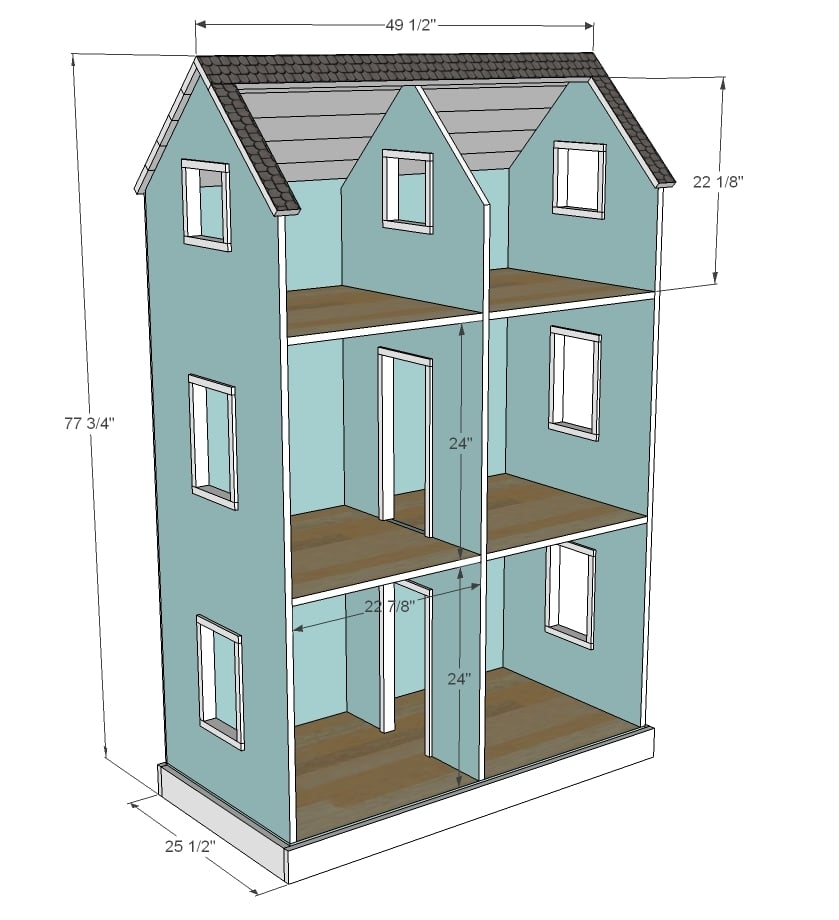

Free American Girl Dollhouse / 18 Inch Dollhouse Plans. This three story dollhouse features five large rooms. It's easy to build with our step by step diagrams, shopping and cut list, and lots of reader submitted photos.

We also have lots of American Girl furniture and accessory plans.

Pin For Later!

Preparation

- 2 - sheets 3/4" plywood or MDF

- 1 - sheet 1/4" plywood or MDF (for back)

- 6 - 1x4 @ 12 feet long (add another one for the base if desired)

- 4 - 1x2 @ 8 feet long

- 1-1/4" pocket hole screws

- 1-1/4" finish nails or staples

WALLS AND FLOORS

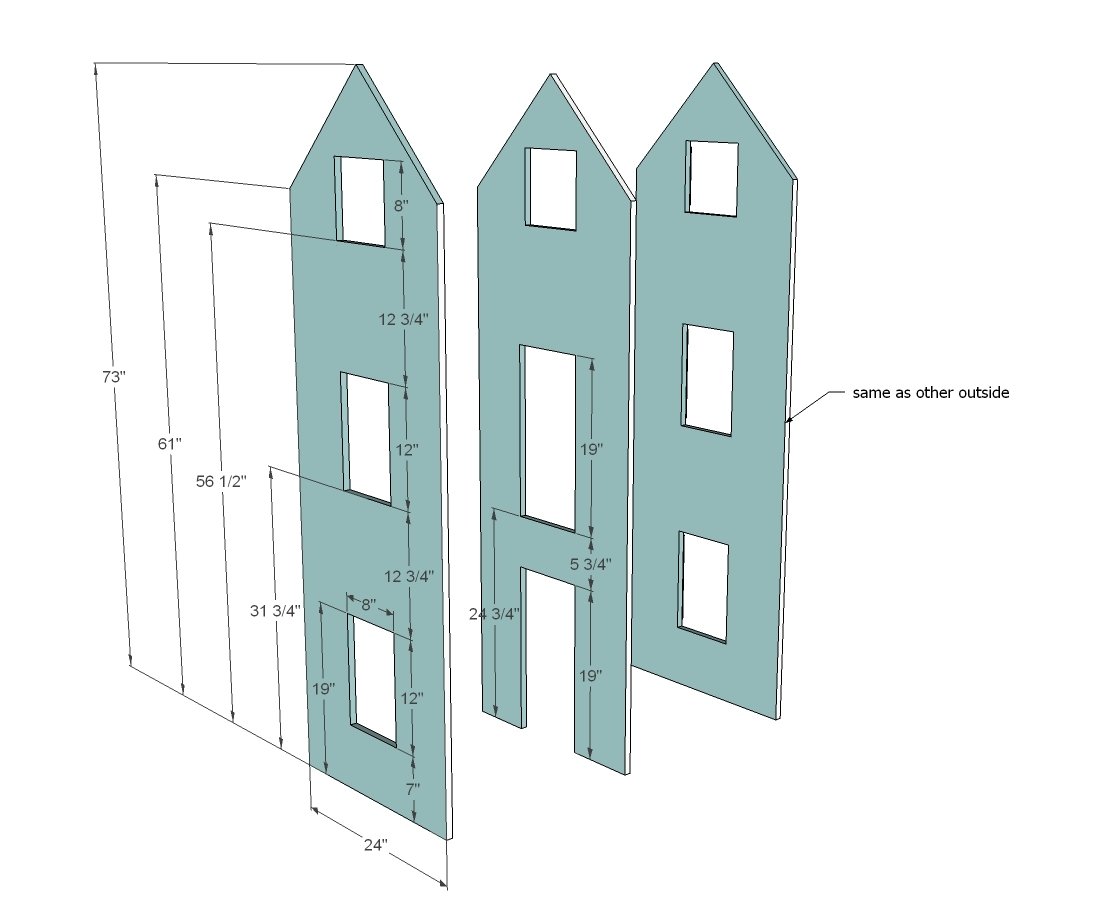

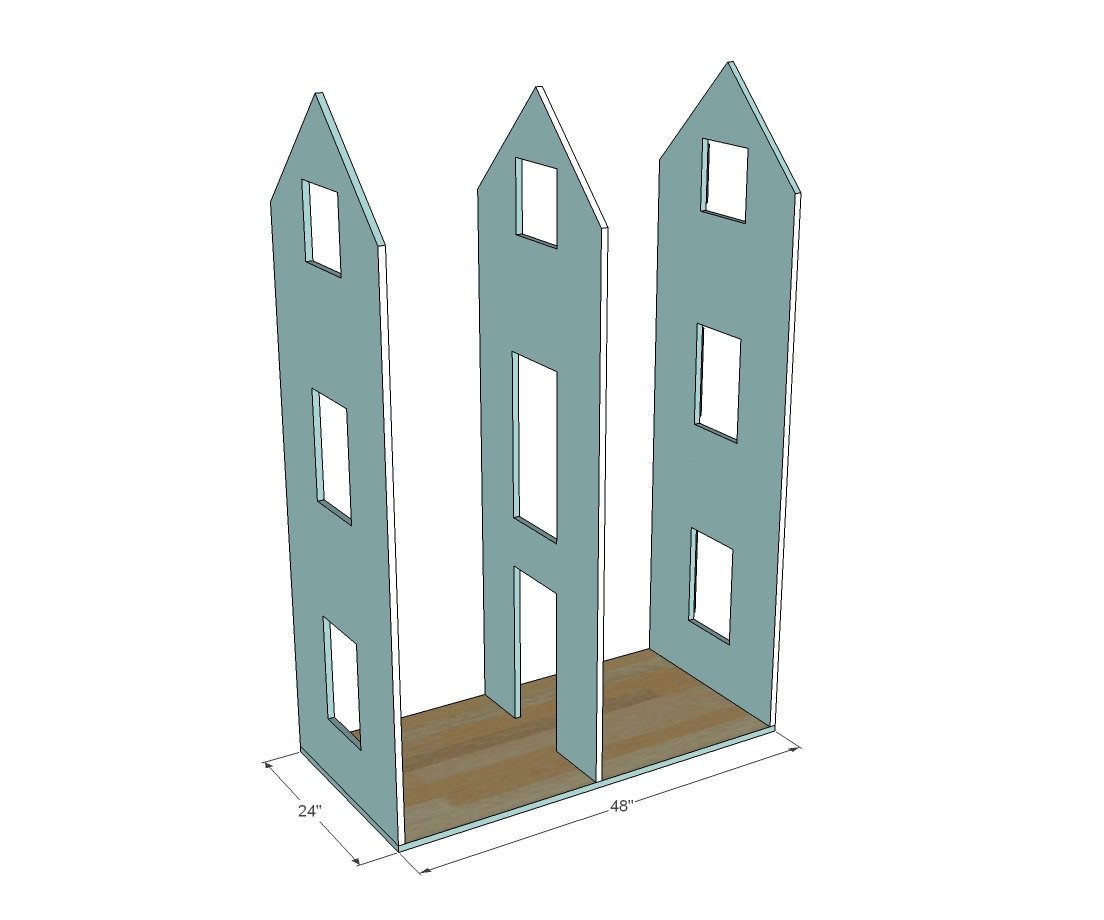

- 3 - 3/4" plywood or MDF @ 23-3/4" x 73" (sides and center divider)

- 1 - 3/4" plywood or MDF @ 23-3/4" x 48" (bottom)

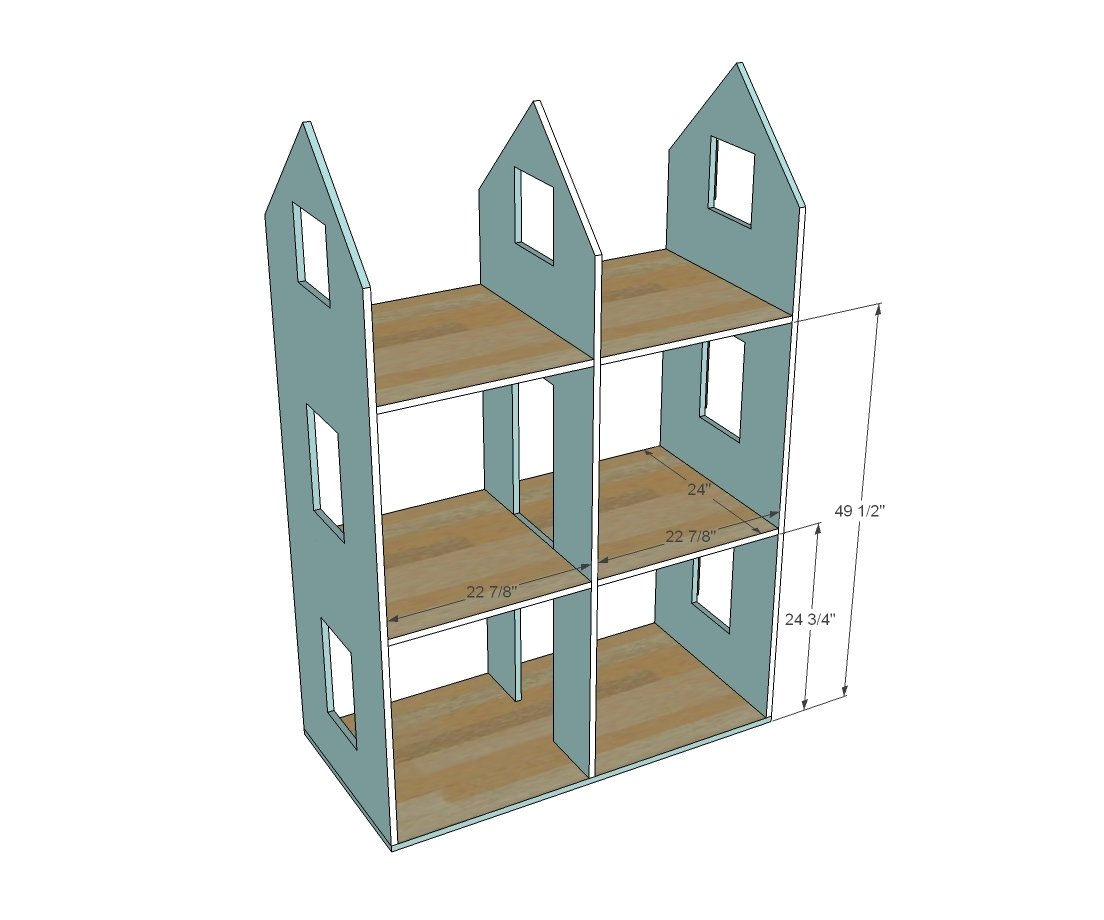

- 4 - 3/4" plywood or MDF @ 23-3/4" x 22-7/8" (upper floors)

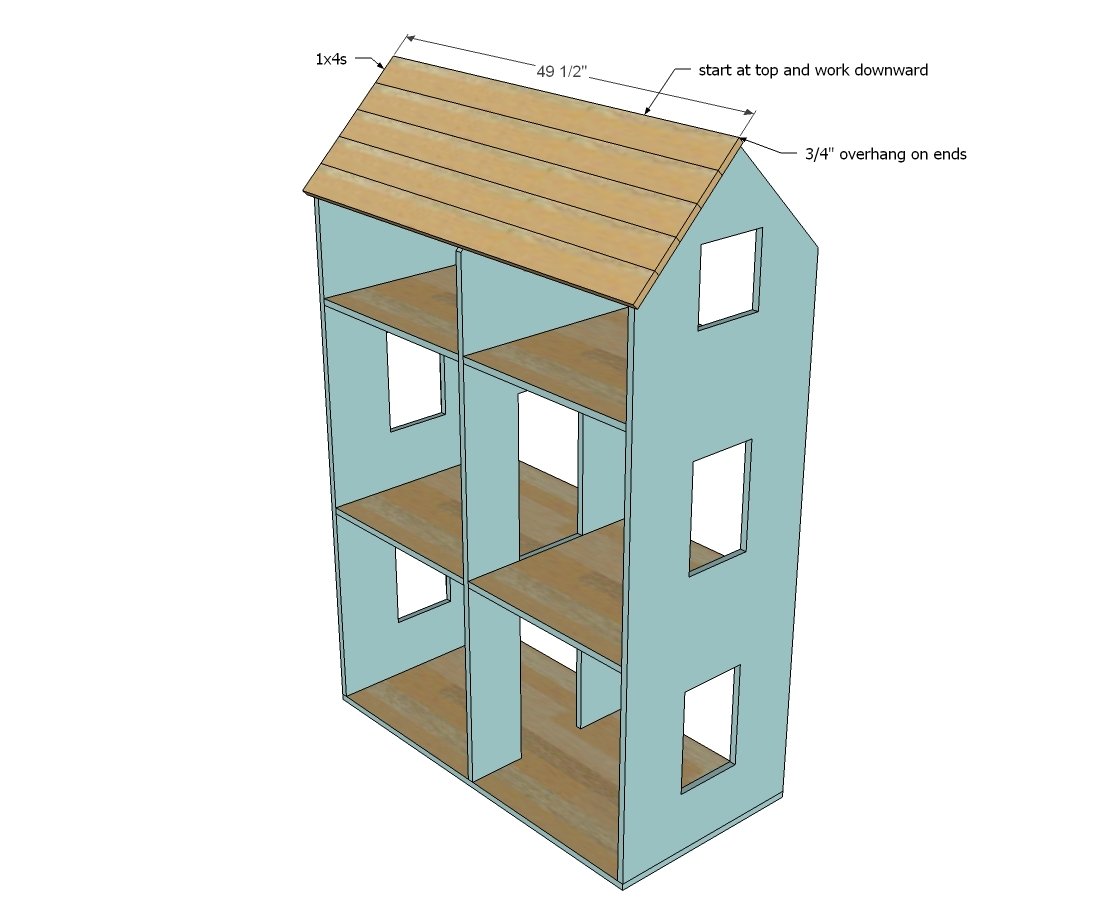

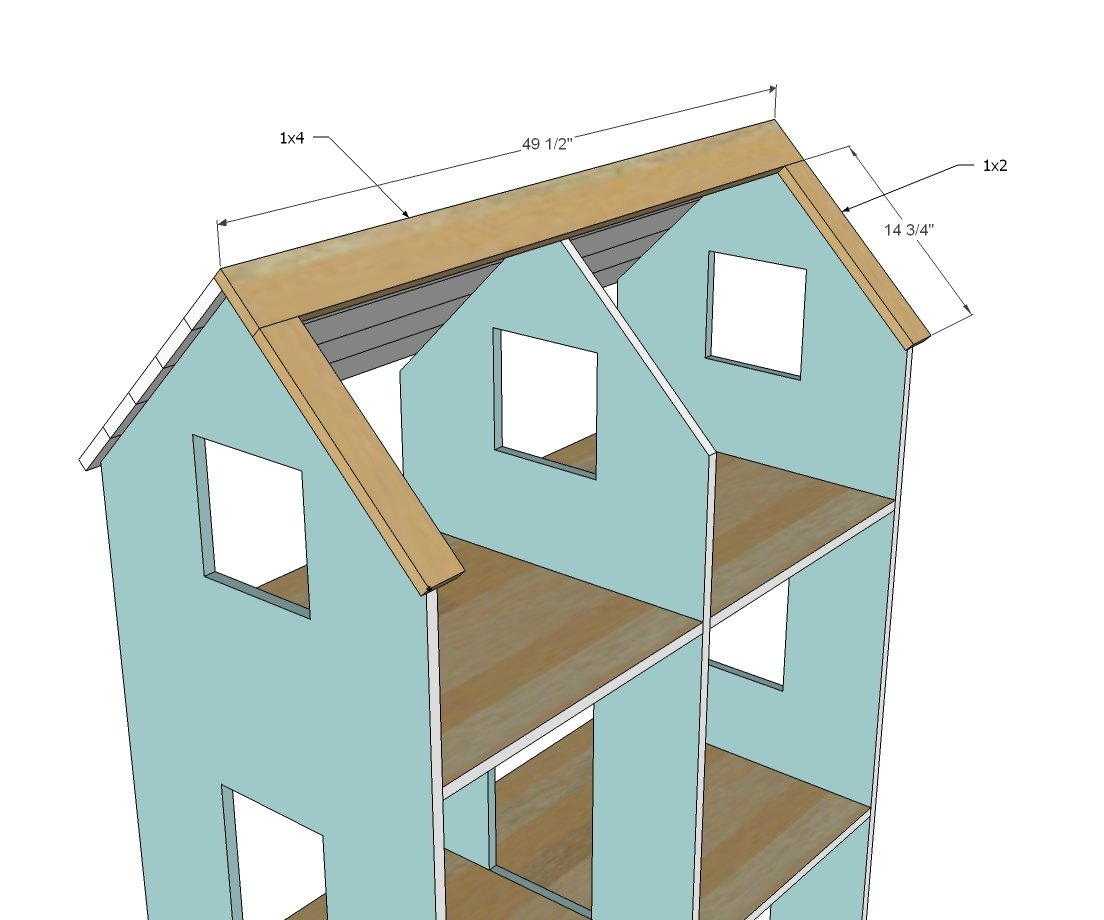

ROOF

- 5 - 1x4 @ 49-1/2" (OR 1- 3/4" plywood @ 49-1/2" x 17-1/2" (measure and cut to fit))

- 1 - 1x4 @ 49-1/2"

- 2 - 1x4 @ 14-3/4"

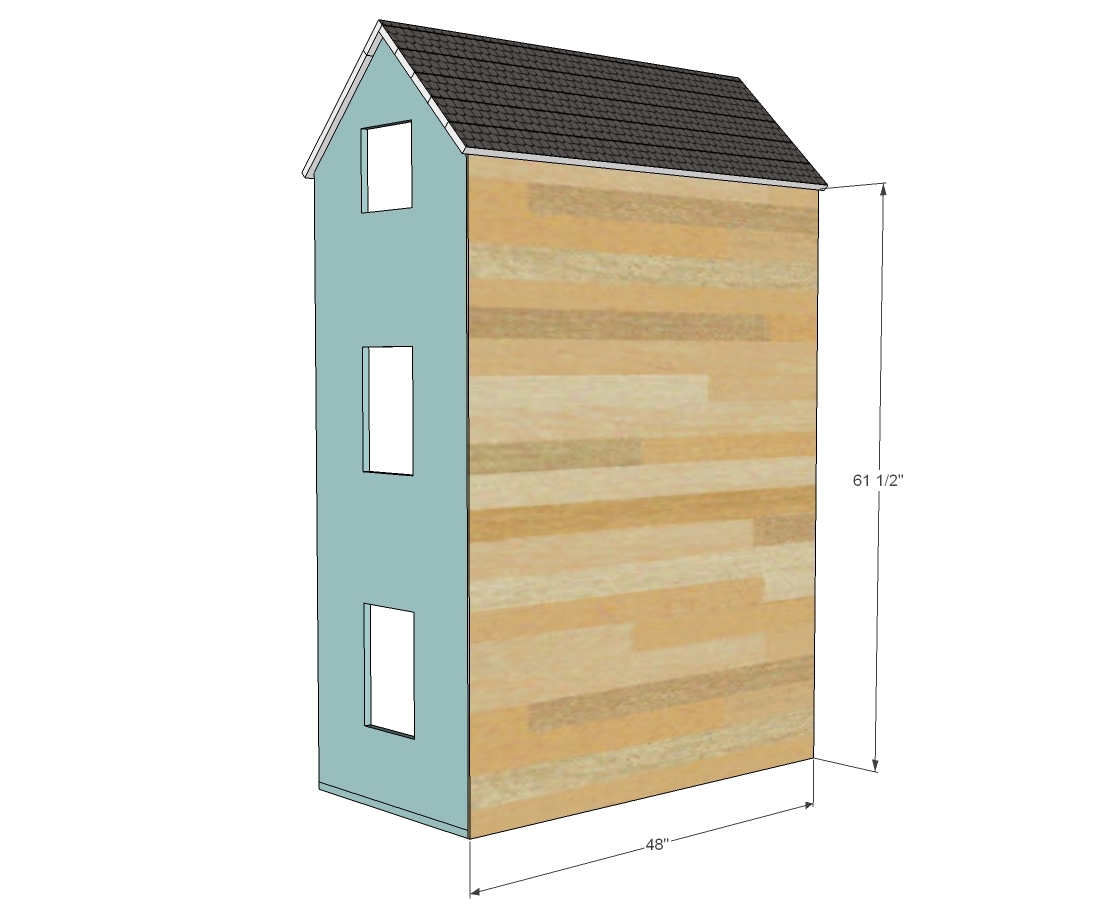

BACK

- 1 - 1/4" plywood @ 48" x 61-1/2"

WINDOWS - CUT TO FIT

Please read through the entire plan and all comments before beginning this project. It is also advisable to review the Getting Started Section. Take all necessary precautions to build safely and smartly. Work on a clean level surface, free of imperfections or debris. Always use straight boards. Check for square after each step. Always predrill holes before attaching with screws. Use glue with finish nails for a stronger hold. Wipe excess glue off bare wood for stained projects, as dried glue will not take stain. Be safe, have fun, and ask for help if you need it. Good luck!

Instructions

Step 1

First, cut out all the pieces. If you don't have a truck or tablesaw, it might be easier to have your home improvement store rip your plywood into 22-3/4" widths, 8 feet long. Then cut the longest pieces first. The top roof angle is 45 degrees. You can easily find this by finding the center of your side and middle panels (at the top). This distance should be 11-7/8" from the sides. Then measure down 11-7/8", and draw a diagonal between the two points. Then mark out all windows and doors and cut out with a jigsaw.

Step 2

Step 3

Step 4

Step 5

Step 7

Step 8

It is always recommended to apply a test coat on a hidden area or scrap piece to ensure color evenness and adhesion. Use primer or wood conditioner as needed.

Comments

jimmypaul

Sat, 04/05/2014 - 11:02

all projects

PDF . is anyone having problems downloading plans on PDF , I checked several projects an it appears that the PDF is not working ,, or is it just onmy end ????

Thank You

Mom24girls

Thu, 02/05/2015 - 17:31

Price

Is the price $100-$150 if you have wood on hand? I just left Lowes and one piece of nice plywood would be $50! Any help would be amazing!!!

Ana White Admin

Fri, 02/06/2015 - 11:25

Varies

Hi, the price can vary from town to town. Having scraps on hand can help cut down on cost. It would probably be closer to $200, if that is the price where you live. I would call around and try the price match and beat by 10% if possible. Hope this helps!

pwrcarpenter

Thu, 10/22/2015 - 03:42

stronger floors

If you make the floors run all the way across and cut the center divider into 3 pieces this will

make the floors much stronger with less sag and less chance of screws pulling out.

since the picture shows a little girl sitting on the floor I would highly suggest this. :)

dustintphelps

Tue, 11/24/2015 - 14:26

A Little Help Please!

I am looking at the cut list and wondering how this was made with only 2 sheets of 3/4 plywood. Seems as though you would need 3. Am I missing something here?

In reply to A Little Help Please! by dustintphelps

Stephen Peters

Wed, 11/25/2015 - 17:10

How many sheets of 3/4" plywood

Hi dustintphelps,

I just looked over the cut list and you can get this doll house out of two sheets of 3/4" Plywood......as long as the roof is made from 1x4's. It could be missed that the three upright peices will have about 24" left over to make the floor peices. I hope that helps. Have fun with your build! ~Stephen

Piesq

Tue, 12/01/2015 - 12:11

Unless I am missing something

Unless I am missing something, there is no way this can be built with only two 4' x 8' sheets of plywood. The two outside pieces take up basically one full sheet. the middle piece takes up half of a second sheet, leaving you with about a 2' x 8' piece. This remaining 2' x 8' piece gets split in half, leaving two 2' x 4' pieces, used for the bottom floor and middle floor. You now are left with nothing but random scraps from the two plywood sheets and no floor for the third floor.

smitjd

Sat, 12/05/2015 - 16:33

Your correct, I just

Your correct, I just completed this build, and the material list shows everything for the house in the photos with the little girl sitting inside. If you notice the diagrams are different. Once you make your cuts for the outside walls, you will have 2 pieces that would be used for the inside walls on the first and second floors, as you can see the third floor in the pictures does not have a middle wall, unlike the diagram.

amyg74

Mon, 12/07/2015 - 05:35

window and door frames

Are the window and door frames made out of the 1x2s? I have completed the steps for cutting the outside, walls, windows and doors, and now I am on framing them. I want to be sure I am using the rigt size pieces to frame. Please confirm that the 1x2s are for the window frames. thank you.

In reply to window and door frames by amyg74

Ana White

Wed, 12/09/2015 - 17:57

Yes 1 x 2's measure and cut

Yes 1 x 2's measure and cut to fit your window openings as you go.

JLynn

Fri, 12/25/2015 - 13:54

Question

I LOVE this house! My plan is to go to Lowes/Homd Depot and play helpless asking them to do my cuts for me. I don't own a saw out a fear my spouse would get "brave" and try some project and chop off his fingers LOL, but we can follow plans. SOOOOOO I think we'll be ok with this?

My question is if you make the floors go all the way across and cut the middle into small sections, does it make the floor stronger? My plan is to add 2 inches in width to each room?

nbarnhouse

Wed, 01/29/2020 - 07:34

Built with little experience - hard but not impossible

Had the hardest time cutting out the squares for the windows. They were not straight, but once I trimmed them, they weren't as noticeable. Someone mentioned in the comments above to not cut the horizontal shelves, so that is what we did. Left those boards long and then cut the vertical wall boards and used them to help support the "floors". I hit a lot of snags, but was able to complete it and my daughter loves it. I'd say I spent $250. I did save a lot of trouble by checking the purchase list against the cut list and double checking all measurements. It turns out only some plywood is exactly 48" wide, most is not.

mr500

Mon, 11/16/2020 - 08:37

If you go over to CutList…

If you go over to CutList Otimizer (google it) and put in the cut list it will show you how to cut the pieces . You can get it all out of 2 sheets. CO is free and its web based so nothing to DL

And NO this is not spam or click bate lol