Free plans to make a farmhouse table with just a drill, saw and countersink bit! No pocket holes required! Step by step plans from ana-white.com

Preparation

- 6 - 2x4 @ 8 feet long (cut longest boards first to conserve lumber)

- 3 - 2x2 @ 8 feet long

- 5 - 2x8 @ 6 feet long

- 2 1/2" exterior star bit screws (Can use interior screws for interior projects)

- Exterior Wood Glue (again, can use interior wood glue for interior use)

- 2 1/2" pocket hole screws are optional if you have a pocket hole jig

- 2" brad nails (galvanized for exterior)

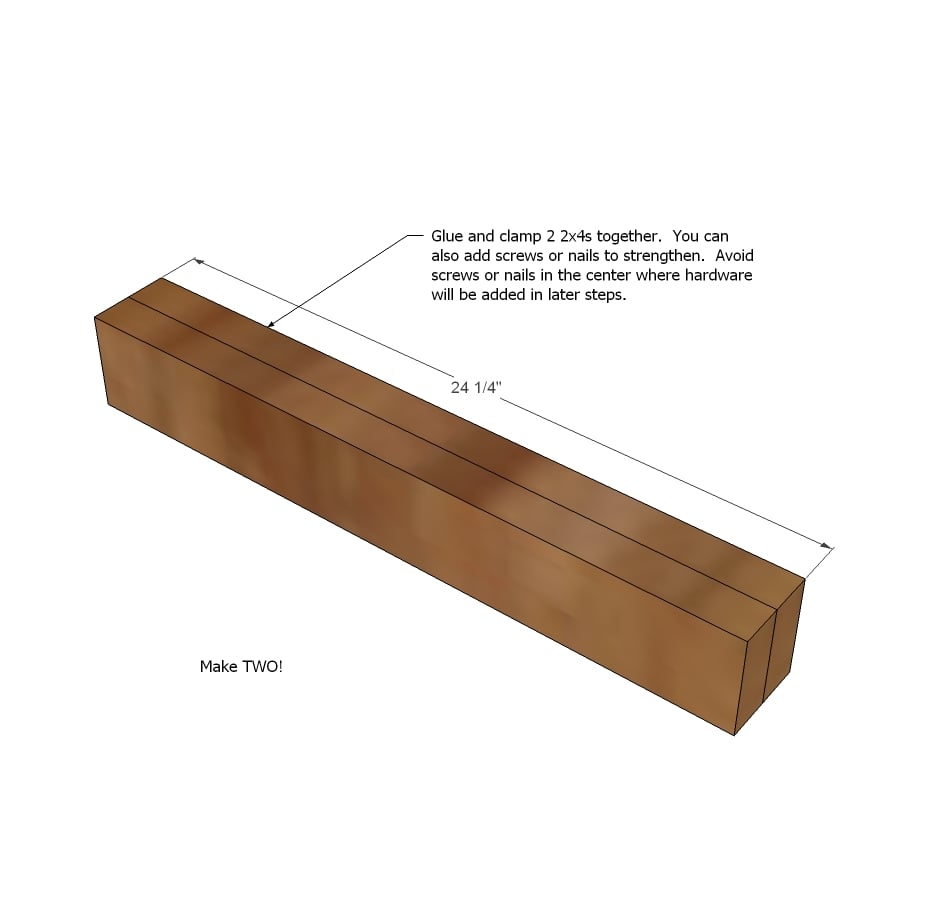

- 4 - 2x4 @ 24 1/4" (End Stretchers)

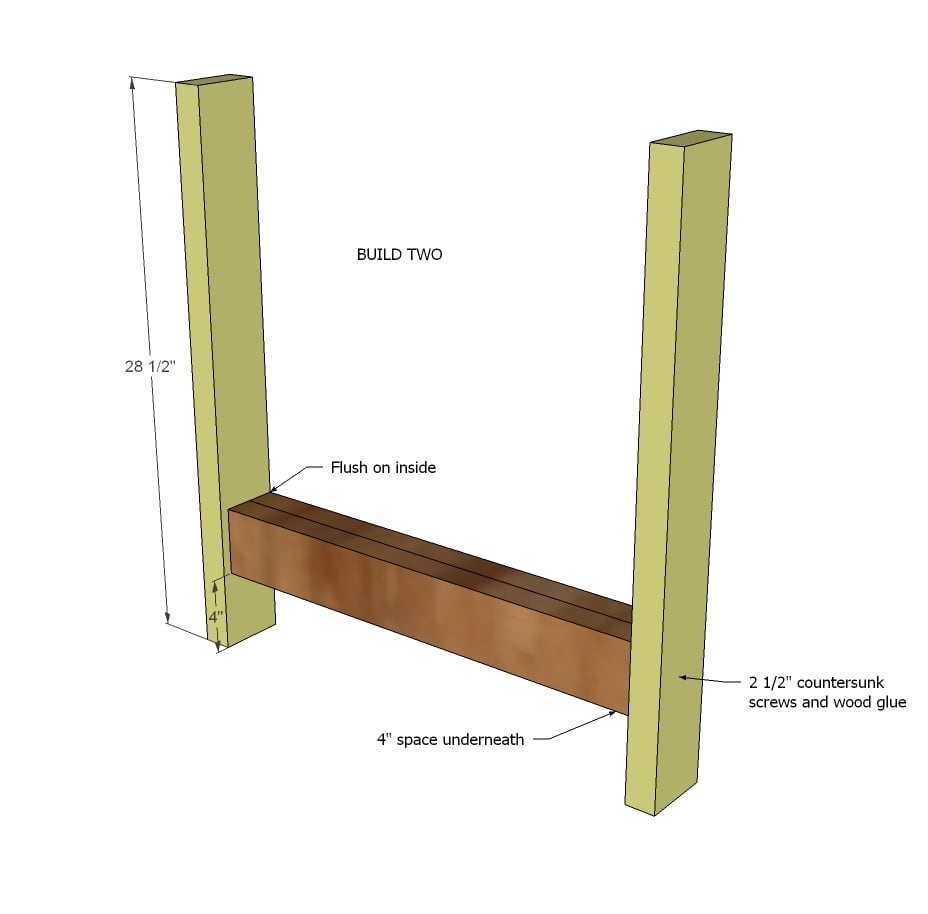

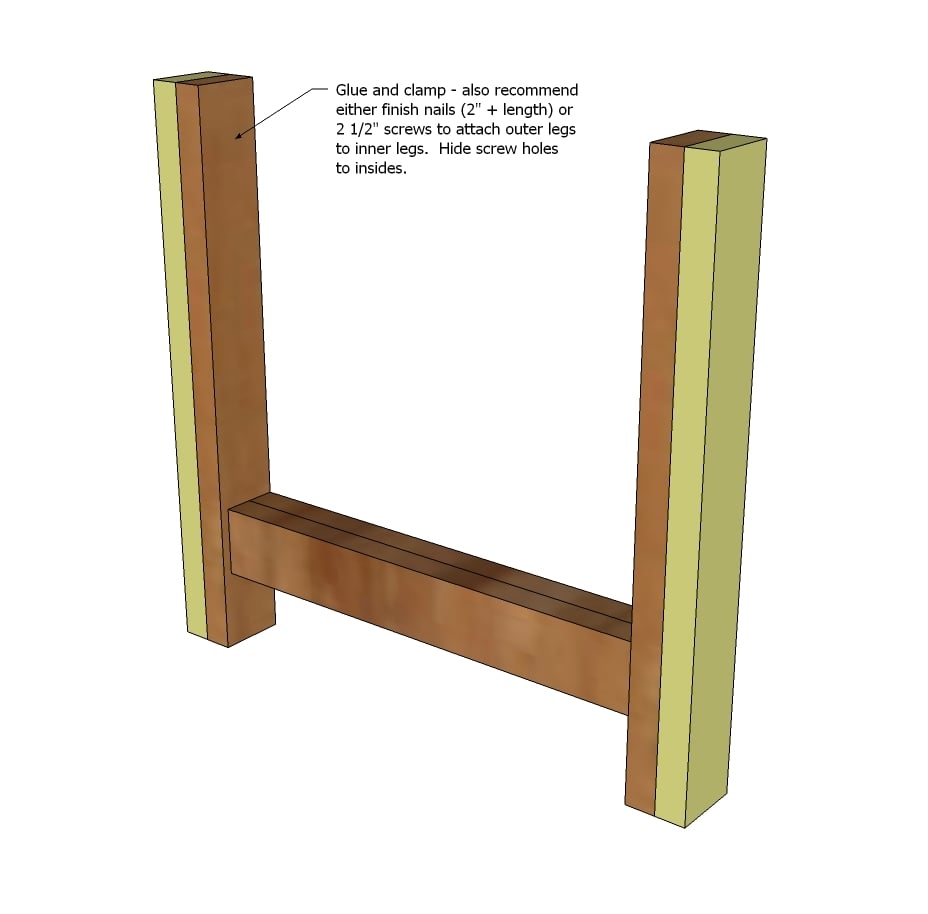

- 8 - 2x4 @ 28 1/2" (Legs)

- 2 - 2x4 @ 30 1/4" (End Aprons)

- 2 - 2x4 @ 69" (Side Aprons)

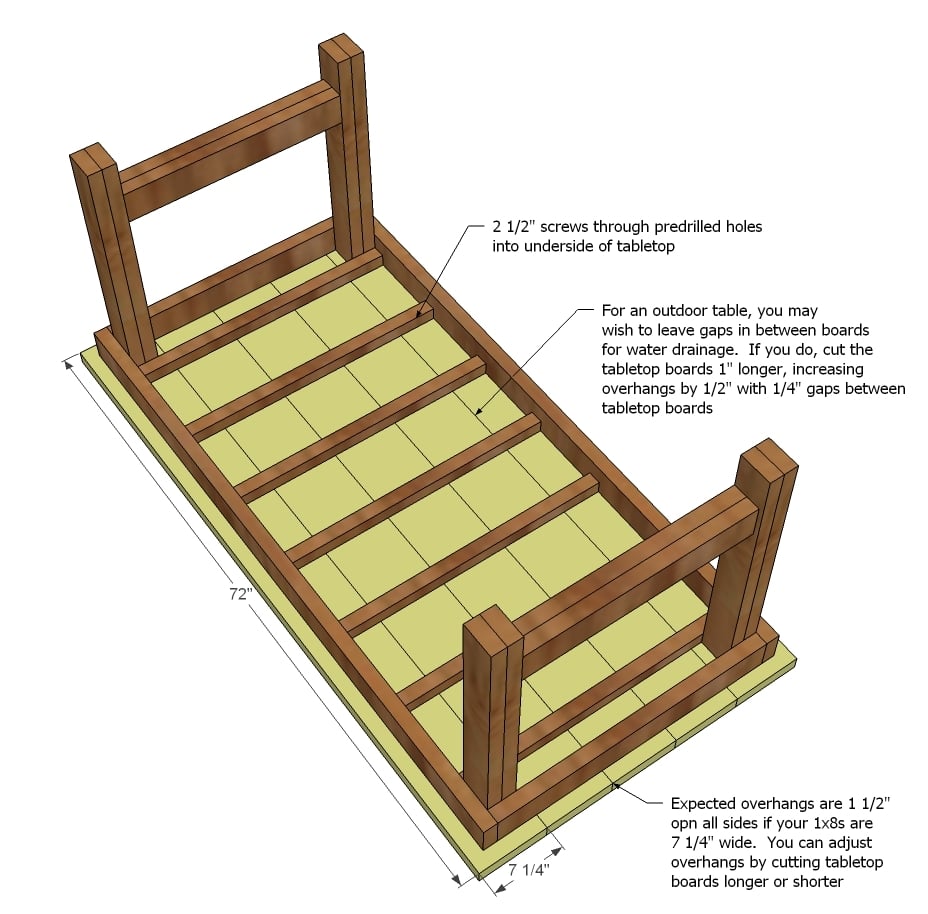

- 7 - 2x2 @ 30 1/4" (Tabletop Supports)

- 5 - 2x8 @ 72" (Tabletop Boards)

Please read through the entire plan and all comments before beginning this project. It is also advisable to review the Getting Started Section. Take all necessary precautions to build safely and smartly. Work on a clean level surface, free of imperfections or debris. Always use straight boards. Check for square after each step. Always predrill holes before attaching with screws. Use glue with finish nails for a stronger hold. Wipe excess glue off bare wood for stained projects, as dried glue will not take stain. Be safe, have fun, and ask for help if you need it. Good luck!

Instructions

Step 1

Step 4

Step 6

Step 7

Step 8

Add hardware to base - check out the Happier Homemaker for more details on how they did that.

It is always recommended to apply a test coat on a hidden area or scrap piece to ensure color evenness and adhesion. Use primer or wood conditioner as needed.

Comments

dmcarwin

Tue, 04/23/2013 - 13:08

Beautifully Done!

Great Plans! I love this table!

babysteps

Tue, 04/23/2013 - 17:02

Better than the inspiration piece!

Beautiful table, much better than the Pottery Barn version.

Chellebebuilding

Tue, 04/23/2013 - 17:36

Gorgeous

Simply gorgeous. The robust look is great for the outdoors. I may have to make one for the summer. Congrats Melissa & Hubby.

jojabis

Thu, 04/25/2013 - 17:53

the hardware

would you have to use a stretcher?? I'm just wondering since the legs seem so beefy.

Crimson0087

Fri, 06/14/2019 - 19:01

How many of your tables have…

How many of your tables have warped or cracked?

email4tina

Sun, 06/14/2020 - 17:21

Ok to make 8 feet long?

Can this table be made 8 feet long? Or would it be too heavy?

RobH2020

Fri, 08/21/2020 - 03:11

Depends what you mean by too…

Depends what you mean by too heavy. It would be pretty heavy, but two average men should be able to move it short distances.

Also depends on the wood you use. If you get mahogany it's going to be different to pine.

RobH2020

Fri, 08/21/2020 - 03:10

Thanks for these plans!!…

Thanks for these plans!! They were so incredibly helpful.

I've just finished making my own version, changing the dimensions slightly. Was 1200mm long in the end (too short in the end, should've been 1.5m but I messed up with the lumber delivery and didn't want to change it) and 820mm wide (4 x 200m boards, with 5mm gap between).

Would post a photo but not sure how!