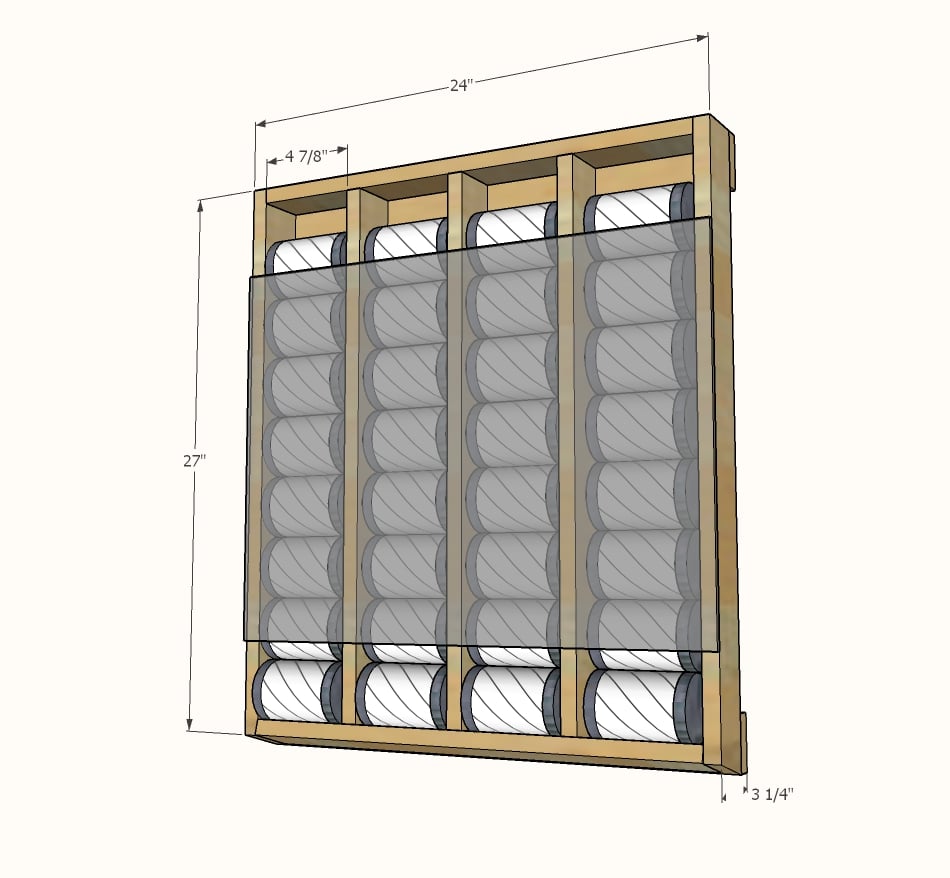

This can organizer will free up so much pantry space! It fits 32 cans in less than 4" on the wall. The clear acrylic glass (in an off the shelf size) keeps cans visible so you know when you are running low, and automatically rotates older cans to the front.

It's made of inexpensive 1x3s and is screwed together with a drill. It's super easy to hang too! Our free plans and video walk you through the process, so even a novice DIYer can tackle this project!

Preparation

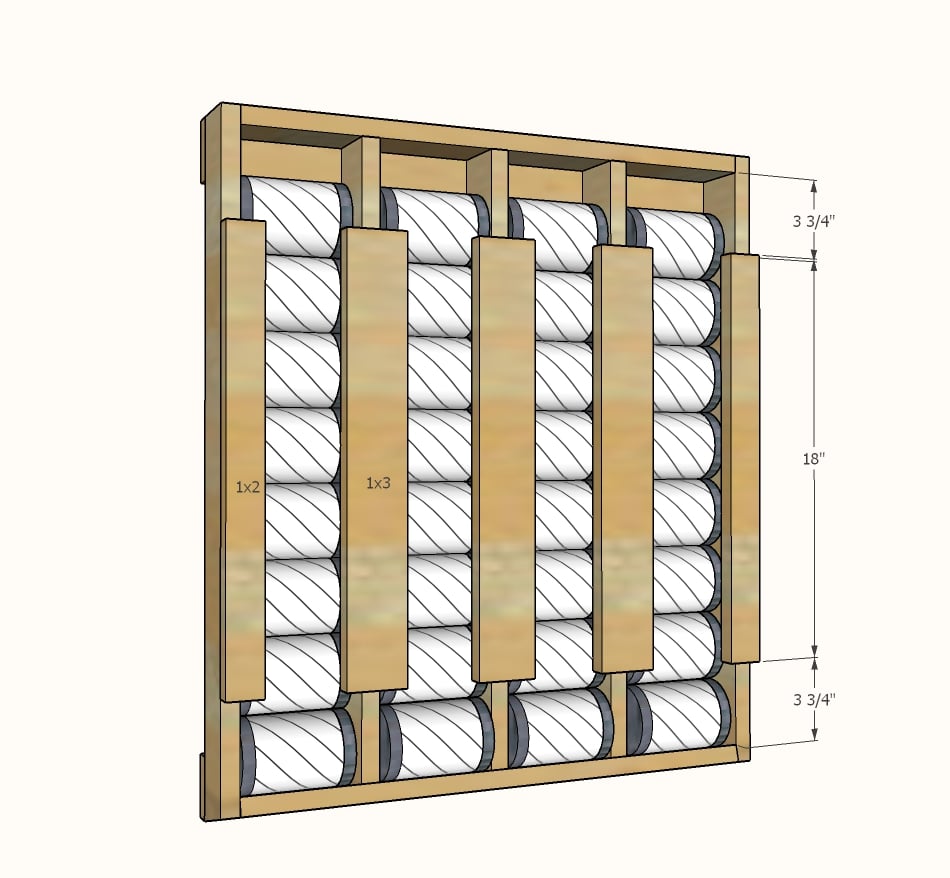

- 18" x 24" sheet of acrylic glass like this from Lowes or 1x2s and 1x3s can be substituted

- 3 - 1x3 @ 8 feet long

- 50 - 2" self tapping wood screws

- 15 - 1-1/4" wood screws for attaching acrylic glass to the front, make sure the back of the screw head is flat to avoid breaking the acrylic glass (can use Kreg Jig screws) - if using the acrylic glass

- Wood glue

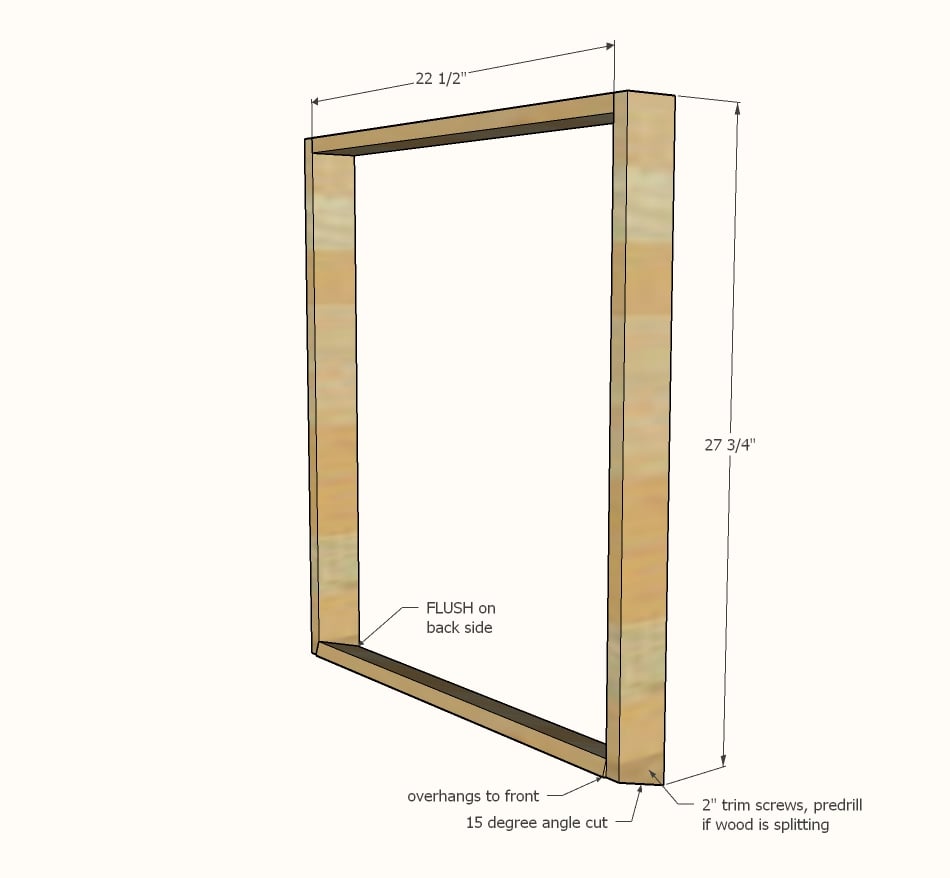

2 - 1x3 @ 22-1/2"

2 - 1x3 @ 27-3/4" - long point measurement, one end cut at 15 degrees off square

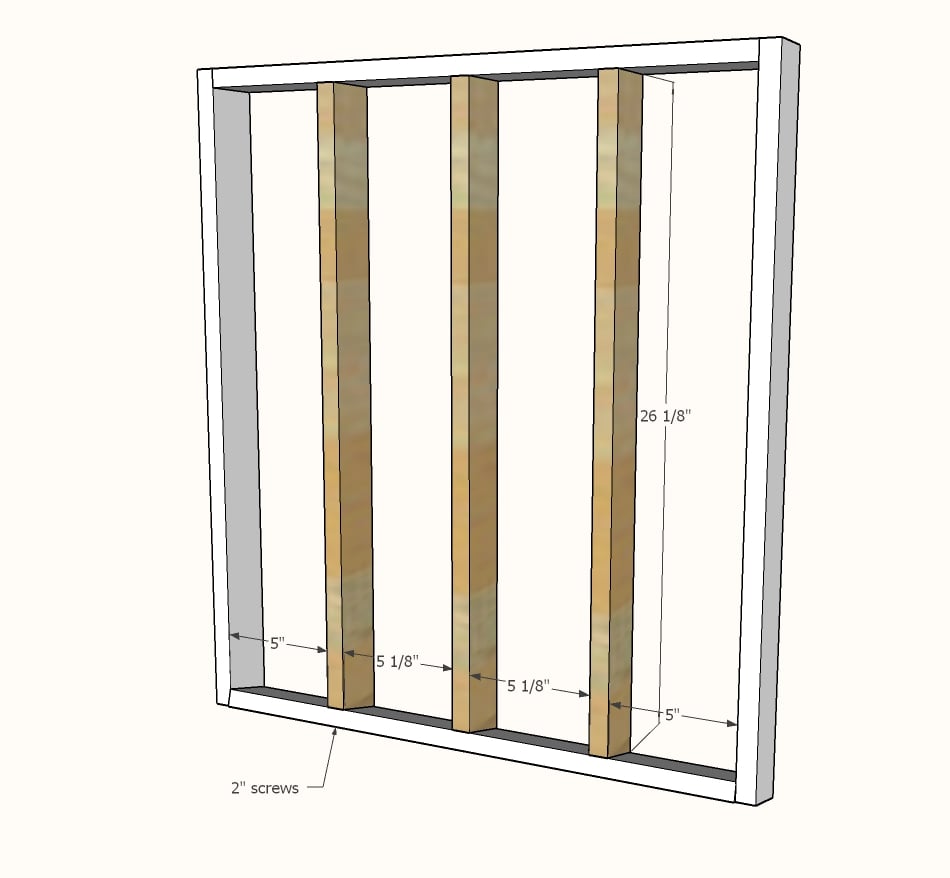

3 - 1x3 @ 26-1/8" - long point measurement, one end cut at 15 degrees off square

2 - 1x3 @ 24"

Cut the 1x3 boards with a compound miter saw.

Instructions

Step 1

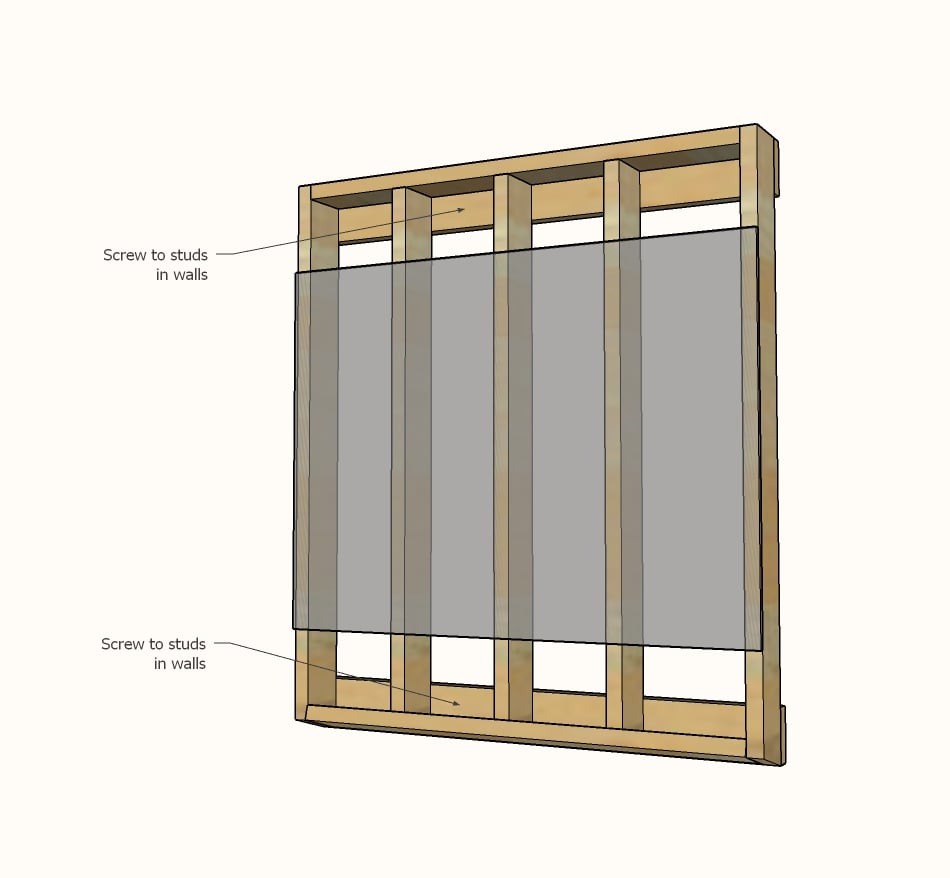

Attach sides to top and bottom pieces.

Note that the back should be completely flush, the front of the angled bottom will overhang.

Use glue and 2" screws.

If wood is splitting, predrill holes with a drill bit sized to match the screw shaft (not including the threads).

Use the speed square to adjust the project for square before glue fully dries.

Step 3

Step 4

I painted everything white with Behr Marquee satin in off the shelf white.

Comments

sduerk

Tue, 10/29/2019 - 11:22

project dimensions

Great idea. Thanks Ana.

I got stuck on a project yesterday that I don't understand. Your plan above addresses it. I built a bench with 3 cubbies under it for kids "stuff". I could not figure out mathematically how to determine how wide every cubby should be with my 3/4" dividers. I thought I should take the width of the bench, subtract out the width of the dividers (2x3/4 = 1.5") and divide by three. However, I always ended up with one cubby being much larger than the other two. What was I doing wrong? Thanks in advance for your help and thank you for your awesome website.

Scott

In reply to project dimensions by sduerk

Ana White

Fri, 11/01/2019 - 14:48

Sometimes wood can be…

Sometimes wood can be thicker (or thinner) or other small issues that add up.

What I often will do is place all the dividers in the shelf, all to one side. Then measure the opening that is left, and divide by the number of desired openings.

DiNeums70

Sat, 07/11/2020 - 10:43

Perfect Ana! Thanks for that…

Perfect Ana! Thanks for that tip. KISS-keep it simple stupid, I always forget this!!

Thanks for making your plans so easy to follow. The diagrams are so very helpful.

Happy Building!

Di

jtholland

Sat, 11/02/2019 - 12:34

For the pantry

For the pantry

merlinpatt

Tue, 03/03/2020 - 09:05

Cans scrape wall?

Do the cans scrape the wall as they fall? What can I do to prevent the cans from you touching the wall?

In reply to Cans scrape wall? by merlinpatt

jiffyone2001

Wed, 10/07/2020 - 22:15

Put a piece of quarter inch…

Put a piece of quarter inch thick backing on it.

abelandaddie@y…

Mon, 07/27/2020 - 08:02

My cans are too fat (regular…

My cans are too fat (regular sized cans) for the glass to go over it using 1x3s :(