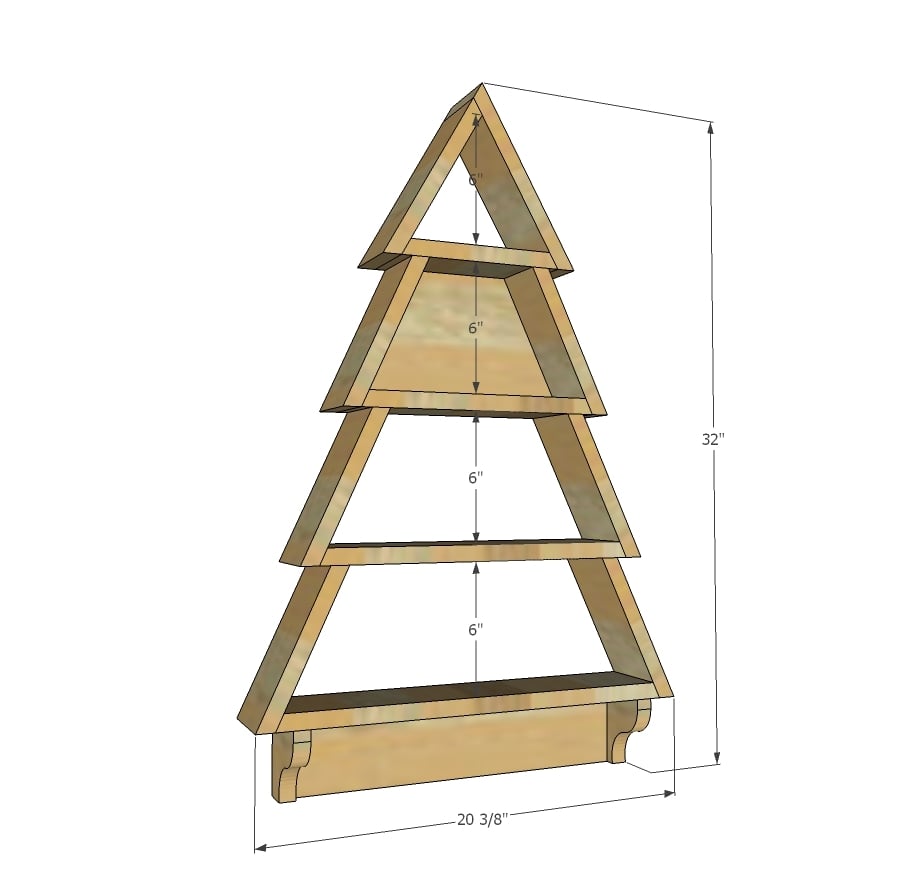

Free build plans for this wood Christmas Tree Shelf.

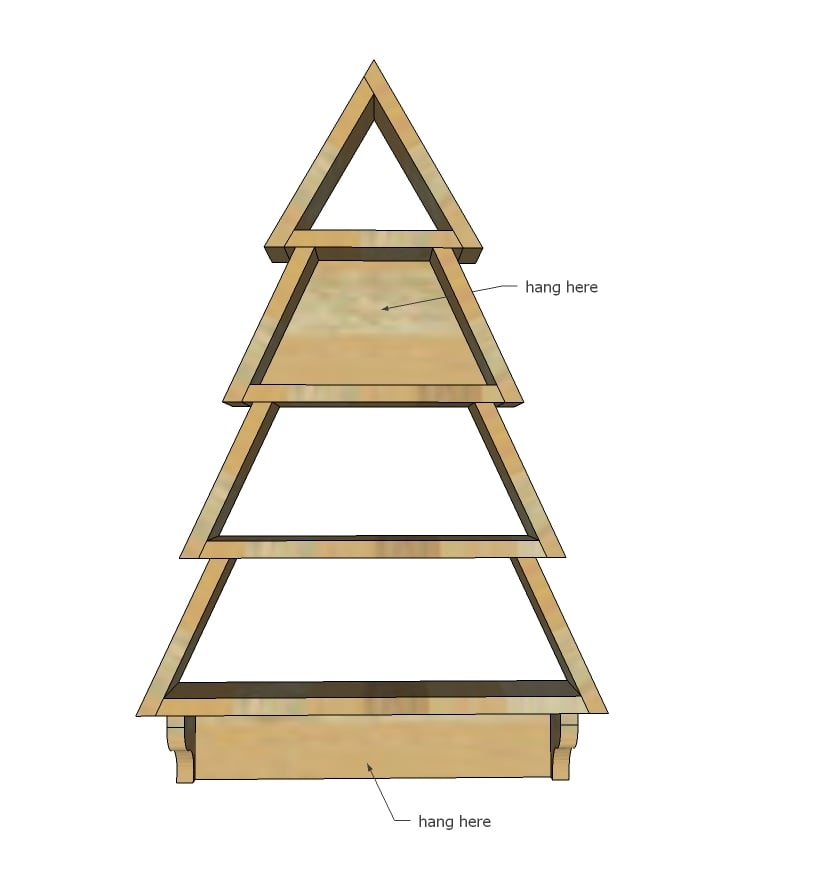

Decorate and display with a Christmas Tree Shelf! Perfect for Advent Calendar, displaying Christmas Cards, or hanging stockings. Our tree shelf features four shelves and hooks. Built by Jaime Costiglio, free step by step plans from Ana-White.com

Collections

Dimensions

Dimensions for Christmas Tree Shelf shown in diagram

Preparation

Shopping List

- 12 feet of 1x4 or 1x3 boards (I used 1x3s in the video, Jaime used 1x4s)

- 1/4" plywood 6" x 15" or larger (for just one portion, will need more plywood for covering multiple portions)

- 1-1/4"and 3/4" brad nails

- 3 hooks

- Hanging kit or screws for hanging to studs in wall

Cut List

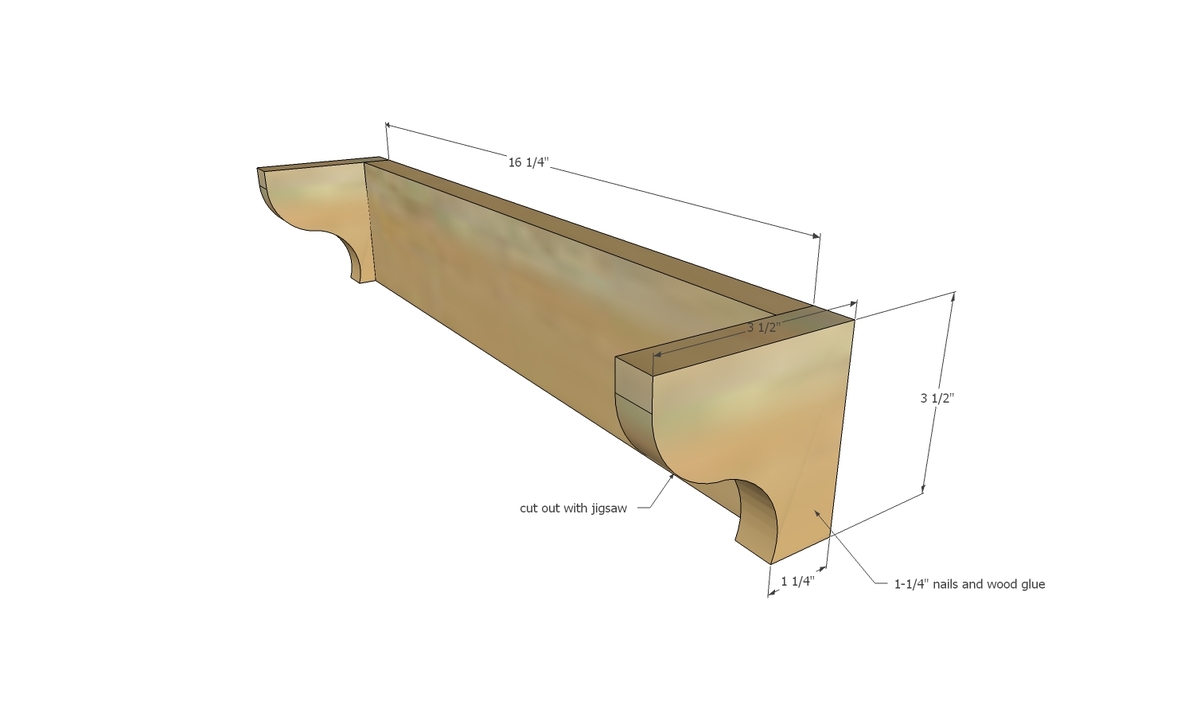

You can directly substitute 1x3s for 1x4s in the below cut listTRUNK

- 1 - 1x4 @ 16-1/4"

- 2 - 1x4 @ 3-1/2" or 1x3 @ 2-1/2"

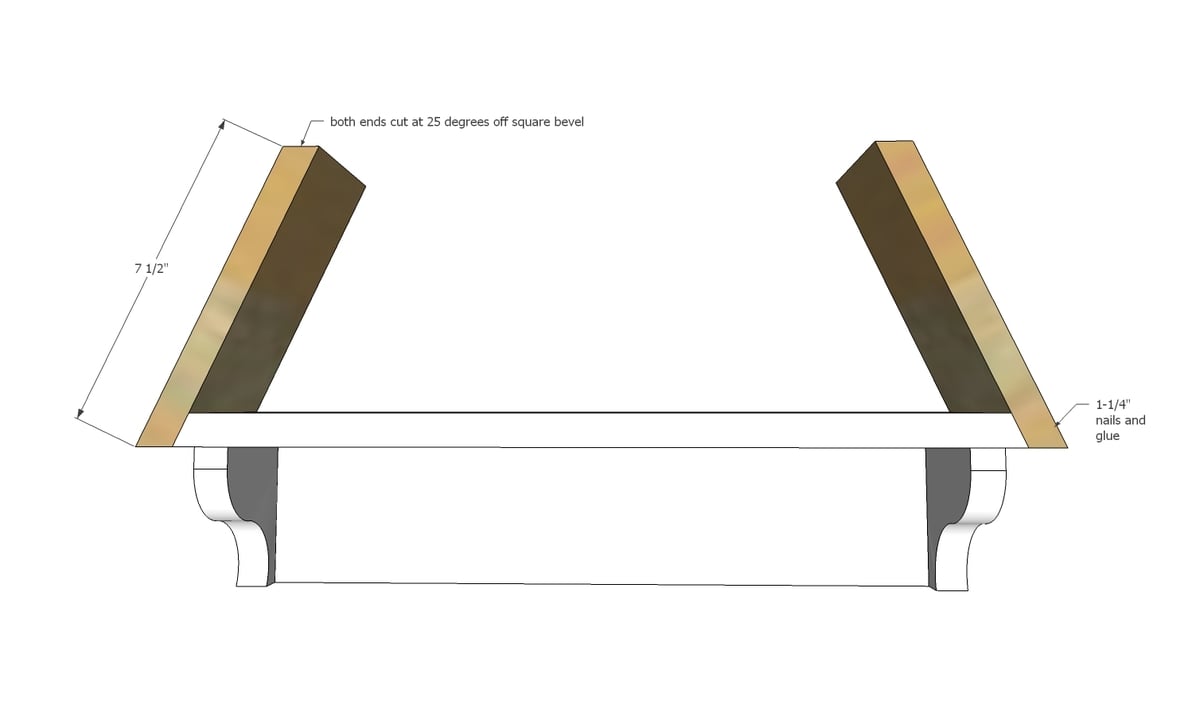

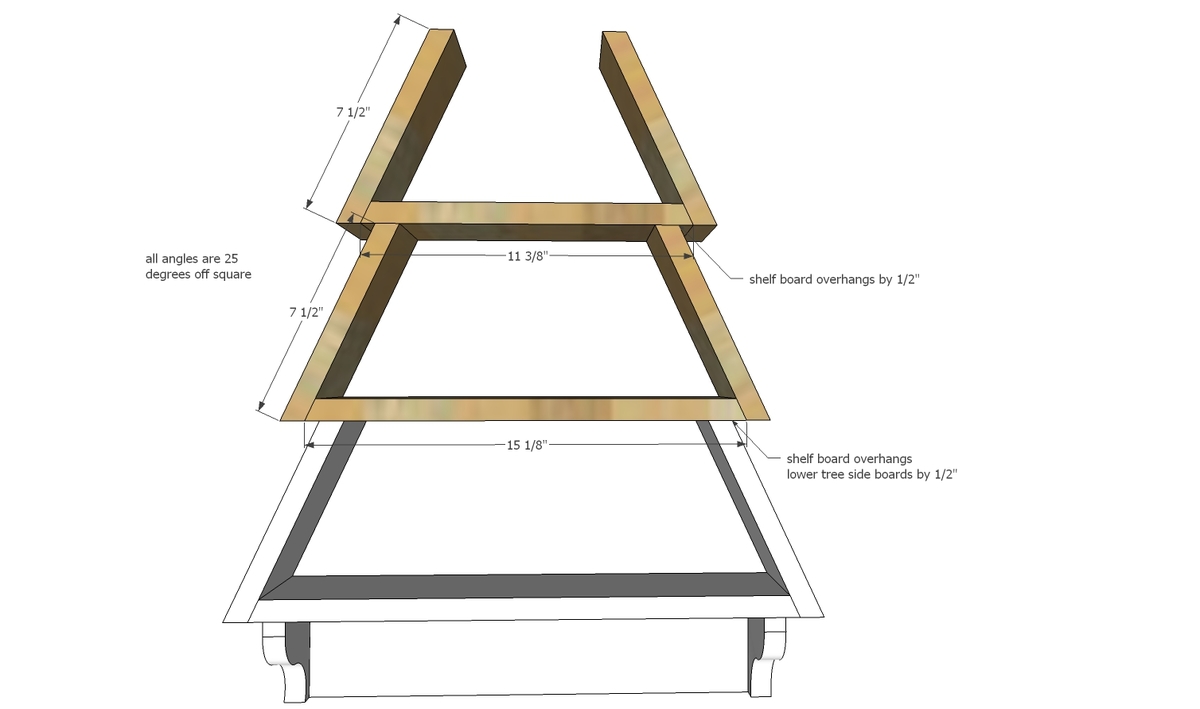

MAIN TREE - SAW BEVEL IS 25 DEGREES

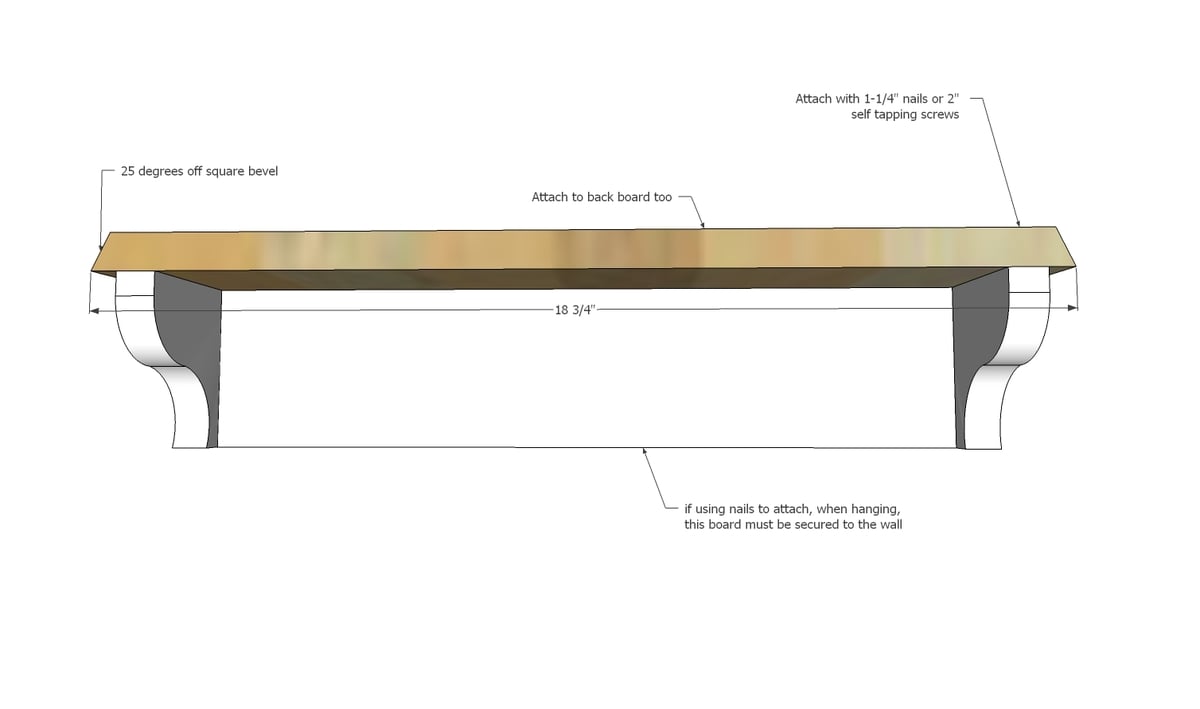

- 1 - 1x4 @ 18-3/4" longest point to longest point both ends cut at 25 degrees bevel

- 6 - 1x4 @ 7-1/2" long point to short point, both ends cut at 25 degrees bevel

- 1 - 1x4 @ 15-1/8" longest point to longest point both ends cut at 25 degrees bevel

- 1 - 1x4 @ 11-3/8" longest point to longest point both ends cut at 25 degrees bevel

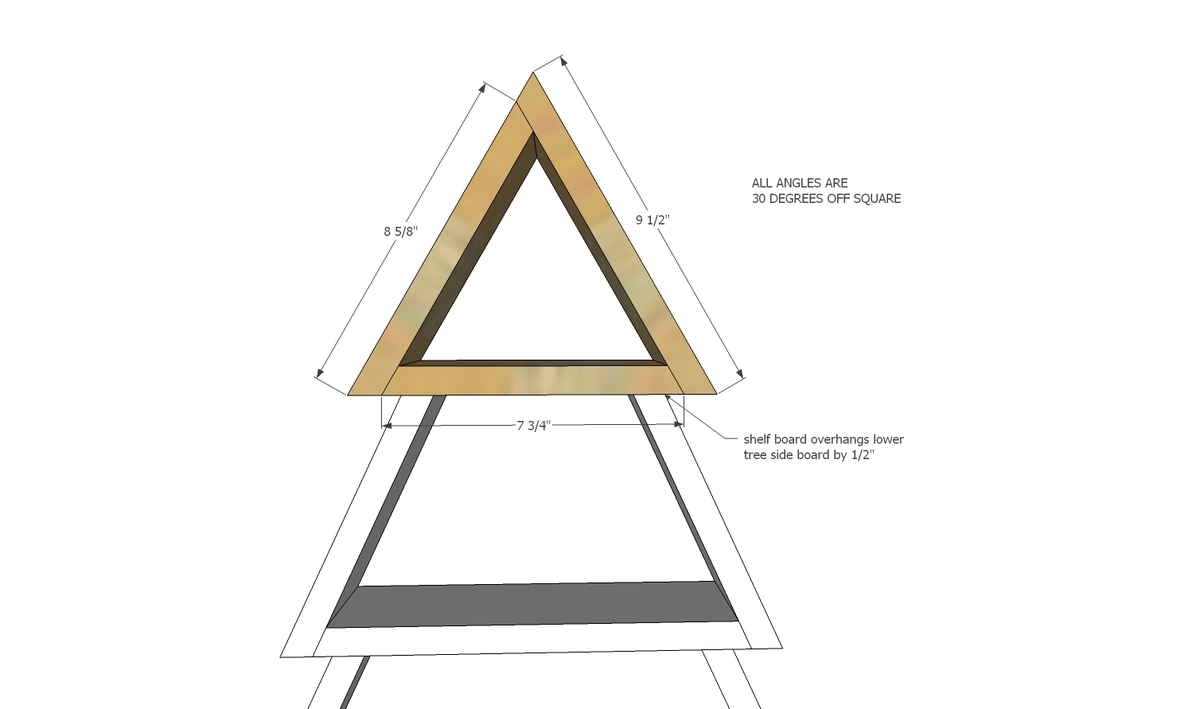

TREETOP - CHANGE SAW BEVEL TO 30 DEGREES

- 1 - 1x4 @ 7-3/4" long point to long point, both ends cut at 30 degrees bevel

- 1 - 1x4 @ 8-5/8" long point to long point, both ends cut at 30 degrees bevel

- 1 - 1x4 @ 9-1/2" long point to long point, both ends cut at 30 degrees bevel

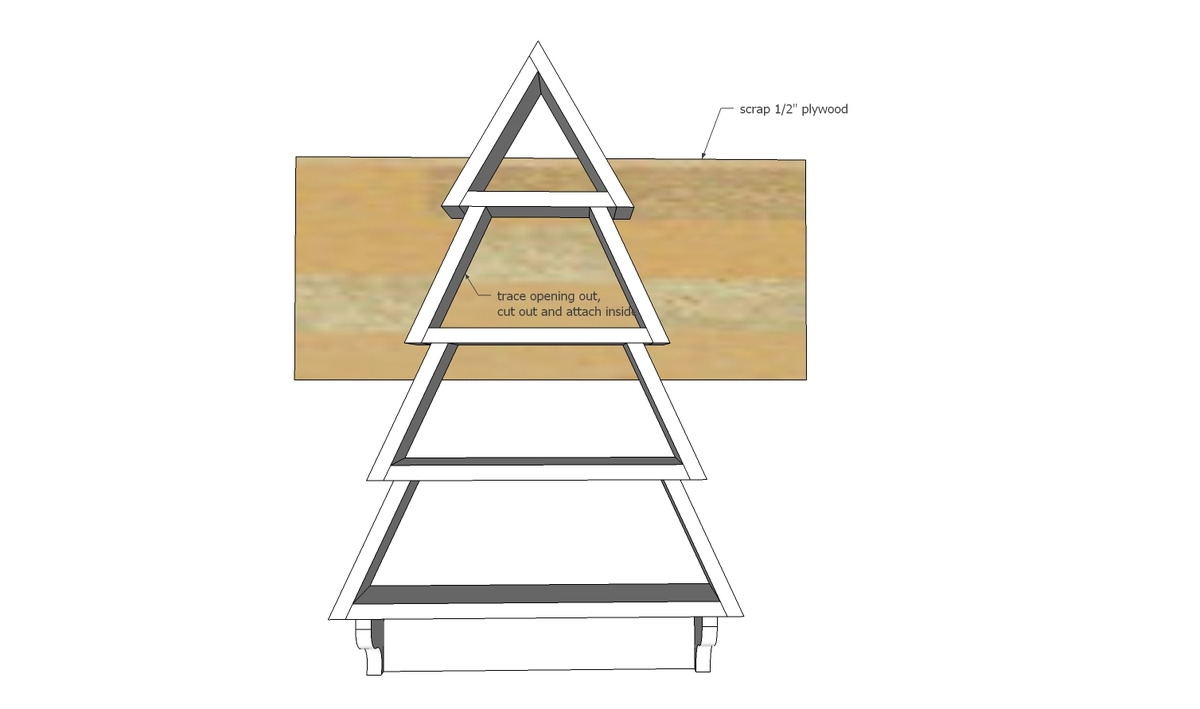

- Scrap 1/4" plywood for filling in second shelf approximately 6" x 15"

General Instructions

Use proper safety and read all power tool manuals and follow safety guidelines while using power tools.

Instructions

Step 1

Step 5

Step 6

Finishing Instructions

Preparation Instructions

Fill all holes with wood filler and let dry. Apply additional coats of wood filler as needed. When wood filler is completely dry, sand the project in the direction of the wood grain with 120 grit sandpaper. Vacuum sanded project to remove sanding residue. Remove all sanding residue on work surfaces as well. Wipe project clean with damp cloth.

It is always recommended to apply a test coat on a hidden area or scrap piece to ensure color evenness and adhesion. Use primer or wood conditioner as needed.

It is always recommended to apply a test coat on a hidden area or scrap piece to ensure color evenness and adhesion. Use primer or wood conditioner as needed.

Project Type

Seasonal And Holiday

Comments

buckey91

Wed, 11/25/2015 - 11:02

This is so beautiful, and

This is so beautiful, and great for someone without a mantel! I'm terrible with angles, would anyone know if I would have to change the angles if I made it larger?

Franco61

Fri, 10/23/2020 - 09:39

I don't believe you have to,…

I don't believe you have to, as long a you keep the tree top at 30 degrees and the rest at 25 degrees.

Lucy2222

Thu, 09/20/2018 - 10:19

Why is such a big piece of

Why is such a big piece of plywood needed when only a very small piece is used

Tsu Dho Nimh

Thu, 09/27/2018 - 16:47

It doesn't have to be that big

She's just showing you that you lay the tree on top of the scrap of plywood to do the marking.

As long as you have a bit showing around the edges you will be fine.

tizlad

Tue, 09/29/2020 - 05:20

How would you work out the…

How would you work out the measurements if your mitre saw only tilts left, so hence the short point is on top not right as in the video with the long point on top

Backwoods Builds

Wed, 10/07/2020 - 17:16

Put your material on the…

Put your material on the right> Side of the mitre, then after you have made your first cut you can spin your board and still achieve the same results. This will give you the ability to make your long to long measurements with out having to flip your mitre.

In reply to How would you work out the… by tizlad

Cheryl and Rich

Thu, 10/22/2020 - 09:10

Angle cuts from long point to long point.

You need to turn the wood over. I draw a pencil line on the sides to make sure I get the angles the way I want them before cutting.

In reply to How would you work out the… by tizlad

Cheryl and Rich

Thu, 10/22/2020 - 09:10

Angle cuts from long point to long point.

You need to turn the wood over. I draw a pencil line on the sides to make sure I get the angles the way I want them before cutting.

JillyMel

Sun, 11/15/2020 - 16:07

How do you hang this up??

How do you hang this up??

jabweese

Sun, 12/06/2020 - 22:59

How to hang this tree??

What’s the best way to hang this? My husband built me this for my birthday and surprised me today but I’m trying to figure out the best way to hang. What type of hanger?? Love this project!

RecoveringEngineer

Sun, 11/14/2021 - 17:32

Not stable enough

May be a dumb question but do you have to use a brad nailer and not just a hammer? I have no problems through Step 3 and I've got wood glue plus 2 brad nails holding the angled pieces on. But when I go to step 4 it isn't stable enough. When I try to hammer in the nails to secure the horizontal piece the force and angle starts to pull the bottom of the vertical boards out that I attached in the previous step.

[email protected]

Sat, 12/18/2021 - 13:28

You'll definitely need a…

You'll definitely need a brad nailer for this project because of what you describe. One of my brads didn't go on all the way and I attempted to use a hammer to drive it the rest of the way in, but felt like it was too much for the project to handle. Instead I used a Dremel to grind the part of the nail sticking out