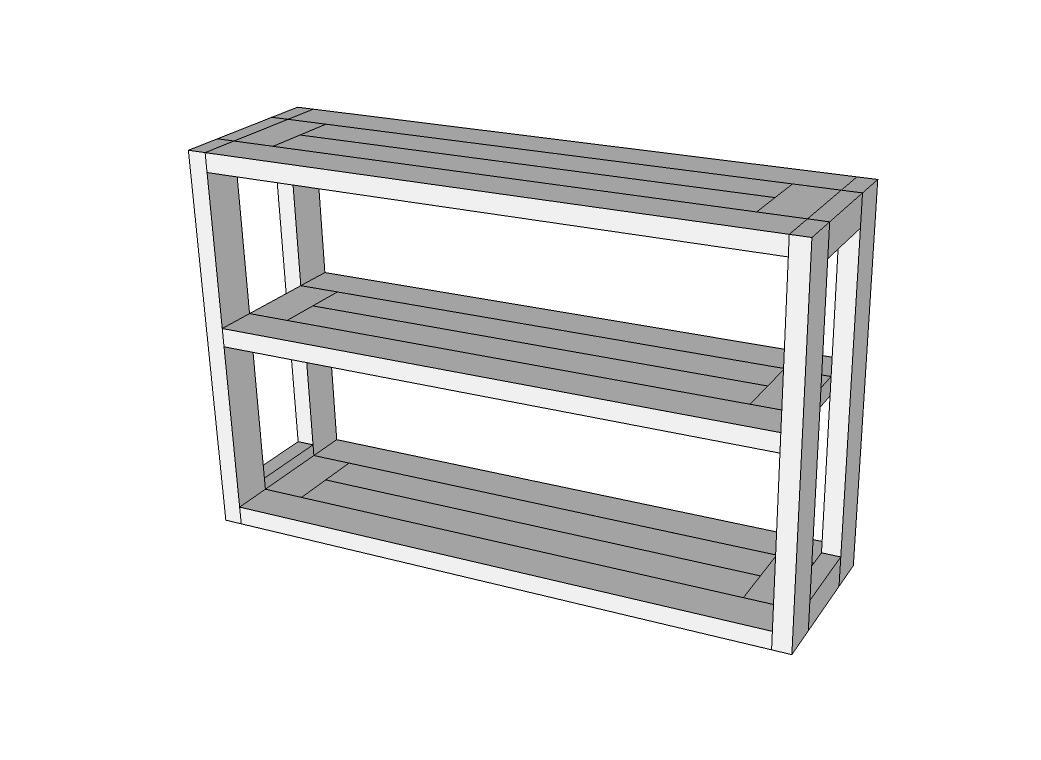

Rustic, yet industrial dining cart, see more about the project at http://decorandthedog.net/decorandthedog/2014/1/19/diy-dining-cart-tuto…

Preparation

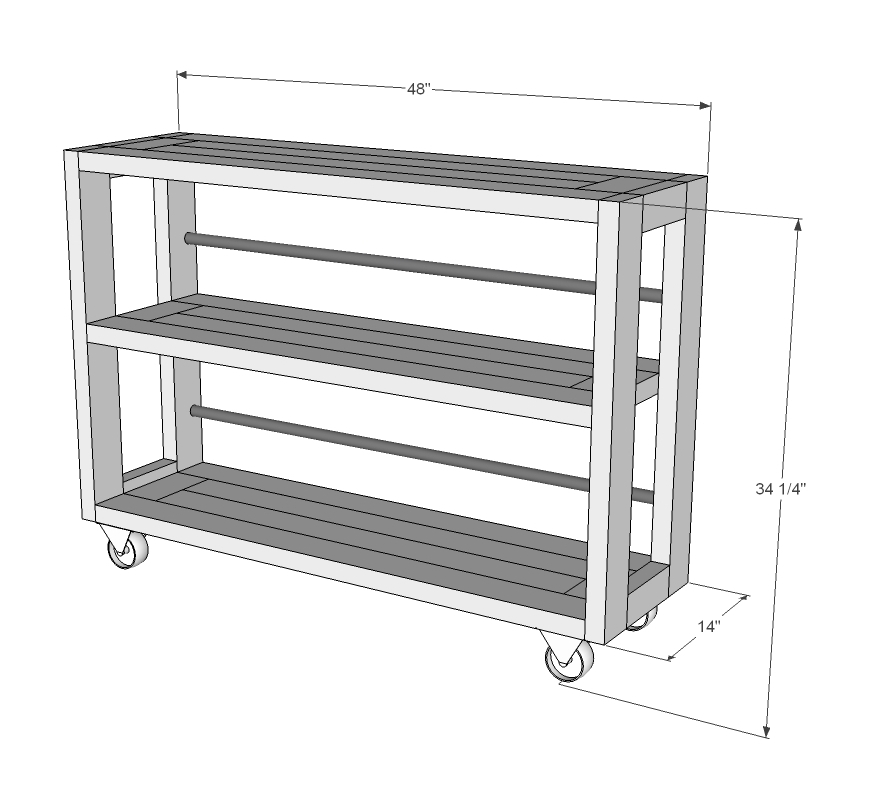

8 - 2"x4"x8'

2"x3" - Only need 28", so get the smallest one possible, or rip a 2"x4" down

2 - 3/4" x 6' black iron pipe

4 - black iron end caps

4 - industrial wheels

2 - corner brackets

2 1/2" pocket hold screws

Kreg jig

wood glue

Construction adhesive (we use Loctite Power Grab)

Black spray paint

Small nails or upholstery tacks

2"x4"

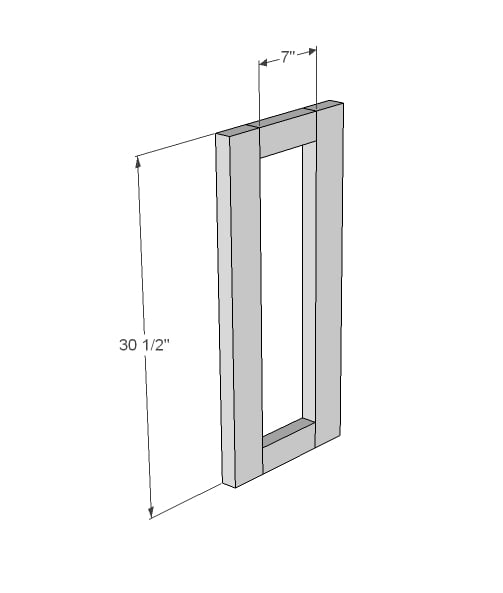

4 - 30.5" (sides)

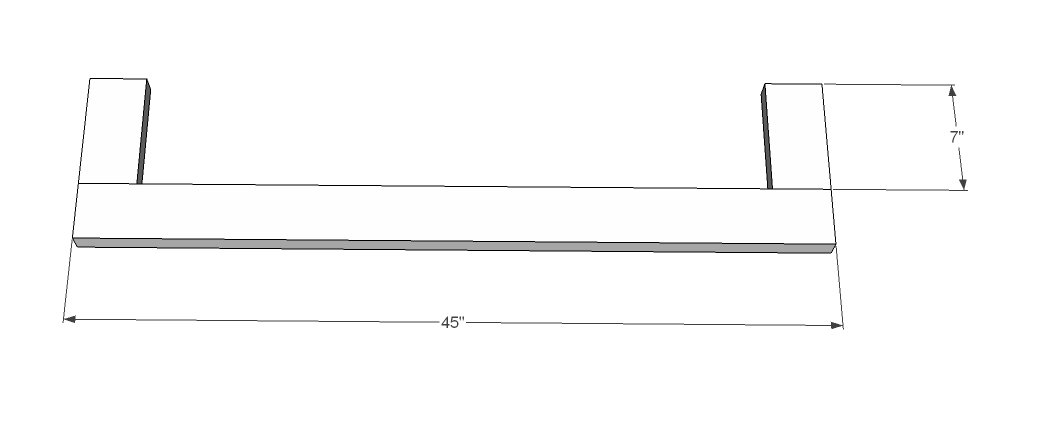

6 - 45" (outsides of shelves)

6 - 38" (middles of shelves

6 - 7" (ends of shelves)

2"x3"

4 - 7" (middles of sides)

Please read through the entire plan and all comments before beginning this project. It is also advisable to review the Getting Started Section. Take all necessary precautions to build safely and smartly. Work on a clean level surface, free of imperfections or debris. Always use straight boards. Check for square after each step. Always predrill holes before attaching with screws. Use glue with finish nails for a stronger hold. Wipe excess glue off bare wood for stained projects, as dried glue will not take stain. Be safe, have fun, and ask for help if you need it. Good luck!

Instructions

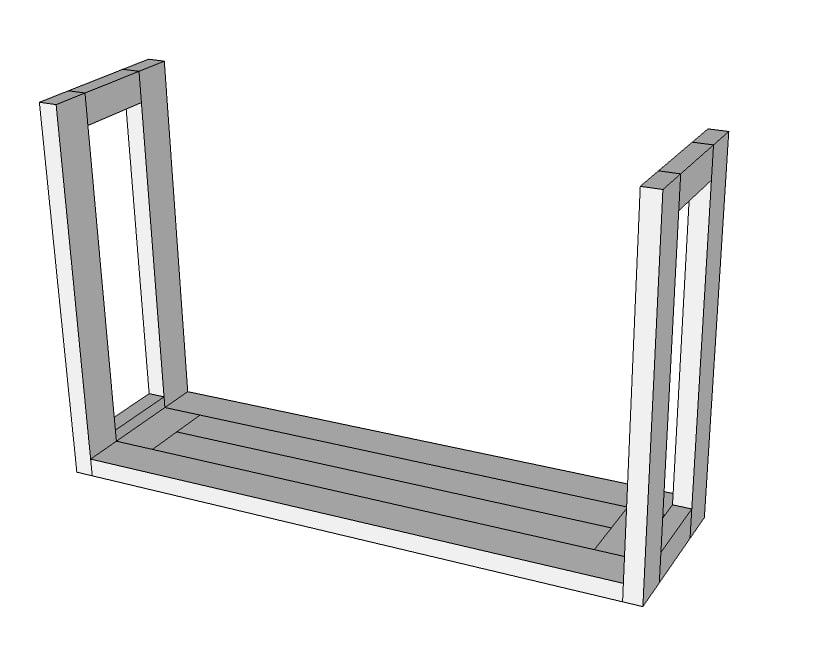

Step 1

Step 2

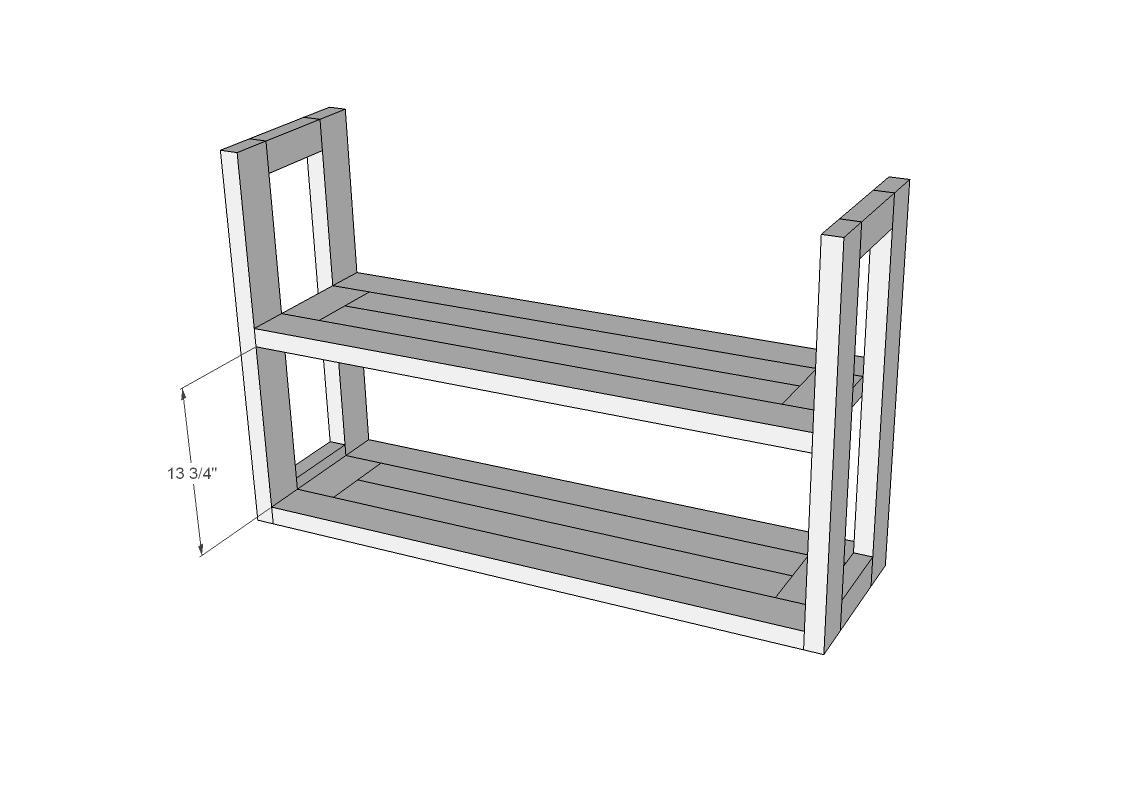

Step 3

Step 7

Step 8

Sand any remaining uneven surfaces. Stain or paint and poly. We used Rust-Oleum wood stain in weathered gray.

Step 9

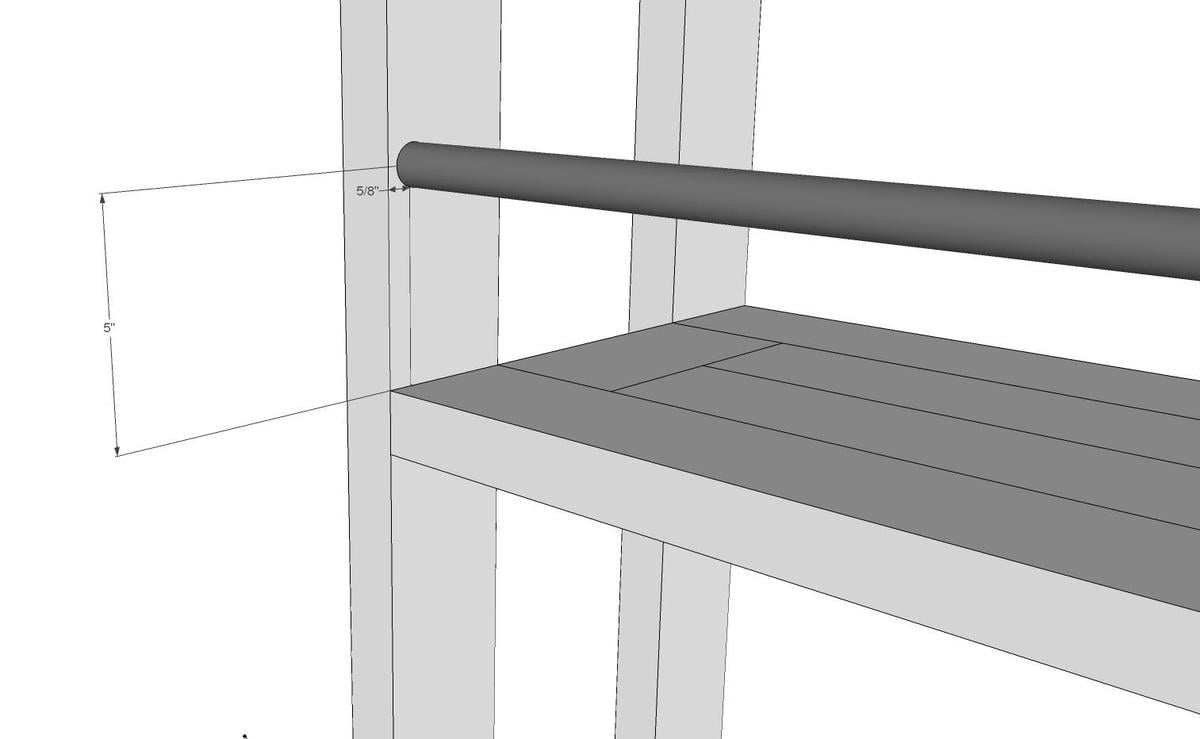

Using a hack saw, cut the black iron pipe so when a cap is placed on one end it will go into the opposite hole about 3/4". Test fit the cut, leaving it in the board, measure the remaining length needed (probably about 1 1/2" or so). Cut that length off of the remaining pipe, making sure to keep the threaded part. I did this in order to keep the threads on both sides so the cap will screw on. There is probably a tool that will put threads on the end of the pipe after it is cut but I don't do that much work with this material so this seemed cheaper than buying a tool only to use it once. Put end cap on short piece. Test fit making adjustments as necessary. Put construction adhesive around the end of the cap and down pipe a bit, and on the longer pipe put adhesive on the end once just before putting it into the opposite hole. Repeat for second shelf. Let glue dry.

Step 10

If you cannot find vintage corner brackets and wheels, use new brackets (inexpensive ones from any hardware store) and beat them up a bit with a hammer. We spray painted ours black. We purchased these wheels and gave them the same treatment.

Attach the corner brackets with nails or tacks to the top front corners. We used upholstery tacks. Note: You will have to spray paint nail or tack heads to match brackets.

It is always recommended to apply a test coat on a hidden area or scrap piece to ensure color evenness and adhesion. Use primer or wood conditioner as needed.