Build your own dining bench - matches the Simple Modern Outdoor Table

Collections

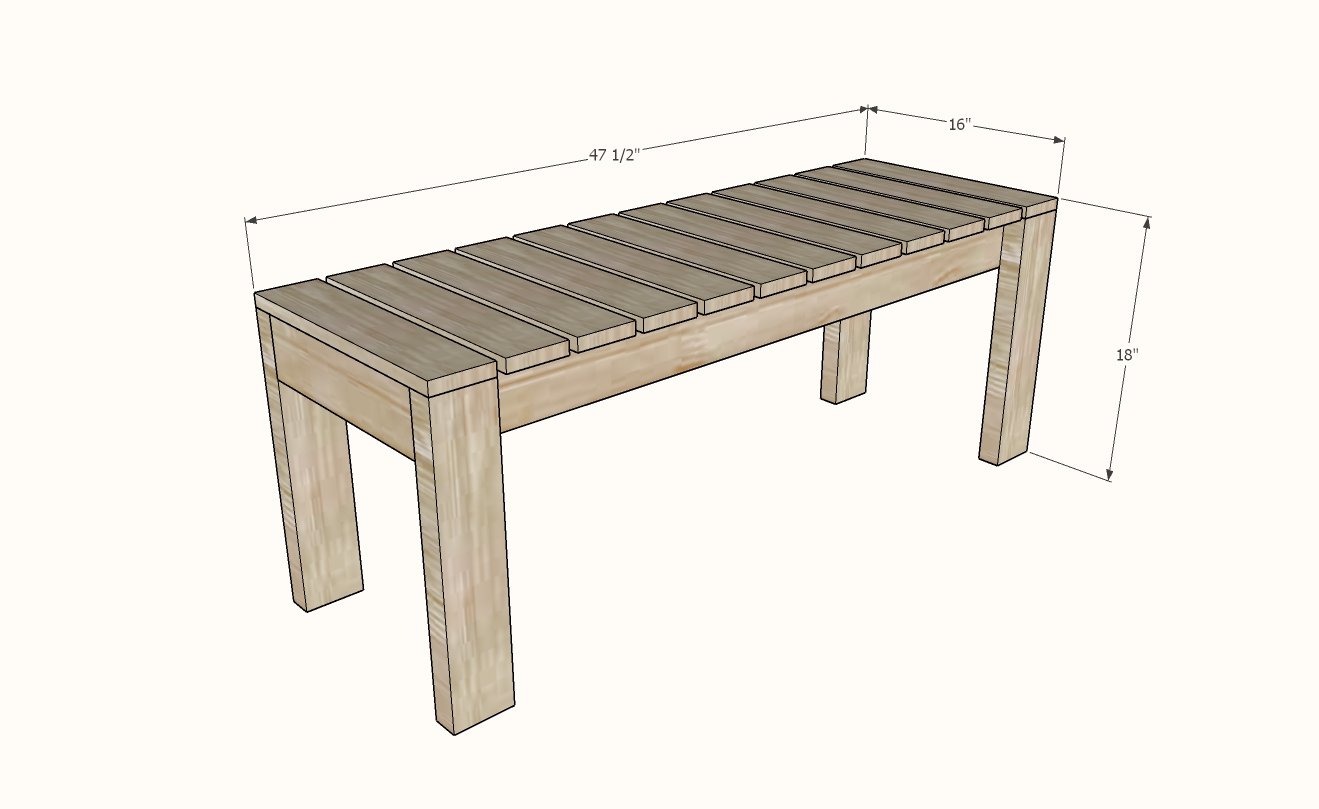

Dimensions

Dimensions shown in diagram

Preparation

Shopping List

Shopping List is Per 1 Bench

- 2 - 2x4 @ 8 feet long

- 2 - 1x4 @ 8 feet long

- 20 - 2-1/2" long exterior screws (look for the star bit ones)

- 50 - 1-1/2" long exterior screws (look for the star bit ones)

Cut List

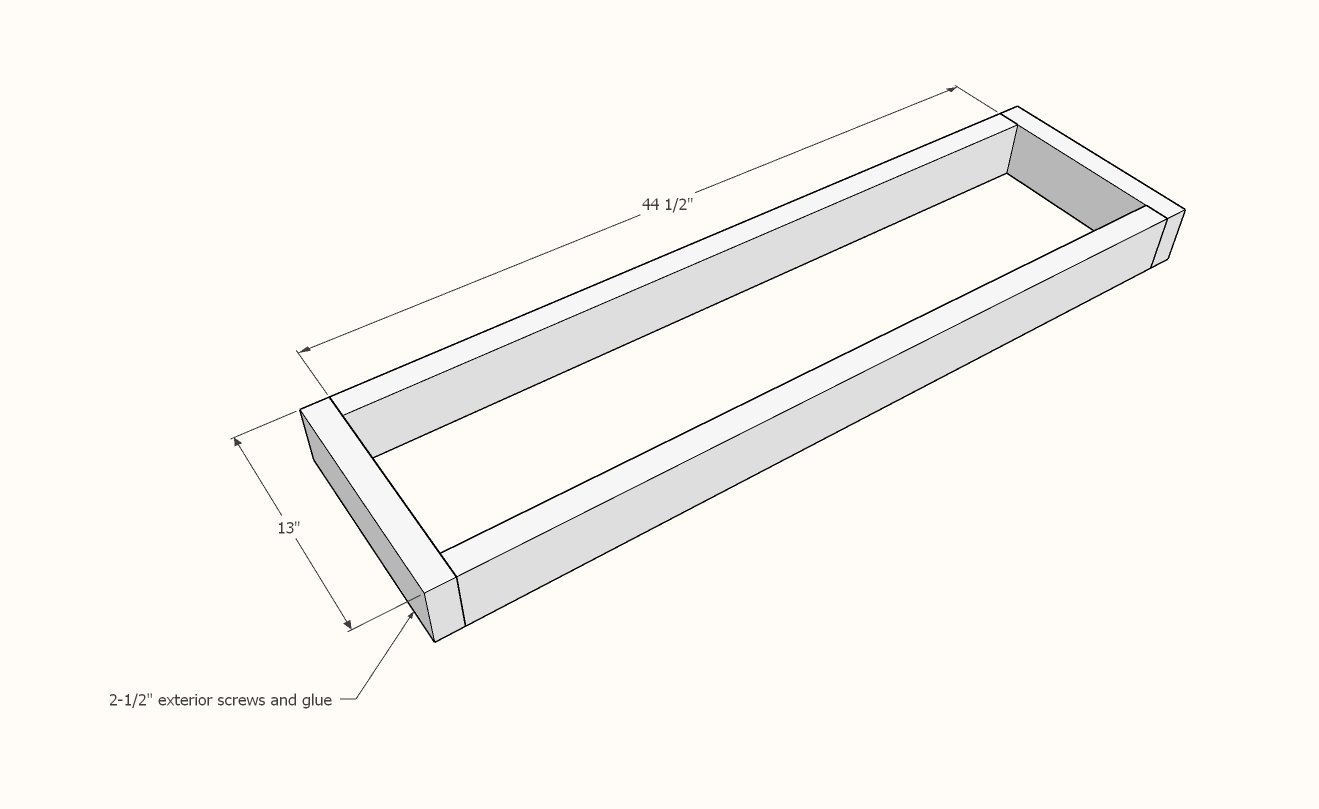

- 2 - 2x4 @ 12-7/8" - Frame ends

- 2 - 2x4 @ 44-1/2" - Frame sides

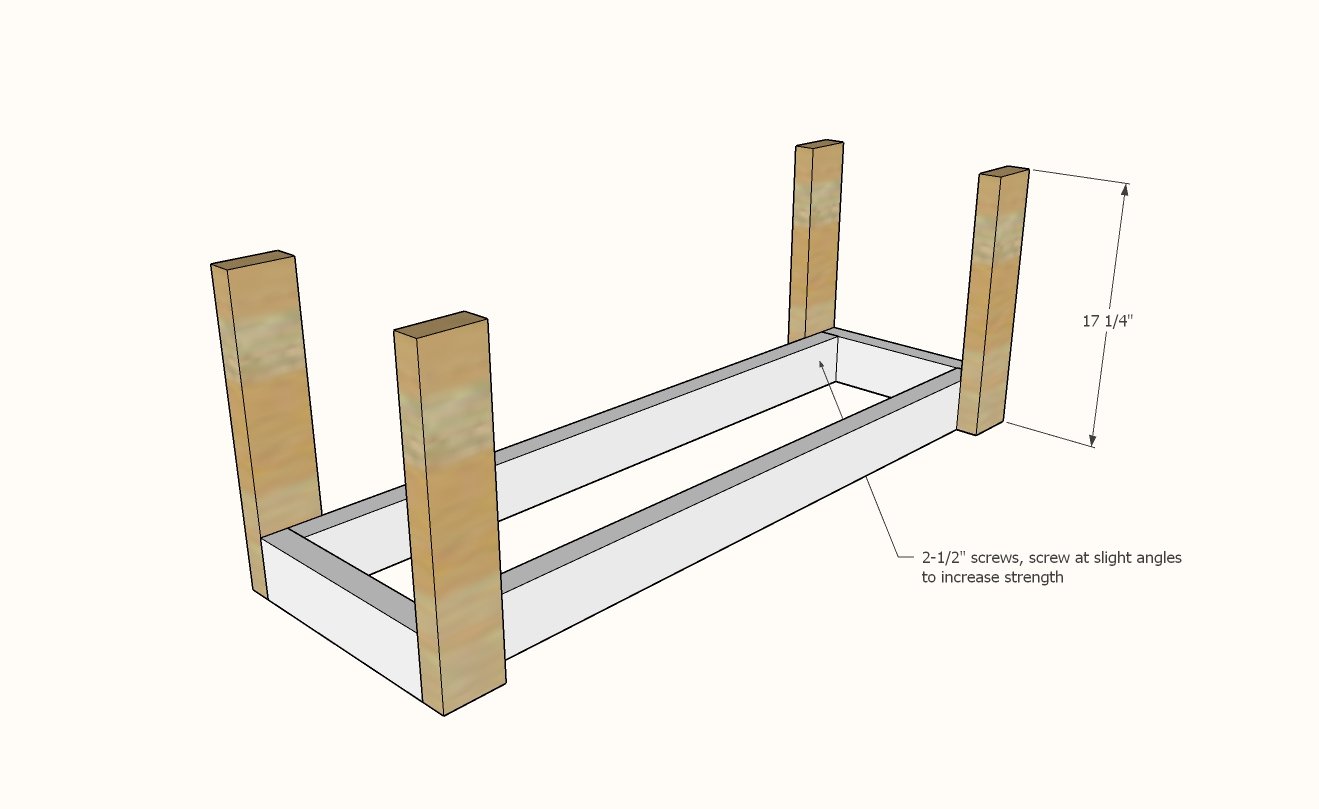

- 4 - 2x4 @ 17-1/4" - Legs

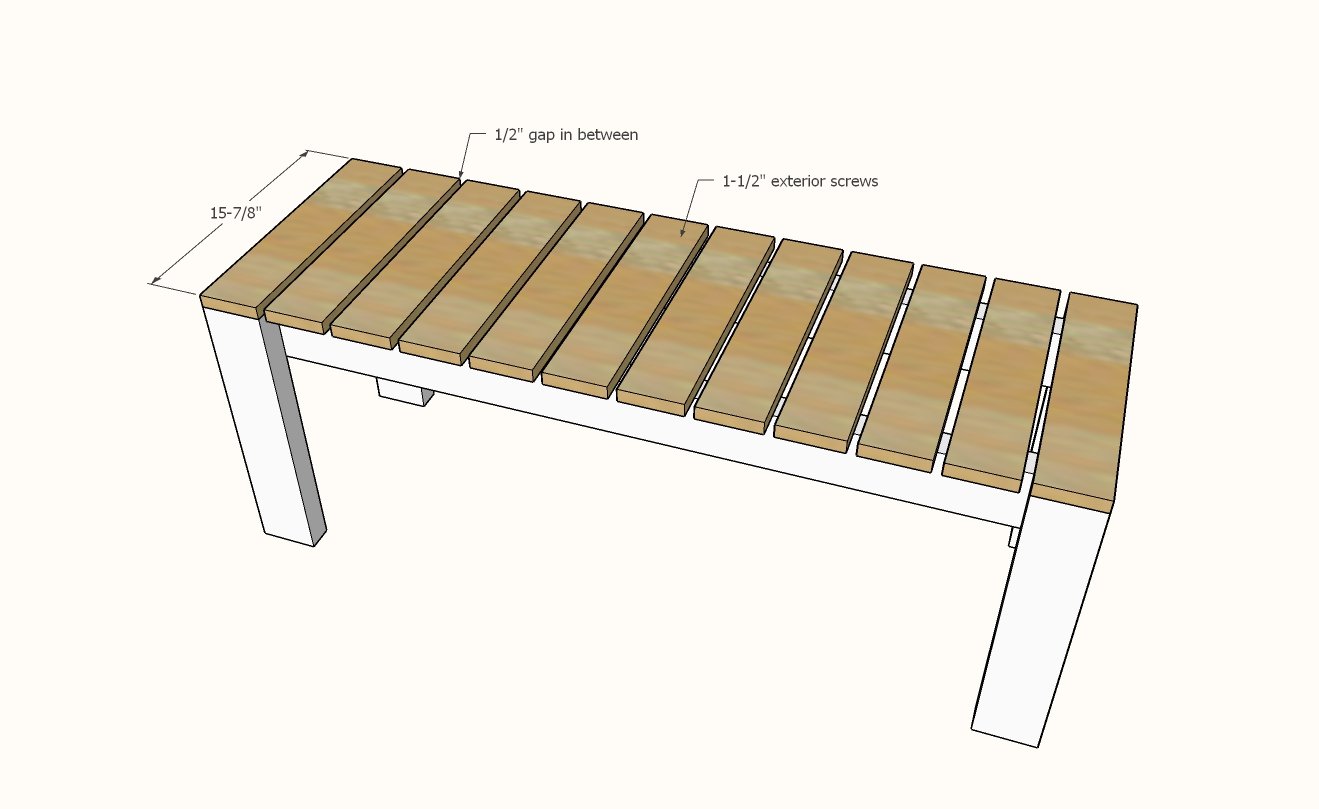

- 12 - 1x4 @ 15-7/8" - Bench Slats

Instructions

Step 1

Project Type

Room

Comments

priscillastone

Tue, 05/21/2019 - 07:16

shopping list

What length are the boards should I get?

@julia@

Fri, 06/04/2021 - 13:53

Adding a back and arms

Hi Ana! I love your plans and am currently building the Simple Outdoor Dining Table. I'm brand new to woodworking, so this is my first project and the benches will be my second!

If I want to add a back and arm rests to this bench — and add cushions to the seat — what dimensions do you recommend? I took a look at some of the other outdoor sofas and benches, but I don't yet have the knowledge to make adjustments myself.

Thanks in advance!