Free plans to build Rustic X Kitchen Island with drawers in - double width - plans from Ana-White.com

Preparation

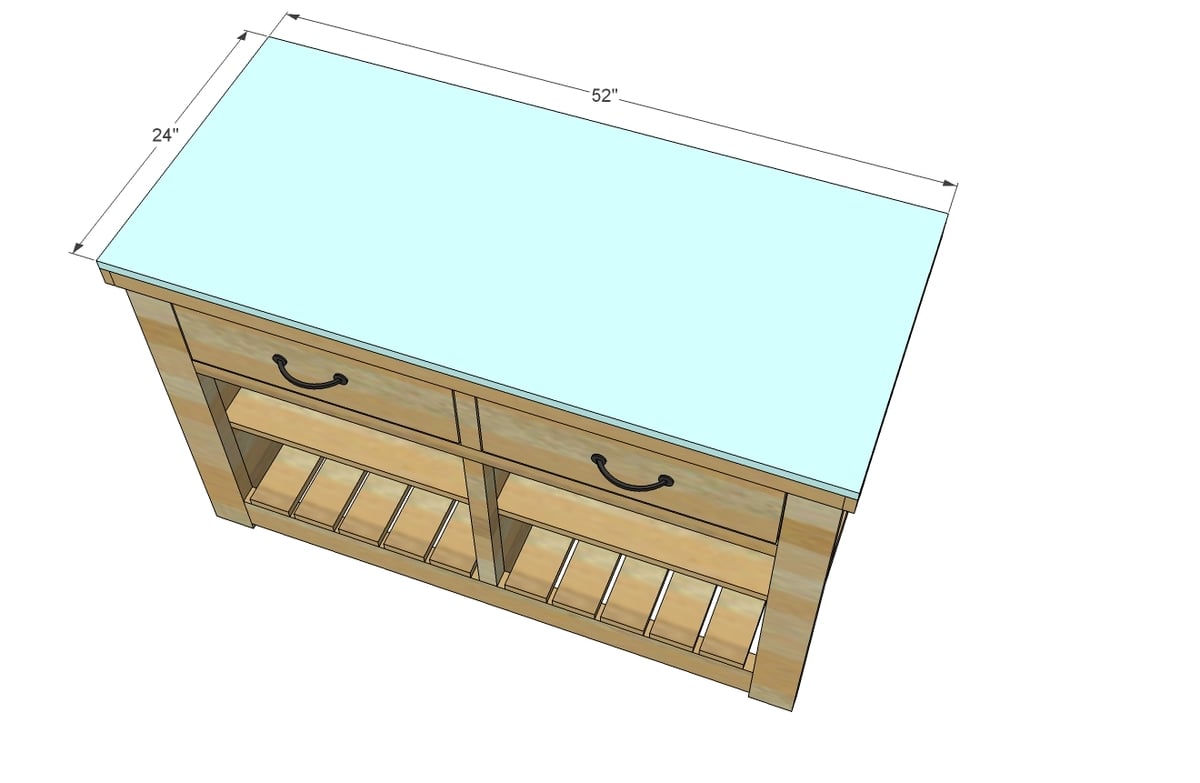

- 1 - 3/4" thick top 24" x 52" (recommend a premade project panel)

- 5 - 2x4 @ 8 feet long

- 3 - 2x2 @ 8 feet long

- 1 - 1x12 @ 8 feet long (cut the 31 1/2" long pieces from this board)

- 1 - 1x12 @ 4 feet long (cut the shelves from this board)

- 3 - 1x3 @ 8 feet long

- 3 - 1x2 @ 8 feet long

- 1 - 1x6 @ 10 feet long

- 1 - 1x8 @ 4 feet long

- 4' 1x10 board for the drawer stops

- 2 - 10"x18" 1/2" plywood pieces for drawer bottoms (can be scraps or purchase a 1/4" sheet)

- 4 caster wheels that can be mounted on bottom of 2x4

NOTE: Cut list and shopping list has been updated per reader comments on 9/18/2013

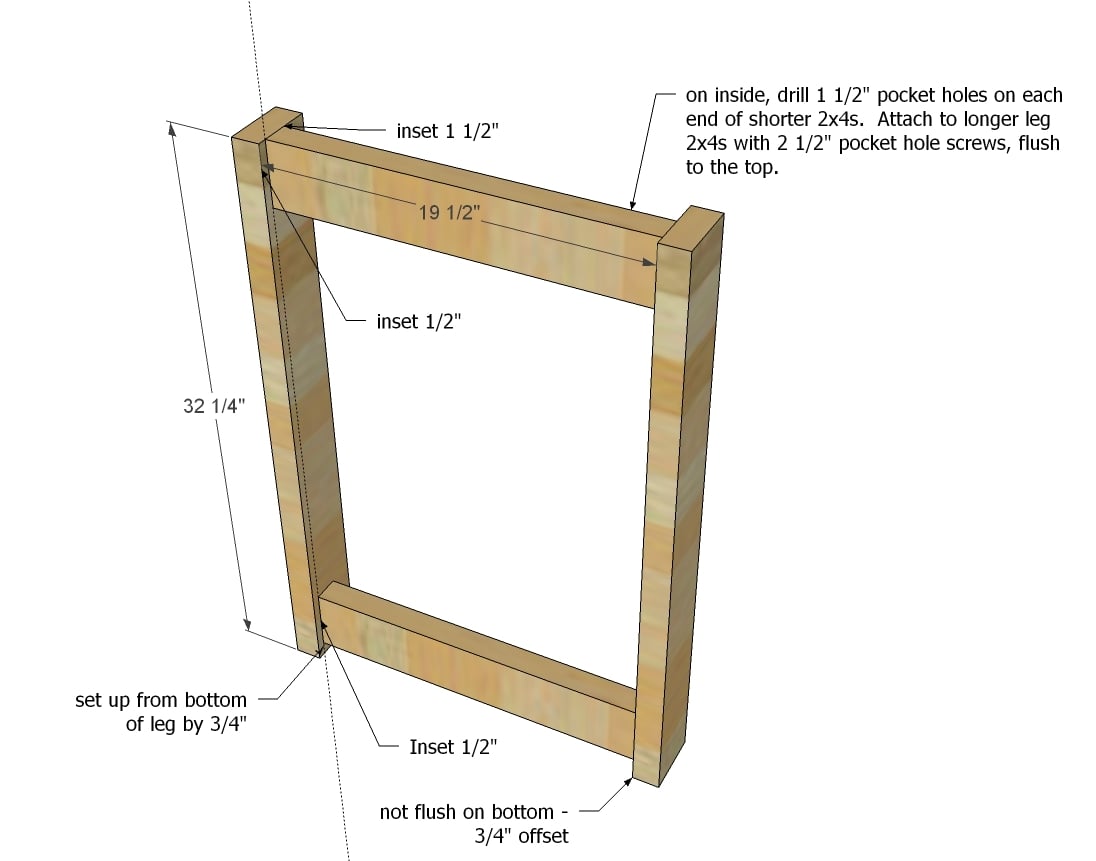

- 4 - 2x4 @ 32 1/4" (legs)

- 4 - 2x4 @ 19 1/2" (leg top/bottoms)

- 2 - 2x4 @ 27 5/8" (long point to long point, both ends cut parallel at 45 degrees)

- 4 - 2x4 @ 13 3/4" (longest point measurement, one end cut at 45 degrees)

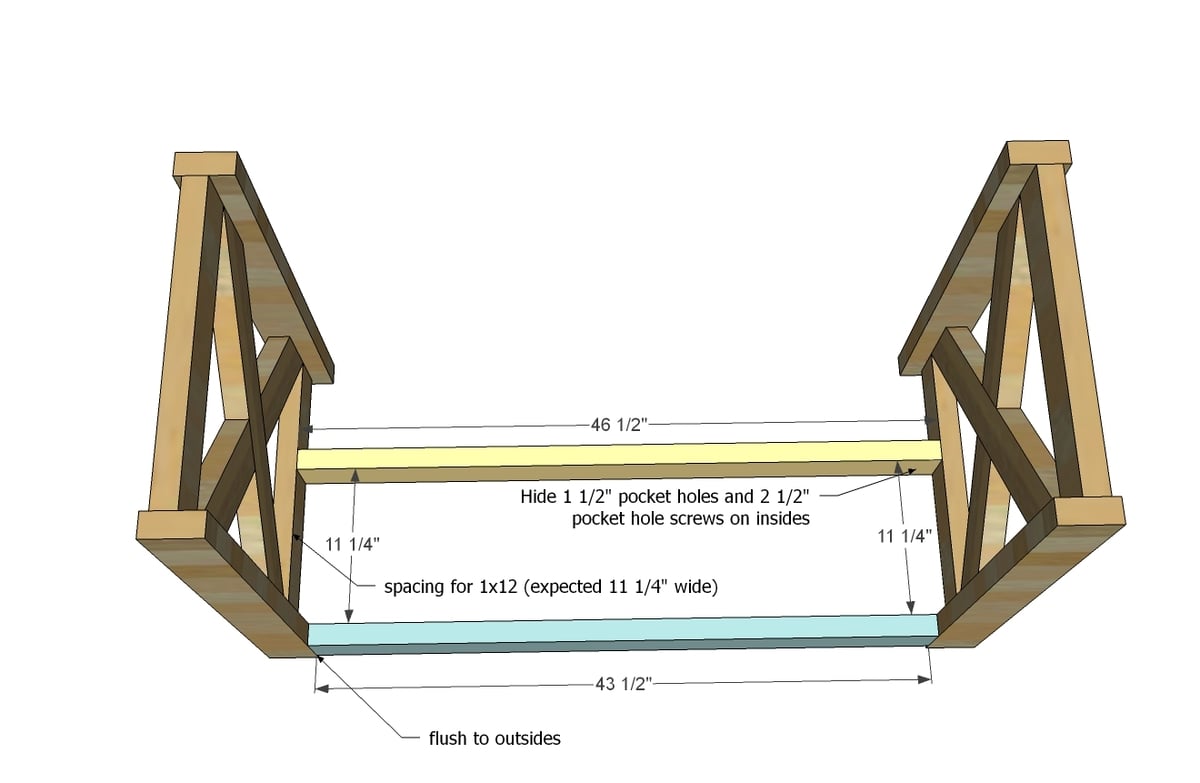

- 1 - 2x4 @ 43 1/2" (front bottom apron)

- 1 - 2x4 @ 46 1/2" (middle bottom apron)

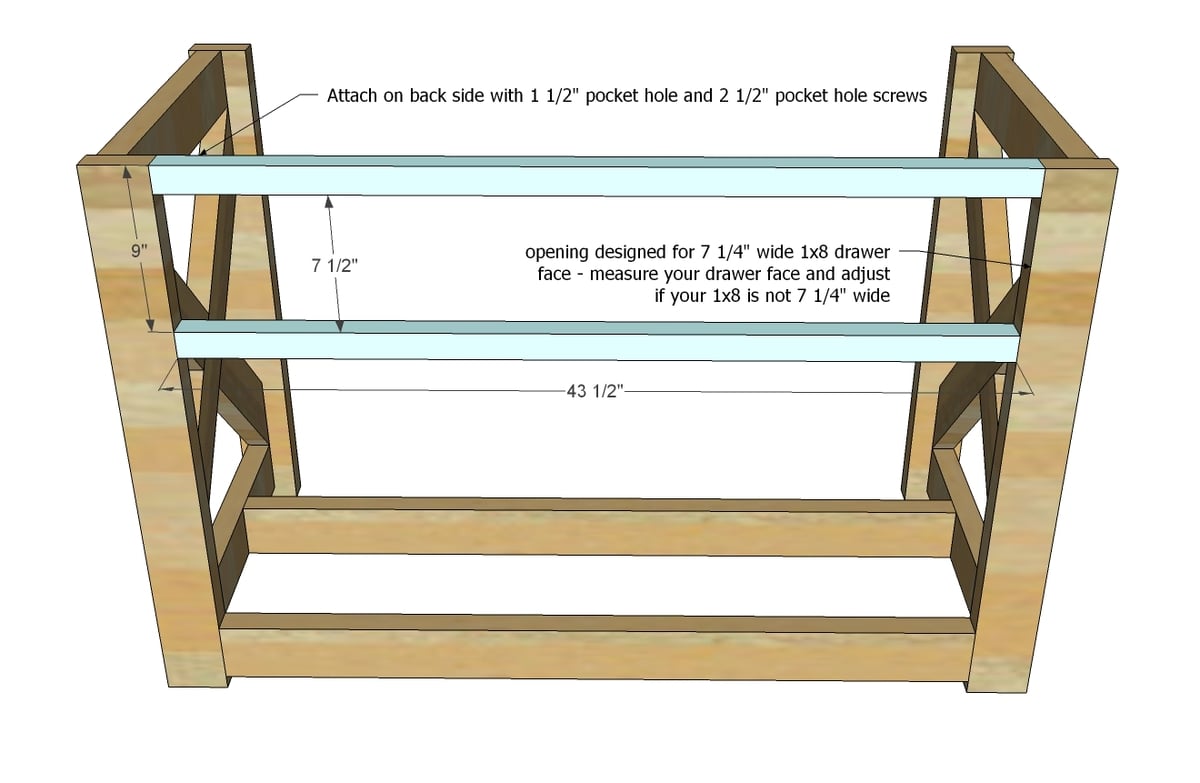

- 3 - 2x2 @ 43 1/2" (top aprons/bottom of drawer trim)

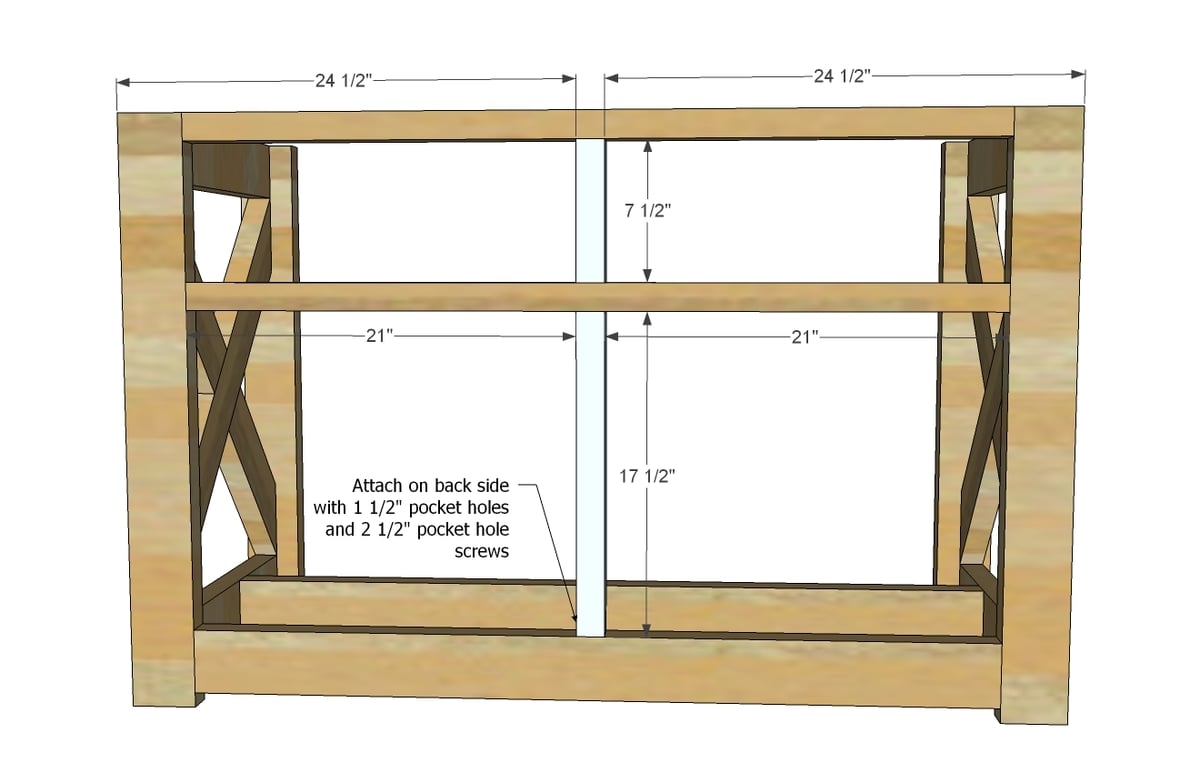

- 1 - 2x2 @ 7 1/2" (drawer center trim)

- 1 - 2x2 @ 17 1/2" (shelf area center trim)

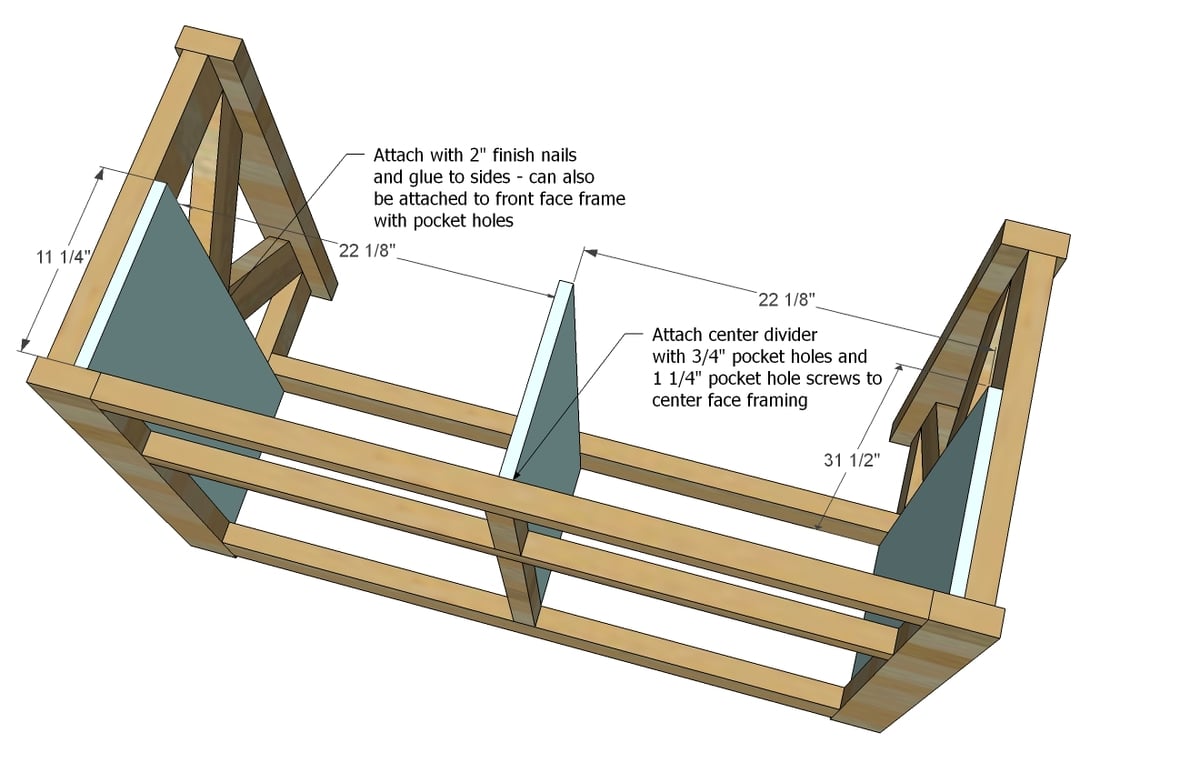

- 3 - 1x12 @ 31 1/2" (shelf sides)

- 2 - 1x10 @ 22 1/8" (drawer area backs)

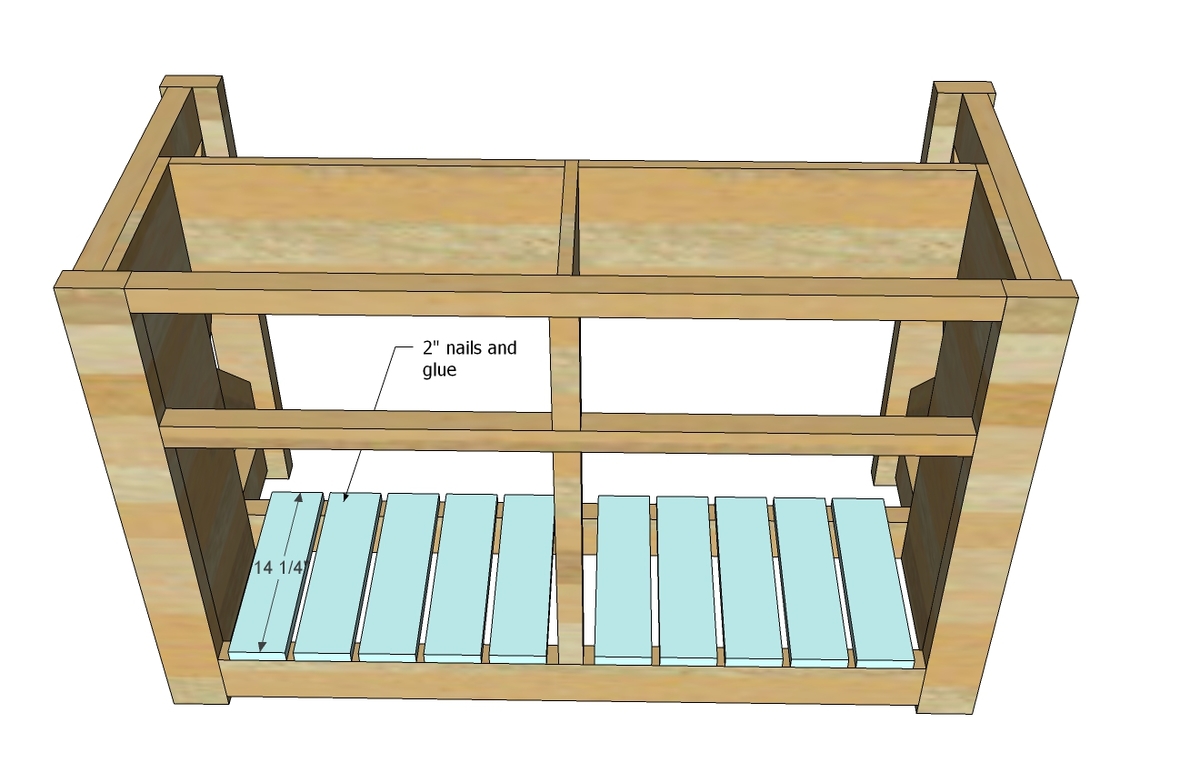

- 14 - 1x3 @ 14 1/4" (bottom shelf slats)

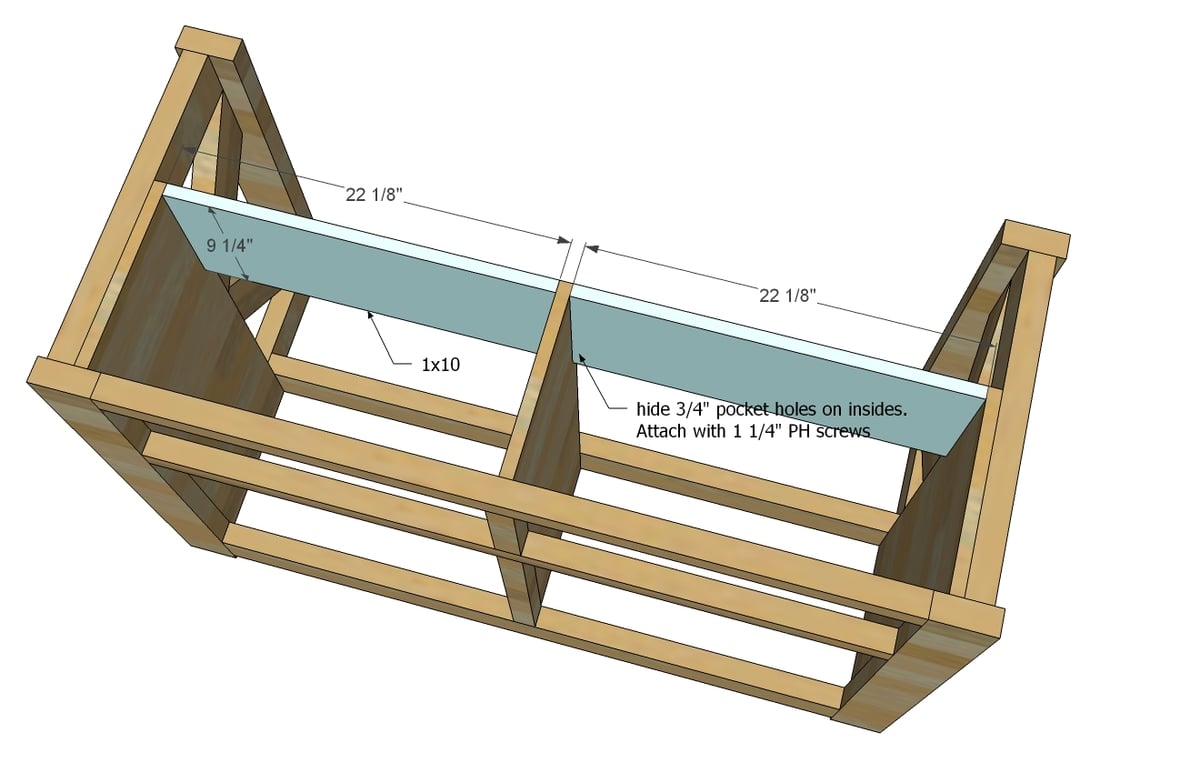

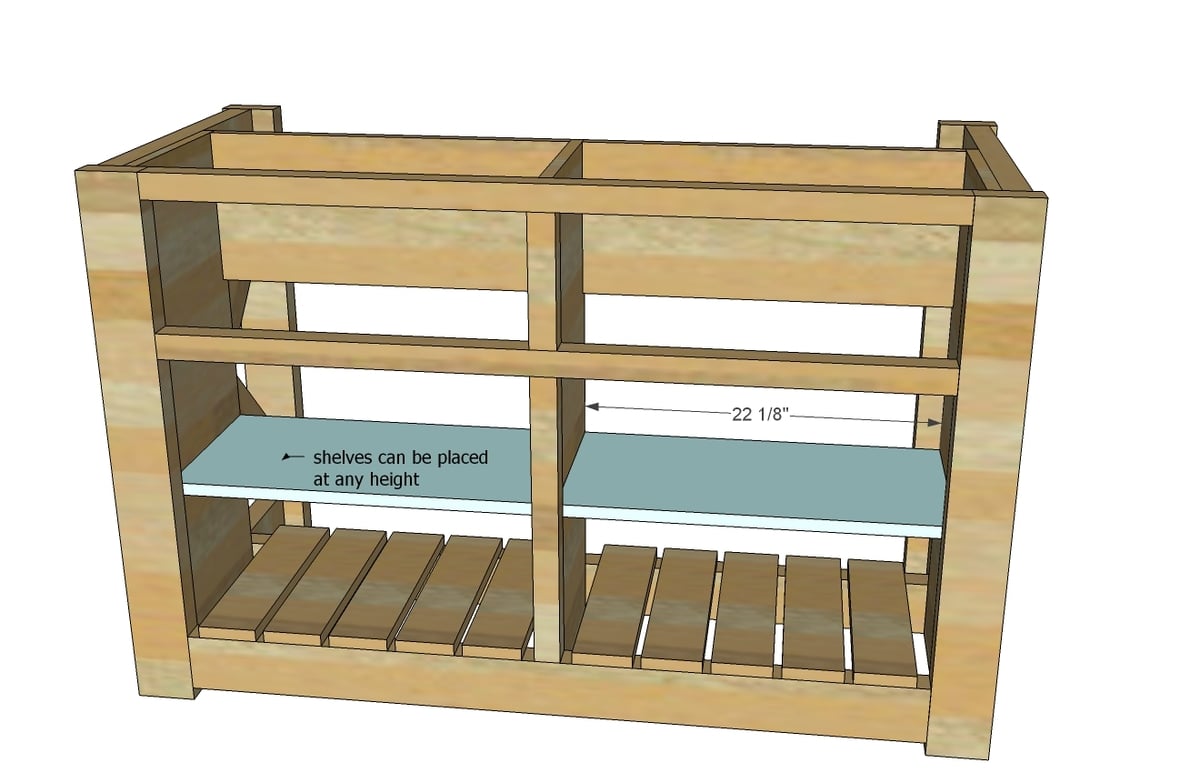

- 2 - 1x12 @ 22 1/8" (shelves)

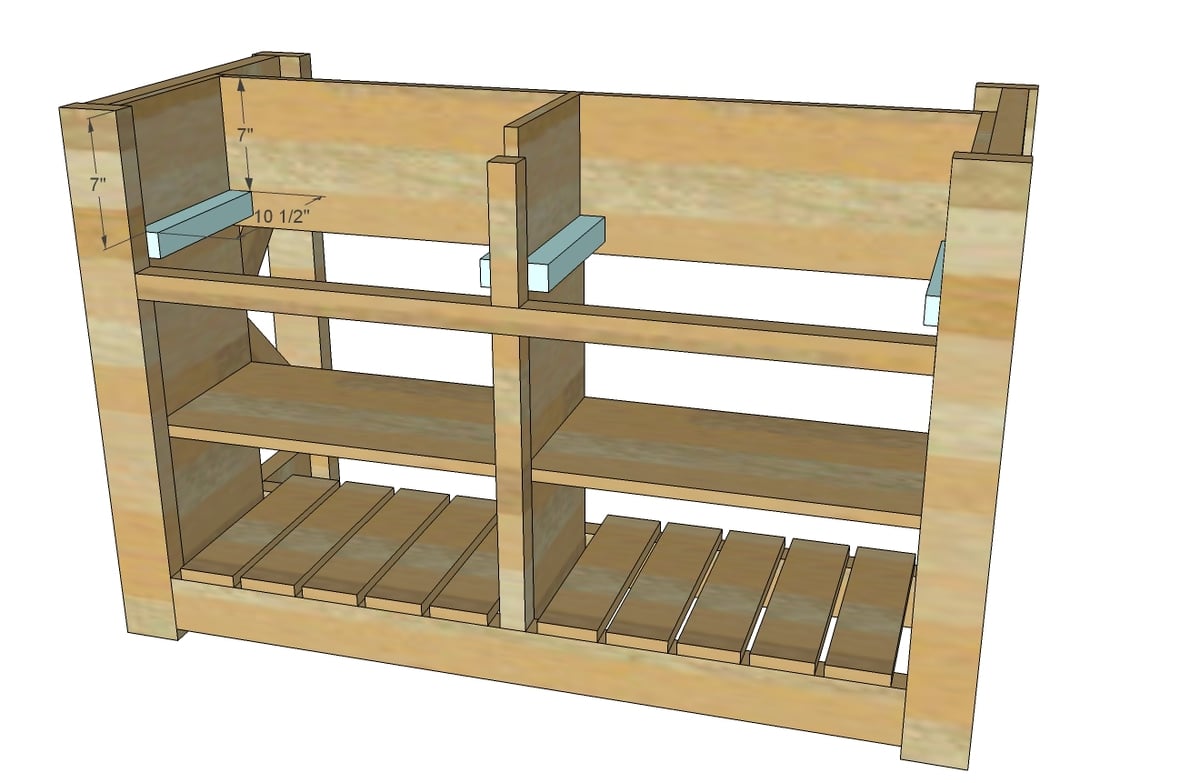

- 4 - 2x2 @ 10 1/2" (drawer slides)

- 2 - 1x2 @ 24" (top trim sides)

- 2 - 1x2 @ 50 1/2" (top trim front/back)

- 1 - 3/4" thick top 24" x52"

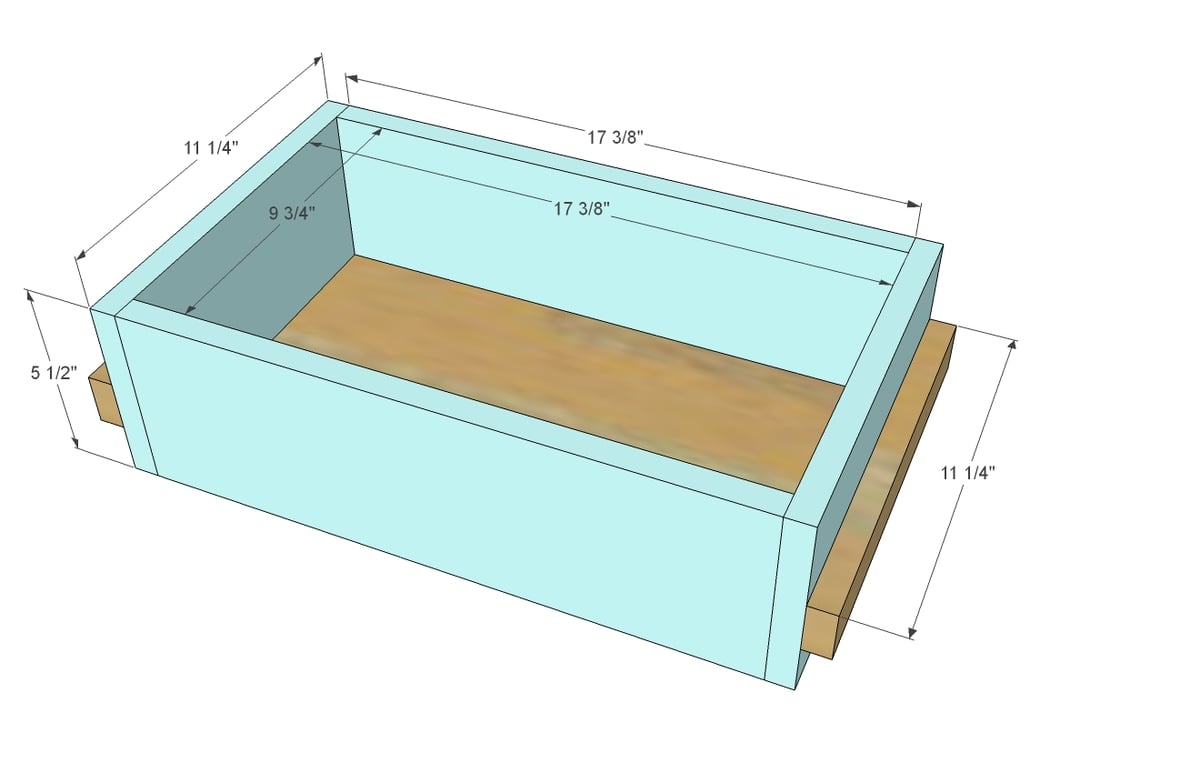

DRAWERS - measure and cut to fit so there's an 1/8" gap on each side!!! Measurements given should be used as a guide only.

- 4 - 1x6 @ 11 1/4" (drawer sides)

- 4 - 1x6 @ 17 3/8" (drawer front and back)

- 2 - 1/2" plywood 9 3/4" x 17 3/8" (drawer bottoms)

- 4 - 1x2 @ 11 1/4" (drawer slide cleats)

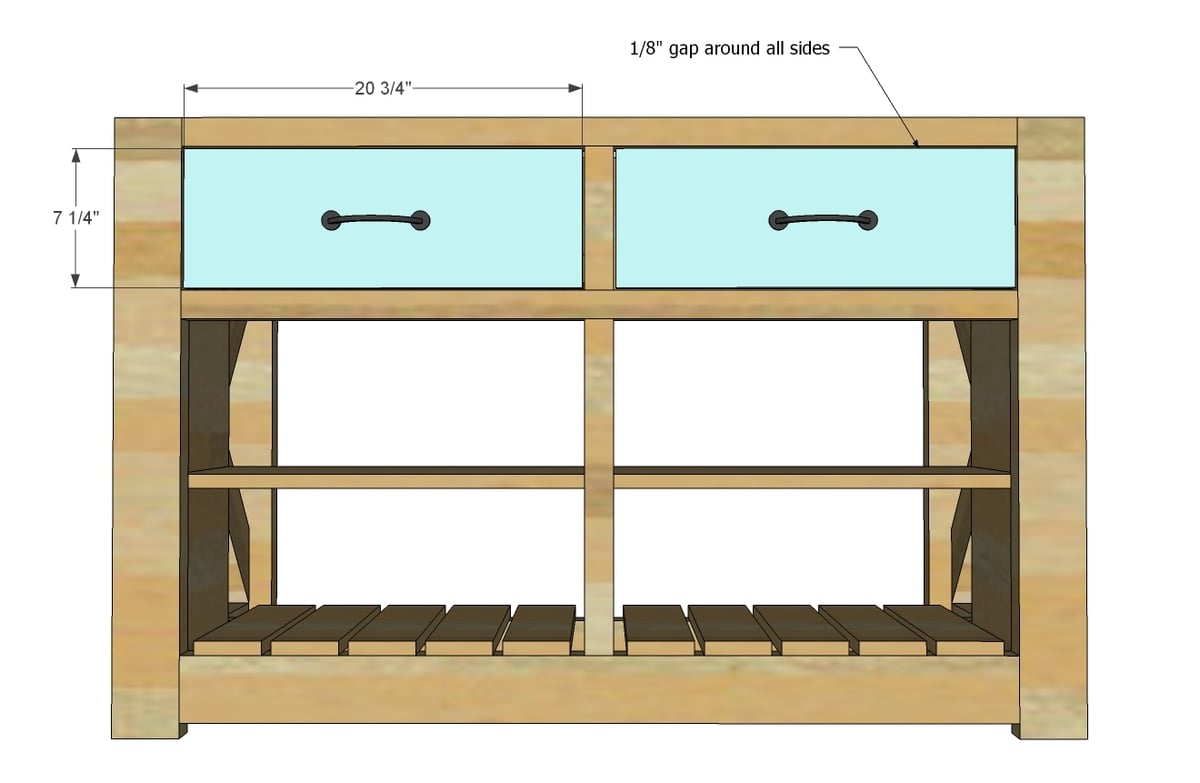

- 2 - 1x8 @ 20 3/4" (drawer faces)

NOTE: Cut list and shopping list has been updated per reader comments on 9/18/2013

Please read through the entire plan and all comments before beginning this project. It is also advisable to review the Getting Started Section. Take all necessary precautions to build safely and smartly. Work on a clean level surface, free of imperfections or debris. Always use straight boards. Check for square after each step. Always predrill holes before attaching with screws. Use glue with finish nails for a stronger hold. Wipe excess glue off bare wood for stained projects, as dried glue will not take stain. Be safe, have fun, and ask for help if you need it. Good luck!

Instructions

Step 1

Step 3

Step 4

Step 6

Step 9

Step 10

There's a few different ways to do the drawers, but since they are so shallow (less than 12") it's hard to find small drawer slides. The 2x2s act as cleats to hold the drawer in the opening. Apply candle wax to top to make the drawer slide easier.

Attach with just 2 2" screws for now - you may need to adjust to get the drawer to slide just right.

Step 11

Build your drawers as shown above - but build to fit the opening. Measure between the 2x2s and subtract 1/4" (1/8" for each side) and make this the overall width of your drawer box (not including the 1x2 cleats)

If you use pocket holes to build the drawer, place on outsides of front and back - they will get hidden by drawer face.

Step 12

Step 13

Step 15

It is always recommended to apply a test coat on a hidden area or scrap piece to ensure color evenness and adhesion. Use primer or wood conditioner as needed.

Comments

katie0910

Thu, 09/19/2013 - 14:58

Building this now!

Thank you so much for these great plans! I bought my wood today and I'm building it right now. I just wanted to point out that the shopping list is missing a 4' long 1x10 board for the drawer backs. Can't wait to upload a brag post of the finished product!

phillysuperfuzz

Sat, 01/18/2014 - 12:40

Tip on the drawers

I am building this now too.... almost finished! I just wanted to give a tip on the drawers. If you only use 2x2s for the bottom drawer slides, the drawers will tip forward as you pull them up. It would be best to put matching 2x2 cleats on top. That way, you can pull the drawer out and not have to hold it up.

Claulino

Sun, 02/08/2015 - 06:16

Praise

My congratulations , you are an amazing woman!

I loved this job , I'm starting this table hope I can leave it as beautiful as yours.

Thank you very much.

Claulino

Meus parabéns, você é uma mulher incrível!

Adorei este trabalho, já estou iniciando esse projeto espero que eu consiga deixa-lo tão bonito quanto o seu.

Muito obrigado.

Claulino

caliotto

Fri, 06/26/2015 - 22:04

Hi all.

Hi all.

I'm building this island this coming week but have to resize it to fit the granite I purchased for another island option. I wanted to stain it to match an oak table but can't afford oak for this whole project. Have decided to paint it white. Does anyone have any suggestions for the type of wood I should use that is easy to work with, finished nicely, and is sturdy enough to hold a piece of granite 18x48x2?

Thank you for your help!!

sumitbansal

Tue, 07/14/2015 - 07:44

Garbage Bin

Hello there,

I really like this Island and would like to try it out. This will be my first DIY project. Hope I will able to finish it .

.

Has anyone considered putting in Garbage bin pull out in this island?