Versatile Shop Cart with inserts for miter saw and kreg jig...or just a workbench top

Preparation

- MDF or Plywood 3/4" - 2 sheets

- Plywood - 1/4" 2' x 4'

- 3 - 1 x 3 x 8

- 4 - 1 x 4 x 8

- 1 - 1 x 2 x 8

- 1-1/4" kreg screws

MDF or Plywood 3/4"

- (2) 36 x 24

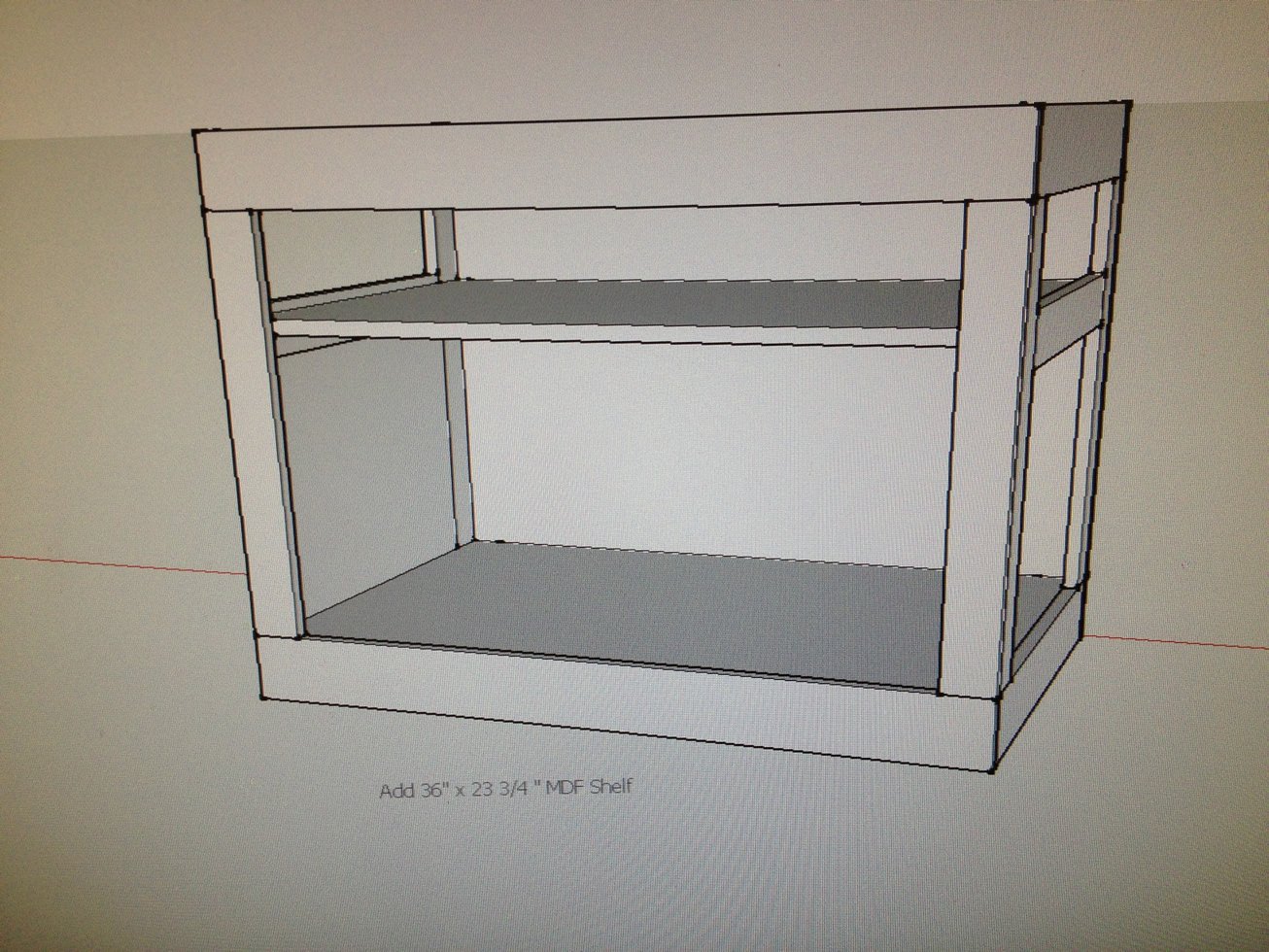

- (1) 36 x 23 3/4 plywood

1/4" Plywood - 36 x 23

3/4 Pine

- (4) 1 x 4 x 37.7

- (4) 1 x 4 x 24

- (8) 1 x 3 x 21

- (2) 1 x 3 x 19

- (2) 1 x 2 x 23 3/4

Please read through the entire plan and all comments before beginning this project. It is also advisable to review the Getting Started Section. Take all necessary precautions to build safely and smartly. Work on a clean level surface, free of imperfections or debris. Always use straight boards. Check for square after each step. Always predrill holes before attaching with screws. Use glue with finish nails for a stronger hold. Wipe excess glue off bare wood for stained projects, as dried glue will not take stain. Be safe, have fun, and ask for help if you need it. Good luck!

Instructions

Step 1

Step 2

Step 4

Insert the top MDF or Plywood 3/4 " piece. Inset this down 3/4 of an inch to leave room for all the inserts you can make

drill pocket holes all the way around the mdf or plywood piece to attach.

easy way for a little help is to attach two 1 x 2 pieces 1.5" down for support while you are putting the mdf sheet in place

Step 7

Step 9

Step 10

Step 11

It is always recommended to apply a test coat on a hidden area or scrap piece to ensure color evenness and adhesion. Use primer or wood conditioner as needed.

Comments

davidmauer14

Tue, 02/26/2013 - 14:53

Thanks for the plans

There as good Ana's plans. I will probably adapt the plans to build my own version of this shop cart, but I'll use 2x4s to strengthen it. And I'll add my own suggestion for a work top.

D.

DorothyJean

Sun, 04/12/2015 - 09:05

2X4's?

Hi David;

I am a newbie, I like this cart tho'. Would you be replacing all the 1X4's/1X3's with 2x4's? or just the 1X4's?

adecesare4

Wed, 02/27/2013 - 21:35

Thanks David!

Sure...sounds like a perfect plan...it is very sturdy as but 2 x 4's will definitely do that...and your top idea was great as well...I did do that...just didnt take a pic of that....

David suggested also making a workbench insert that basically would use a 35 7/8" x 23 7/8 inch insert piece with another piece that would be slightly larger like 40 x 26 attached above it to make a nice solid workbench station as well. Great ideas, love collaboration