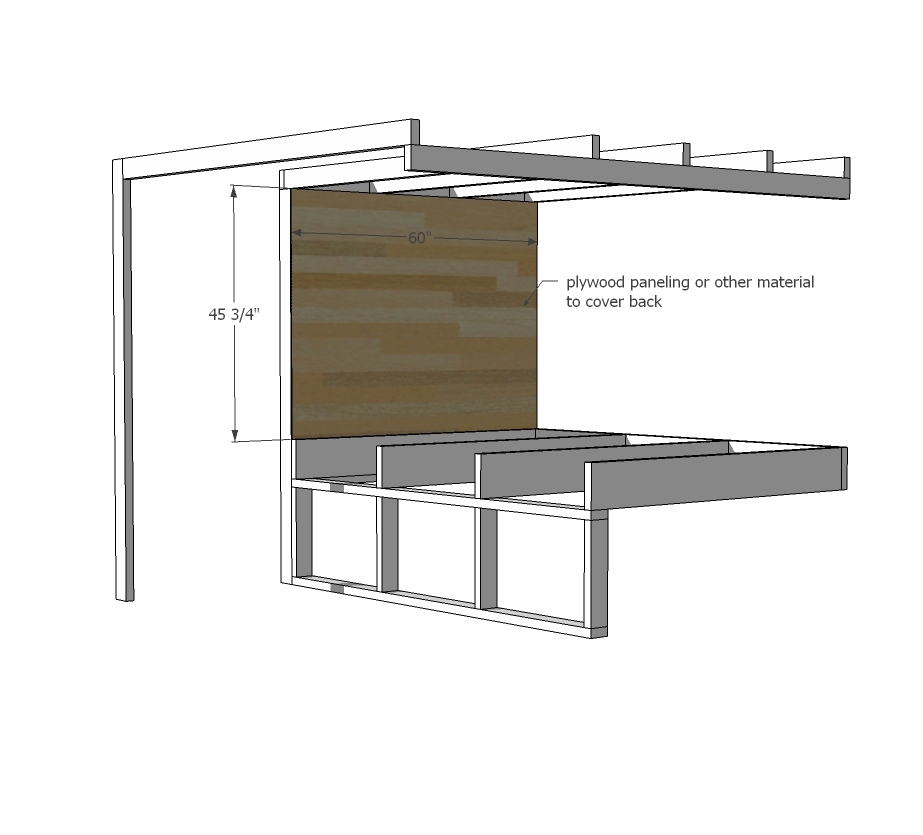

WALL

- 1 - 4x4 @ 52"

- 1 - 4x4 @ 71"

- 4 - 2x4 @ 53"

- 2 - 2X4 @ 13" - LADDER SUPPORTS

- 1 - 2X4 @ 8" - LADDER SUPPORT

- 1 - 1/4" PLYWOOD OR PANELING @ 45-3/4" X 60"

- 1 - 3/4" PLYWOOD @ 52-3/4" X 12-3/4" (HIDDEN STORAGE DOOR)

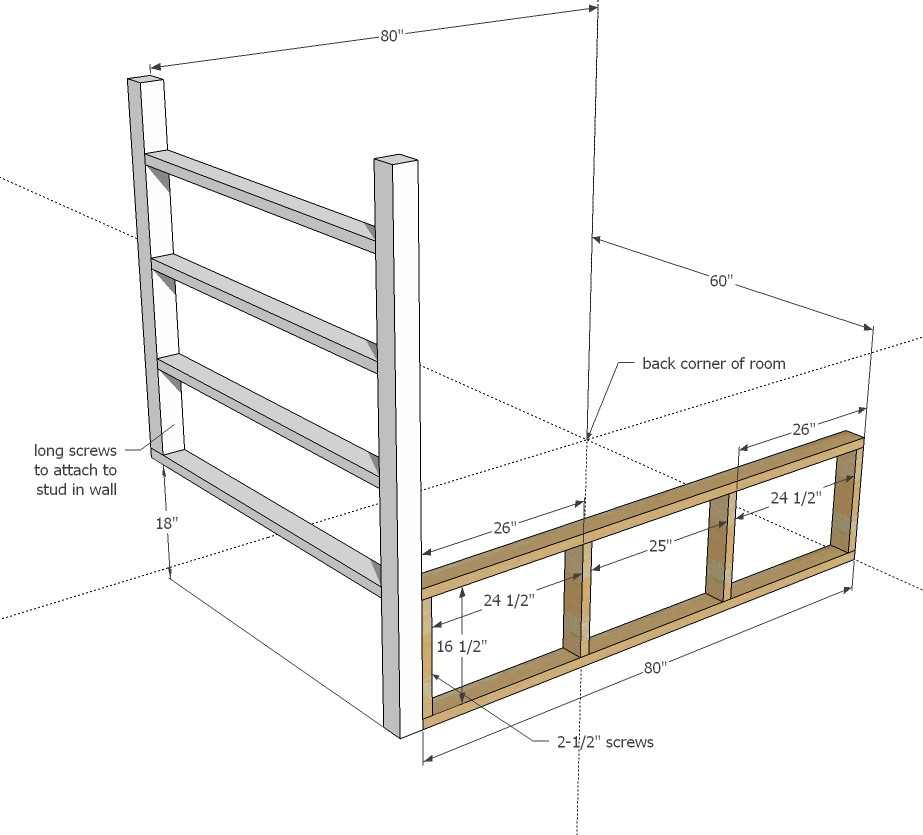

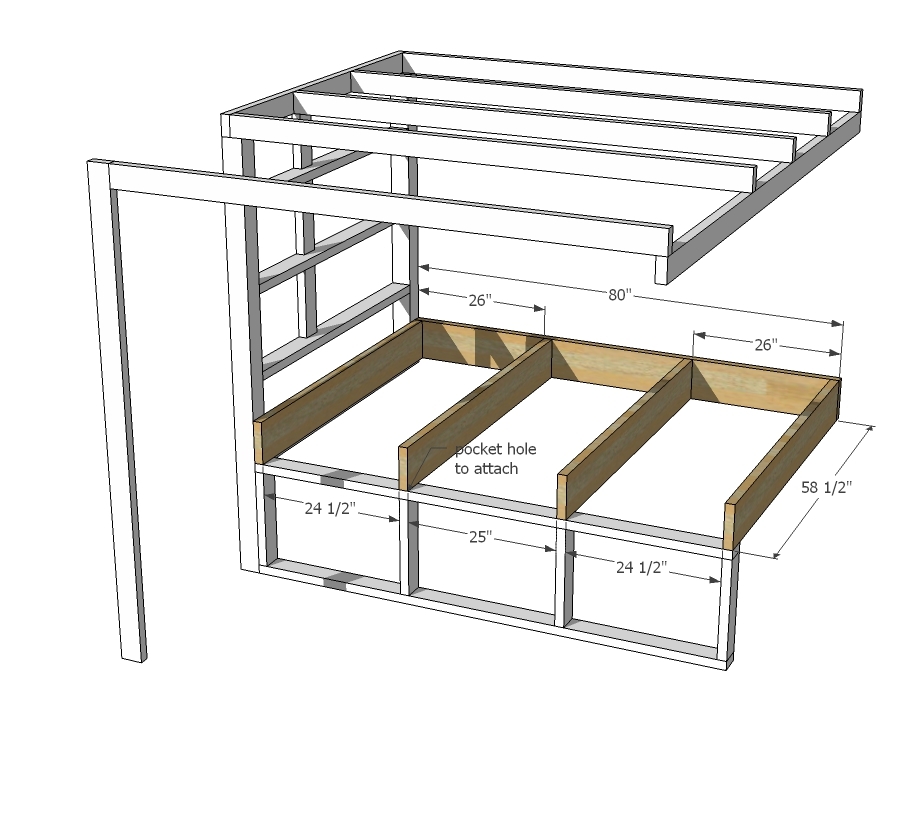

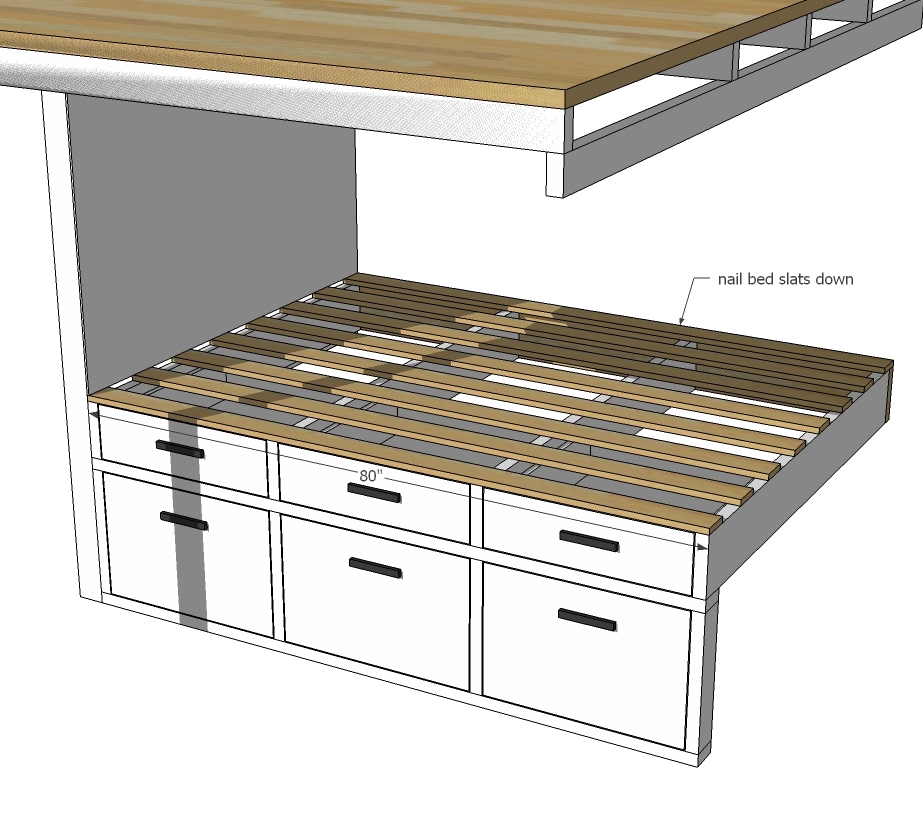

QUEEN BED

- 2 - 2x4 @ 80"

- 4 - 2x4 @ 16-1/2"

- 1 - 2X8 @ 80"

- 4 - 2X8 @ 58-1/2"

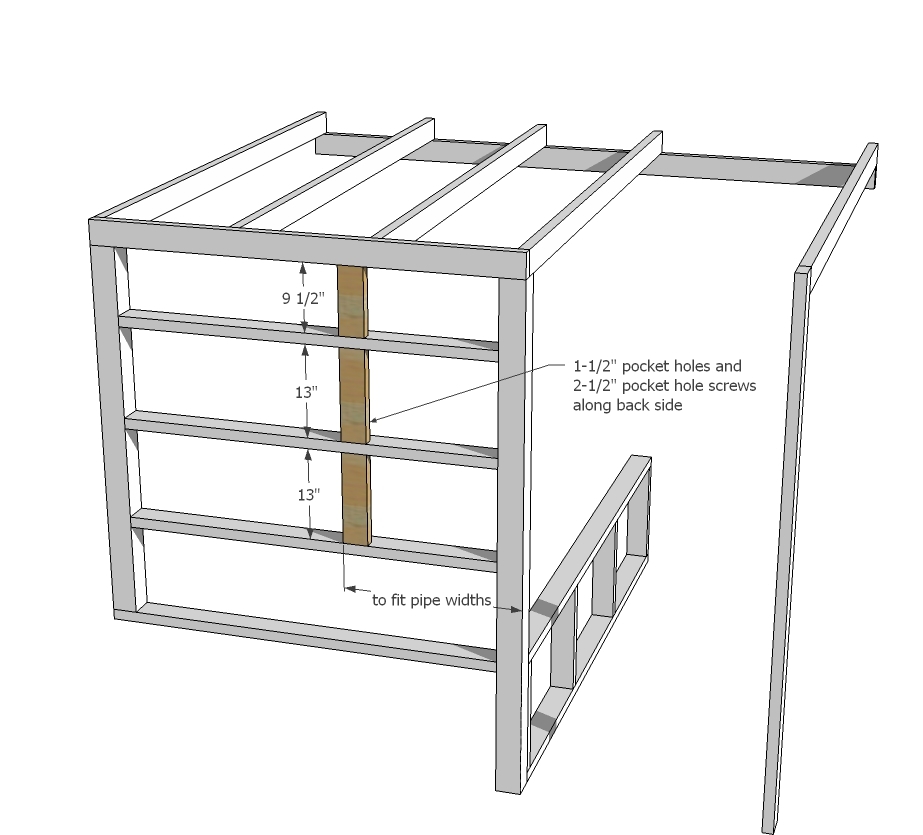

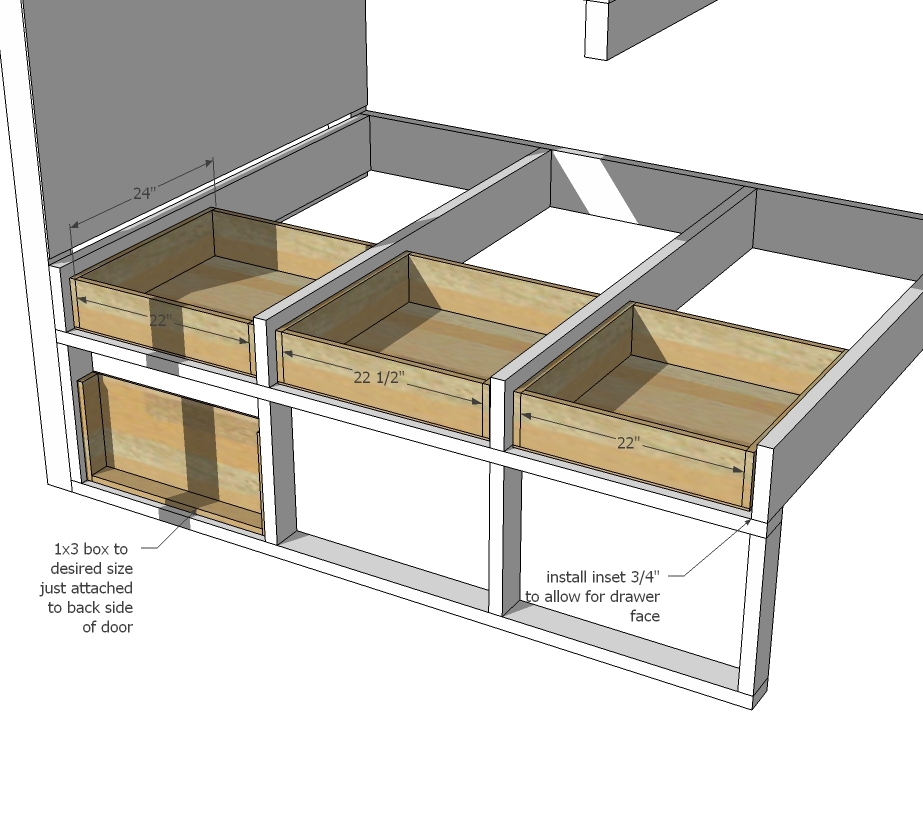

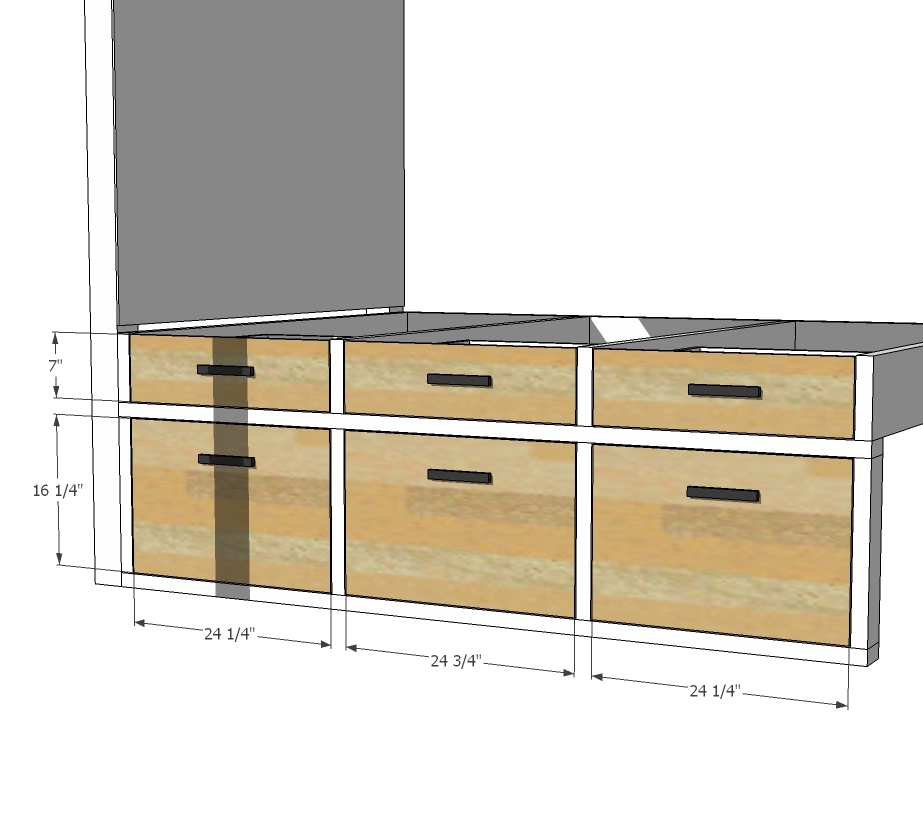

QUEEN BED DRAWERS (CUT TO FIT)

- 6 - 1x6 @ 24"

- 4 - 1x6 @ 22"

- 2 - 1x6 @ 22-1/2"

- 2 - 1/4" plywood @ 24" x 23-1/2"

- 1 - 1/4" plywood @ 24" x 24"

- 2 - 3/4" plywood or 1x8s ripped to fit 7" x 24-1/4"

- 1 - 3/4" plywood or 1x8s ripped to fit 7" x 24-3/4"

- 2 - 3/4" plywood 16-1/4" x 24-1/4"

- 1 - 3/4" plywood 16-1/4" x 24-3/4"

- Bed slats are total of 80" long

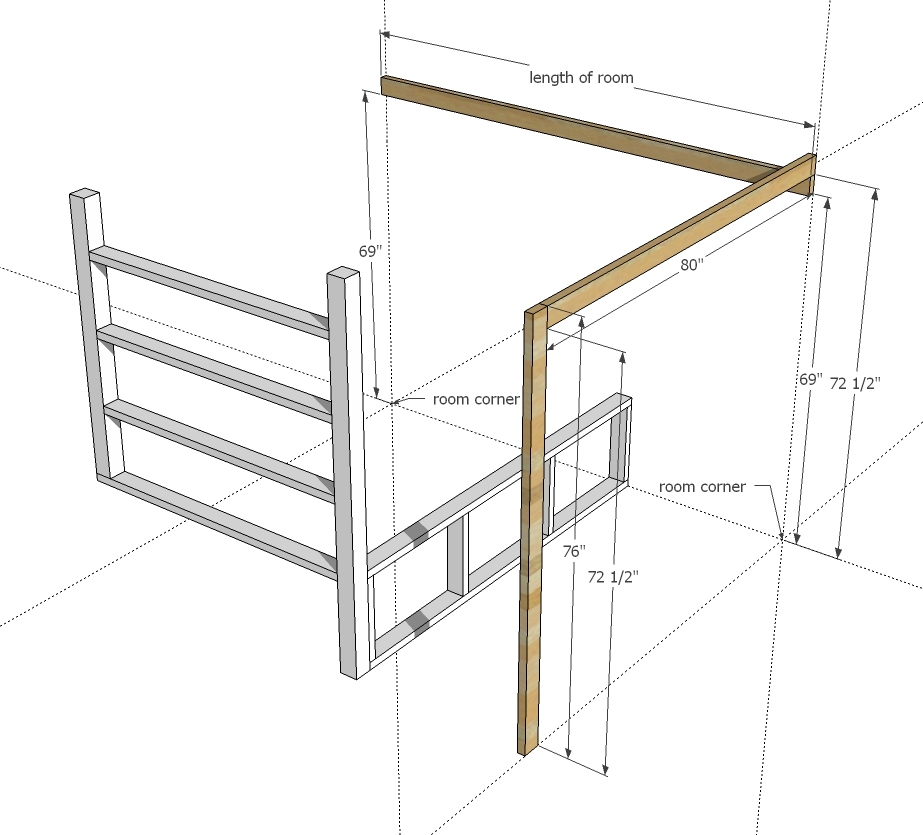

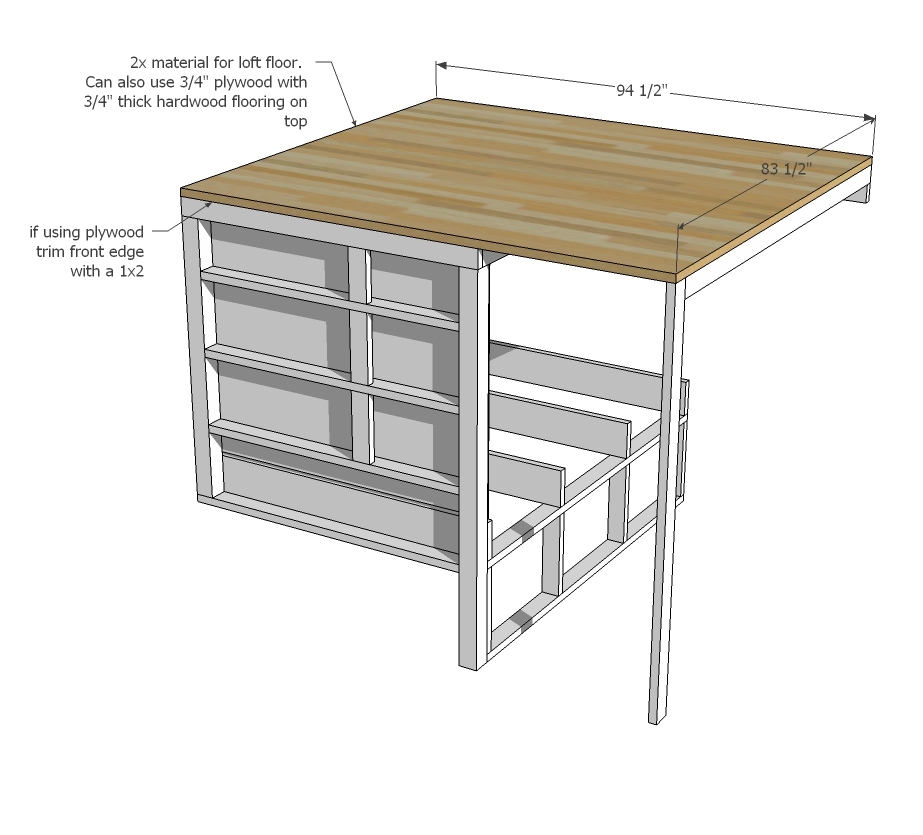

WALL CLEATS 1 - 2x4 @ 76"

- 1 - 2X4 @ 80"

- 1 - 2X4 @ LENGTH OF ROOM (OURS WAS 94-1/2")

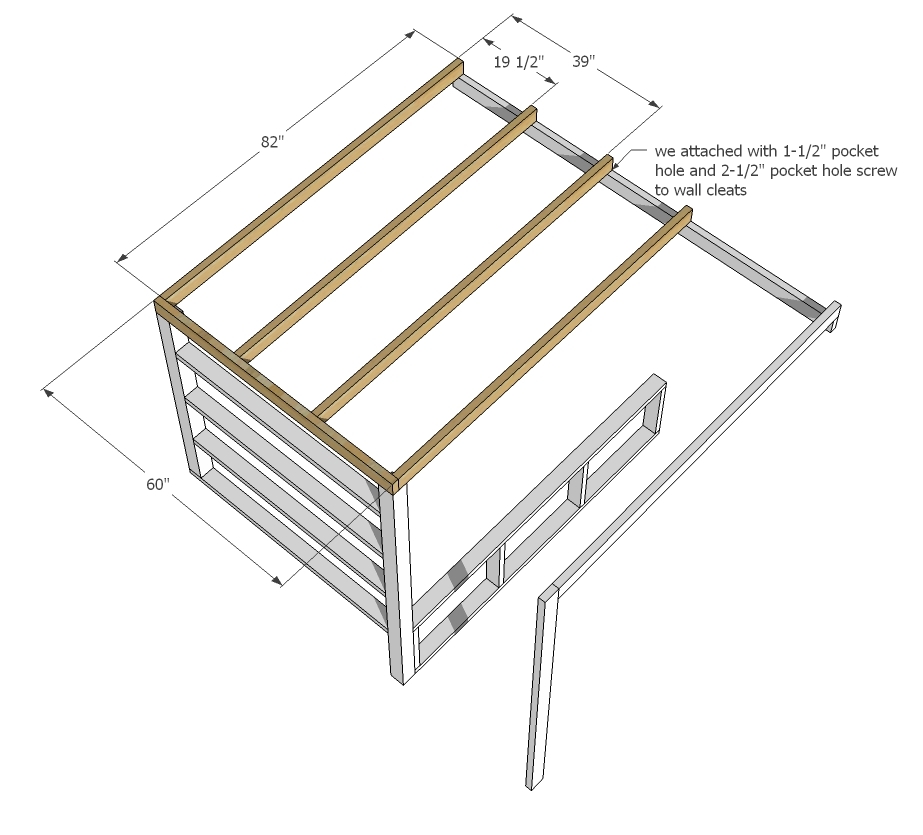

LOFT FLOOR FRAMING

- 1 - 2X4 @ 60"

- 4 - 2X4 @ 82"

- 2X6 TONGUE AND GROOVE FOR FLOORING/CEILING

Instructions

Step 1

Step 2

Next, build the 2x4 bed support. We made ours using the self tapping wood screws (2-3/4" length but similar lengths would work just fine). Make sure this area is very square. Then attach the two pieces to the walls in the room and together using the 2-3/4" screws. You will need longer lag screws to attach 4x4s to the wall.

Step 6

I decided to use the 2x8s to support the mattress because it creates a nice sized cavity for drawers. 2x4 or 2x6 framing would have been fine too if you are not doing the drawers. If doing drawers take extra care to make sure the boards are attached square so you don't have a cockeyed drawer that doesn't slide right.

Comments

Ana White

Fri, 04/22/2016 - 11:26

CUT LIST

Also add 1 additional 2x4 @ 60" to the cut list.

Angelika1962

Sun, 04/24/2016 - 11:09

Kitchen plans

I have enjoyed all 12 episodes of your Tiny House build, but I am still waiting for your plan on how you built your kitchen in this Tiny House! When should I expect to see it, or did I miss something! Lol! Thanks, Angie

In reply to Kitchen plans by Angelika1962

Ana White

Mon, 04/25/2016 - 11:00

The kitchen plans are coming

The kitchen plans are coming in the next few weeks, stay tuned!:)

Lareej

Thu, 06/02/2016 - 23:56

Hinging the queen bed like the trundle

Love this design. Quick question though would it be terribly difficult or too heavy to make that upper section of the queen bed (with the pull out drawers) into a box with those cool hinges like the trundle has to utilize all that space? Thanks p.s. The house looks awesome.

imamommy87

Wed, 07/27/2016 - 07:57

Modified plans

Can you modify these plans for a full size bed with twin trundle?

Priscillarae1

Tue, 08/16/2016 - 06:13

Tiny house wall

Hi. I was wondering what you used on the interior walls of the tiny house? Thanks

mconrad

Fri, 01/06/2017 - 10:10

What kind of wood

What kind of wood should I use for loft bed in your tiny house? We are building this at our lake house.

In reply to What kind of wood by mconrad

Ana White

Mon, 01/23/2017 - 09:08

Hello, we used construction

Hello, we used construction grade lumber to build, mostly 2x4s and 4x4s. All materials should be available at Home Depot or similar.

mconrad

Fri, 02/24/2017 - 21:57

The chairs in the loft

We are almost done making this loft bed in our lake house. As soon as it is done i will post pictures. I was wondering where you got the chairs that make into beds that i see in your picture of the tiny house loft?

Thanks

Margie Conrad

In reply to The chairs in the loft by mconrad

Ana White

Sat, 02/25/2017 - 21:00

https://www.amazon.com/Your

https://www.amazon.com/Your-Zone-Convertible-Sleeper-Lounger/dp/B00L6YW…

jessalvarado17

Wed, 02/21/2018 - 10:51

plans for a smaller unit?

Hi there I am wanting to build two of these this weekend for my large family. At some points my celings are 6 foot high. Could you possibly help me modify these plans (since I am new at doing this kind of stuff)! Any advise is great. I would like to do this asap!