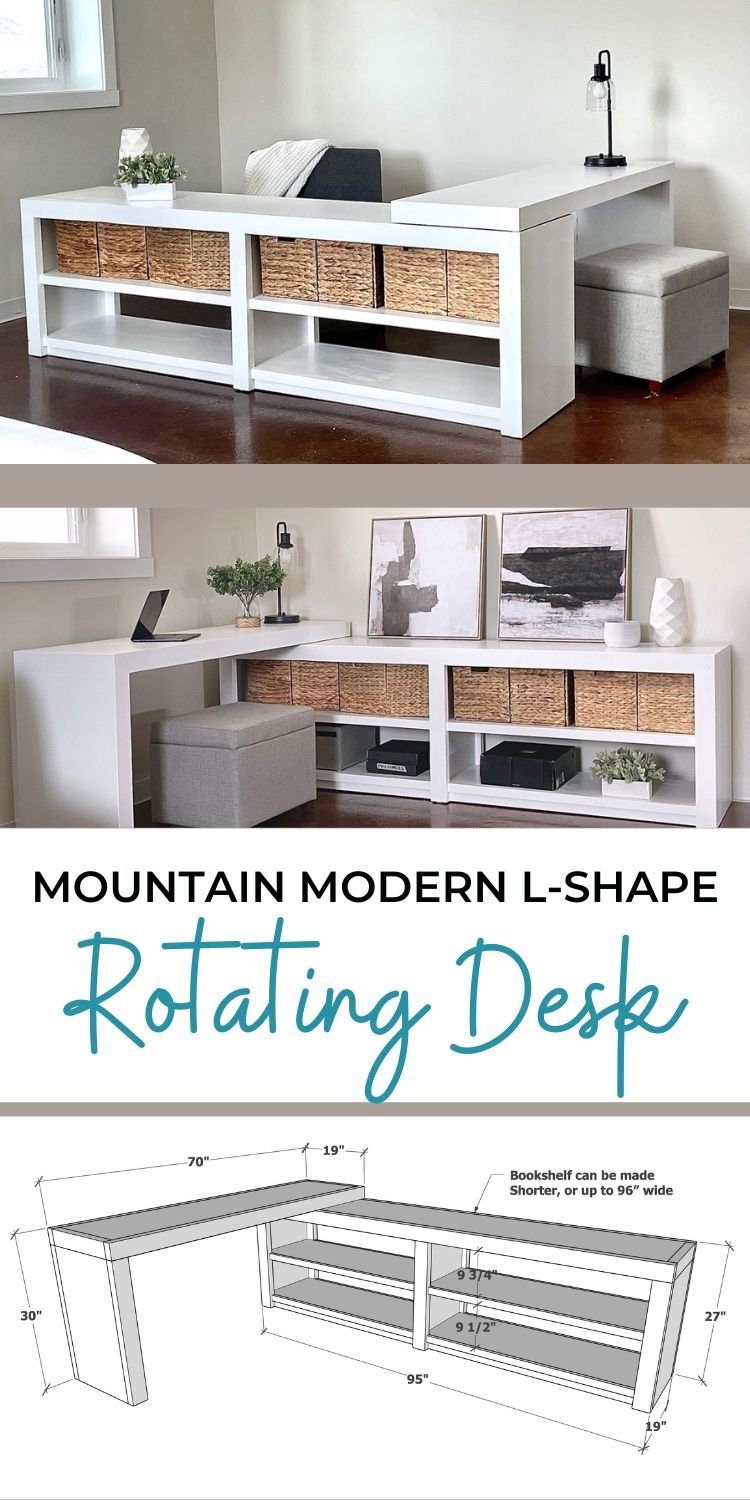

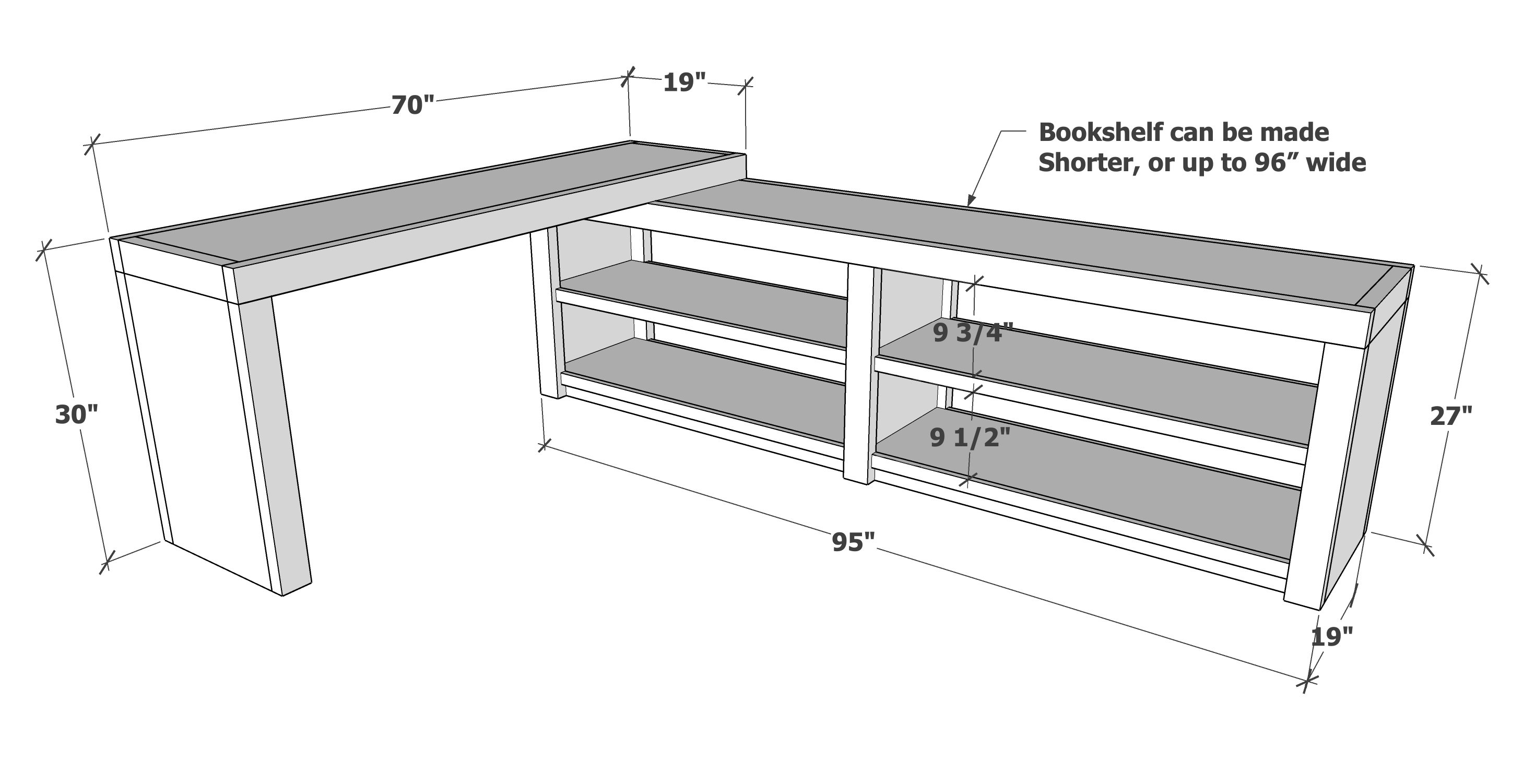

Modern, clean lines paired with a flexible design that can be configured to accommodate different room shapes, projects and users - this desk system features ample storage and a generous desktop. Finished on all sides, this desk can be centered in a room. It's built from two sheets of plywood and some 2x4s. The total cost was around $200.

This is a free project plan with step by step instructions to help you build your own custom desk.

Related: Mountain Modern Bookshelf Plans

Pin For Later!

Preparation

- 2 sheets of 3/4" thick cabinet grade plywood, ripped intro 6 strips, 15-3/4" wide x 8 feet long

- 6 - 2x4x10, pine (yellow toned), ripped down to 3" wide (take 1/4" off each side for square edges)

- 2 - 1x3 @ 8 feet long

- 5 - 1x2 @ 8 feet long

- 24 - 2-1/2" pocket hole screws

- 150 - 1-1/4" pocket hole screws

- 1-1/4" brad nails

- wood glue

- 12 felt pads (1" diameter or similar) for protecting bottoms of bookshelf, desk feet and bottom of desk where it sits on the bookshelf)

3/4" Plywood Cuts - Rip the 3/4" plywood into 6 strips, each 15-3/4" wide

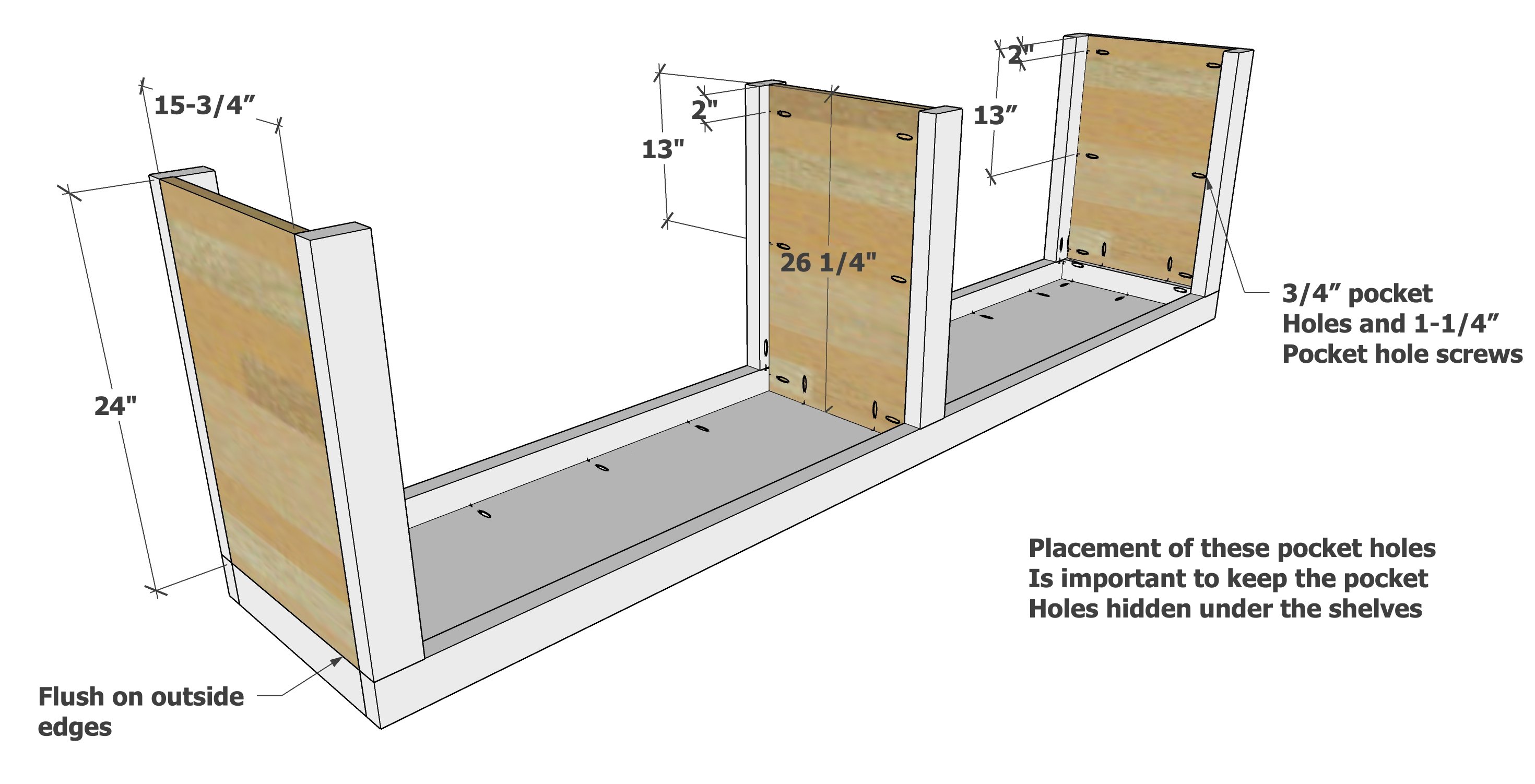

- 1 - 3/4" plywood @ 15-3/4" x 92" - bookshelf top (drill 3/4" pocket holes along all four edges)

- 2 - 3/4" plywood @ 15-3/4" x 24" - bookshelf sides (drill 3/4" pocket holes on top and side edges, place as shown in step 4)

- 1 - 3/4" plywood @ 15-3/4" x 26-1/4" - bookshelf center (drill 3/4" pocket holes on top and side edges, place as shown in step 4)

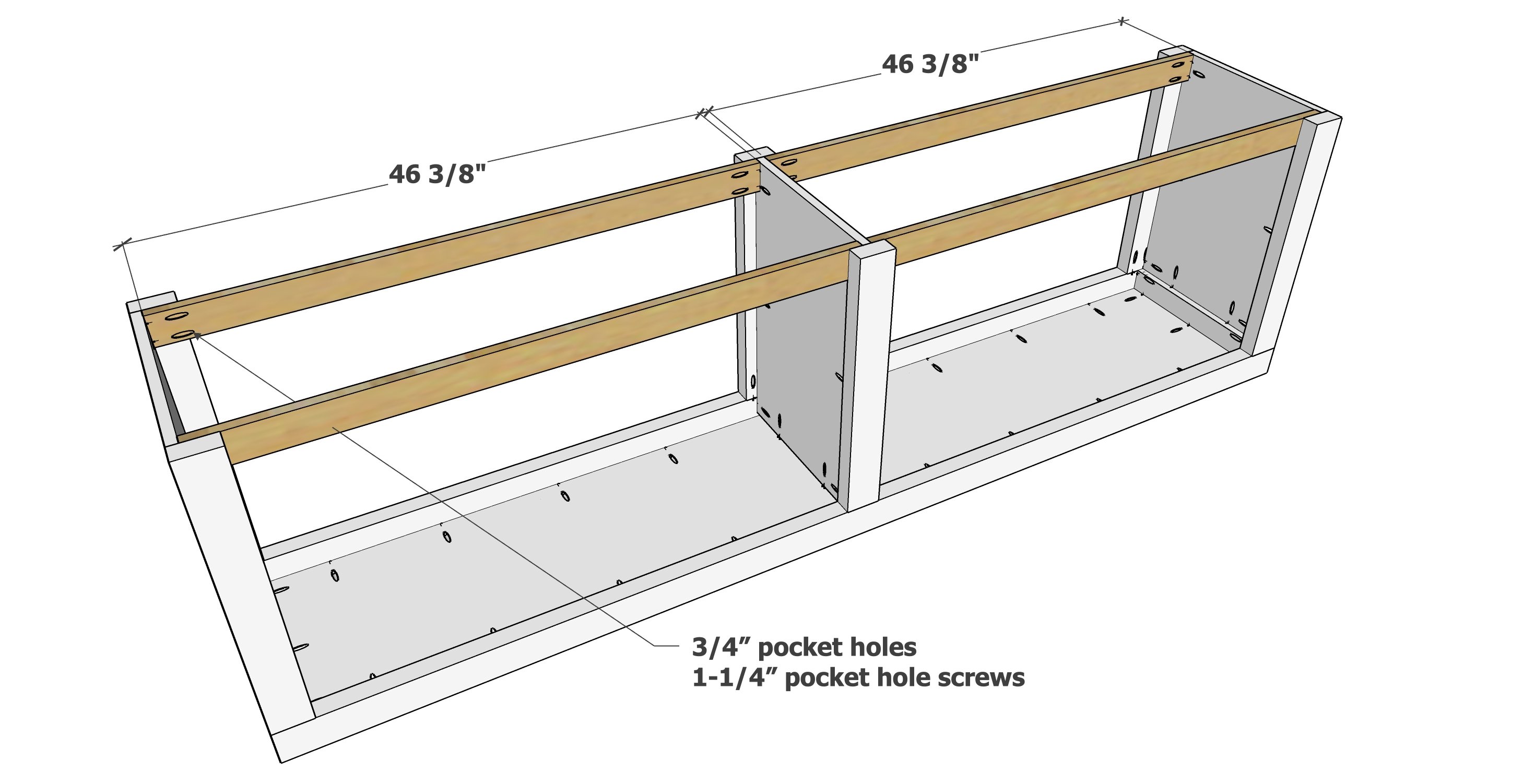

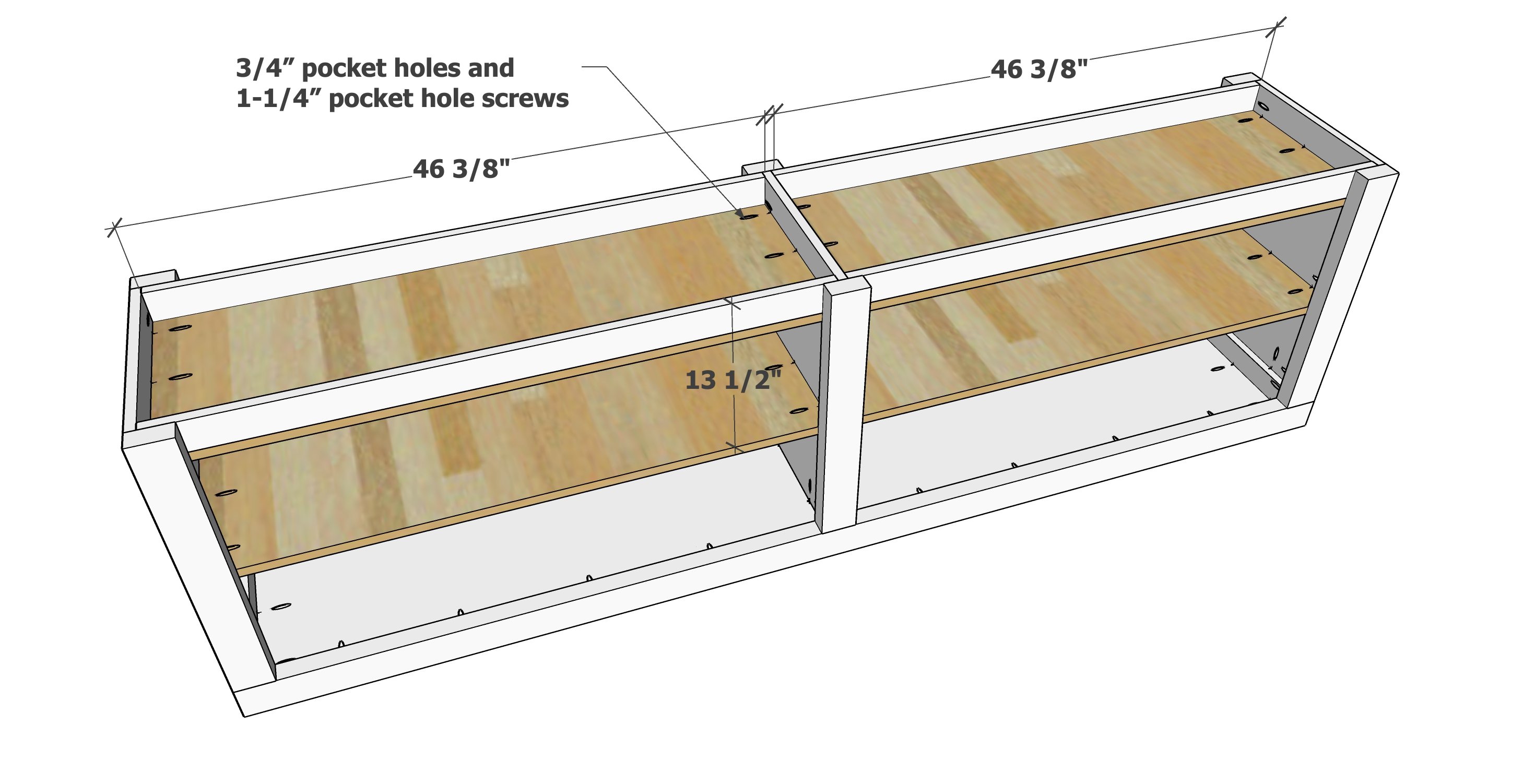

- 4 - 3/4" plywood @ 15-3/4" x 46-3/8" - shelves (drill 3/4" pocket holes on ends only)

- 1 - 3/4" plywood @ 15-3/4" x 67" - desk top (drill 3/4" pocket holes along all four edges)

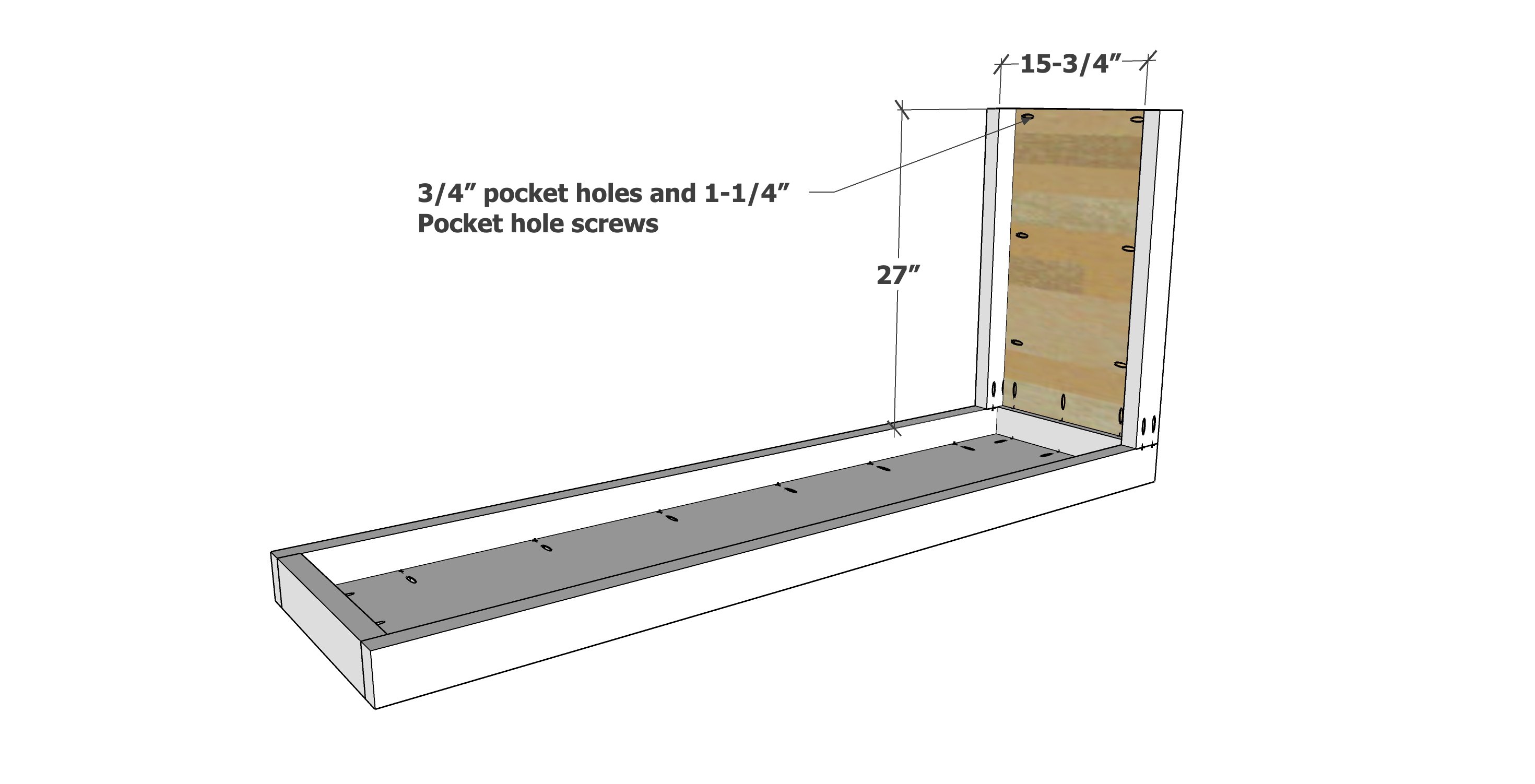

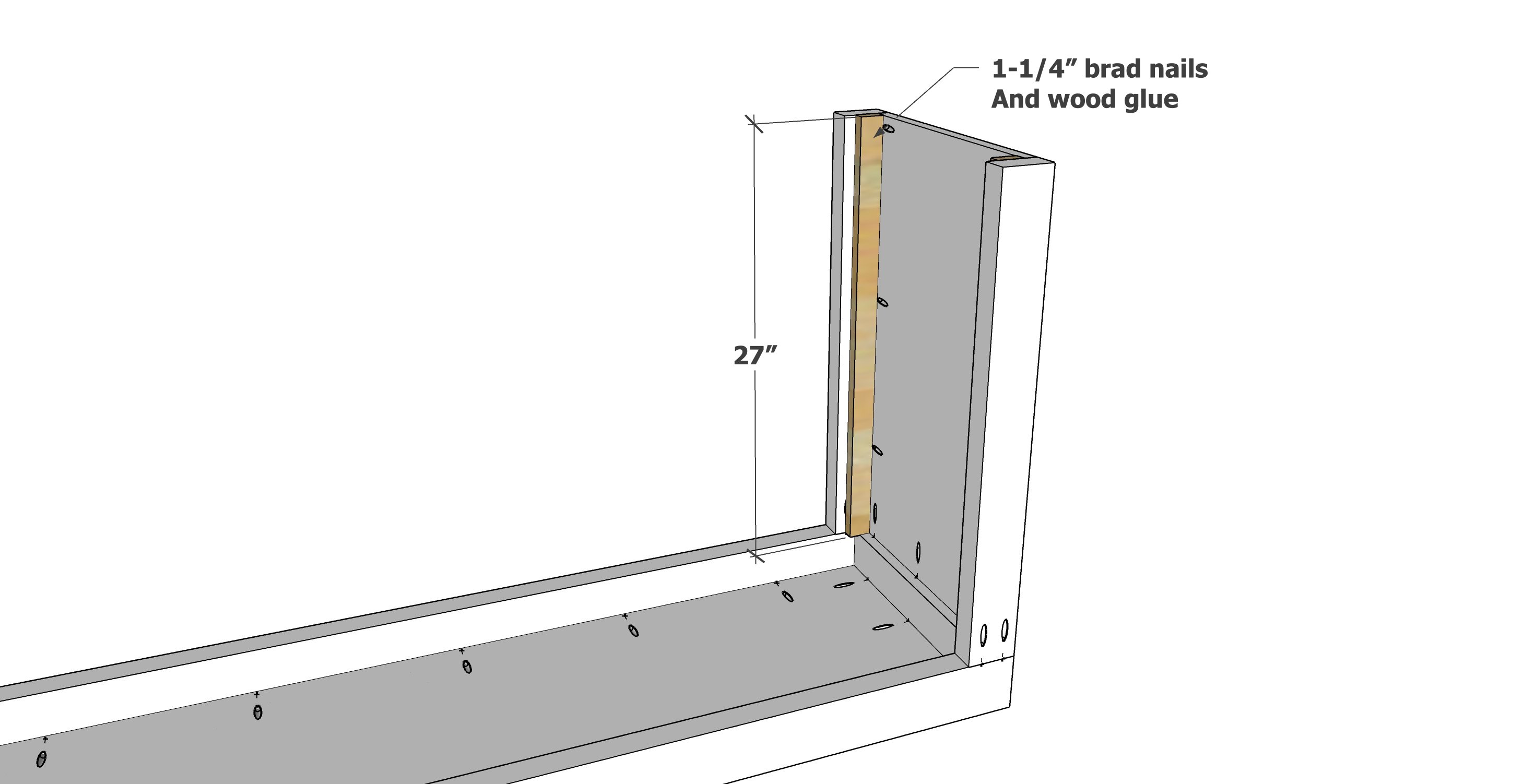

- 1 - 3/4" plywood @ 27" - desk leg - matches height of bookshelf (drill 3/4" pocket holes along top and side edges)

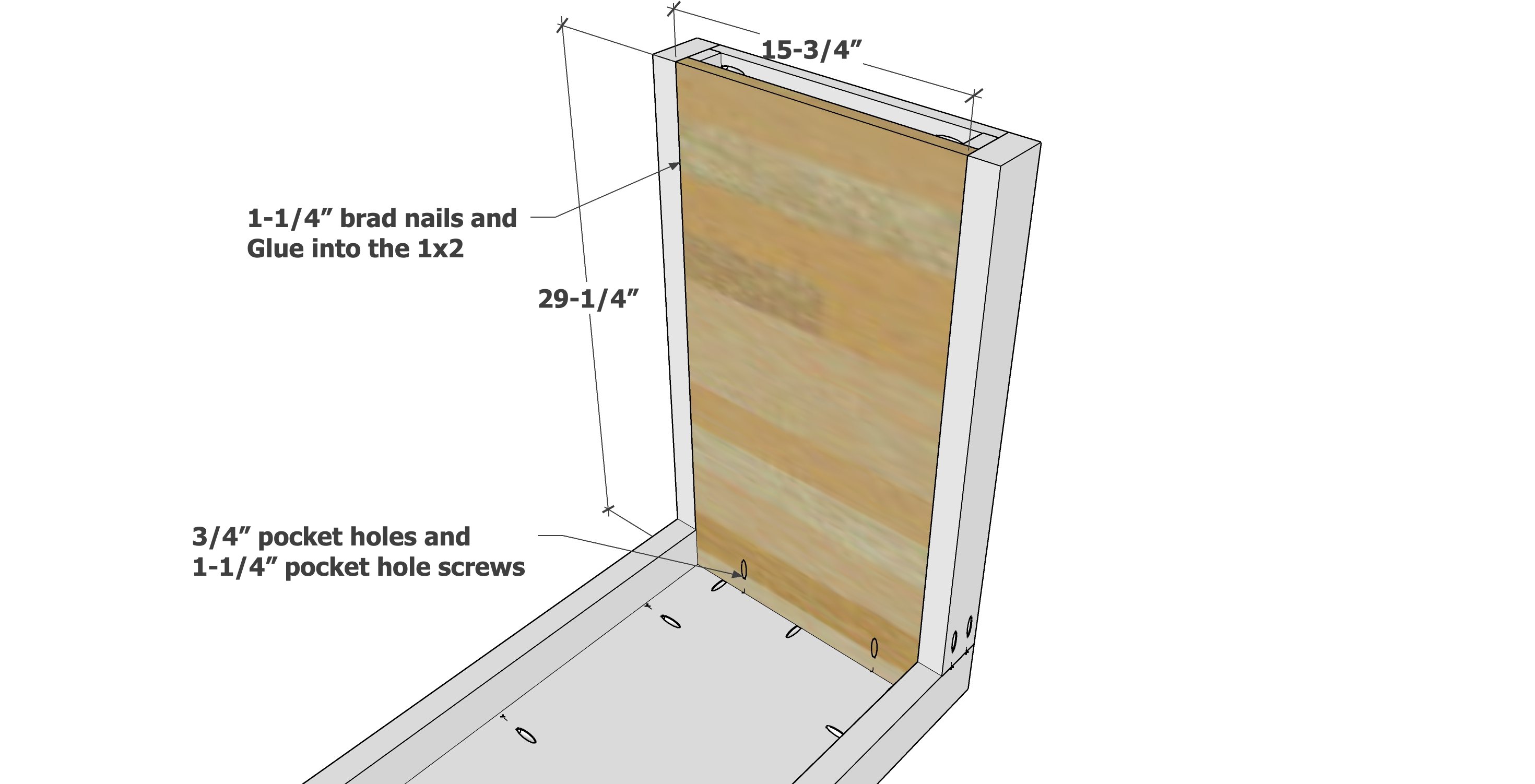

- 1 - 3/4" plywood @ 29-1/4" - desk inside leg (drill 3/4" pocket holes on top edge only)

2x4 cuts - rip 2x4s down to 3" wide first

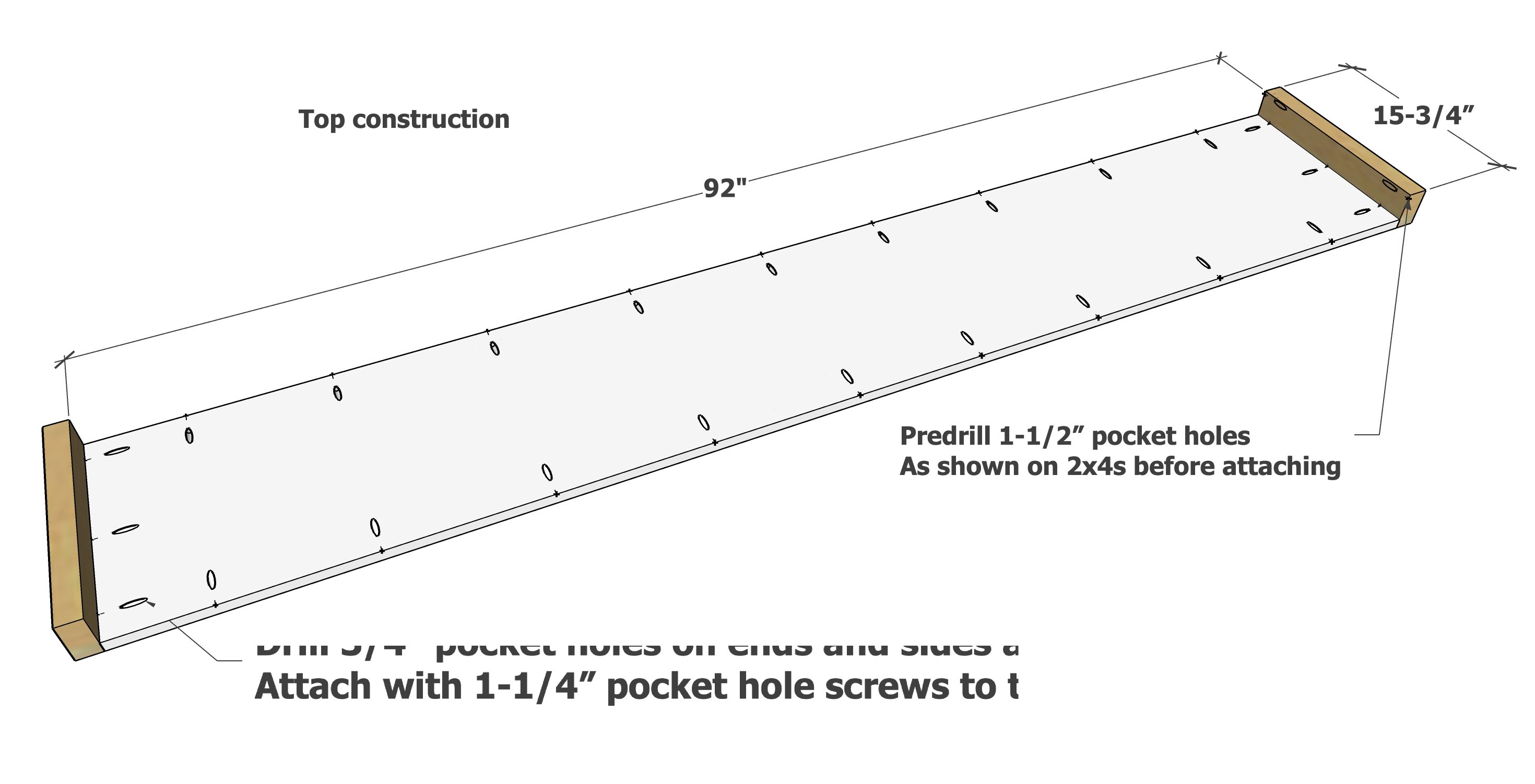

- 4 - 2x4 @ 15-3/4" - ends for tabletops (drill 1-1/2" pocket holes on each end)

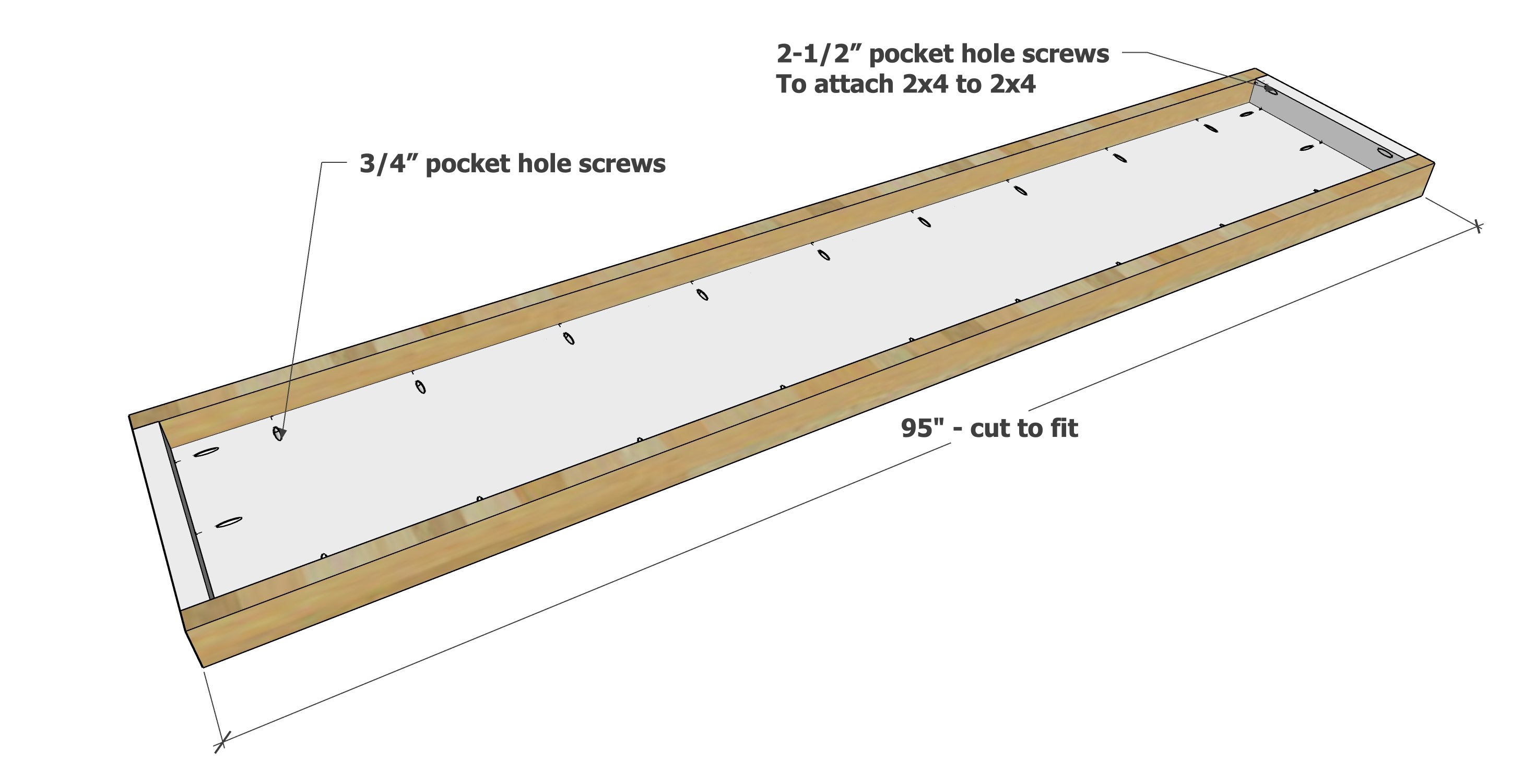

- 2 - 2x4 @ 95" - sides of bookshelf tabletop - measure and cut to fit

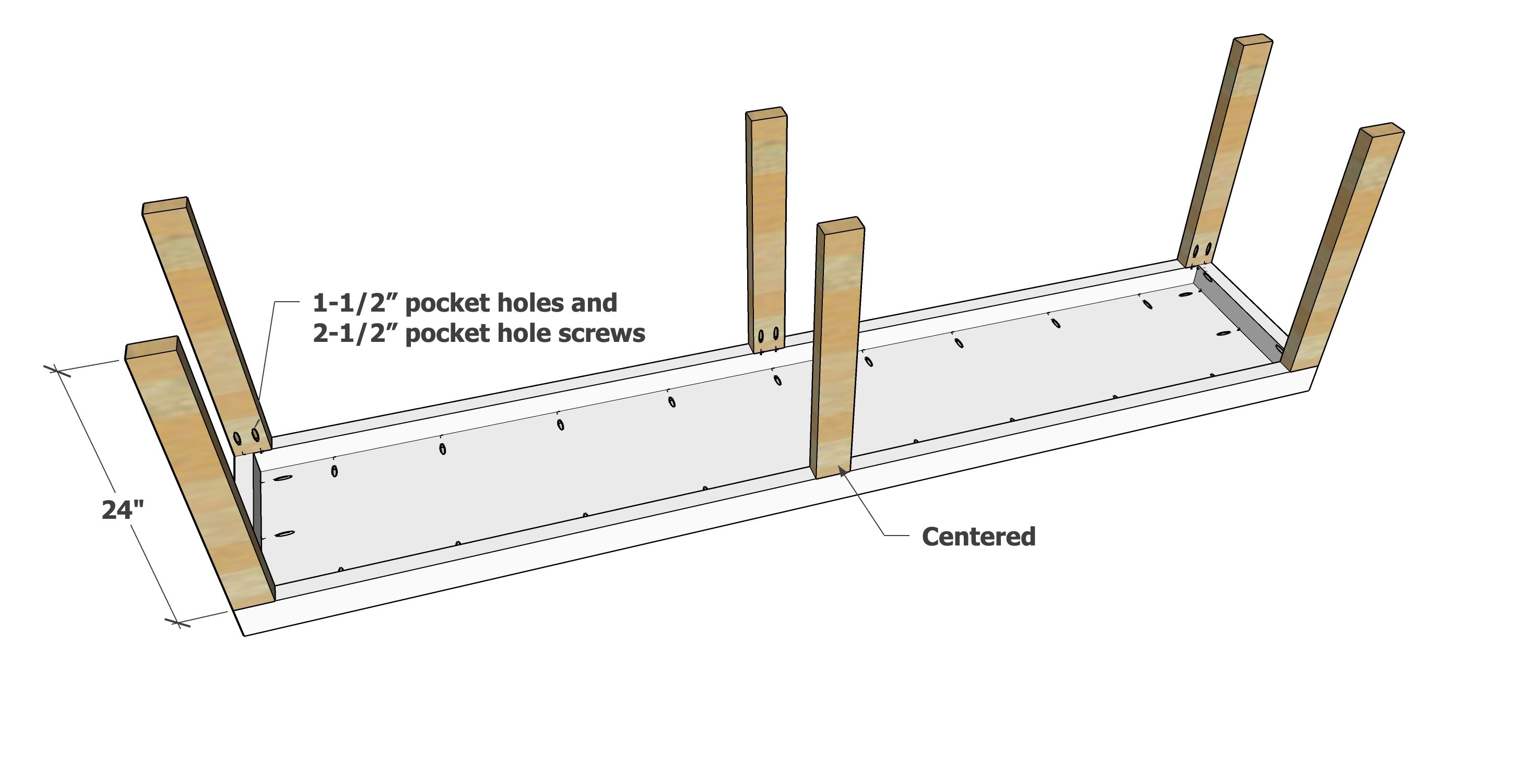

- 6 - 2x4 @ 24" - bookshelf legs (drill two 1-1/2" pocket holes on one end)

- 2 - 2x4 @ 70" - sides of desk tabletop - measure and cut to fit

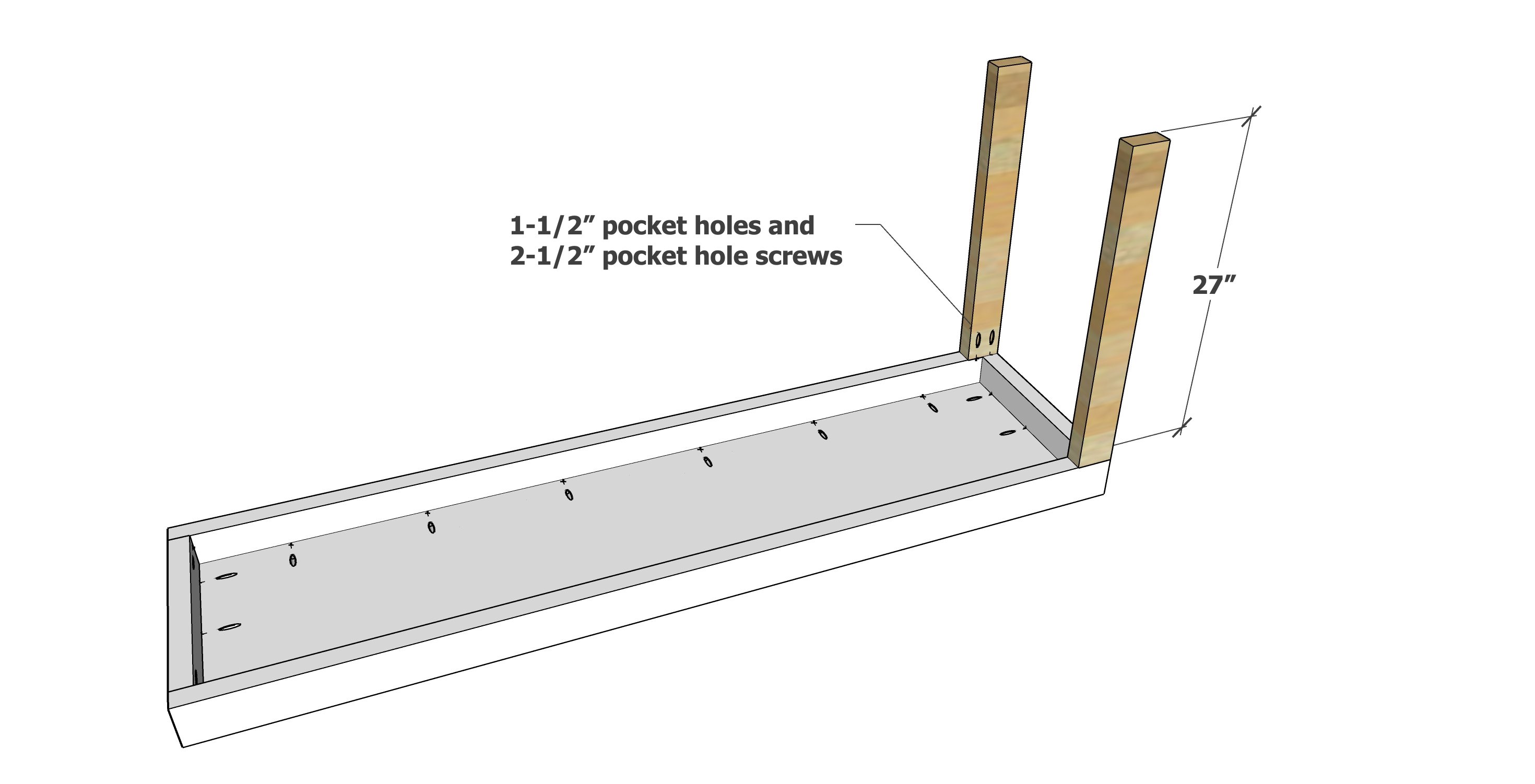

- 2 - 2x4 @ 27" - matches height of the bookshelf - desk legs (drill two 1-1/2" pocket holes on one end)

1x Trim Pieces

- 4 - 1x3 @ 46-3/8" - bottom supports (drill 3/4" pocket holes on ends and along top edge)

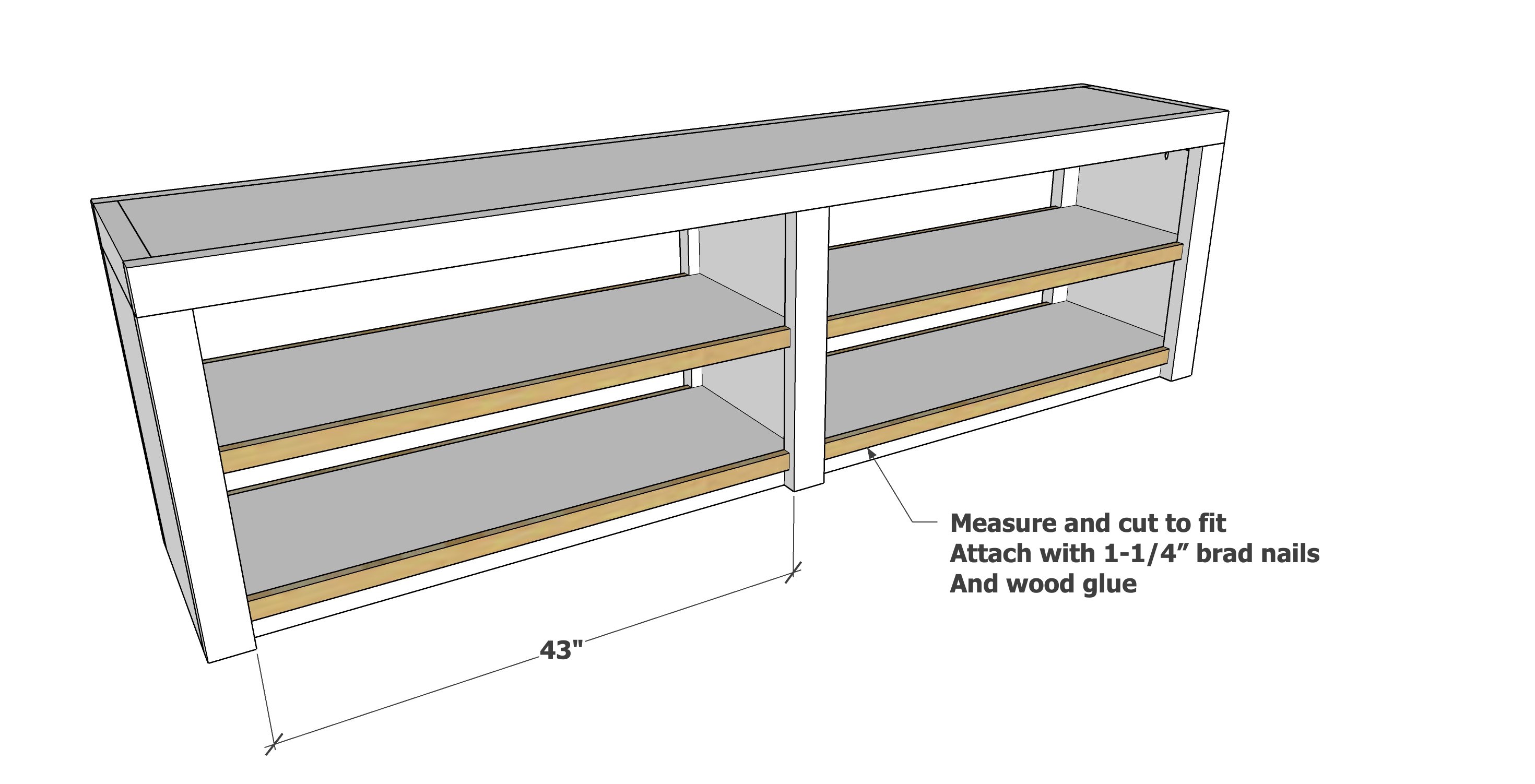

- 8 - 1x2 @ 43" - shelf trim, cut to fit

- 2 - 1x2 @ 27" - desktop leg trim

TIP: Drill the 1-1/2" pocket holes first in the 2x4s.

Then set the pocket hole jig to 3/4" setting and drill remaining holes.

This is to avoid having to reset the jig for different wood thicknesses multiple times.

Instructions

Step 2

Step 4

Step 7

Step 10

Remove sanding residue with vacuum with soft bristled brush.

Wipe with damp lint free cloth.

I did a light sanding between coats with fine sandpaper, wiping sanding residue off with damp cloth.

After the paint dried, I added the felt pads to the bottom of legs and the underside of the desktop where it sits on the bookshelf.