These beautiful side tables are DIY! For about $20, you can build your own with our free, step by step plans with video, detailed diagrams and lots of photos. From Ana-White.com

Pin For Later!

Preparation

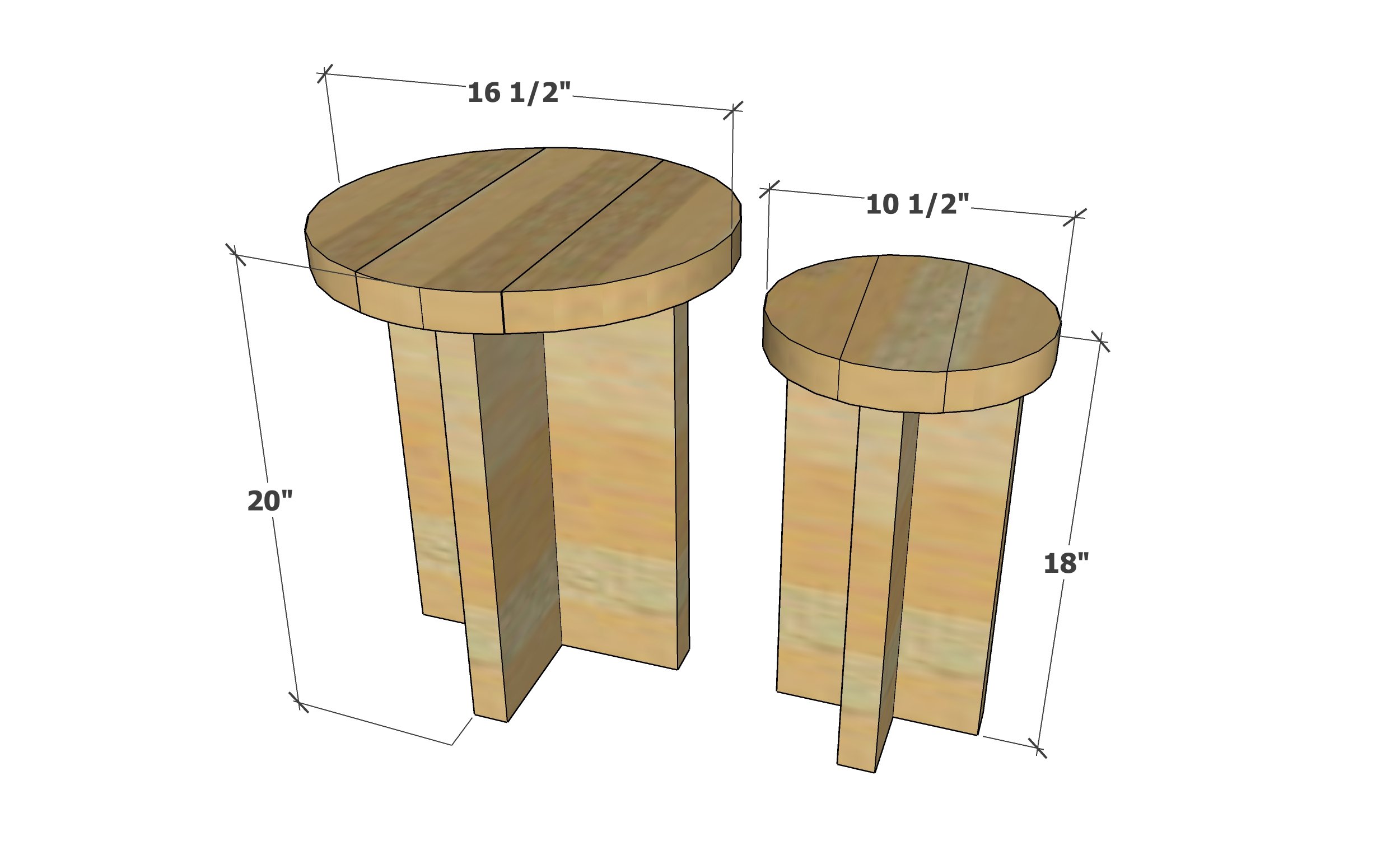

For 2x4 Side Table

- 1 - 2x4 @ 8 feet long (soft pine, yellow toned boards with minimal knots, cracks and warps)

- 1 - 2x2 @ 20" long (must be 1-1/2" x 1-1/2")

- 2" self tapping trim screws (16)

- 1 - 1/2" pocket hole screws (4)

For 2x6 Side Table

- 1 - 2x6 @ 12 feet long (soft pine, yellow toned boards with minimal knots, cracks and warps)

- 1 - 2x2 @ 24" long

- 2" self tapping trim screws (16)

- 1 - 1/2" pocket hole screws (6)

For 2x4 Side Table

- 4 - 2x4 @ 16-1/2"

- 2 - 2x2 @ 9" - long point measurement, one end cut at 45 degrees

- 3 - 2x4 @ 10-1/2"

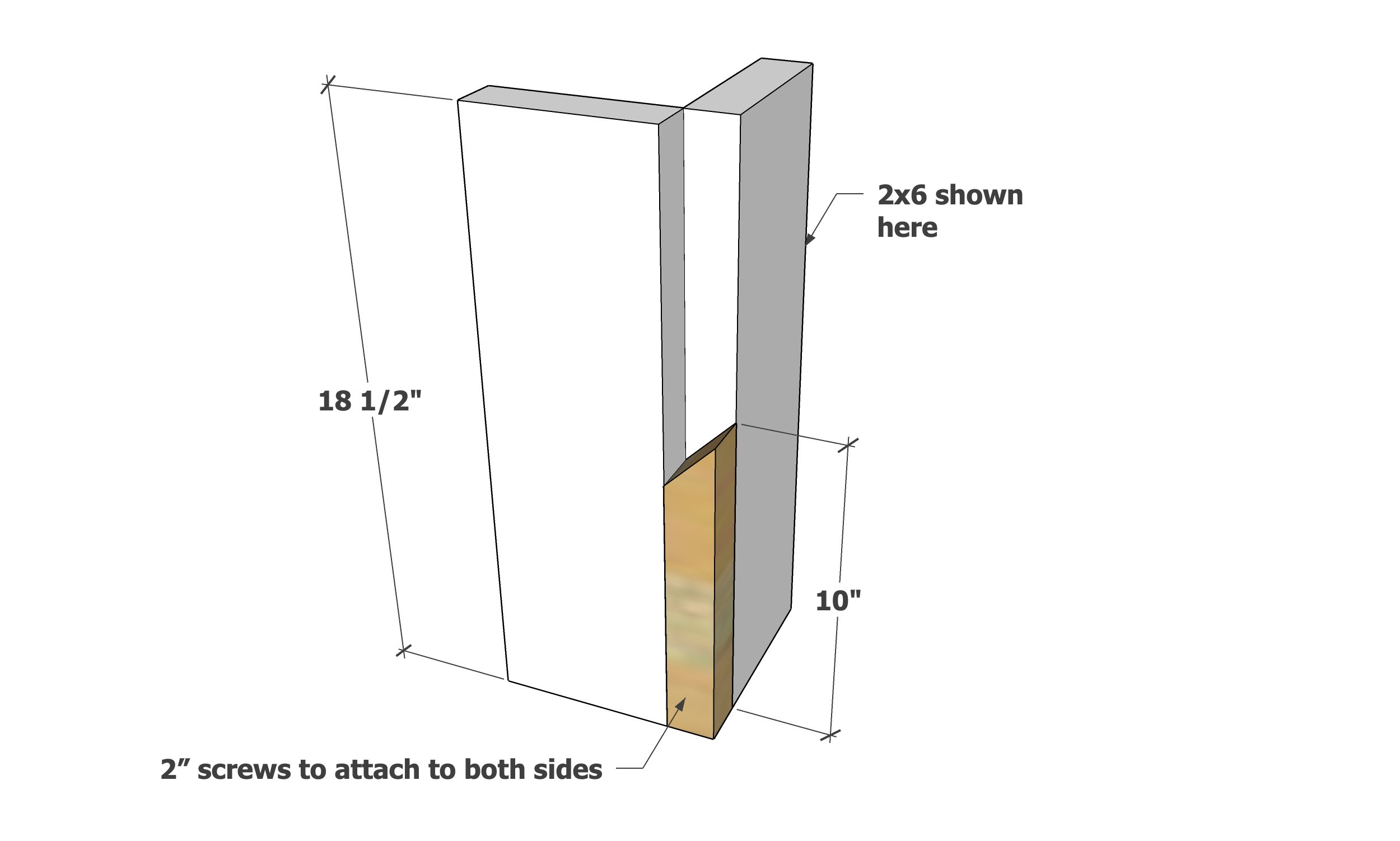

For 2x6 Side Table

- 4 - 2x6 @ 18-1/2"

- 2 - 2x2 @ 10" - long point measurement, one end cut at 45 degrees

- 3 - 2x6 @ 16-1/2"

Instructions

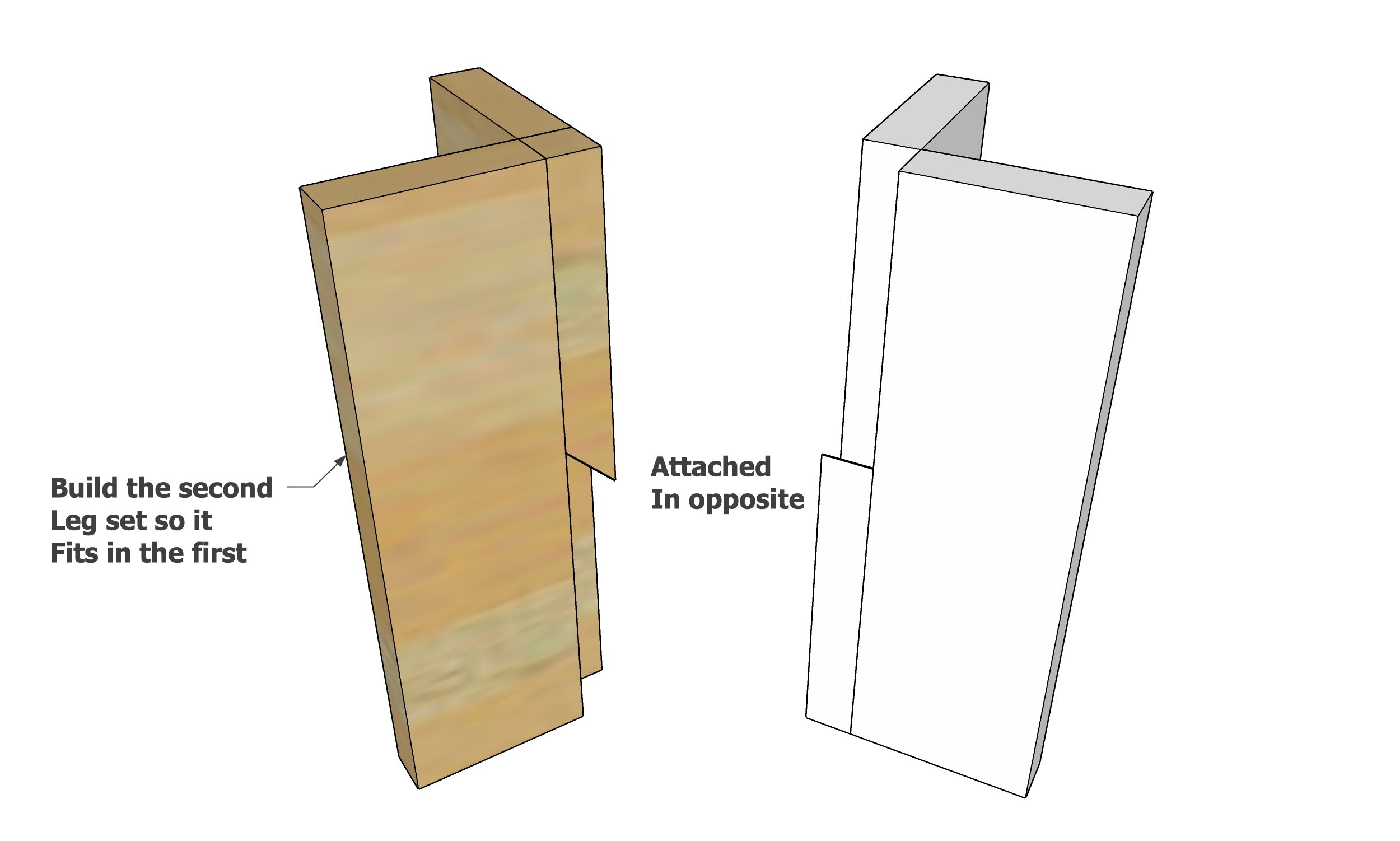

Step 1

Step 2

Step 3

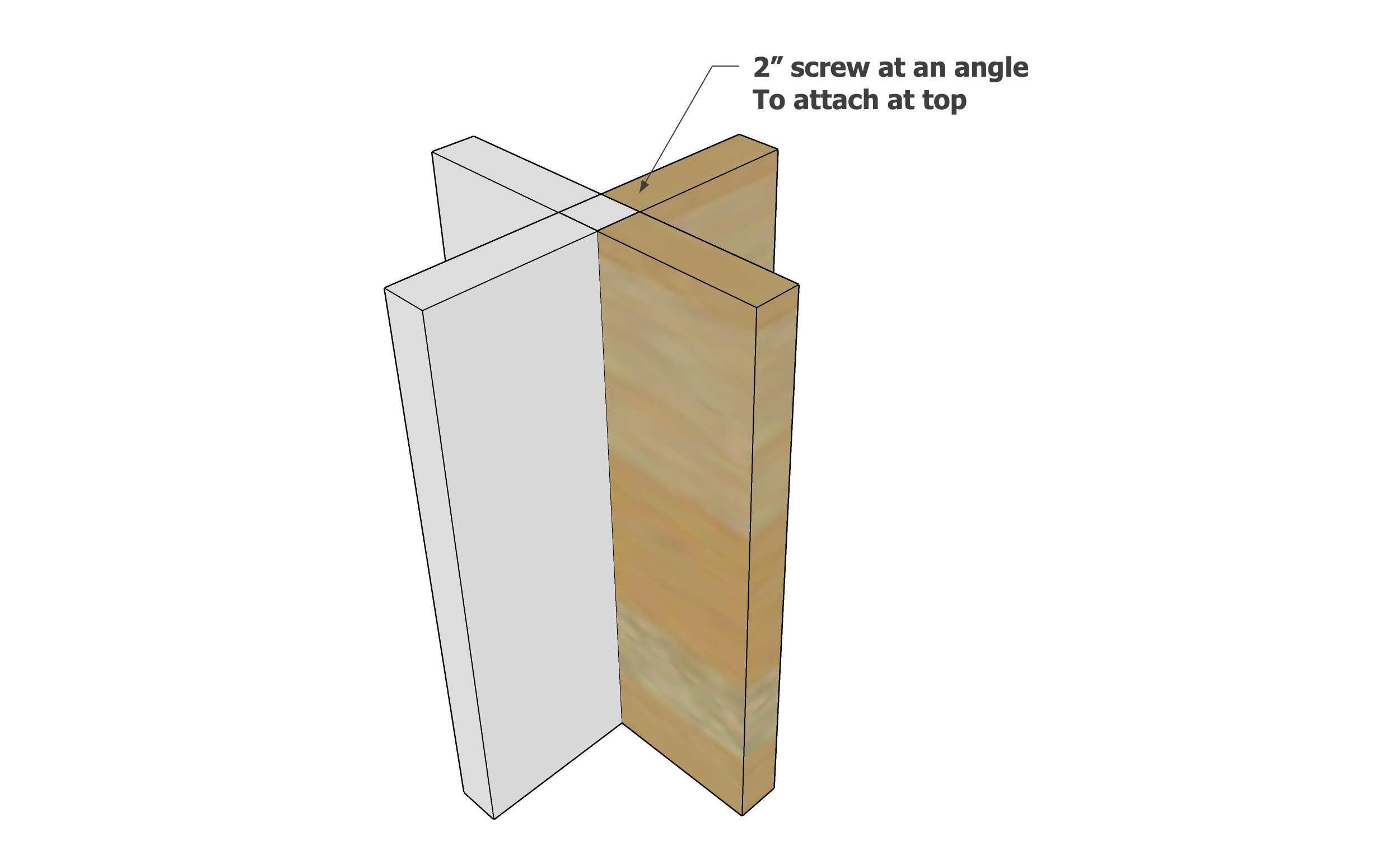

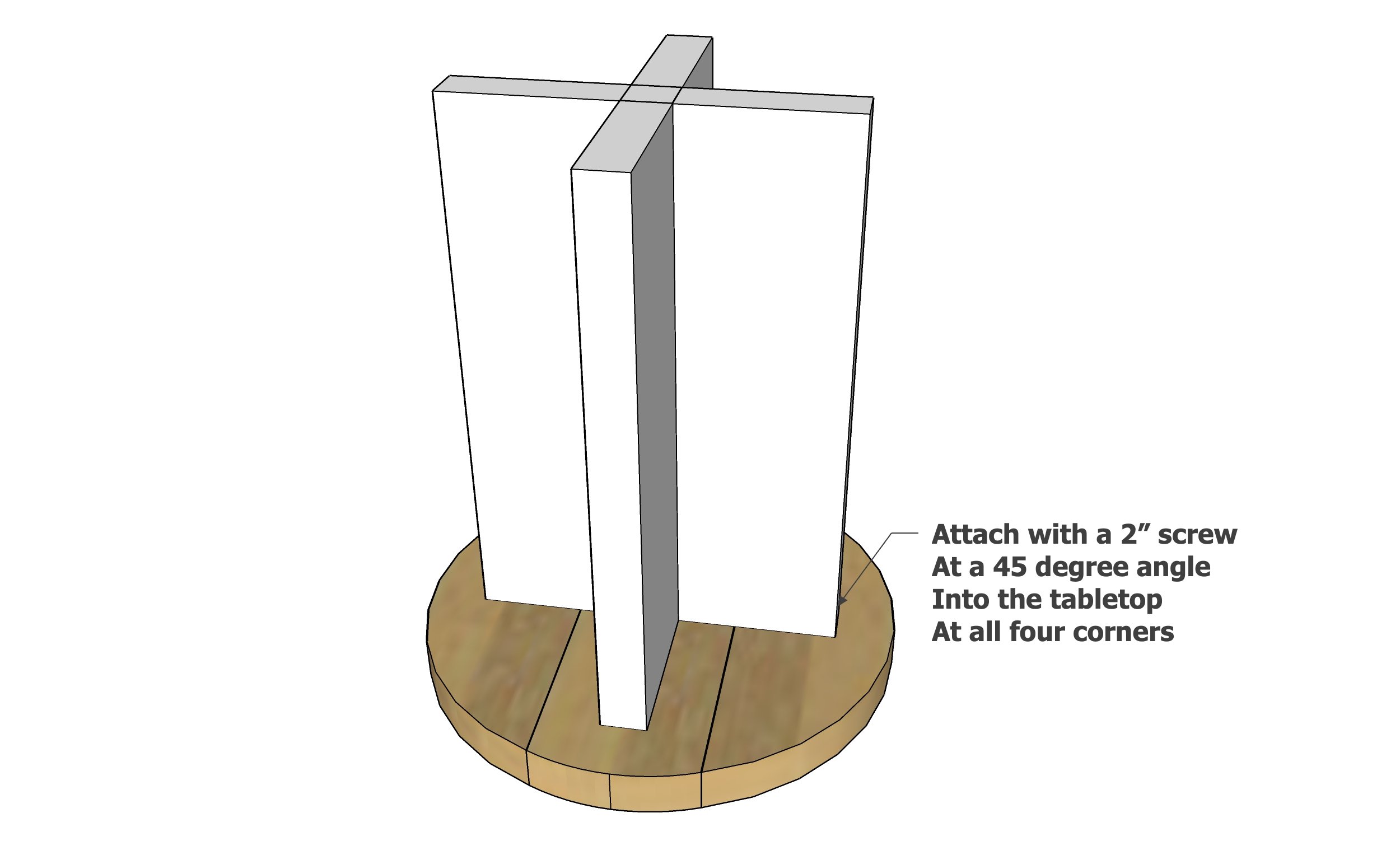

Set the two pieces together and lock in. Then attach at the top and bottom with 2" trim screws at an angle.

To attach the screws at an angle, first start the screw as normal, but once the screw is about 1/2" in, begin to rotate it as you drive the screw so it finishes screwing in at a 45 degree angle. Practice this technique first on a scrap wood piece.

Repeat the screws for the bottom of the legs set.

Step 4

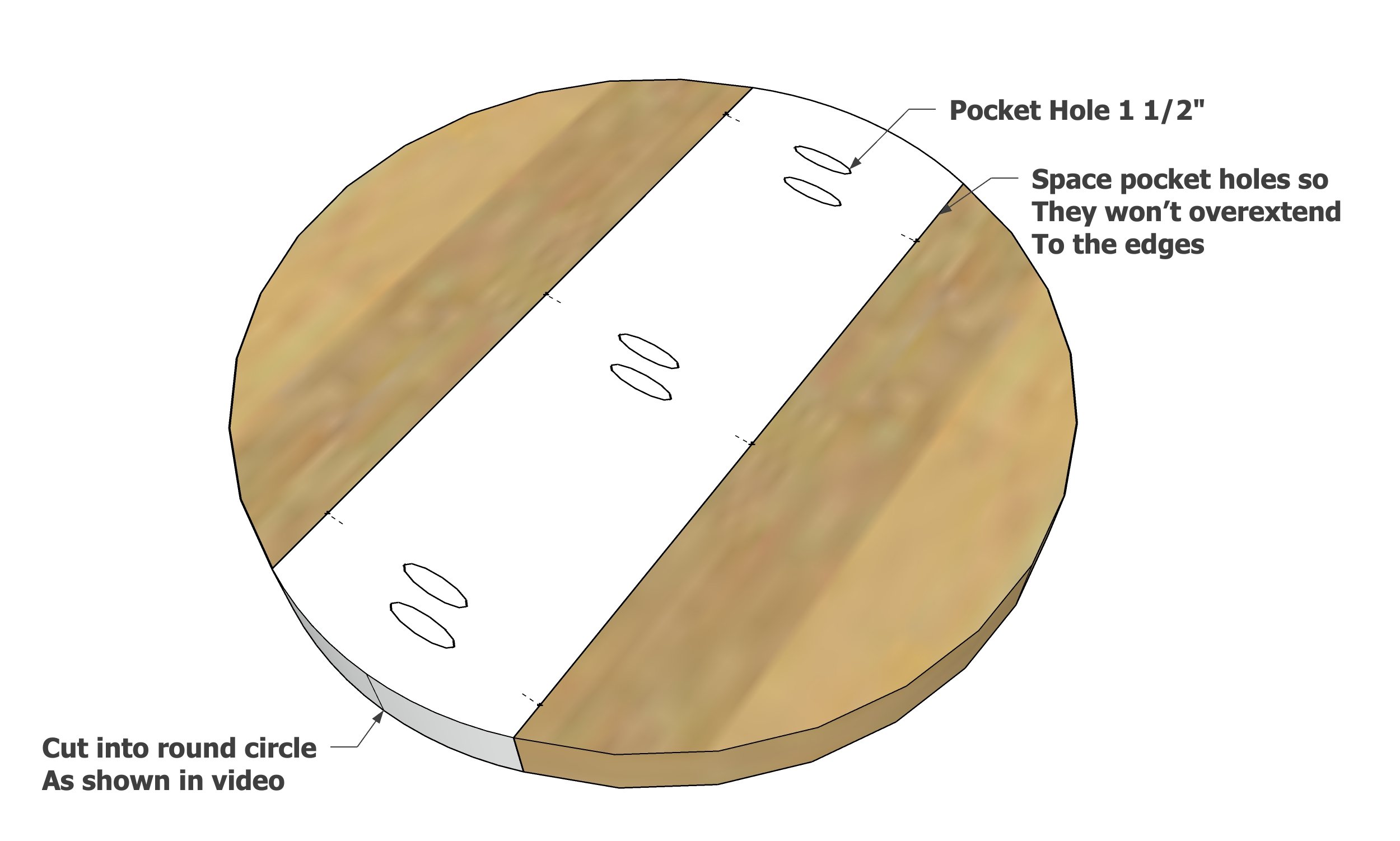

Cut the tabletop boards. Then layout and mark out the circle cuts. Carefully place pocket holes so the pocket holes won't show when the circle is cut.

Drill 1-1/2" pocket holes and attach together with 2-1/2" pocket hole screws.

Cut the tabletop - in the video I used a circular saw, but a jigsaw, bandsaw, router or tablesaw could also be used.

Remove all sanding residue with a vacuum and then wipe off any remaining with a damp, lint free cloth.

It was too orange and transparent, so I added a layer of whitewash (white paint watered down and wiped off)

I finished with a coat of polyurethane.

A final 220 grit light sanded was done to make the project super smooth.