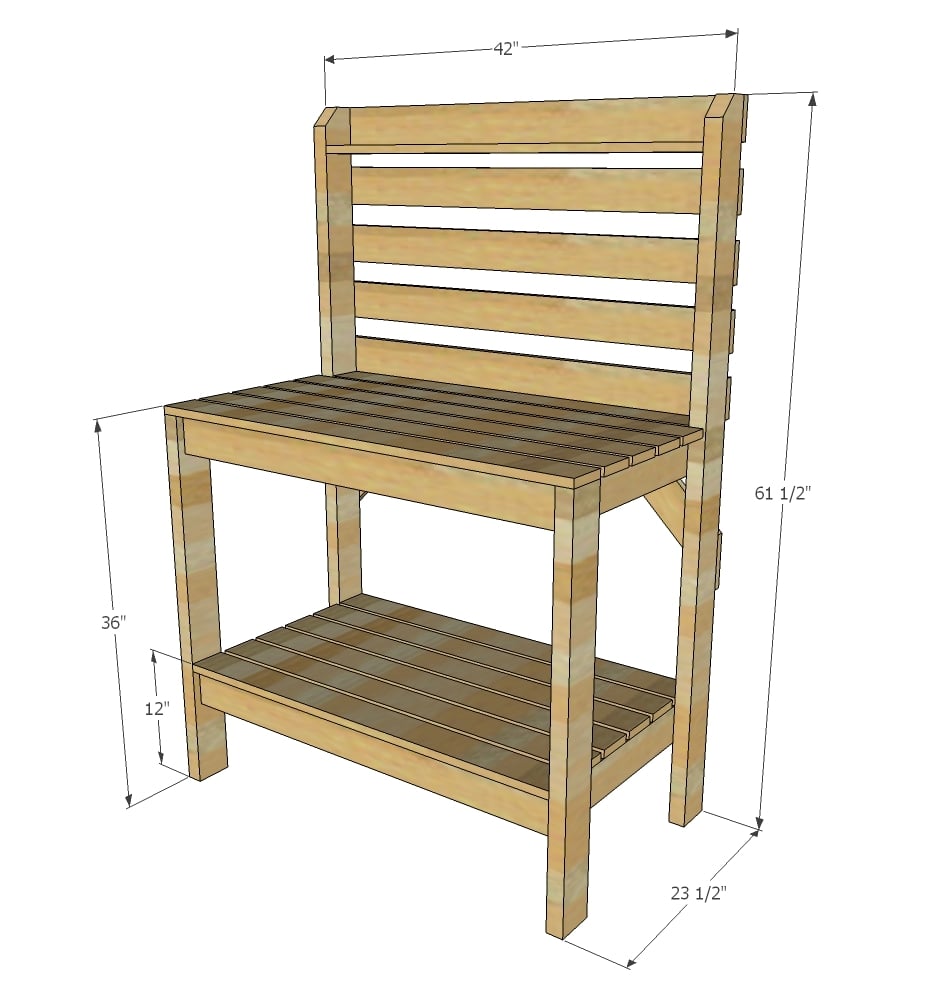

How to build a potting bench - super easy and looks great - this is a free woodworking plan featuring step by step diagrams, shopping and cut list, everything you need to build your own potting bench.

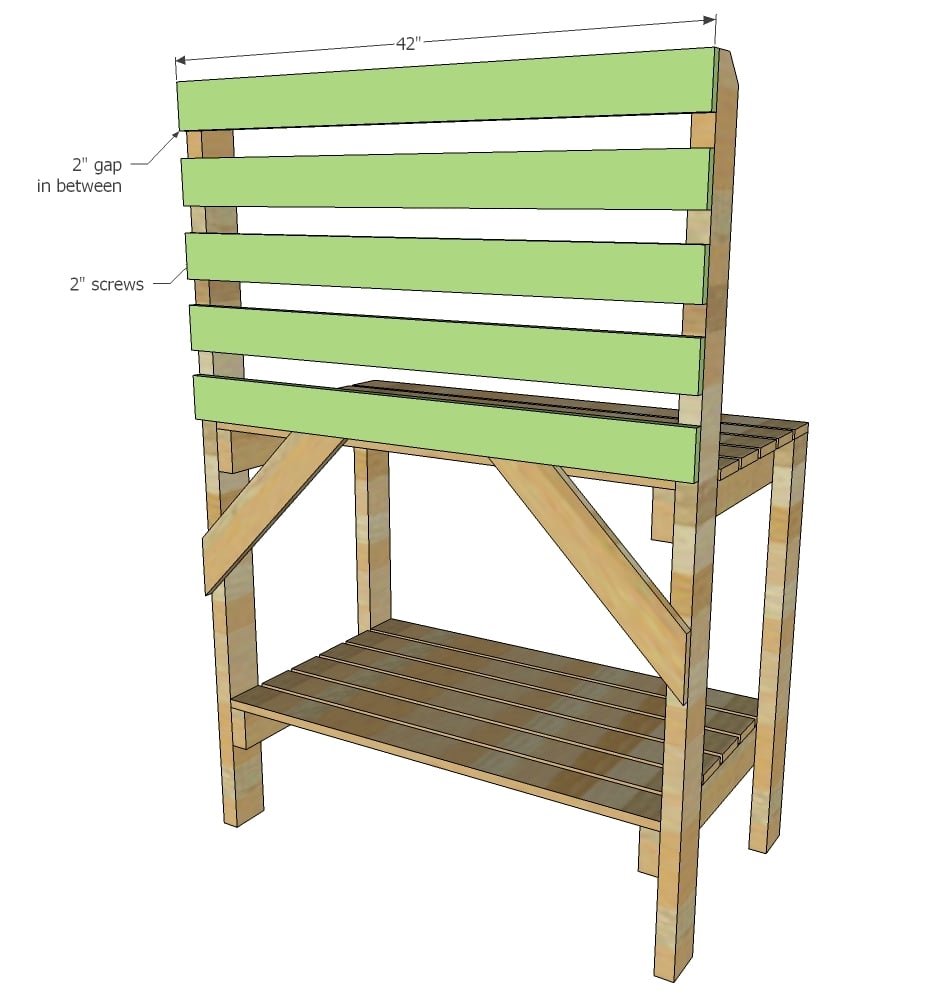

We love this simple design with a back hutch with shelf and rails for hanging tools. The bottom shelf is perfect for storing accessories and supplies for all your potting needs.

Preparation

- 8 – 1x4 @ 8 feet long

- 2 – 1x4 @ 10 feet long

- 4 – 2x4 @ 8 feet long

- 2-1/2” and 2” exterior self tapping screws

- Wood glue

- 2 – 2x4 @ 61-1/2” (back legs)

- 2 – 2x4 @ 35-1/4” (front legs)

- 4 – 2x4 @ 22” (side aprons)

- 10 – 1x4 @ 39” (front aprons, short shelf boards, back shelf)

- 10 – 1x4 @ 42” (long shelf boards, back boards)

- 2 – 1x4 @ 24” both ends cut at 45 degrees, long point to short point measurement (cross support)

Instructions

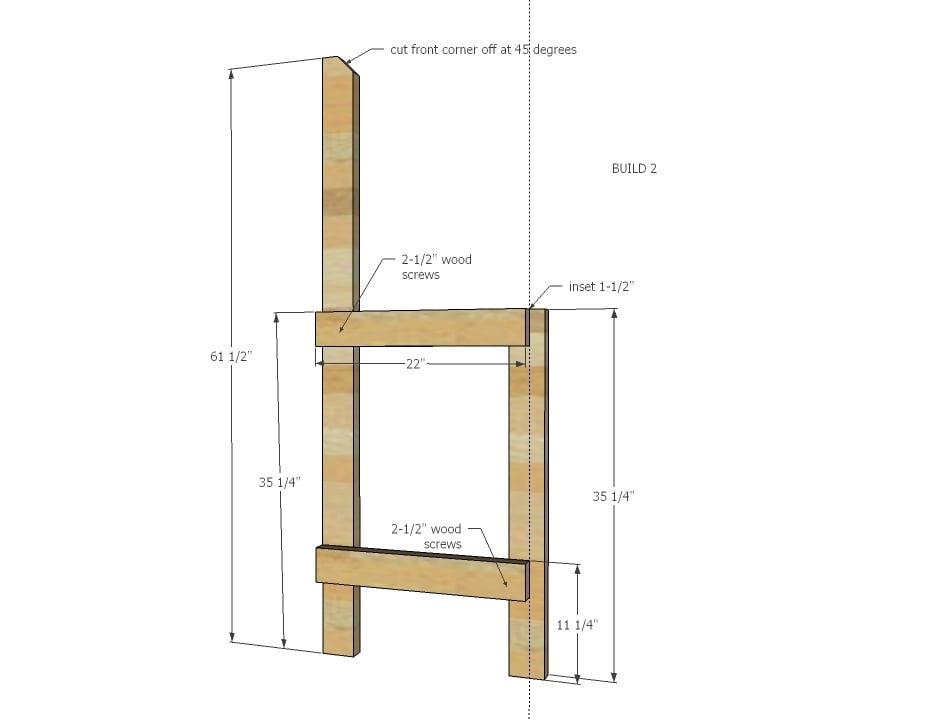

Step 1

Mark the back legs from the bottom at 11-1/4” and 35-1/4”. Attach with 2-1/2” self tapping exterior wood screws the 22” long side aprons to the back legs, matching marks with tops of aprons. Then mark the front legs 1-1/2” in from front edge and also 11-1/4” up from bottom of leg. Attach other side of 22” long side aprons to the front legs.

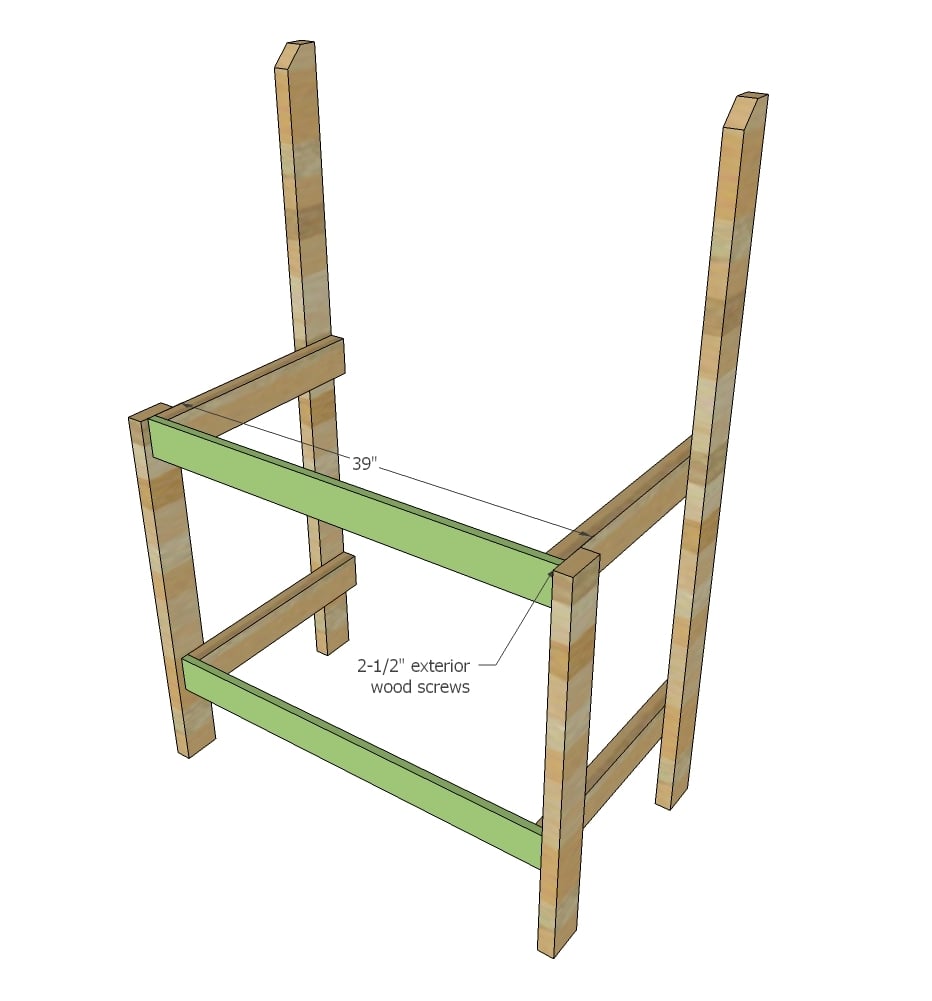

Step 3

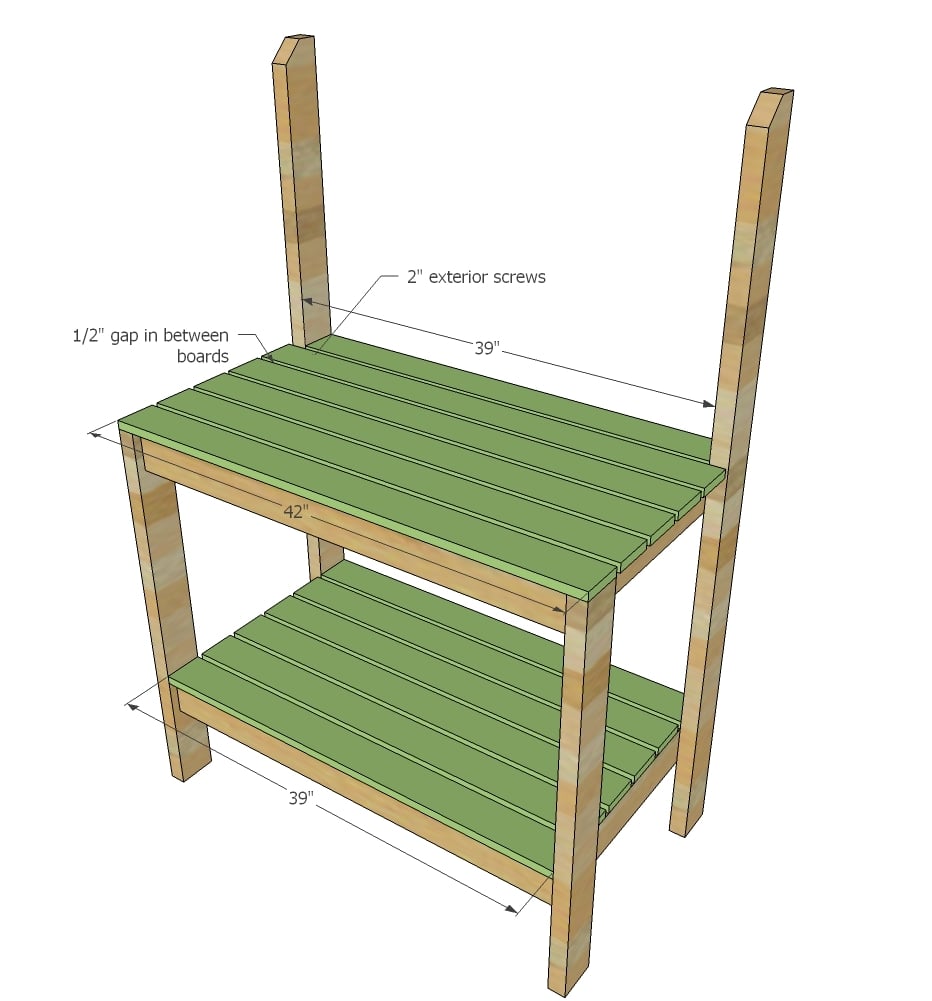

Step 4

It is always recommended to apply a test coat on a hidden area or scrap piece to ensure color evenness and adhesion. Use primer or wood conditioner as needed.

Comments

handmadewithash

Wed, 04/08/2015 - 19:08

Thanks so much for the video.

Thanks so much for the video. You make it look so easy! :)

biz_kid1

Sat, 04/11/2015 - 14:46

Love it!

And I need to make one, too, so I can work on our garden! :) Thanks for sharing!

ilove2create

Sun, 04/12/2015 - 22:36

Love the potters bench

I just built this bench and love it. I also really like those hooks. Where did you get them? Thanks for all the great plans, I've made quite a few pieces.

In reply to Love the potters bench by ilove2create

Ana White

Mon, 04/13/2015 - 11:30

You can get the hooks at just

You can get the hooks at just about any home improvement or home store.

Just ask for "over-the-cabinet" hardware.

kangel546

Sun, 04/05/2020 - 08:24

I can’t find these hooks…

I can’t find these hooks anywhere! :( I love them because they’re movable. Do you happen to have an online link as to where I could find them? TIA!

rmatteo94

Wed, 05/06/2020 - 06:28

They're a bit pricey, but…

They're a bit pricey, but this is the closest hook I could find! Good luck!

https://www.flyingbulldogs.com/liberty-b19376-sn-over-the-cabinet-singl…

Kimber1216

Thu, 06/16/2016 - 01:14

Material/cut list

Hi Ana,

So excited to make this bench! Was wondering, on the video you have a material list:

(8) 1x4x8

(2) 1x4x10

(4) 2x4x8

Could you please tell me what cuts are made to the (2) 1x4x10's? Thank you so much!

In reply to Material/cut list by Kimber1216

Ana White

Thu, 06/16/2016 - 10:00

https://www.ryobitools.com

https://www.ryobitools.com/nation/projects/4031

Rowland A Shepard

Thu, 03/11/2021 - 08:37

cuts optimized with cutlist optimizer

# Panel Cut Result

1 4×120 y=39 4×39 \ -

2 4×81 y=39 4×39 \ -

3 4×42 y=39 4×39 \ surplus

1 4×96 y=24 4×24 \ -

2 4×72 y=24 4×24 \ -

3 4×48 y=42 4×42 \ surplus

1 4×96 y=42 4×42 \ -

2 4×54 y=42 4×42 \ surplus

1 4×96 y=39 4×39 \ -

2 4×57 y=39 4×39 \ surplus

1 4×96 y=42 4×42 \ surplus

Rowland A Shepard

Thu, 03/11/2021 - 08:57

cuts optimized with cutlist optimizer

1 2x ( 120" @ 30, 39, 39 )

2 1x ( 96" @ 24, 24 and 42

3 4x (96" @ 42 and 42

4 2x (96" @ 39 and 39

5 1x (96" @ 42

seansun01

Sun, 06/02/2019 - 15:39

Fun Project!

This was an awesome project. I shopped for the materials in the morning and built it in the afternoon. The shopping list and plans were fabulous. I had to adjust slightly since I used pressure treated wood and the 1x4’s were 3/4 x 1 5/8 instead of 3/4 x 1 1/2. It came out perfect though and seems sturdy and quite functional. I added a piece of aluminum to the top to keep soil from falling through when potting plants. I love it when a project comes out as planned!

KendCo

Sun, 05/31/2020 - 22:45

Some tips

I've only made a hand full of wood workings projects but had no problem building this (in just a day too!)

The only issue I had was which cuts went where when it came to the 1x4s (since there's two different lengths) here's what I went with so I could have a bunch of useable offcuts:

All 8ft 1x4 boards: cut a 39" and a 42" from the same board. This will give you 8 of each of those and 8 15" offcuts

Both 10ft 1x4 boards: cut a 39", a 42" and a 22" in both

You should then have all the boards you need with the most useable offcuts. They're even the same length @15"! I have another project in mind for the leftovers making this a zero waste project :)

I didn't need to predrill the 2x4s but it's pretty much mandatory for the 1x4s

Hope this helps!

jess8336

Wed, 06/17/2020 - 12:11

Wood thpe

Is there a specific type of wood that should be used?

aimes91225

Wed, 07/08/2020 - 09:11

AWESOME POTTING BENCH!!!!!!

Thank you so much for this easy to do AWESOME potting bench. My dad and I built this in about 2 hours as a surprise for my mom. Got it stained and varnished the next day! Such easy to read instructions and pictures! Thank you again!!!

Copper21786

Tue, 03/09/2021 - 18:51

Do you think rolllers could…

Do you think rolllers could be put on this to move in and out of garage/shed? Too heavy?

mrgwt

Sat, 05/08/2021 - 20:50

Totally awesome thank you

Totally awesome thank you