Free plans to build a play kitchen sink and stove with a real working sink! This is an easy build project and makes the cutest little play set. Free step by step plans with diagrams from Ana-White.com

Pin For Later!

Preparation

SINK SHOPPING LIST

- 1 - 1x12 @ 5 feet long

- 1 - 1x4 @ 18" long

- 1 - 1x3 @ 8 feet long

- 1 - 1x10 @ 16-1/2" long (shelf)

- 1 - 1x2 @ 5 feet long

- 1/4" plywood, minimum size 18" x 19-1/4" plus scrap piece for door backs

- Sink with running water, sized about 16" x 10-3/4", I used this one

- 1-1/4" and 5/8" brad nails

- wood glue

- 1-1/4" pocket hole screws for building the doors and top

- 4 surface mount hinges and 2 magnetic clasps

STOVE SHOPPING LIST

- 1 - 1x12 @ 6 feet long

- 1 - 1x4 @ 15"

- 1- 1x3 @ 8 feet long

- 1 - 1x10 @ 13-1/2" long (shelf)

- 1 - 1x2 @ 15" long

- 1/4" plywood, minimum size 15" x 19-1/4"

- acrylic glass piece 9" x 11"

- 1-1/4" and 5/8" brad nails

- wood glue

- 1-1/4" pocket hole screws for building doors

- 2 surface mount hinges and 1 magnetic clasp

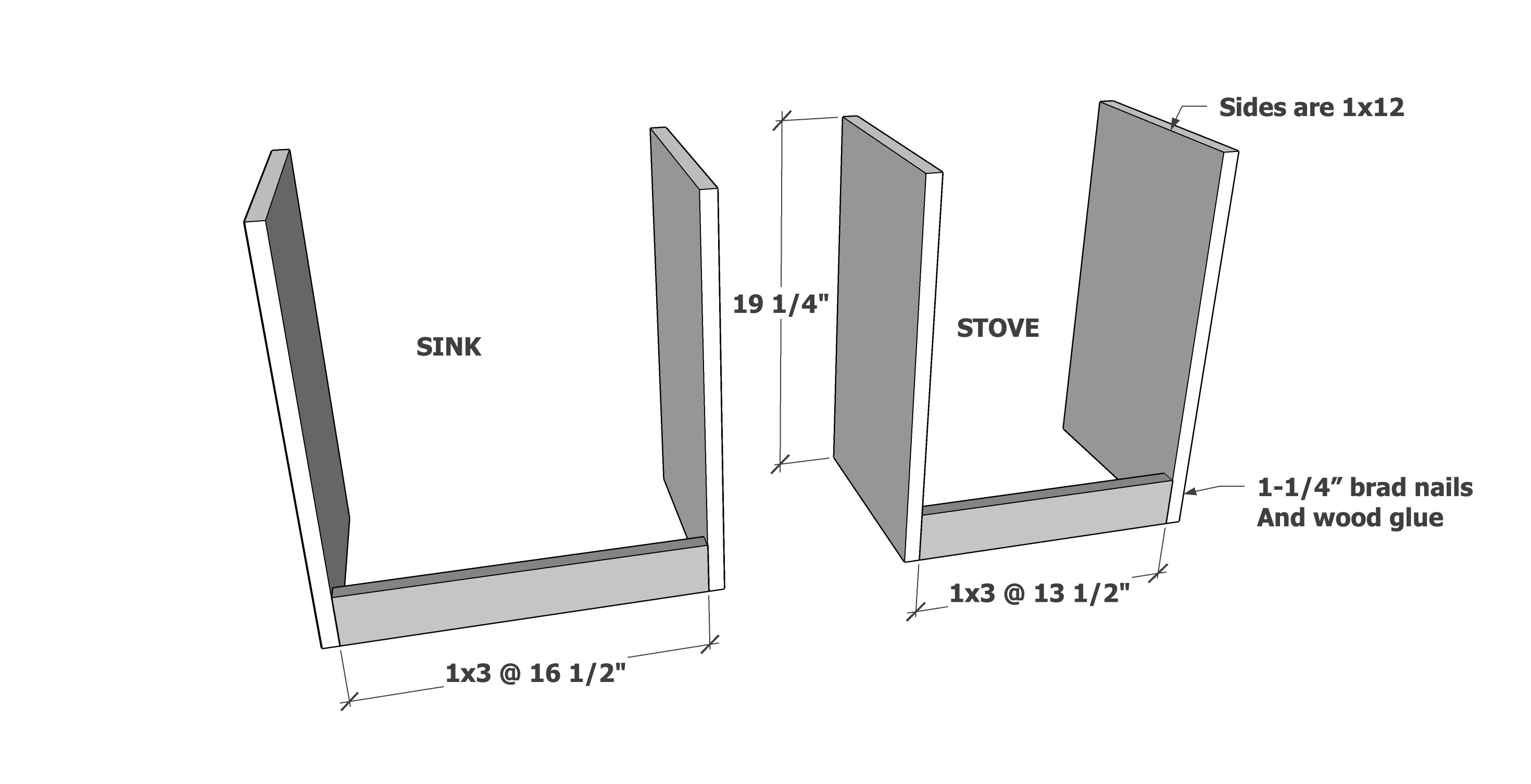

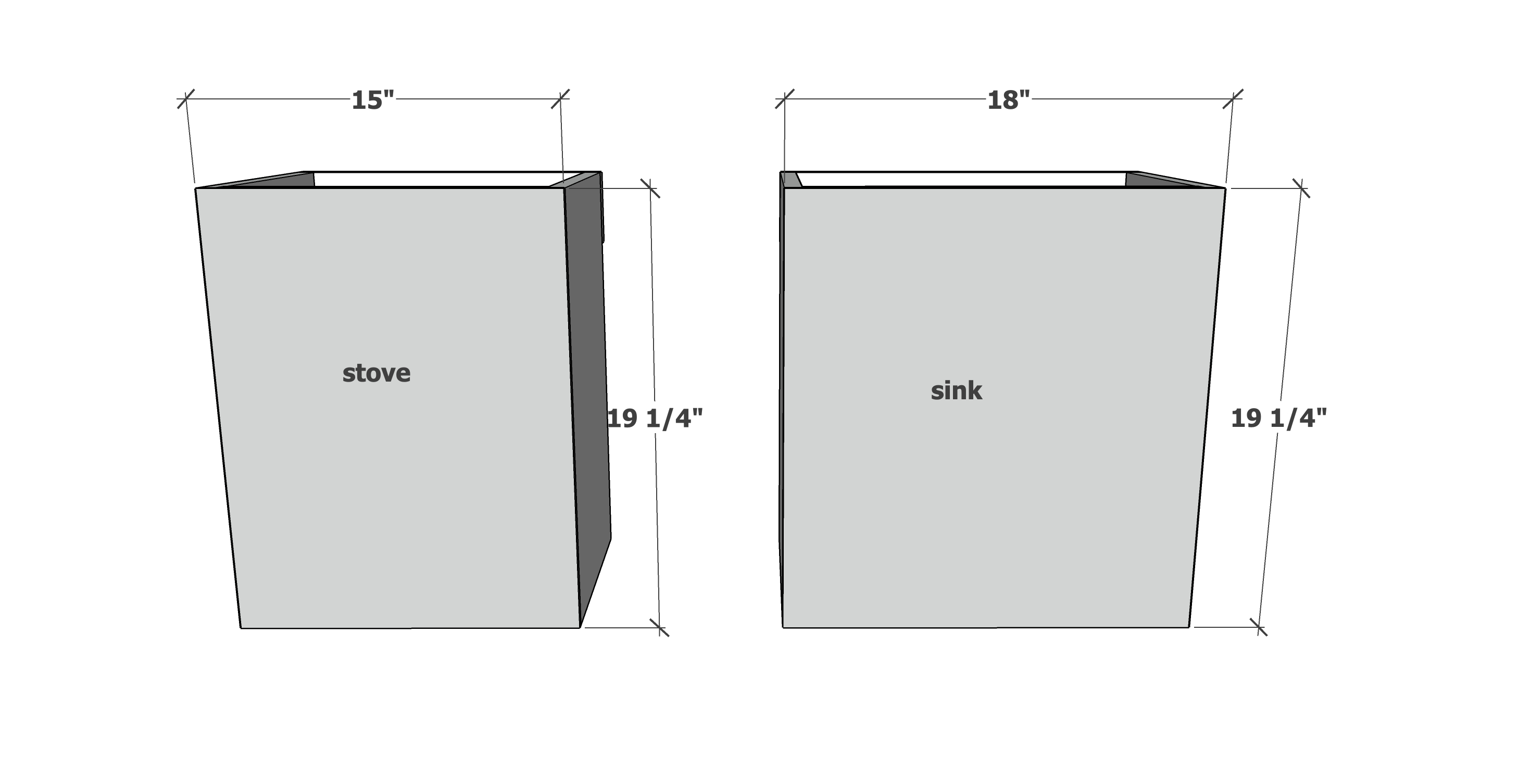

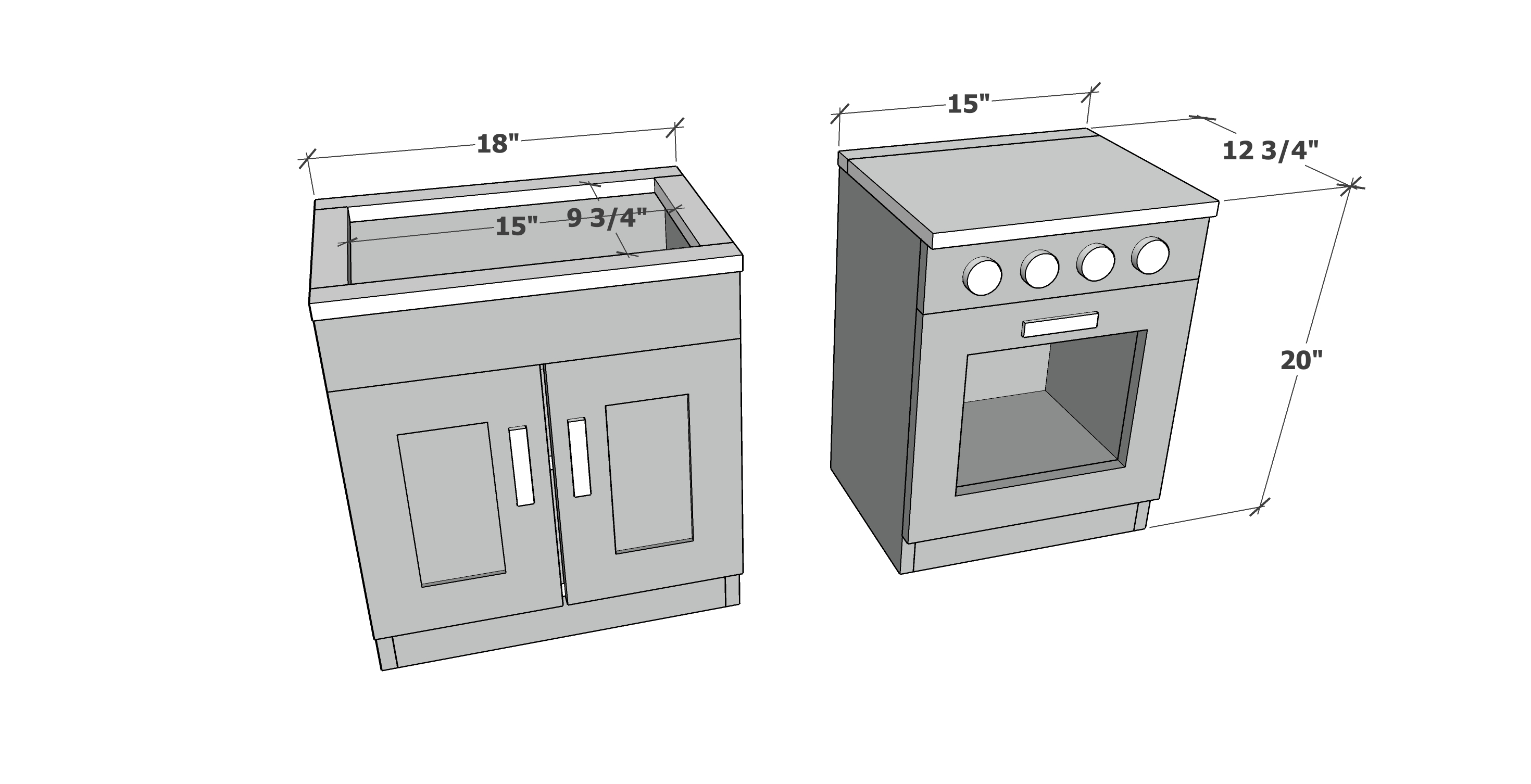

SINK CUT LIST - Measure the sink dimensions first and adjust plans as needed to fit

- 2 - 1x12 @ 19-1/4" - sides

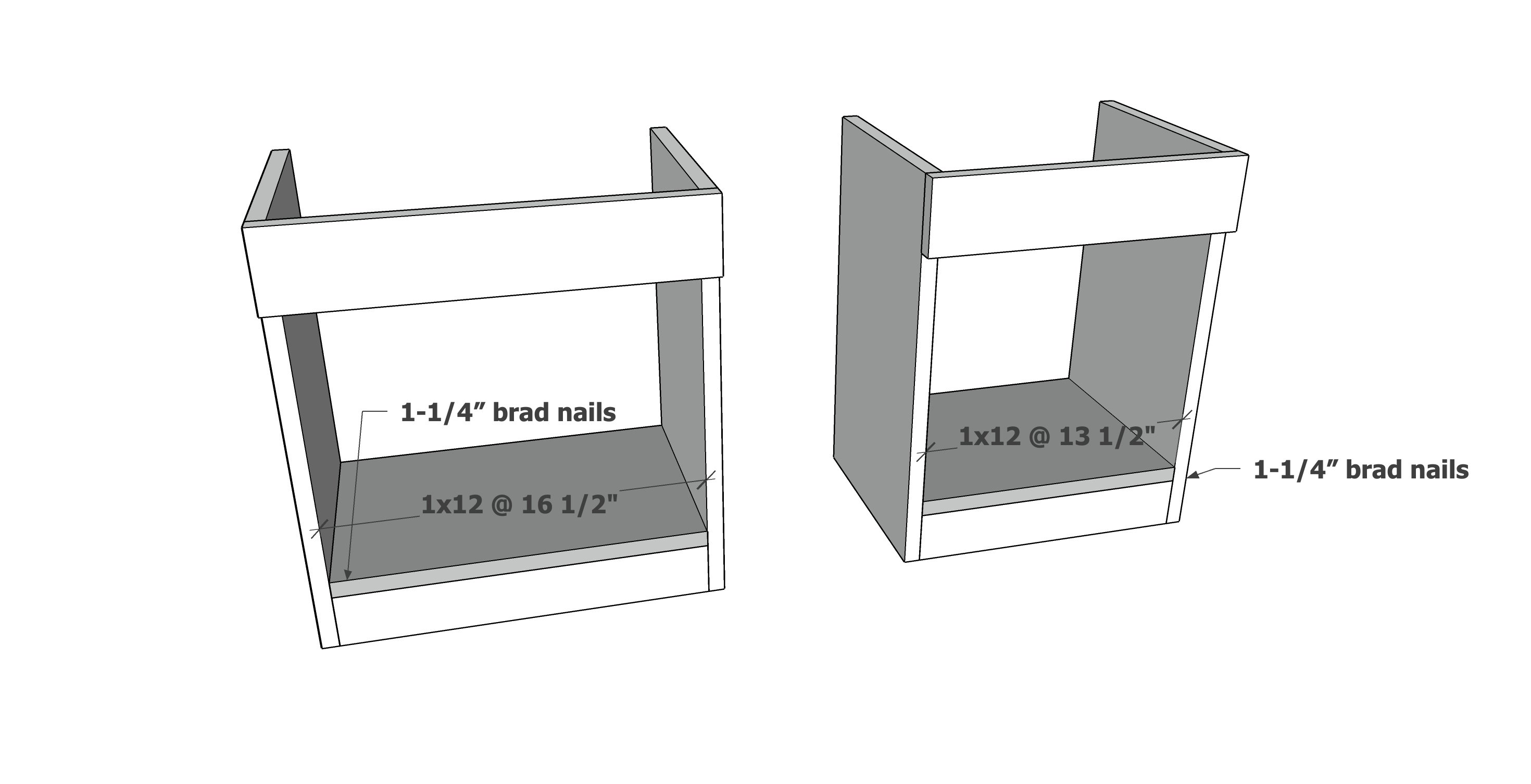

- 1 - 1x12 @ 16-1/2" - bottom

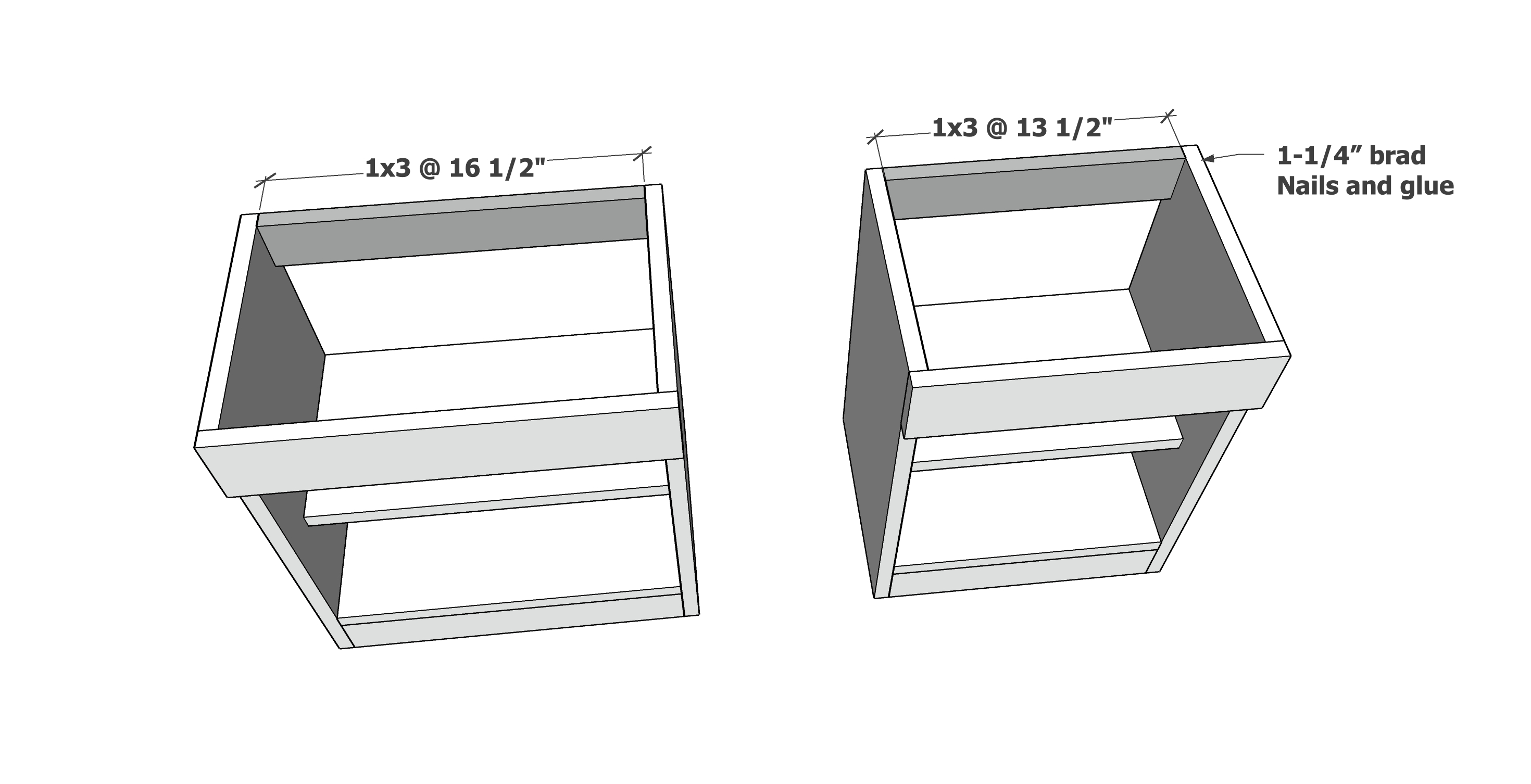

- 2 - 1x3 @ 16-1/2" - toekick and back top support

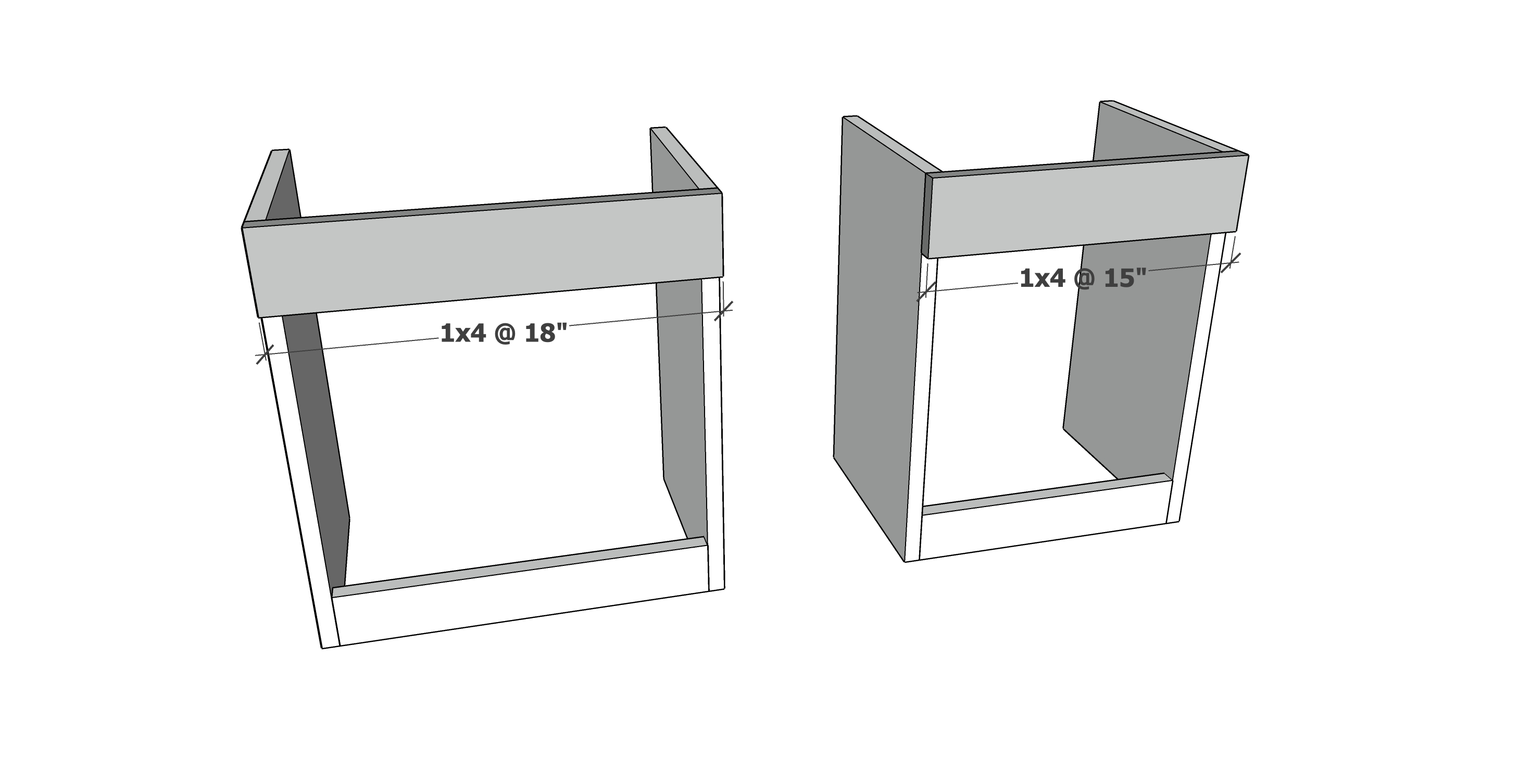

- 1 - 1x4 @ 18" - front

- 1 - 1x10 @ 16-1/2" - shelf

- 1 - 1/4" plywood @ 19-1/4" x 18" - back

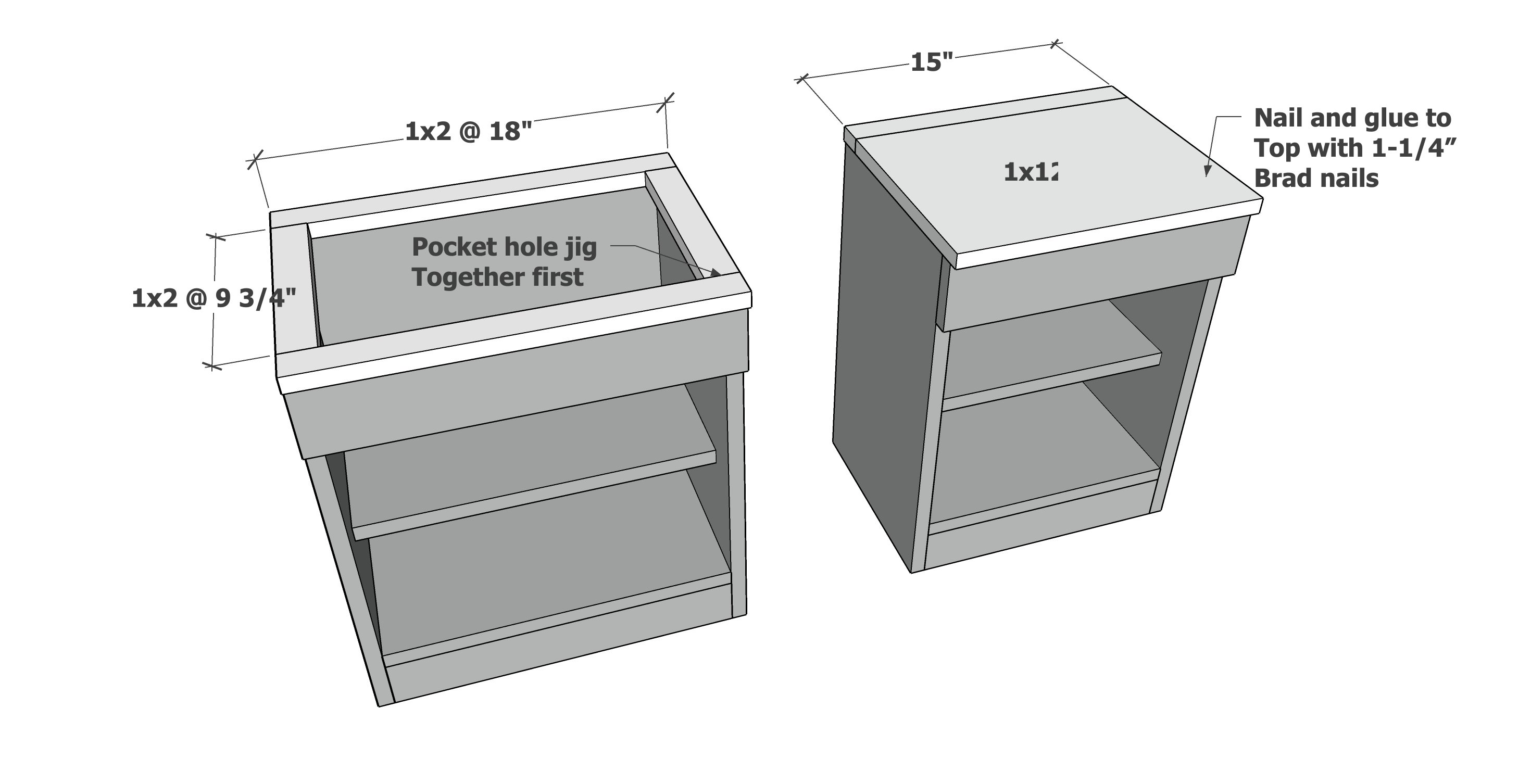

- 2 - 1x2 @ 18" - top front and back

- 2 - 1x2 @ 9-3/4" - top sides

STOVE CUT LIST

- 2 - 1x12 @ 19-1/4" - sides

- 1 - 1x12 @ 13-1/2" - bottom

- 2 - 1x3 @ 13-1/2" - toekick and back top support

- 1 - 1x4 @ 15" - front

- 1 - 1x10 @ 13-1/2" - shelf

- 1 - 1/4" plywood @ 19-1/4" x 15" - back

- 1 - 1x2 @ 15" - top back

- 1 - 1x12 @ 15" - top main

Cut boards according to the cut list.

Use a compound miter saw for professional looking cuts.

For cutting the 1/4" plywood, a table saw is best but a circular saw can be used, with the plywood elevated up on foam or scrap wood blocks to prevent the circular saw from cutting the table - also make sure the wood is fully supported, even after the wood has been cut to prevent the saw blade from being pinched.

Instructions

Step 4

Step 6

Step 7

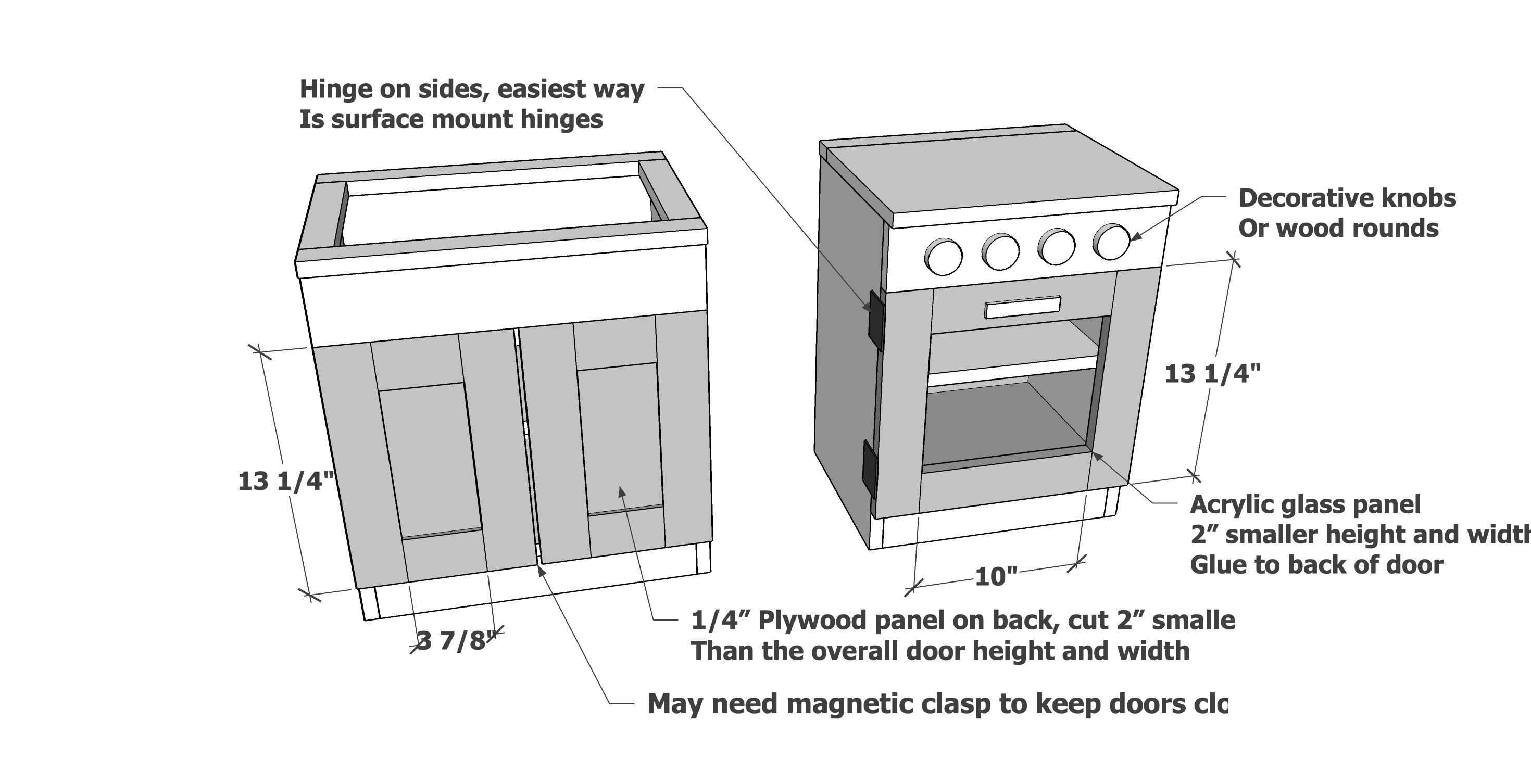

For the doors, use 1x3s to make the frames. Attach frames together with 3/4" pocket holes and 1-1/4" pocket hole screws (two per joint).

Then attach 1/4" plywood to the back with 5/8" brad nails and wood glue. Plywood panels should be about 1" larger than the center opening, not the full size of the door back.

Attach the acrylic glass to the stove with suitable glue or predrill and use small hardware screws.

Attach with hinges on the sides and use magnetic clasps to keep closed.

Advanced users can use Concealed Hinges for Frameless Cabinets.

Add knobs and handles.

The stove knobs are spaced 3" apart, starting from the center working outward.