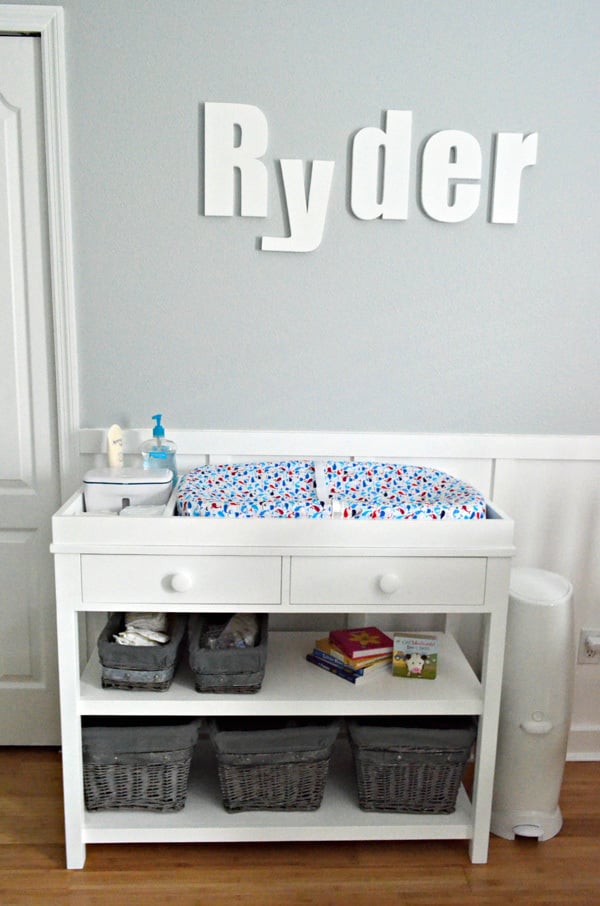

Here's a great baby changing table plan! Featuring two small drawers, two big shelves, and a large top perfect for changing, get all of baby's things ready and organized. Free step by step plans from Ana-White.com

Preparation

- 1/2 Sheet of 3/4” plywood or MDF

- 2 - 2x2 @ 8 feet long

- 3 - 1x2 @ 8 feet long

- 1 - 1x6 @ 10 feet long

- 1 - 1x4 @ 12 feet long

- 1/4” plywood piece at least 16” x 35”

- 2 - 1x3 @ 8 feet long (for topper)

- 1-1/4” pocket hole screws

- 2 - sets of 14" drawer slides

- 1-1/4" and 3/4" brad nails

- wood glue

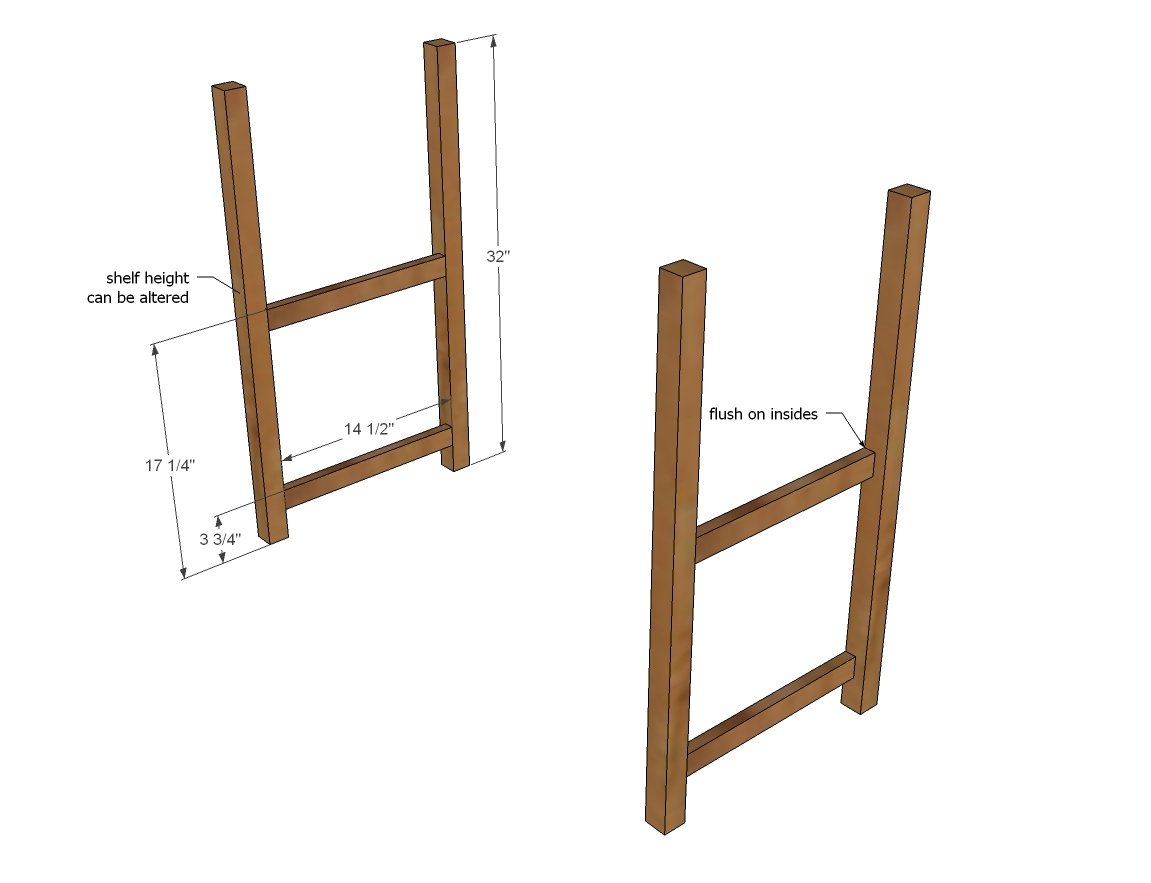

- 4 - 2x2 @ 32” - legs

- 4 - 1x2 @ 14-1/2” - side trim

- 4 - 1x2 @ 38” - front and back trim

- 2 - 3/4” plywood @ 14-1/2” x 38” - shelves

- 2 - 1x6 @ 14-1/2” - sides

- 1 - 1x6 @ 38” - back

- 1 - 3/4” plywood @ 17-1/2” x 41”

- 2 - 1x2 @ 38” - drawer trim

- 6 - 1x2 @ 4-3/4” - drawer trim

DRAWERS

- 4 - 1x4 @ 15-1/2” (sides)

- 4 - 1x4 @ 15-3/8” (front/back)

- 2 - 1/4” plywood @ 15-1/2” x 16-7/8” (bottom)

- 2 - 3/4” plywood or 1x6 @ 4-1/2” x 17-5/8” (front)

TOPPER

- 2 - 1x3 @ 41”

- 3 - 1x3 @ 16"

Please read through the entire plan and all comments before beginning this project. It is also advisable to review the Getting Started Section. Take all necessary precautions to build safely and smartly. Work on a clean level surface, free of imperfections or debris. Always use straight boards. Check for square after each step. Always predrill holes before attaching with screws. Use glue with finish nails for a stronger hold. Wipe excess glue off bare wood for stained projects, as dried glue will not take stain. Be safe, have fun, and ask for help if you need it. Good luck!

Instructions

Step 1

Drill (2) 3/4” pocket holes on each end of the 1x2 @ 14-1/2” long. Attach to the 2x2 legs with 1-1/4” pocket hole screws, flush to inside, keeping pocket holes hidden on insides. NOTE: Upper shelf can be placed at any height. In this plan, the upper shelf is placed to allow 12” height on lower shelf.

Step 2

Step 3

Step 4

On the 1x6 boards, drill 3/4" pocket holes facing upward for attaching the top in later steps. Then drill 3/4" pocket holes on the ends for attaching to the legs.

Attach the 1x6 side and back aprons with 3/4” pocket holes and 1-1/4” pocket hole screws. Also drill 3/ 4” pocket holes on the insides of the aprons facing upward to attach the top in later steps. *Note: the backboard should be flush to the outside of the legs.

Step 5

Step 6

Step 7

Step 8

Build drawers to fit openings and drawer slides. Install drawers in table with drawer slides, insetting 3/ 4” to allow for the drawer face.

The drawer can be built with 1-1/4" brad nails and glue. The bottom of the drawer can be attached with 3/4" brad nails and glue.

Here is a good video on installing drawers:

Step 9

It is always recommended to apply a test coat on a hidden area or scrap piece to ensure color evenness and adhesion. Use primer or wood conditioner as needed.

Comments

kaylathorpe

Sat, 11/01/2014 - 23:13

flush?

What does flush on inside mean? Thank you

abaron03

Sat, 01/31/2015 - 20:32

drawer slides

Can you please help me with step 9? It says to install drawers with drawer slides, but I don't see anything in the shopping list about drawer slides, and I don't see anything about how to install them in the instructions. If you simply insert the drawers into the structure as shown above, it seems like they would be balancing on a small cross section of a 1x2 board. I assume that can't be right. Is there a missing step?

hoodaehoo

Sun, 03/08/2015 - 13:35

I'm wondering the same thing.

I'm wondering the same thing... Where do the slides get mounted to?

rjminn59

Thu, 06/11/2015 - 06:41

Still looking

Has anyone figure out the draws yet

ReclaimedBuilder

Fri, 09/25/2015 - 12:18

An Idea

I am thinking bottom mount center drawer guides?

Something like these perhaps.

http://www.lowes.com/pd_380986-93052-T35072G16_0__?productId=50041754

Search Center mount Drawer slides to get some different images. Should work well.

kpower5

Sat, 12/05/2015 - 03:47

Drawer issue solved !!

Hi All,

I was having the same issue so I added an extra 2x1 in step 6 behind the small bit in the center. I attached it with pocket hole screws and glue and attached the drawer slides on both sides. I've adde a picture of it to my bragpost. Hope it helps.

dsmolkin

Sat, 03/12/2016 - 09:34

How to get flush 90 degree joints

Can't for the life of me get flush 90 joints with a kreg jig and a 90deg clamp. Is this a common problem or is it unusual? New to using the system, so it's probably a user issue.

dsmolkin

Sun, 03/13/2016 - 19:06

Figured it out.

I was moving too fast. Nice and slow is the winner.