Easy how to build reclaimed wood salvaged look rolling shelf - modern industrial style.

Preparation

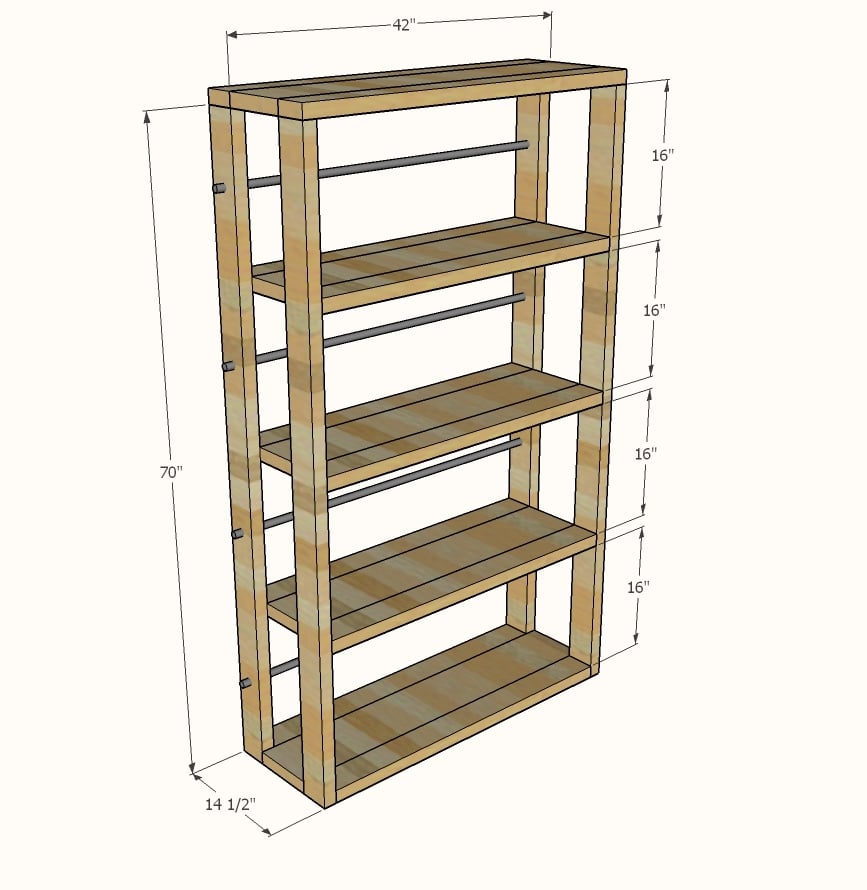

2 - 2x4 @ 12 feet long (cut legs out of these)

5 - 2x4 @ 8 feet or stud length (cut shelf boards out of these)

1 - 2x8 @ 12 feet long

1 - 2x8 @ 8 feet long

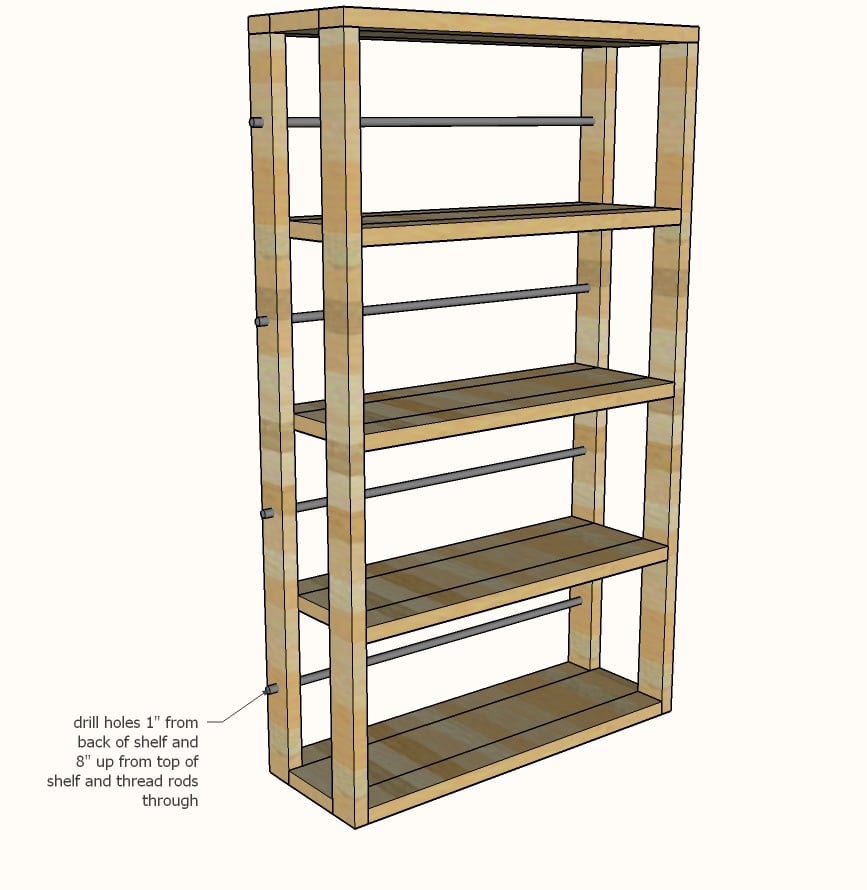

16 feet of 1/2" pipe (I used EMT spray painted black)

8 - corner brackets

4 - caster wheels

2 - 2x4 @ 42"

8 - 2x4 @ 39"

3 - 2x8 @ 39"

2 - 2x8 @ 42"

4 - 2x4 @ 70"

Please read through the entire plan and all comments before beginning this project. It is also advisable to review the Getting Started Section. Take all necessary precautions to build safely and smartly. Work on a clean level surface, free of imperfections or debris. Always use straight boards. Check for square after each step. Always predrill holes before attaching with screws. Use glue with finish nails for a stronger hold. Wipe excess glue off bare wood for stained projects, as dried glue will not take stain. Be safe, have fun, and ask for help if you need it. Good luck!

Instructions

Step 1

Step 2

Step 3

Step 4

It is always recommended to apply a test coat on a hidden area or scrap piece to ensure color evenness and adhesion. Use primer or wood conditioner as needed.

Comments

spiceylg

Thu, 06/25/2015 - 09:35

Love it!

How beautiful! I love it more than the one from RH because of that wood with the saw markings. Besides, their products are ridiculously overpriced! Are you officially moved in now and if so, what will become of that 1/2 of the Momplex that you vacated?

kced01

Wed, 07/01/2015 - 12:20

Love this piece!

Where did you find the hardware and brackets?

Swilliams658

Thu, 02/11/2016 - 08:49

Hardware

Hi Ana! Gorgeous piece. Do you know the size of the casters? Do you have a go-to brand for hardware? Thanks!

Edemardil

Sun, 11/27/2016 - 11:04

Ive bought and read everything.

How the heck do you put the 2x4 and 2x8 together for the shelves?

anita1977

Tue, 11/29/2016 - 07:01

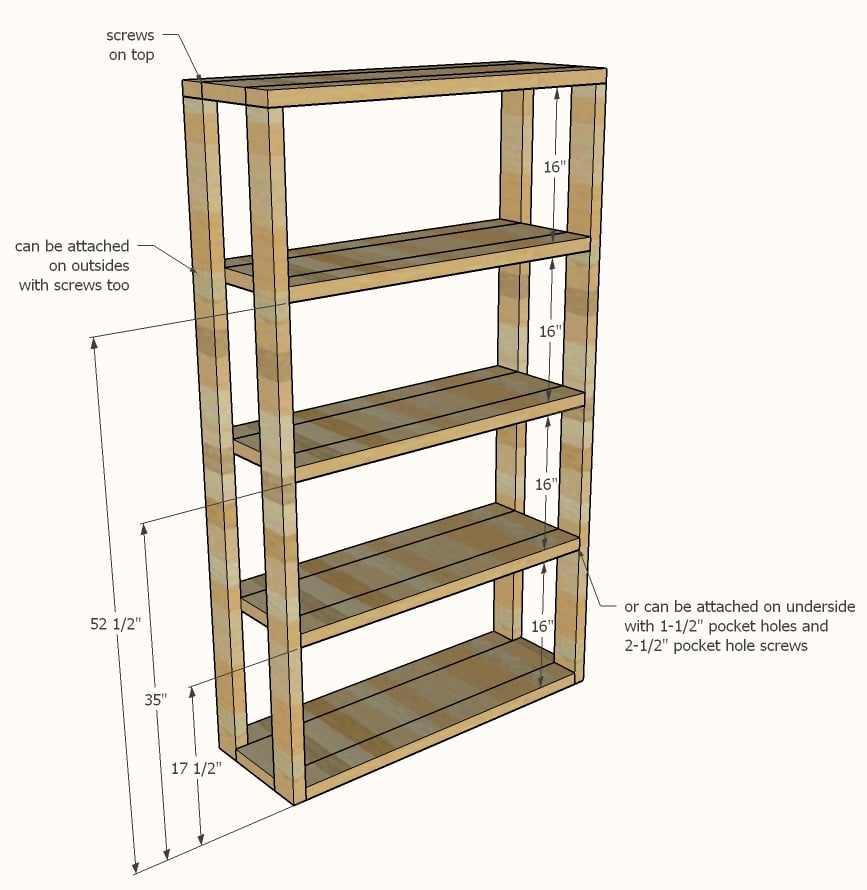

Pocket Holes

First, build all of the shelves as pictured, using 1-1/2" pocket holes and 2-1/2" pocket hole screws. You can also drill pocket holes for attaching legs in next step.

Edemardil

Fri, 12/09/2016 - 08:47

Pocket Holes

So just like that? Not "Drill 2 holes on each ends" or "2 on each end and 2 in the middle" or "Drill from the 2x8 to the 2x4s" or "Drill from the 2x4's to the 2x8's" ? It's not a very informative direction.

cafm1953

Thu, 03/02/2017 - 17:59

Pocket holes

I don't think it matters if you drill from the 2x8 to the 2x4 or 2x4 to the 2x8. Kreg tool recommends drilling a hole approximately 2" from each end, then about every 6" or so for longer boards. Hope this helps.

Edemardil

Thu, 03/02/2017 - 13:08

Nightmare.

Making these has been a nightmare.

jsamans

Wed, 04/22/2020 - 15:45

Pipe needed?

Is the pipe needed for structural support or was it added for the look? Would wood cross-pieces anchored with pocket screws provide the same effect?