This beautiful closet tower is like a piece of furniture in the closet. Simply add closet rods to complete the closet. We love that this tower sits on the floor for easy installation. Free step by step plans from Ana-White.com

Preparation

- 1 - full sheet 3/4" plywood cut into three strips 15-3/4" wide and 8 feet long (you'll need more for additional shelving - this will only cover the tower)

- 1 - full sheet of 1/4" plywood (you won't need this if you do fixed shelves, but if all of your shelves are adjustable like mine, you will need the back for support)

- 2 - 1x2 @ 8 feet long (I used poplar)

- 1 - 1x4 @ 2 feet long (I used pine for my header)

- 1 - 2x2 @ 8 feet long

- 1 - 3/4" x 3/4" inside corner moudling for trimming out header (optional)

- about 6 feet of base moulding

- 1-1/4" pocket hole screws (recommended) or 2" self tapping wood screws

- 1-1/4" brad nails for attaching face frame

- 3/4" nails for attaching back

- wood glue

- Shelf pins

- Plywood Edge banding and an iron

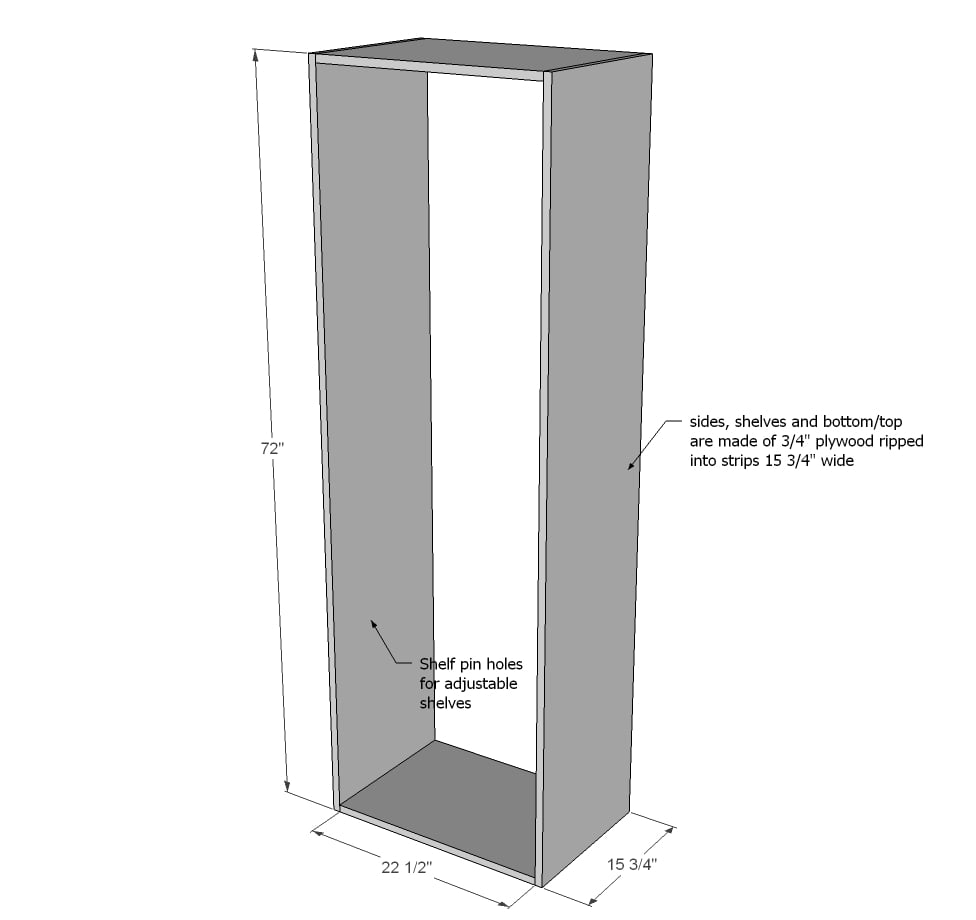

MAIN CARCASS

- 2 - 3/4" plywood @ 15 3/4" x 72" (sides)

- 6 - 3/4" plywood @ 15-3/4" x 22-1/2" (Shelves**, top and bottom)

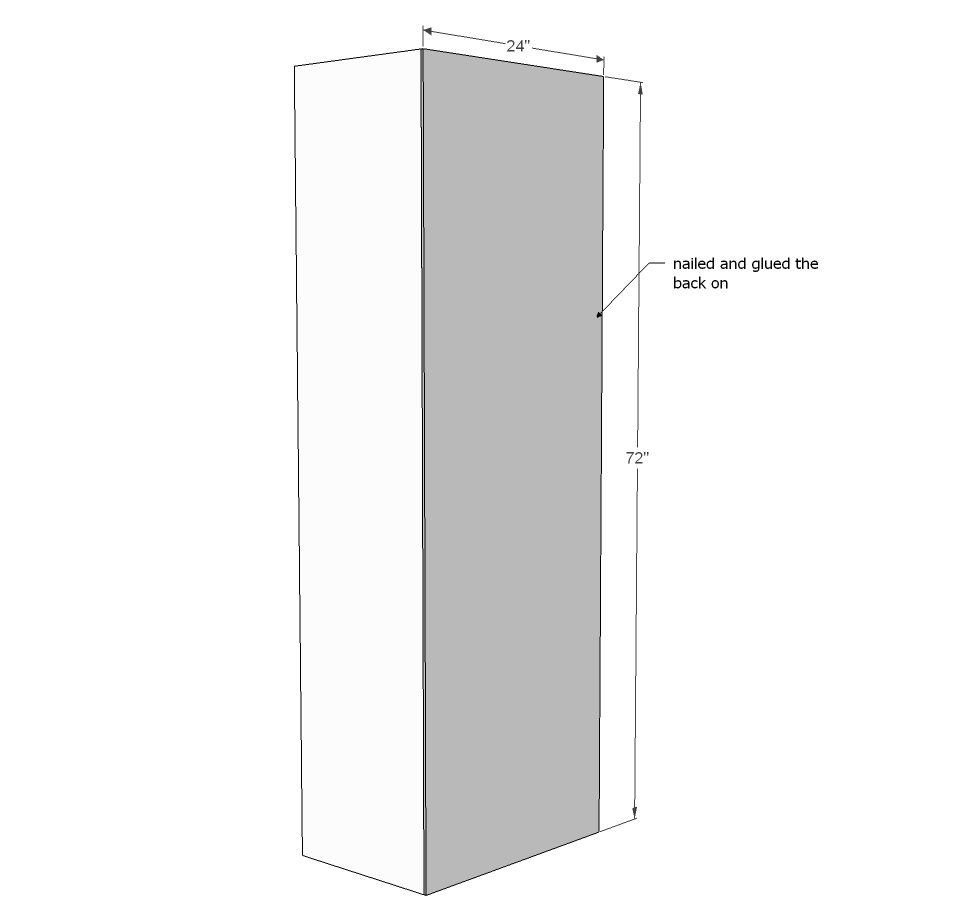

- 1 - 1/4" plywood @ 24" x 72" (back)

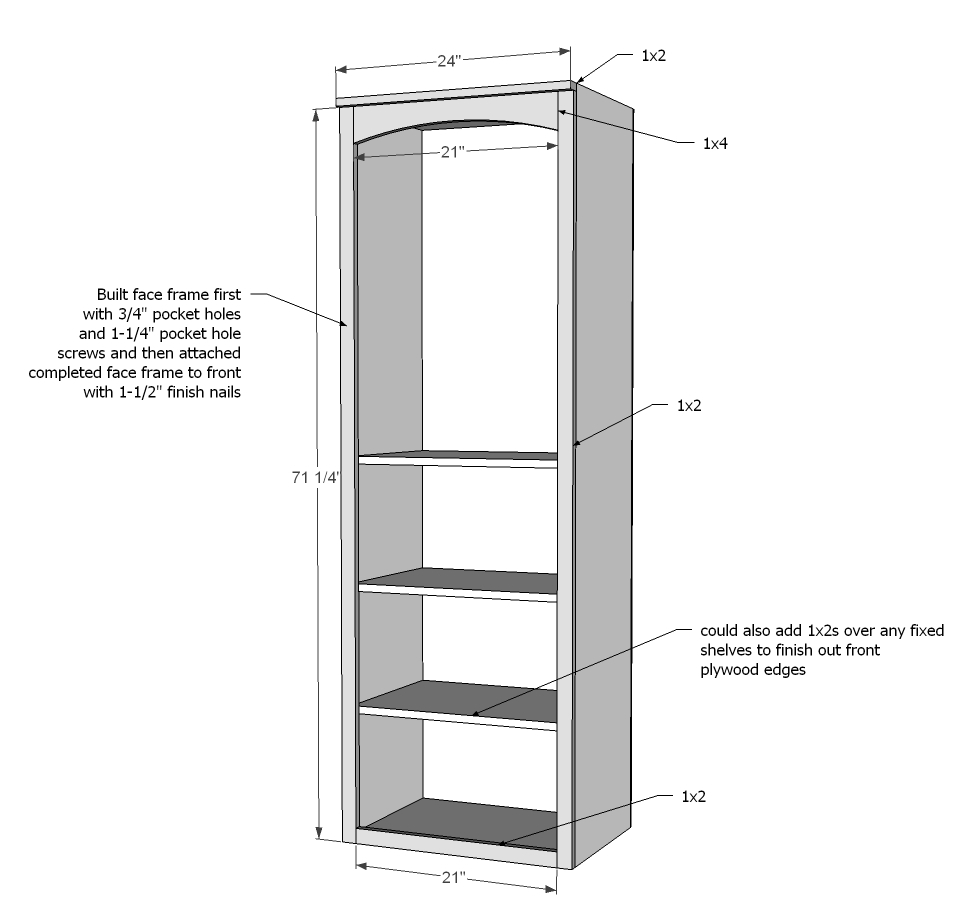

FACE FRAME

- 1 - 1x2 @ 24"

- 2 - 1x2 @ 71 1/4"

- 1 - 1x2 @ 21"

- 1 - 1x4 @ 21"

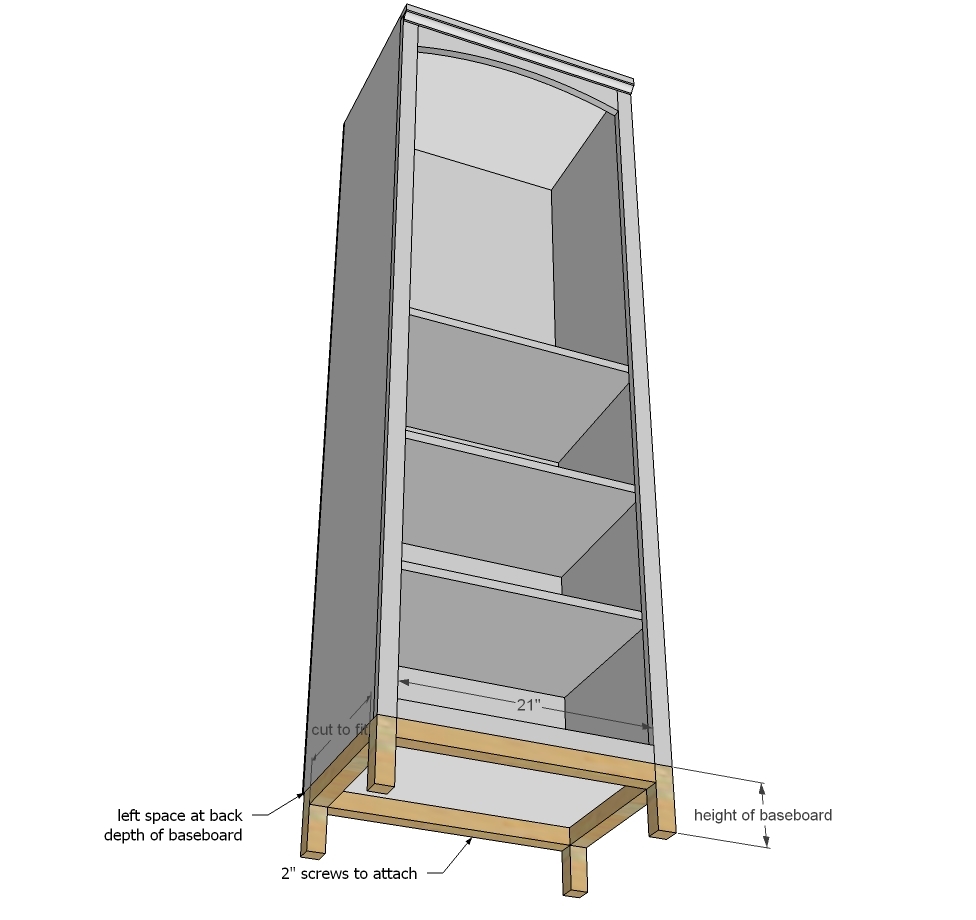

BASE - Optional

- 4 - 2x2 @ height of baseboard

- 2 - 2x2 @ 21"

- 2 - 2x2 @ outside depth of tower MINUS baseboard depth baseboard trim cut to fit

**For shelves that are adjustable with shelf pins (as mine are) you may need to trim the shelves down by 1/4" in width and depth to allow for edge banding and shelf pin spacing)

Please read through the entire plan and all comments before beginning this project. It is also advisable to review the Getting Started Section. Take all necessary precautions to build safely and smartly. Work on a clean level surface, free of imperfections or debris. Always use straight boards. Check for square after each step. Always predrill holes before attaching with screws. Use glue with finish nails for a stronger hold. Wipe excess glue off bare wood for stained projects, as dried glue will not take stain. Be safe, have fun, and ask for help if you need it. Good luck!

Instructions

Step 1

Step 2

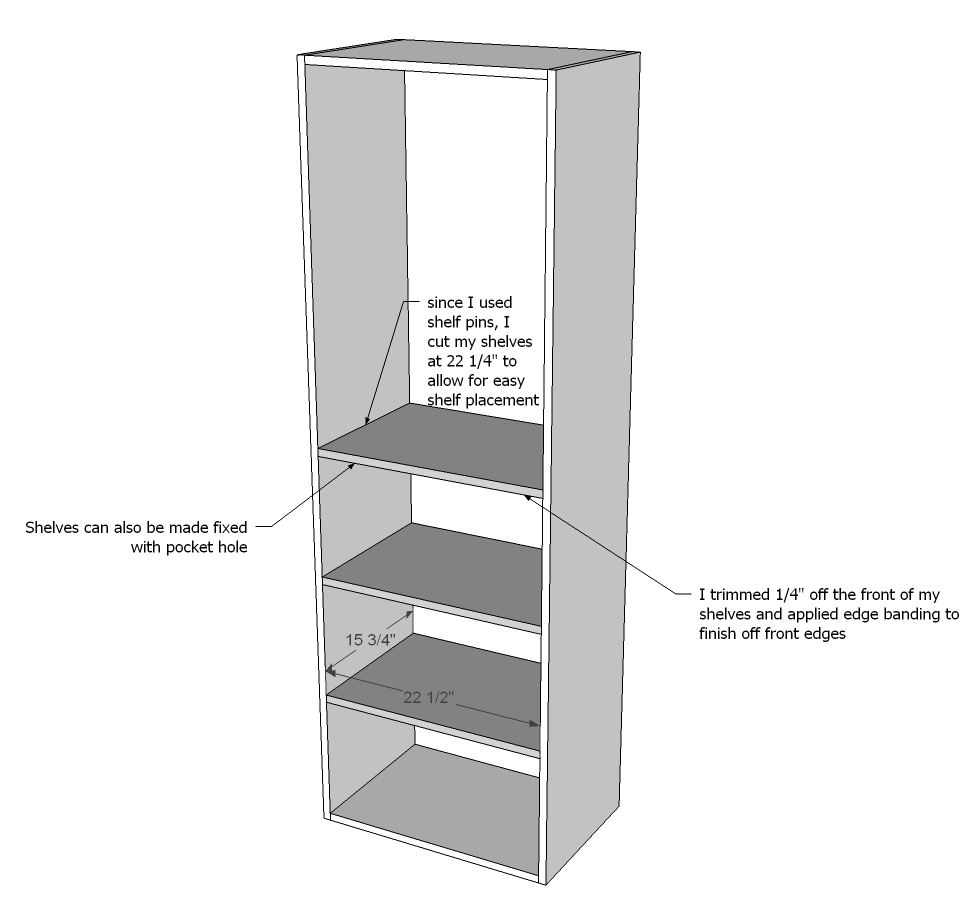

I used a shelf pin jig to drill shelf pin holes for adjustable shelves. If you do this, you will need to trim your shelves down so they fit the shelf pins (for my shelf pins this ended up being 1/4" in overall width) and also trimmed off 1/4" to allow for edge banding and easy shelf placement from the overall depth of the shelf.

For fixed shelves, the shelves can be placed at any height. You will still need to do something to finish off the front plywood edges. For a painted finish, you can apply wood filler to the front plywood edge, sand, and paint. For a stained finish, edge banding is recommended (although I've seen lots of stained plywood edges on modern furniture an it's really works too!). Another option is to integrate 1x2s into the face frame that will cover the front plywood edges.

Step 3

Step 4

Step 6

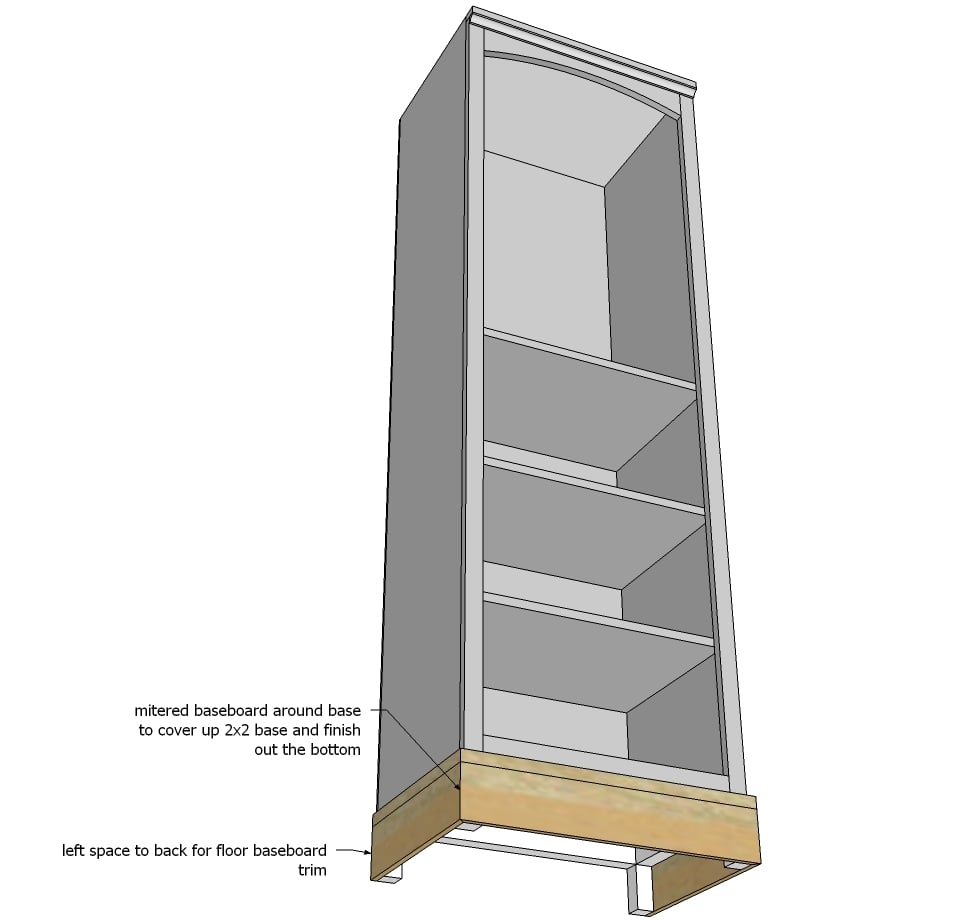

Then I trimmed out the base of the tower in matching baseboard to the closet baseboard, mitering corners and using a finish nailer and glue to attach to the 2x2 base.

I also added the 3/4" x 3/4" inside corner moudling to the top header and cut the top header out with a jigsaw to add detail - but this is all just for decoration - not sturctural.

It is always recommended to apply a test coat on a hidden area or scrap piece to ensure color evenness and adhesion. Use primer or wood conditioner as needed.

Comments

Lady Goats

Tue, 11/19/2013 - 12:55

It's beautiful!

I would totally understand you taking a break between houses (uh, I take a break between cuts), but I'm giddy that you didn't. I love this! Thanks for sharing!

ibjames

Tue, 02/04/2014 - 15:52

45degree cuts for trim

is there a good way to measure for this? I can never get my trim to line up nicely

ibjames

Tue, 02/04/2014 - 15:52

45degree cuts for trim

is there a good way to measure for this? I can never get my trim to line up nicely