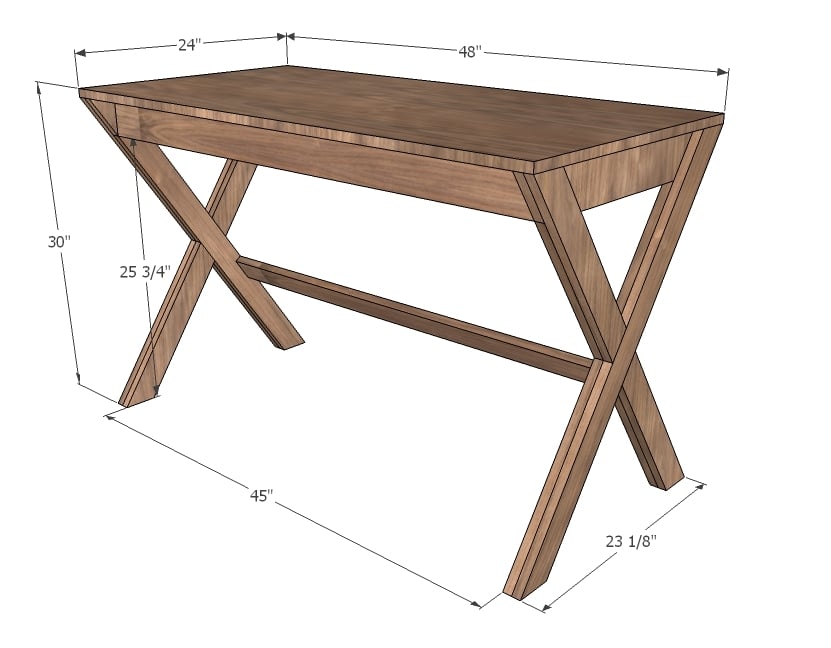

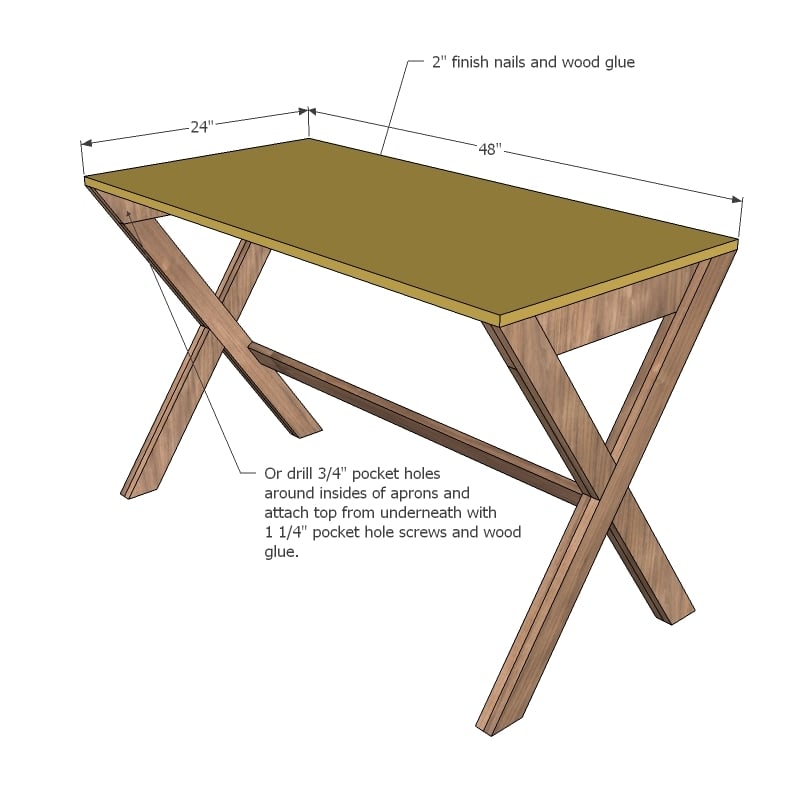

Build a X desk with these free easy do it yourself plans! Features step by step instructions, detailed diagrams, cut list and shopping list.

Preparation

6 - 1x3 @ 8 feet long - Shop around for 1x3s with very sharp, square edges

1 - 1x4 @ 12 feet long

1 - 3/4" plywood or other project panel 24" x 48" suitable for desktop use

1 - 1/4 sheet 1/4" plywood or hardboard

2 - 16" Euro style drawer slides (the cheap white ones that attach to the bottom corners of the drawers)

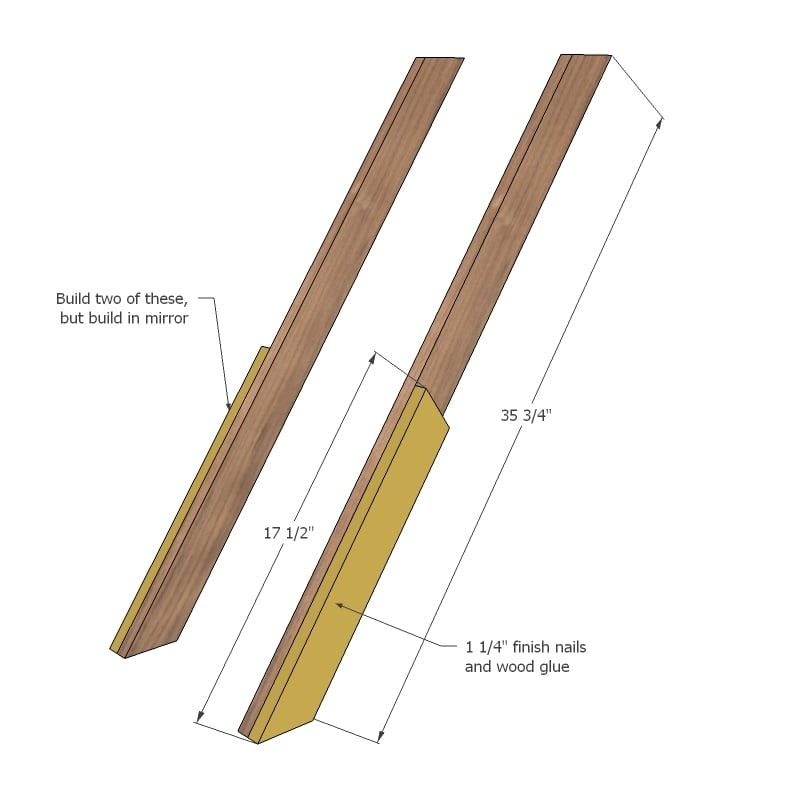

2 - 1x3 @ 35 3/4" - Both ends cut at 35 degrees off square, ends are parallel to each other

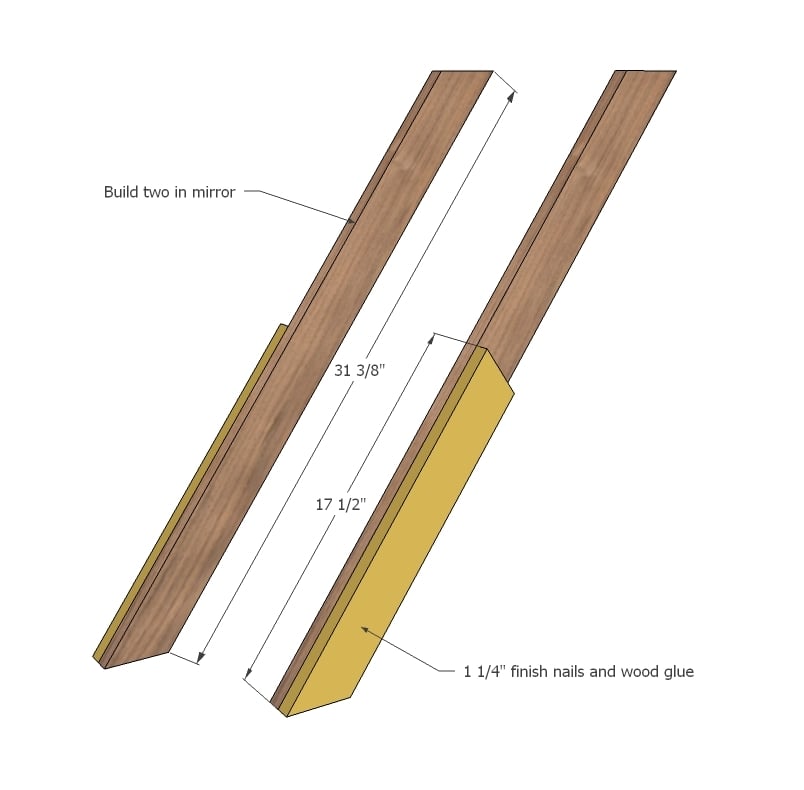

2 - 1x3 @ 31 3/8" - Both ends cut at 35 degrees off square, ends are parallel to each other

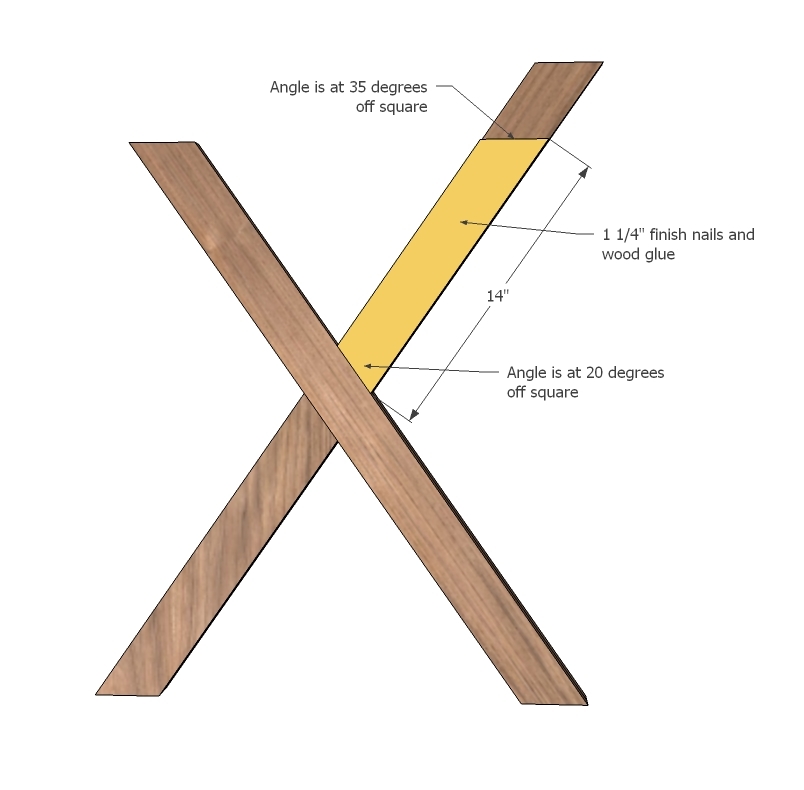

4 - 1x3 @ 17 1/2" - One end cut at 20 degrees off square, other end cut at 35 degrees off square, measurement is longest points - SEE IN STEP 1 AND 2

2 - 1x3 @ 14" - One end cut at 20 degrees off square, other end cut at 35 degrees off square, measurement is longest points - SEE IN STEP 4

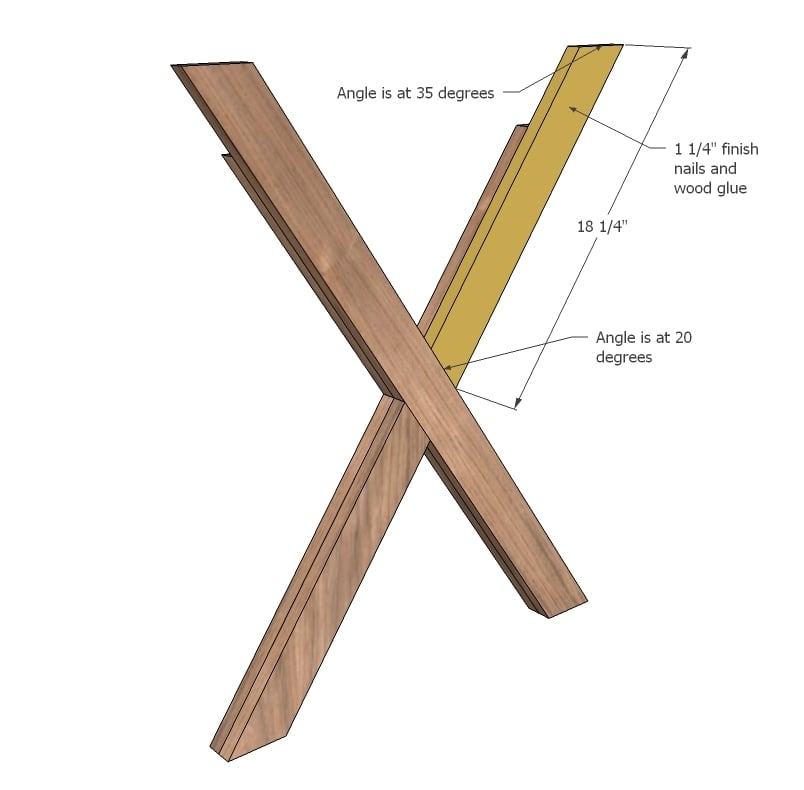

2 - 1x3 @ 18 1/4" - One end cut at 20 degrees off square, other end cut at 35 degrees off square, measurement is longest points - SEE IN STEP 5

2 - 1x4 @ 24" - Both ends cut at 35 degrees off square

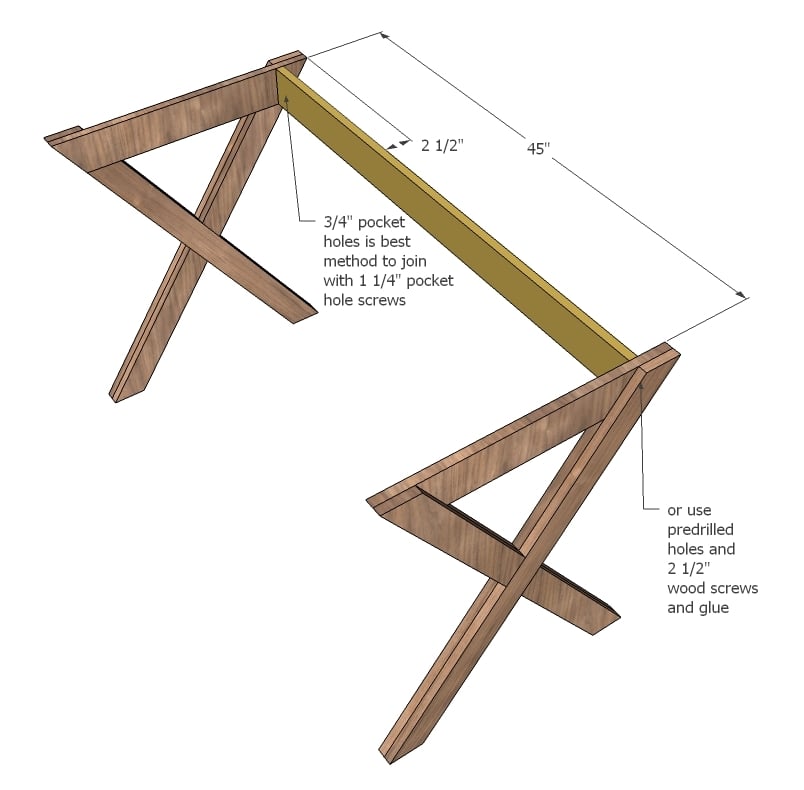

2 - 1x4 @ 45"

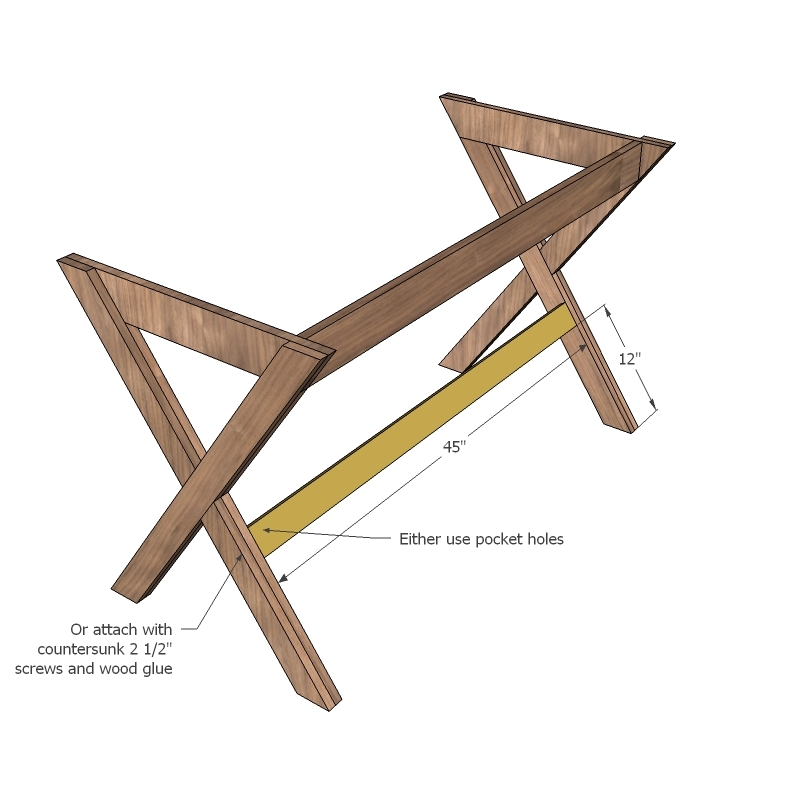

1 - 1x3 @ 45"

1 - 1/4 sheet plywood or other project panel 48" x 24"

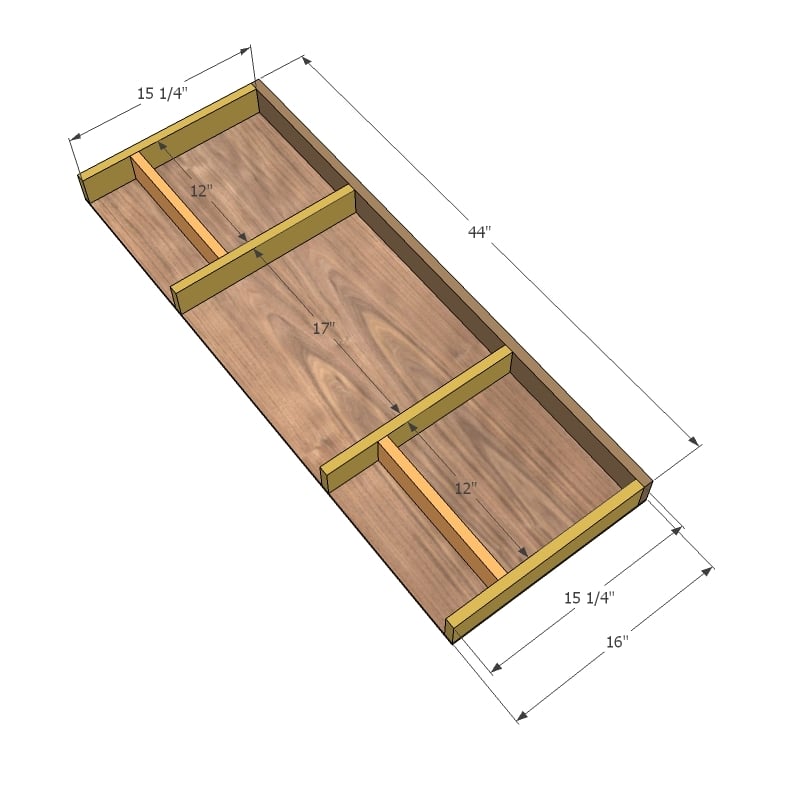

Drawer

4 - 1x3 @ 15 1/4"

2 - 1x3 @ 12"

1 - 1x3 @ 44"

1 - 1/4" plywood or hardboard @ 44" x 16"

Please read through the entire plan and all comments before beginning this project. It is also advisable to review the Getting Started Section. Take all necessary precautions to build safely and smartly. Work on a clean level surface, free of imperfections or debris. Always use straight boards. Check for square after each step. Always predrill holes before attaching with screws. Use glue with finish nails for a stronger hold. Wipe excess glue off bare wood for stained projects, as dried glue will not take stain. Be safe, have fun, and ask for help if you need it. Good luck!

Instructions

Step 1

It would be a good idea to lay out your legs first. A dry run will minimizes mistakes later.

Start with the two longest leg pieces. Notice you will need to build two leg sets that are mirrored. Attach the 17 1/2" long leg pieces to the bottoms with 1 1/4" finish nails and wood glue. Take great care to line edges up - you want to create the illusion of a solid wood leg here. This will save you sanding work later!

Step 2

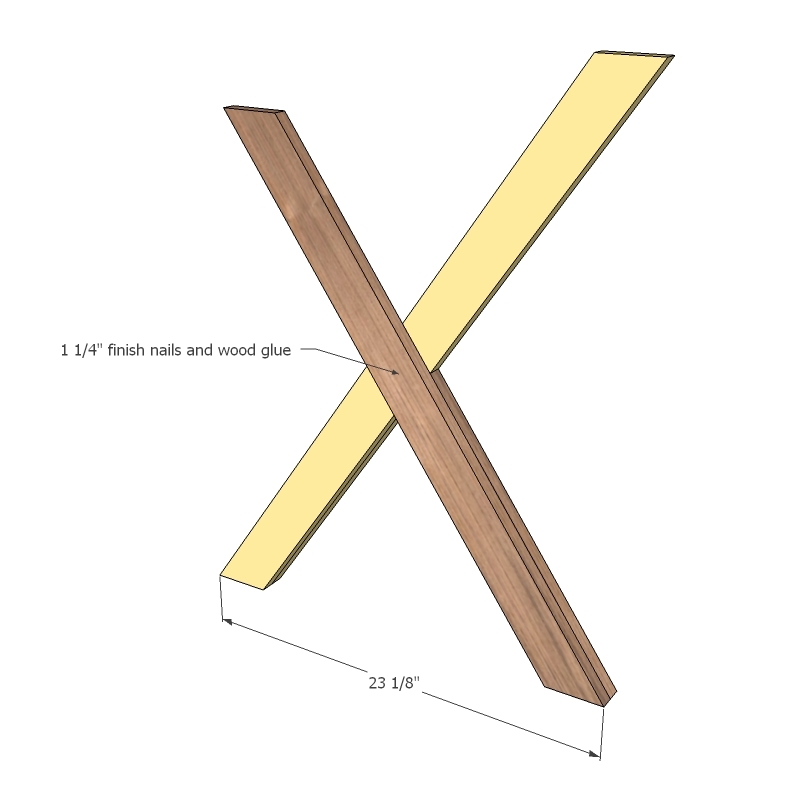

Step 3

Step 7

Step 9

Step 10

Step 11

Attach drawer members to drawer bottom side corners. Attach cabinet members to insides of desk. Follow the instructions in this plan for installing drawers.

It is always recommended to apply a test coat on a hidden area or scrap piece to ensure color evenness and adhesion. Use primer or wood conditioner as needed.

Comments

Lady Goats

Tue, 10/18/2011 - 11:07

YAY! I've LOVED this!

But was never really motivated to figure it out because it looked too tough! THANK YOU!

RHgaijin2

Wed, 10/30/2019 - 19:53

I just completed this and…

I just completed this and made a step by step video. I also posted my brag post too. Mine is the one with the Batman Theme

https://youtu.be/-1gZv50vfN4

Francoise

Tue, 10/18/2011 - 16:49

My dream desk!

I am thrilled. I am delighted. I love this Crate and Barrel desk but couldn't stand the idea of paying over $600 for it. It's the reason I decided to take up woodworking again and then I couldn't find any patterns. Thank you!

LAMD (not verified)

Tue, 10/18/2011 - 18:17

Glass Top?

I've been looking for a table with "X" legs and a glass top and am so excited about this plan. Do you think this would support a glass top? If not, any way to reinforce it so it does? Thanks!

Hillary (not verified)

Tue, 10/18/2011 - 18:39

Glass top

I bet it would be fine if you used at least 1/4" glass and did both the front and back aprons. Maybe even one more support across the middle, parallel to the aprons? You could probably show the plan to your local glass store and get a good answer.

In reply to Glass top by Hillary (not verified)

Ana White

Wed, 10/19/2011 - 09:51

Couldn't say it better than

Couldn't say it better than Hillary did!

LAMD (not verified)

Tue, 10/18/2011 - 18:48

Good idea, thanks! I checked

Good idea, thanks! I checked and a 1/2" thick piece would weigh about 70 lbs. Will definitely look into it.

Stephen (not verified)

Thu, 10/20/2011 - 18:36

PDF file

Rut Roh, I think something went wrong. The link to the PDF file is throwing this error.

TCPDF ERROR: [Image] Unable to get image: file:///home/anawhite/public_html/dev/acquia-drupal-1.2.33/sites/default/files/x%20desk%20pottery%20barn%20crate%20barrel%20plans%203.jpg?1318959564

BTW, I love this desk. I can finally gift this cheap Walmart one I've been using and make a REALLY good and sturdy one.

Thank You.

Guest (not verified)

Sat, 11/05/2011 - 05:51

hey id like to modify the

hey id like to modify the design a bit because i already have the panel for a desktop but im a first timer and quite terrible at design. the size of my board is 29 1/2 x 61 (inches)and i dont know how this affects the angles of the legs which is mymain problem

jesmith11 (not verified)

Fri, 06/08/2012 - 21:04

Adding a plank top

Hello! I love this plan for a desk and think I may have to craftsy soon! Just curious, would there be anyway anyone could think of to make this desk with planks across the top? As a novice builder, I wasn't sure if you could just attach planks to the top without taking away the look of the desk. I am looking for a farmhouse top to the desk I guess. Any thoughts? Thank you for the design!

Jennifer@The C… (not verified)

Fri, 07/27/2012 - 14:51

Brilliant Carpentress

Ana, if you lived in Boston, MA instead of AK I'd track you down and kiss you right now! I love building furniture from scratch and have been working on a set of x-leg stools the past few days and the assembly part has been giving me fits. Just couldn't get the legs together sturdily enough to bear weight. And then I came to this plan, and ah-hah! There is the solution! Thanks so much for sharing your expertise with the world - you've saved me a weekend full of frustration and brain wracking.

anniemar

Thu, 01/22/2015 - 08:04

Love this plan

I love the look of this desk and trying to decide between this and the fancy X desk. Is this desk sturdy? Any wobbling? I'm also think about doing 3 drawers across the front instead of just one large one. The drawers would probably make it a bit more difficult though. Thank you for the feed back!

Phhiggins

Tue, 08/18/2020 - 09:21

X Desk with Drawer

I love this desk and all of Ana White's plans! I may be missing something, but photo of the drawer only shows 3 sides and I did not see anything in the cut list for the front of the drawer box. I also didn't see anything for the drawer front. Is there not a drawer front cut piece?