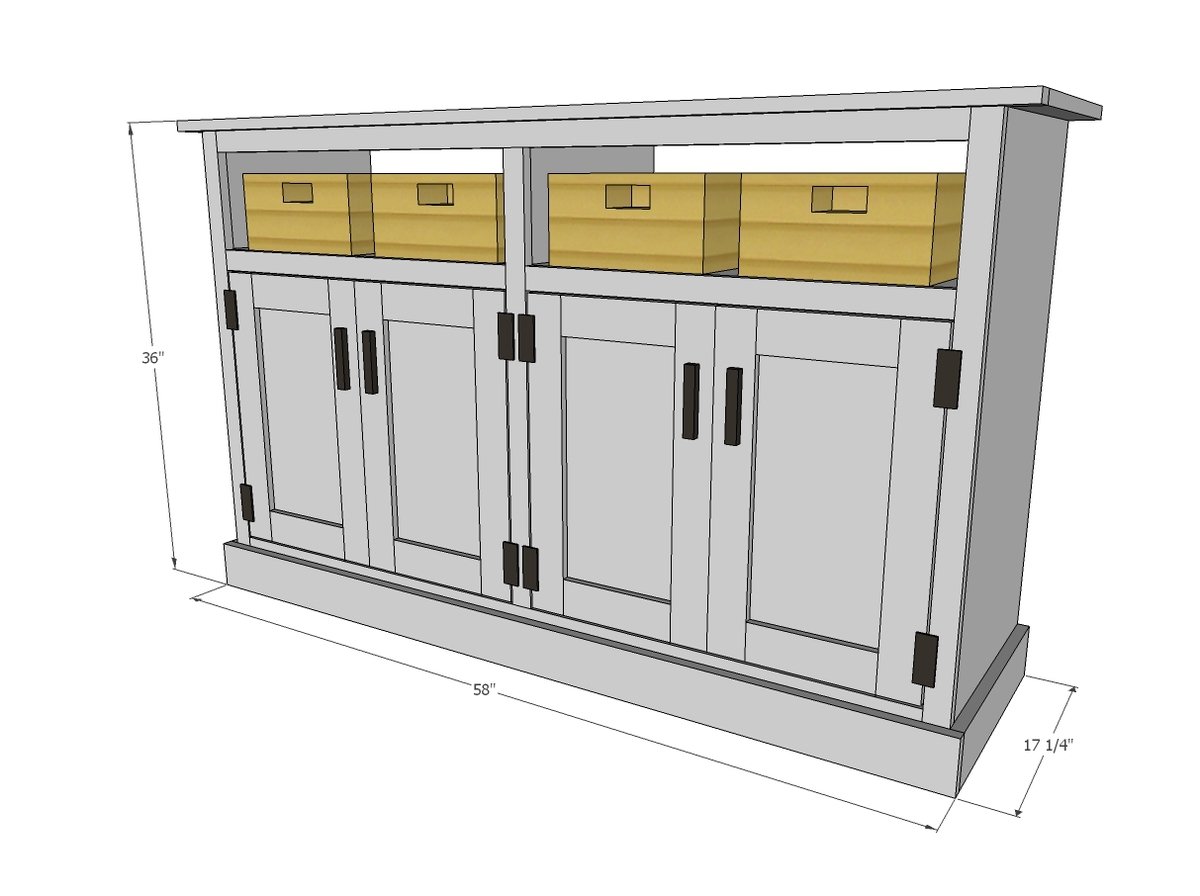

White console table with open shelves. Build your own large entryway console or media center - free plans by ANA-WHITE.com

Pin For Later!

Preparation

- 1 – 4’ x 8’ x 3/4”thick cabinet grade plywood sheet ripped into 15-3/4” wide strips (you can also use 4-1x12x8' boards instead for a narrower depth console table)

- 4 – 1x2 @ 8 feet long

- 1 – 1x4 @ 8 feet long

- 3 – 1x3 @ 8 feet long

- 1- 4’x 8’ x 1/4” thick plywood (for the back)

- 4 sets of hinges

- 4 knobs/pulls

- 4 magnetic clasps

- 1-1/4” and 3/4” brad nails

- 1-1/4” pocket hole screws

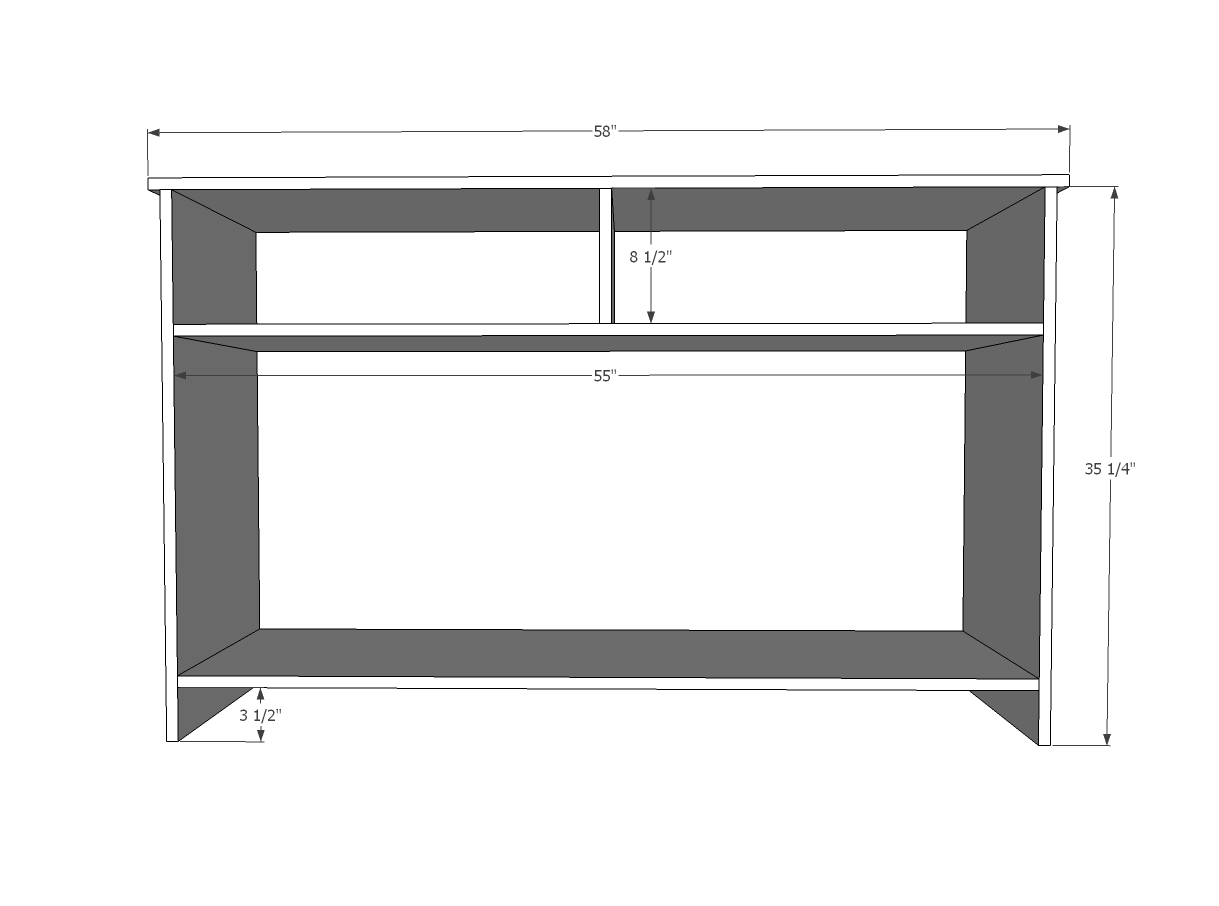

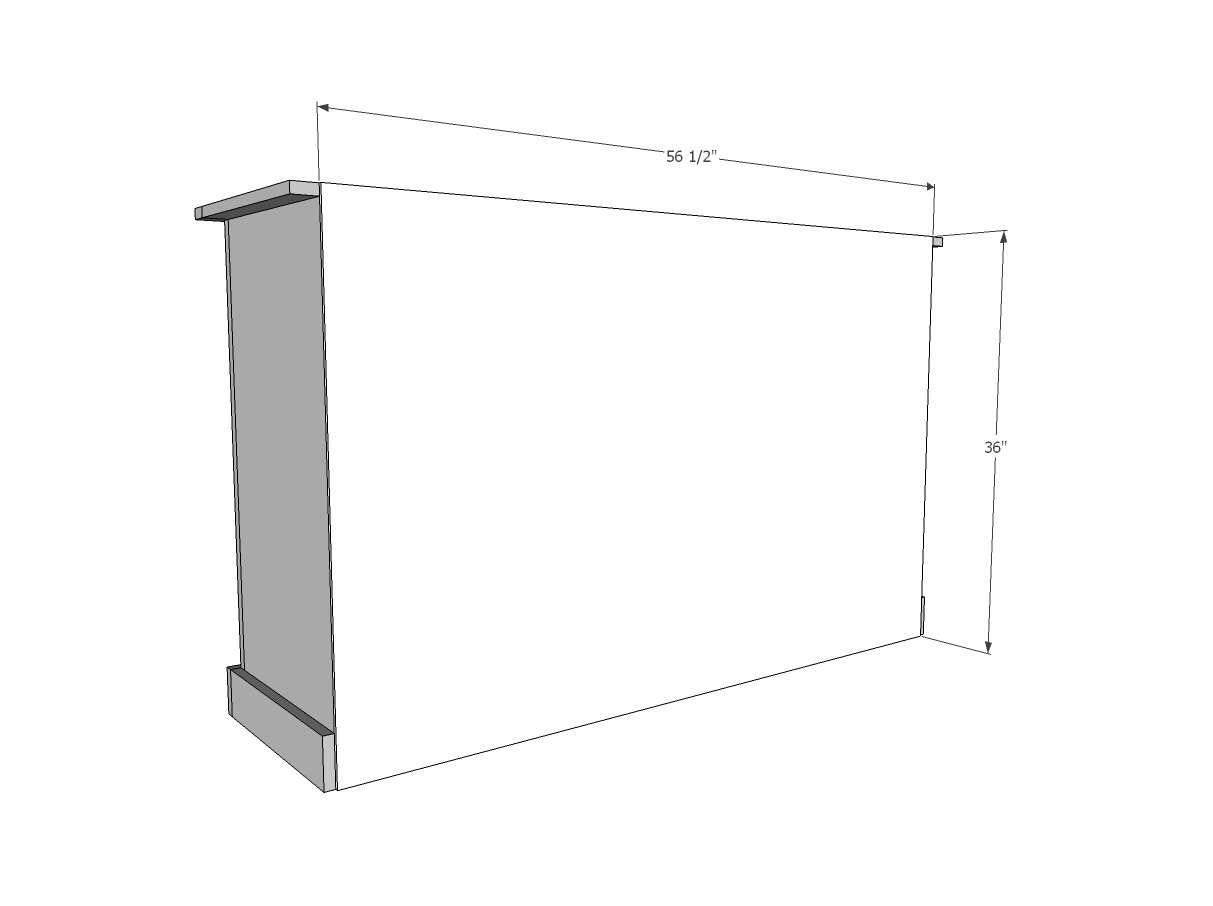

- 1 – ¾” plywood @ 15-3/4” x 58” – top

- 2 – ¾” plywood @ 15-3/4” x 55” – shelves

- 2 – ¾” plywood @ 15-3/4” x 35-1/4” – sides

- 1 – ¾” plywood @ 15-3/4” x 8-1/2” – divider

- 1 – 1x2 @ 58” – face frame top

- 2 – 1x2 @ 35-1/4” – face frame sides

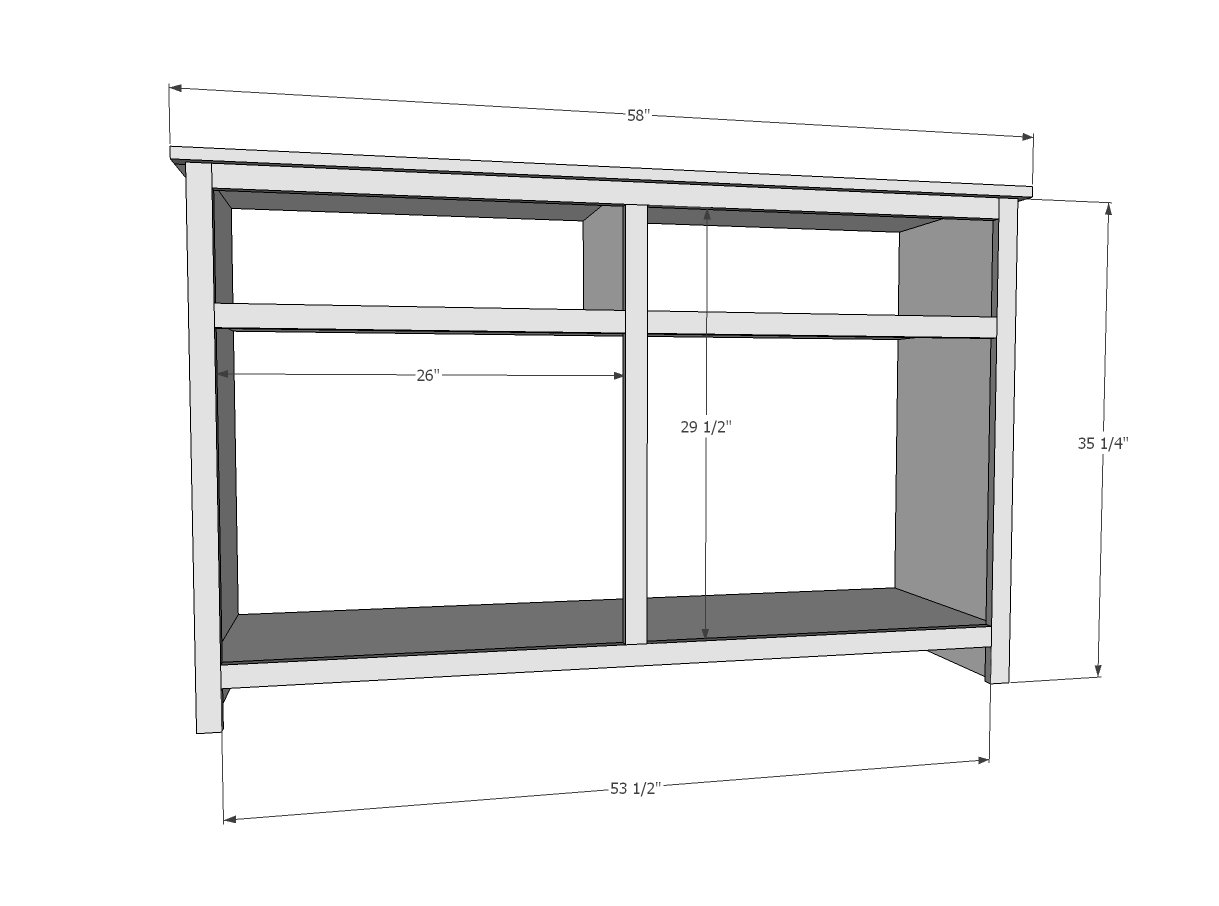

- 2 – 1x2 @ 53-1/2” – face frame stiles

- 1 – 1x2 @ 29-1/2”- face frame center

- 2 – 1x2 @ 26” – face frame shelves

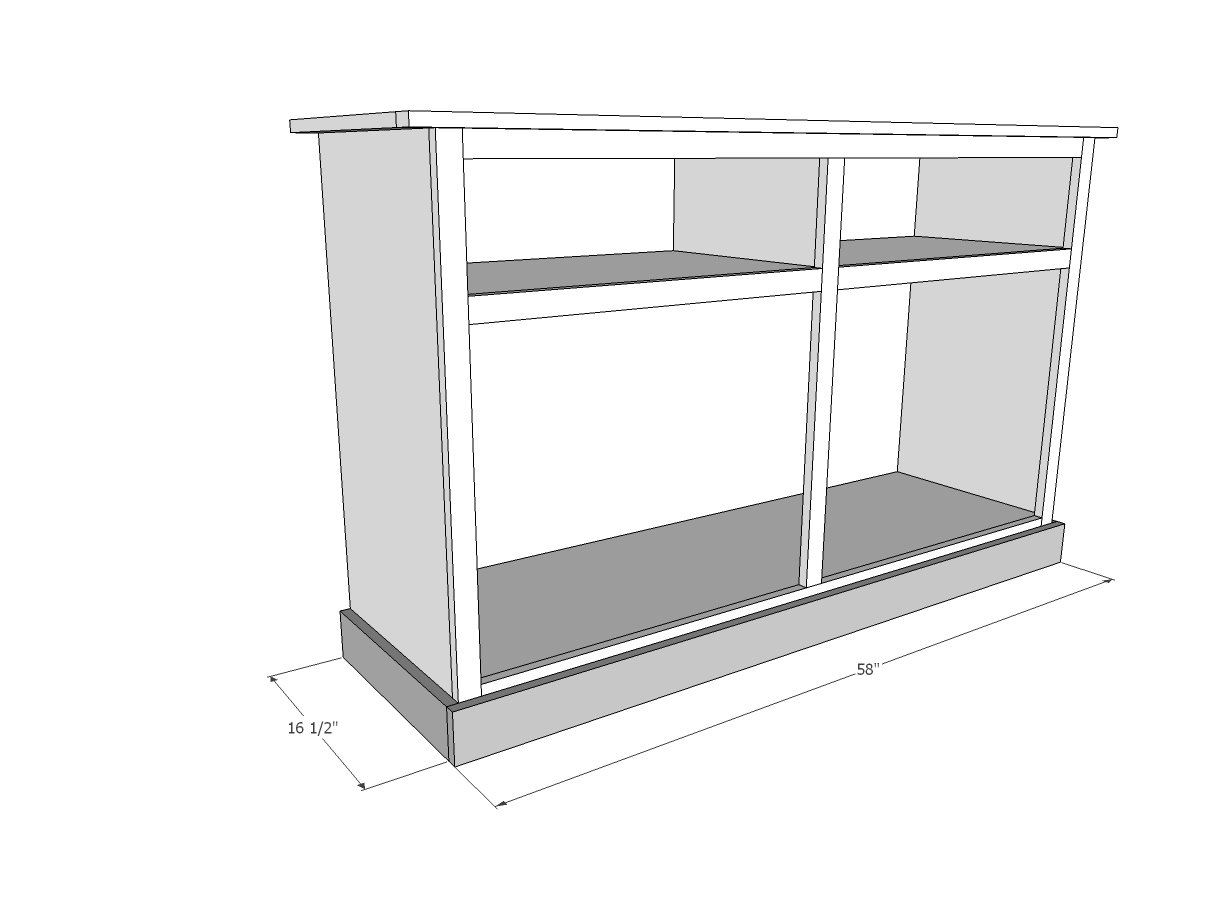

- 1 – 1x4 @ 16-1/2” – base sides

- 1 – 1x4 @ 58” – base front cut to fit

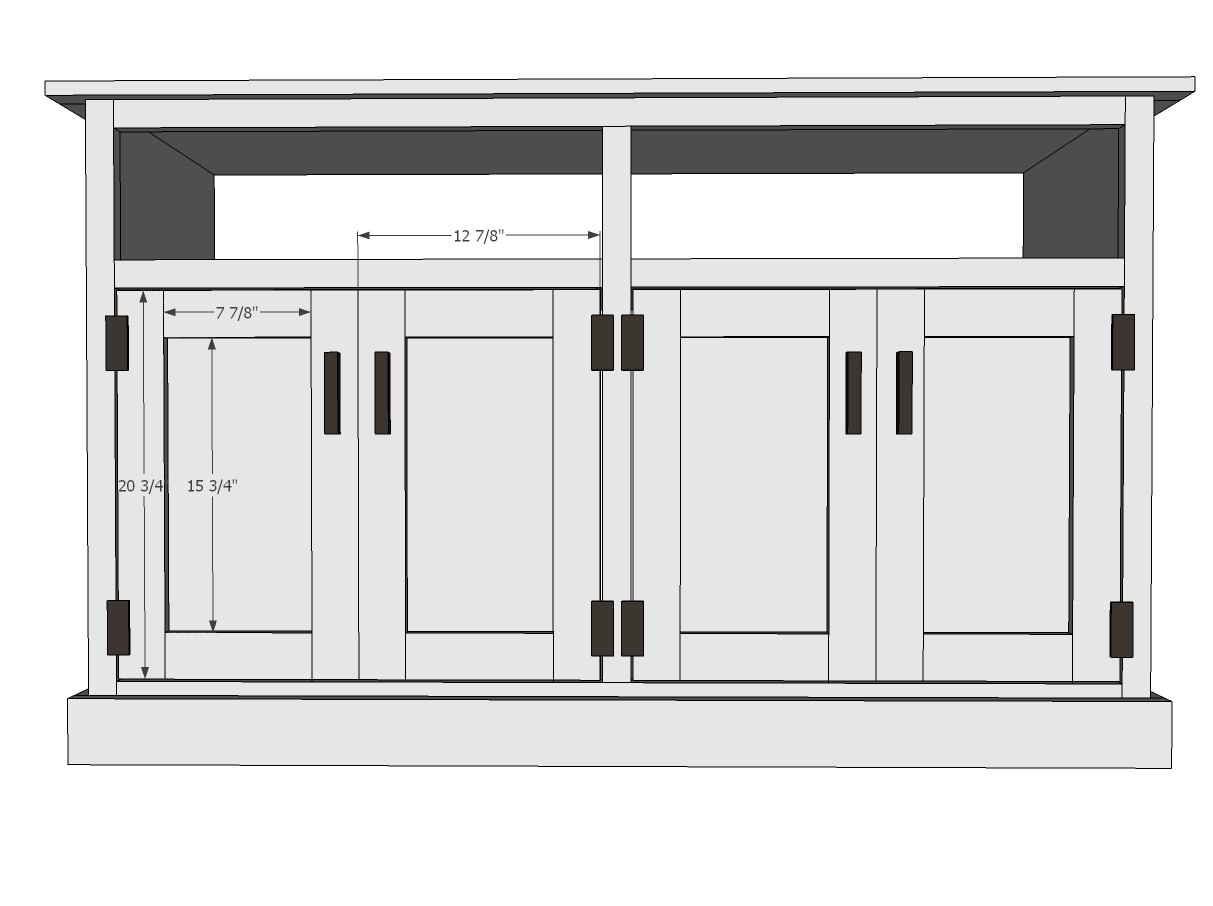

- 8 – 1x3 @ 20-3/4” – door stiles

- 8 – 1x3 @ 7-7/8 – door rails

- 4 - ¼” plywood cut to fit approx. 8” x 15-3/4”

Instructions

Step 1

Rip plywood on tablesaw or with circular saw into strips 15-3/4” wide by 8 feet long. From these strips, cut out pieces for carcass. Assemble the carcass using three ¾” pocket holes and 1-1/4” pocket hole screws per joint, for all joints except center divider.

For center divider, apply glue to both ends and position in center of upper shelf opening. Use 1-1/4” brad nails to secure in place.

Step 2

Using ¾” pocket holes and 1-1/4” pocket hole screws, build face frame on flat level surface. Top face frame piece overhangs front and sides by ¾”.

Nail completed face frame to front of carcass with 1-1/4” brad nails and wood glue.

Additional shelves can be added, but need to be at least 1/2" less in width than the carcass to allow for the door backs to be added in last step.

Step 3

Step 4

Step 5

Assemble door frame pieces using ¾” pocket holes and 1-1/4” pocket hole screws. Cut plywood slightly larger than opening and nail to back with ¾” brad nails and wood glue.

Install doors with hinges. Add knobs or pulls and magnetic clasps.

NOTE: Please watch the video as there is more details on steps for the doors in the video

Comments

Mazur

Thu, 02/06/2020 - 01:39

Nice furniture.

Nice furniture.

emilygoutagny

Mon, 05/04/2020 - 09:01

NICE!

Charm guests right from the door with an entryway table. A console table offers both and style in any room of the house. Check us here

LittlekelPA

Wed, 09/02/2020 - 06:28

First DIY cabinet for me!!

Loved this cabinet; however, I needed something a little bit smaller for my space. Thanks so much for sharing the plans! I made mine half the size and only one door that was on the outside of the face frame not inset like yours. I think it looks pretty cute for my first cabinet. I even used the router table for the first time. :D

kyermalovich

Tue, 02/09/2021 - 07:20

Wood used

Hi what type of wood did you use for 1x2,3,4? Thank you

Alienz17

Mon, 05/24/2021 - 00:49

Love it!!

Just finished making this and absolutely love it!! Thank you so much for these plans.

cayenne

Sat, 01/14/2023 - 14:54

Entryway Console

Hi Ana,

Can you tell me what size bit for my router do I need for the Entryway Console ? I'm just at the point of building the doors and you don't say in your video, what size bit for door's rails and stiles ?